A loom shuttle with a weft tension controller

A technology of tension controller and weft yarn, which is applied in the direction of shuttle, weaving, textiles and papermaking, etc., can solve the problems of uneven weaving and fabric burrs, achieve the effect of improving quality grade, preventing weft yarn breakage, and avoiding fabric burrs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

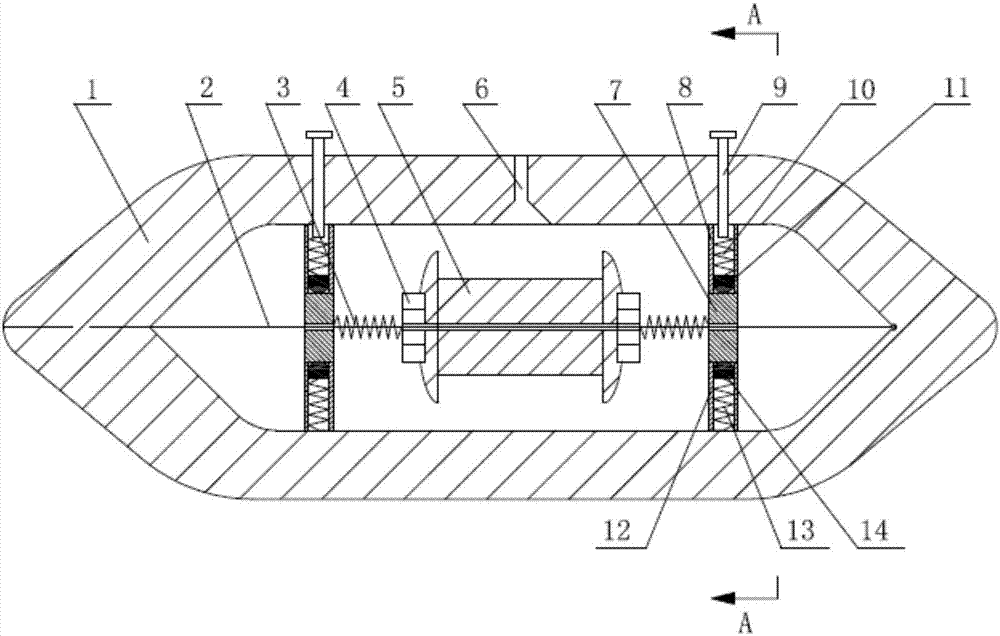

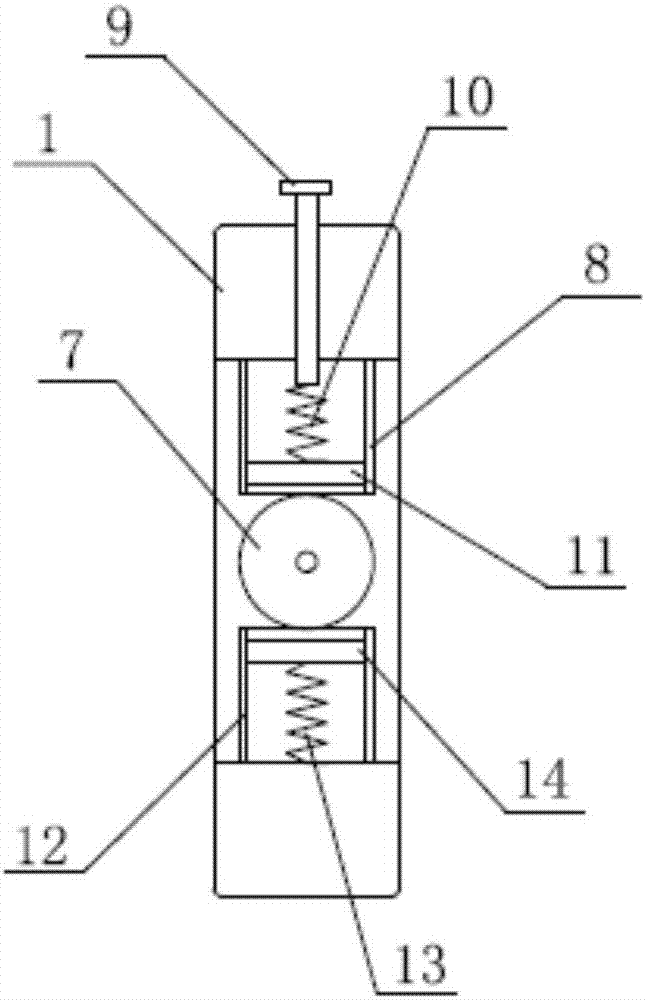

[0019] Embodiment one: see attached figure 1 , 2 As shown, a loom shuttle with a weft yarn tension controller includes a cavity housing 1 with a yarn guide port 6, a bobbin 5 for storing weft yarn, and a rotary spring 3 that can generate torsional moment, and is fixed in the housing laterally. The fixing wire 2. The shell 1 is made of nylon material, which has the characteristics of wear resistance, rolling resistance, impact resistance, good dimensional stability and high fatigue resistance; the surface is coated with excellent wear resistance, antistatic and heat dissipation performance , to meet the needs of the weaving process. The fixed steel wire 2 of the replaceable bobbin 5 is made of fine-grained hot-rolled high-quality steel HRBF500, with a yield strength of more than 500 MPa and an elongation of more than 15%. One end of the fixed steel wire is fixed to the shell, and the other end passes through the groove on the shell. to constrain the position of the steel wir...

Embodiment 2

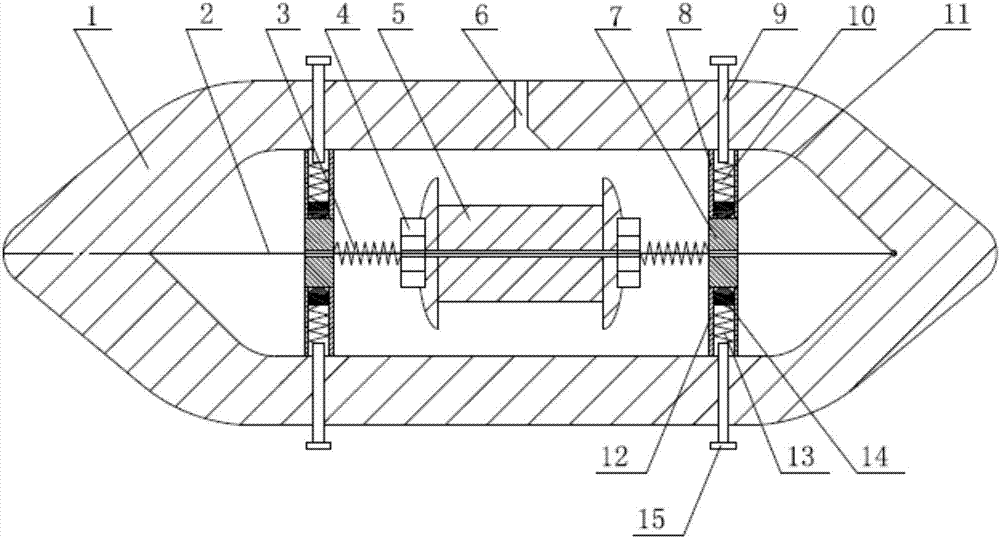

[0022] Embodiment two: see image 3 As shown, a loom shuttle with a weft tension controller is similar in structure to Embodiment 1. As the use time of the shuttle increases, the coefficient of friction between the half cylinder and the rotating disc will change, and the effect of changing the friction force by adjusting the screw will be weakened. At this time, the screw must be adjusted in a large range. Adjustment, and then cause the rotating disc to deviate from the original position inside the shuttle, and problems occur. In order to effectively improve this defect, we can simultaneously increase a lower adjusting screw 15 having the same effect as the upper adjusting screw 9 at a symmetrical position about the center line of the shuttle. When the shuttle is in use, a good effect can be achieved by adjusting this group of mutually symmetrical screws, which mainly includes two aspects. One: The simultaneous action of a group of symmetrical adjustment screws can adjust th...

Embodiment 3

[0023]Embodiment 3: A complete set of components as described in Embodiments 1 and 2 jointly constitute a loom shuttle device with a weft yarn tension control function. This device can change the friction between the semi-cylindrical body and the rotating disc according to different needs. The force realizes the function of controlling the tension of the weft yarn well. Although the device works well, it is relatively complicated. Sometimes the weft yarn does not have high requirements on the tension control effect, it only needs to be kept in a non-relaxed state. Based on this, it is particularly necessary to design a loom shuttle that is simple and easy to process and can keep the weft yarn in a non-relaxed state. This shuttle device omits the weft tension control devices 3, 4, 7, 8, 9, 10, 11, 12, 13 and 14 described in the first and second embodiments, and there are two Grooves, each fixing a weft tension control spring in it, one end of the spring is fixed inside the shu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com