Bidirectional continuous basalt fiber reinforced thermoplastic resin composite sheet material and preparation method thereof

A basalt fiber and reinforced thermoplastic technology is applied in the field of bidirectional continuous basalt fiber reinforced thermoplastic resin composite sheet and its preparation. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

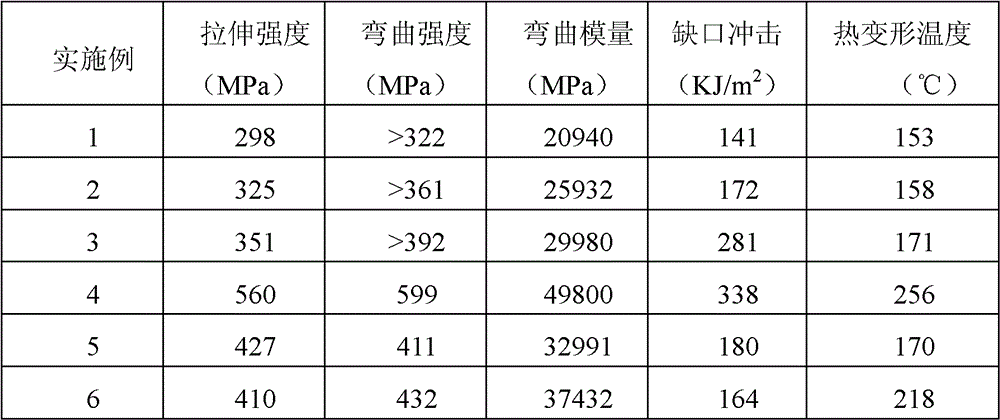

Embodiment 1

[0037]A mixture of 40 parts by weight of polypropylene resin and 0.5 parts by weight of isopropyl triisostearate titanate titanate coupling agent is fully mixed in a high-speed mixer, melted and mixed with parts by weight It is composited with 60 parts of continuous basalt fiber, and made into continuous basalt fiber reinforced polypropylene (PP / BF) unidirectional prepreg tape after flattening, and the continuous basalt fiber reinforced polypropylene unidirectional prepreg tape (prepreg tape specification: thickness 0.2mm, width 650mm, length ≥ 1m) cut into a prepreg tape with a width of 200mm and a length of 1m, and then lay it criss-cross to 15 layers, put it into the mold, and send it into the mold when the temperature reaches 185°C In the hot press, the pressure is 1 MPa, and the holding time is 30 minutes. After the heat preservation is over, it is sent to a cold press with a pressure of 2 MPa and a pressure hold of 30 minutes. The mold is released to obtain a two-way co...

Embodiment 2

[0041] A mixture of 50 parts by weight of polyvinyl chloride resin and 0.2 parts by weight of bis(dioctyloxypyrophosphate) ethylene titanate and triethanolamine chelate titanate coupling agent , after fully mixing uniformly in a high-speed mixer, melt and compound with continuous basalt fiber of 50 parts by weight, and flatten to make continuous basalt fiber reinforced polyvinyl chloride (PVC / BF) unidirectional prepreg tape, the continuous basalt Fiber-reinforced polyvinyl chloride unidirectional prepreg tape (prepreg tape specifications: thickness 0.27mm, width 10mm, length ≥ 5m) is cut into a prepreg tape with a width of 10mm and a length of 5m, and then criss-cross Lay up to 100 layers, put it into the mold, and when the temperature reaches 170°C, send it into a hot press with a pressure of 1.5 MPa and a holding time of 40 minutes. After the heat preservation is over, it is sent to a cold press with a pressure of 2.5 MPa and a pressure hold of 60 minutes. Extruded from the...

Embodiment 3

[0045] The polybutylene terephthalate resin of 50 parts by weight and the mixture of two (dioctyl phosphite base) isopropyl titanate titanate coupling agents of 0.4 parts by weight are mixed at high speed After fully mixing in the machine, it is melted and compounded with continuous basalt fiber of 50 parts by weight, and flattened to make PBT / BF unidirectional prepreg tape, and the continuous basalt fiber reinforced PBT unidirectional prepreg tape (prepreg tape specification : The thickness is 0.3mm, the width is 650mm, and the length is ≥1m) cut into a prepreg tape with a width of 650mm and a length of 1m, and then lay it in a criss-cross pattern to 200 layers, put it into the mold, and wait until the temperature reaches 218°C , into the hot press, pressure 1MPa, holding time 30min. After the heat preservation is over, it is sent to a cold press with a pressure of 3 MPa and a pressure hold of 70 minutes. The mold is released to obtain a two-way continuous basalt fiber reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com