Adsorptive natural gas transporting tank for storing and transporting natural gas

A technology for adsorbing natural gas and natural gas, applied in gas/liquid distribution and storage, fixed-capacity gas storage tanks, container discharge methods, etc. replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

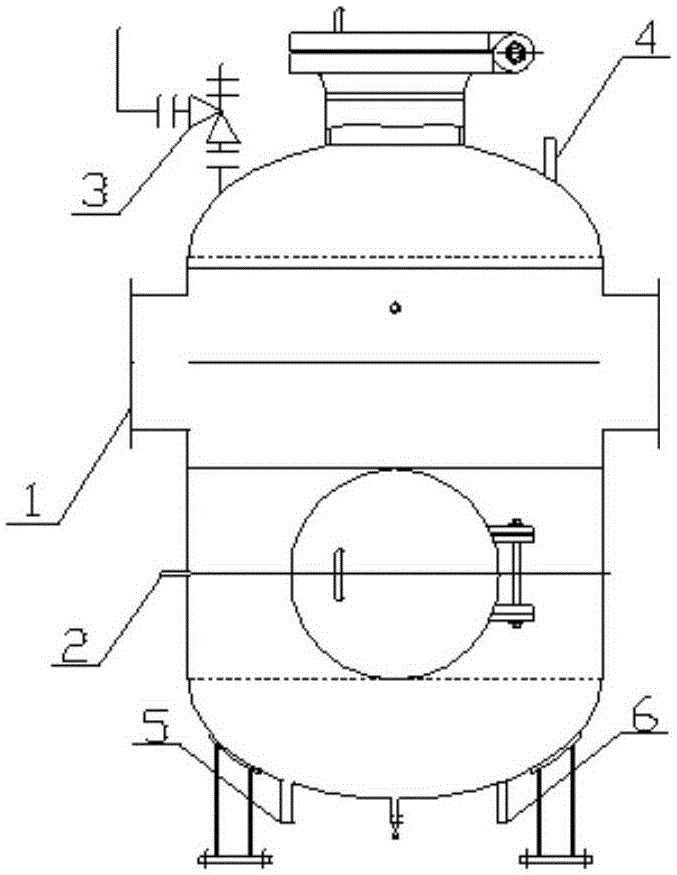

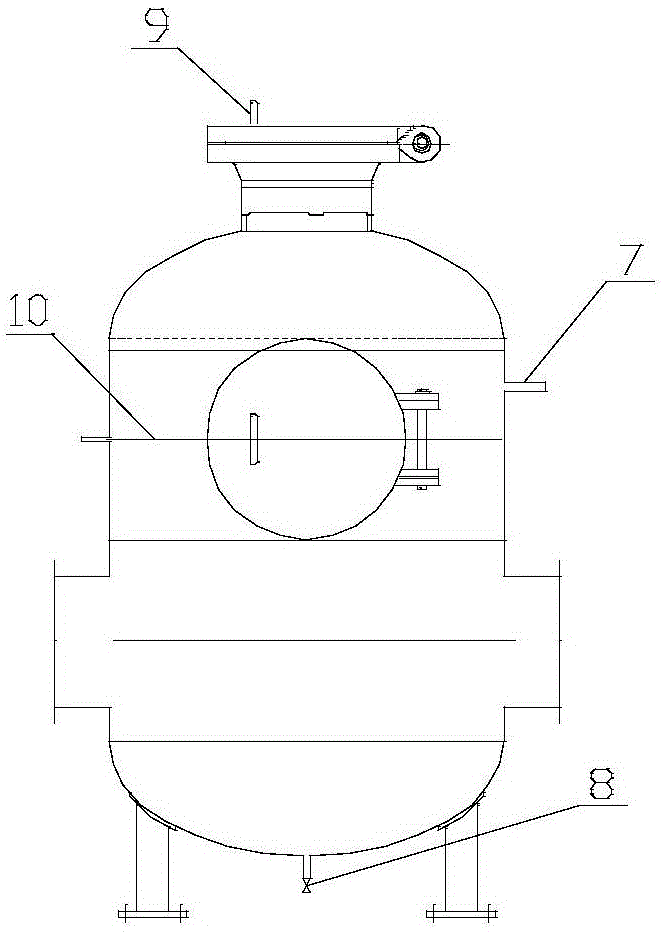

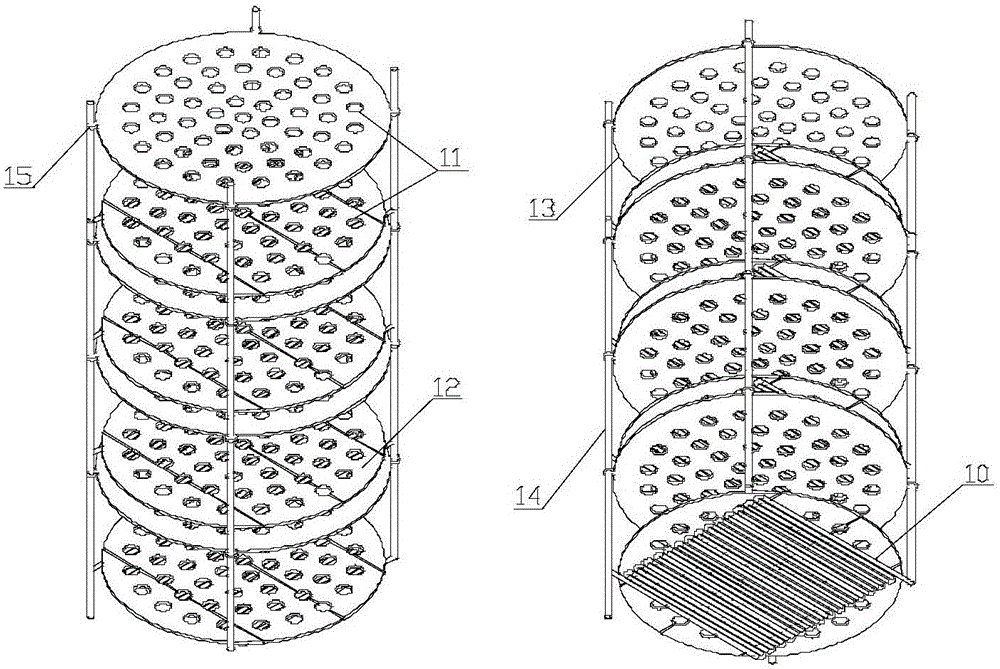

[0038] The total volume of the designed adsorption storage tank is 2.25m3, the diameter is 1300mm, and the height is 2700mm. For the specific shape and structure, see figure 1 shown. The air inlet and outlet adopt metal filter screen (200 mesh). There are 4 temperature measuring ports on the tank body. The nozzle specification is Φ3. The temperature measuring port should be suitable for thermocouples with a size of Φ1. And can be sent to the computer display. The metal tubes inside the adsorption storage tank are not in contact with each other, and the gap spacing is greater than 30mm in the size of the activated carbon. The interior of the adsorption storage tank is divided into 4 layers by the constant temperature coil, and the layer height is 332.5mm. The filling process requires the storage tank to be filled within 12 minutes, while ensuring that the methane volume concentration of the inlet gas is greater than 90%, the water content is less than 5%, and the inlet flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com