Loop-pile cutting circular machine

The technology of circular knitting machine and large plate is applied to circular knitting machines with separate action needles for weft knitting, textile and paper making, weft knitting and other directions, which can solve the problems of insufficient wool density, expensive blankets, and easy shedding of blankets. , to achieve the effect of high gross surface density, no need for shearing, smooth surface without hooks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

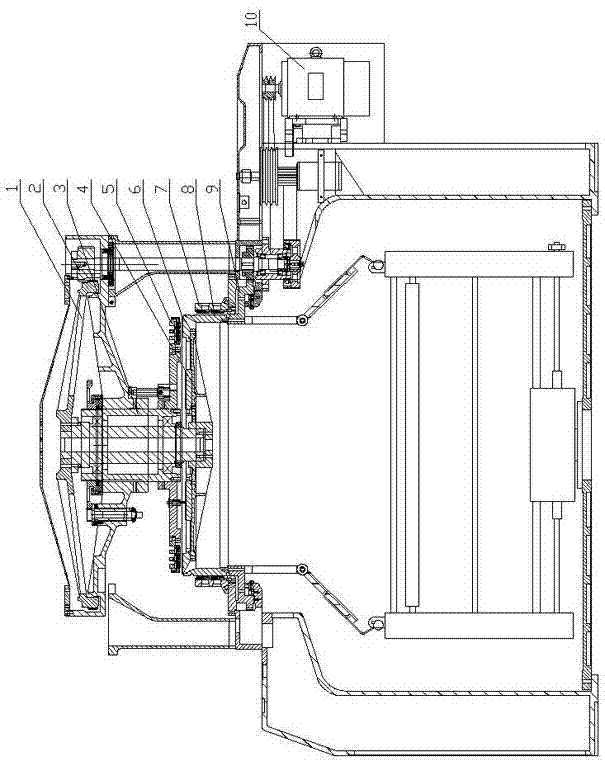

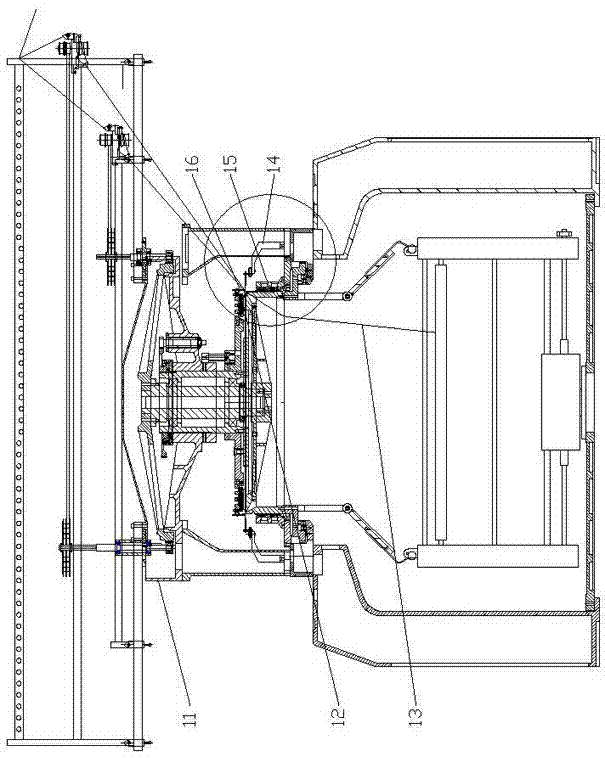

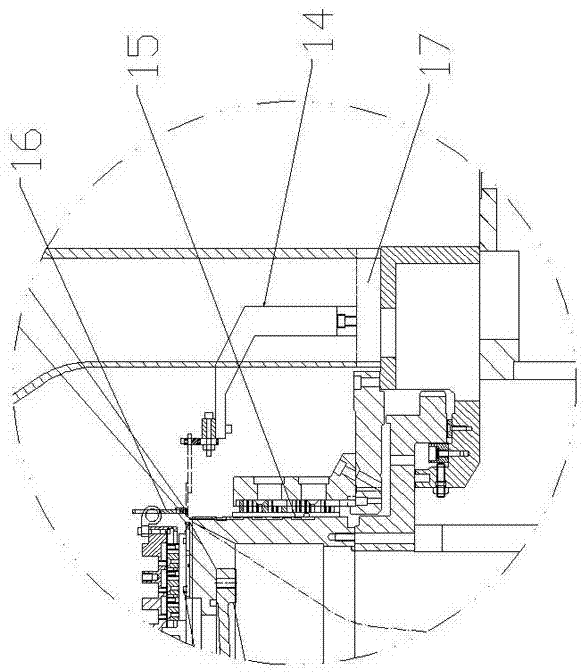

[0030] Refer to attached figure 1 , figure 2 and image 3 , a kind of ring-cutting velvet circular machine, comprising a support, a large plate and a large tripod 11, the large plate 17 is fixed on the top of the support, the large tripod 11 is fixed on the large plate 17 by supporting legs, the large plate 17 is equipped with a large plate gear 9, and A needle cylinder 8 coaxially arranged with the disk gear 9 is fixed on the large disk gear 9, and a lower disk saddle 7 is sleeved on the outside of the needle cylinder 8, and the lower end of the lower disk saddle 7 is fixedly connected to the large disk 17 through a saddle washer . The big tripod 11 is equipped with a big tripod gear 1 that rotates synchronously with the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com