Fibre-polymer compound toughened concrete and preparation method for same

A polymer and concrete technology, which is applied in the field of fiber and polymer composite toughened concrete and its preparation, can solve the problems of poor anti-aging performance of polymers, and achieve the effect of optimizing the maintenance system and optimizing the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

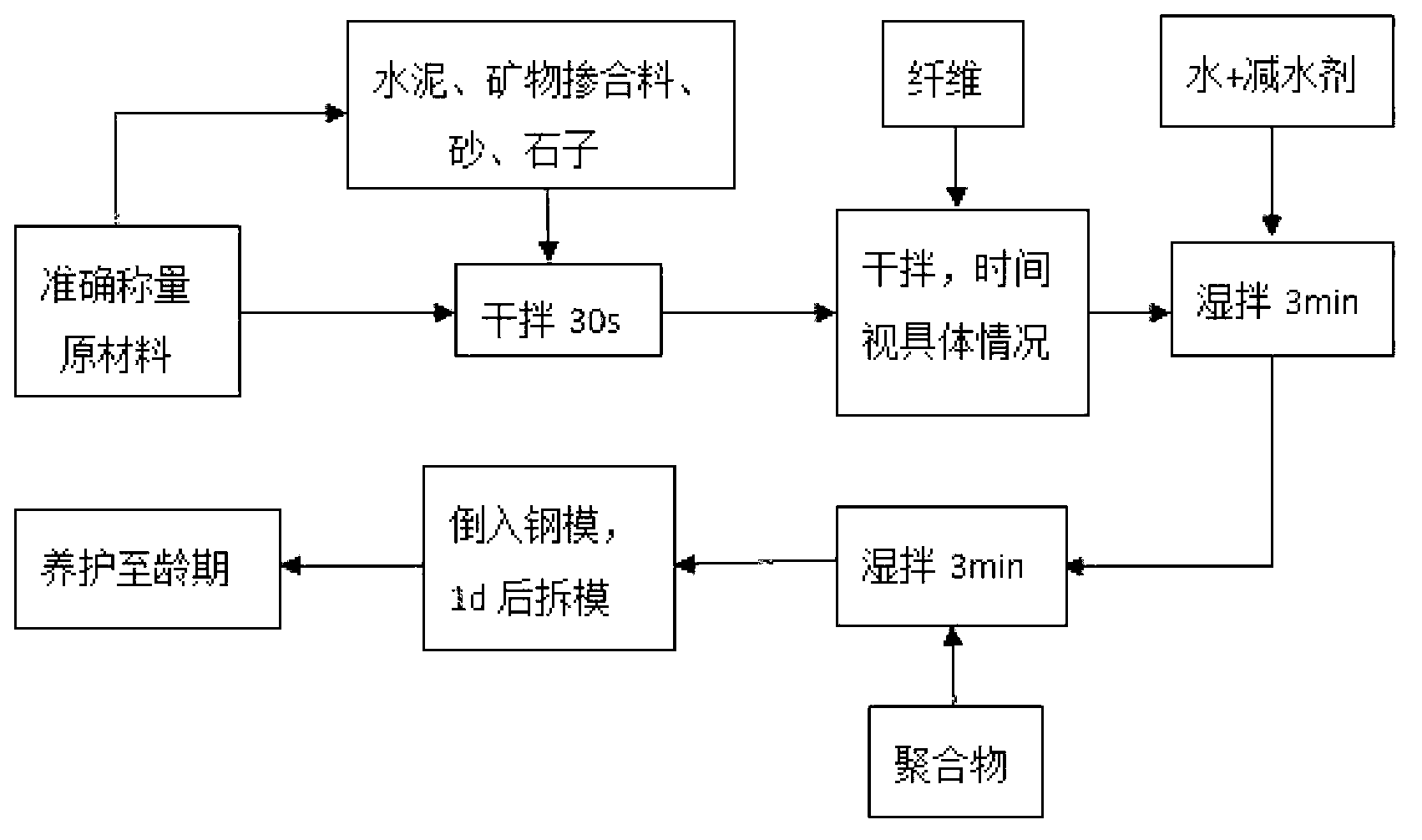

[0048]1. Preparation method:

[0049] 1) Pour gravel, sand, cement, and fly ash into the mixer, and stir evenly for 30 seconds;

[0050] 2) Disperse the fiber, and then slowly sprinkle the fiber with a volume content of 0.08% into the working mixer. After the fiber is completely sprinkled, mix it with the dry material for 30 seconds (the time can be adjusted according to the speed of the fiber) (single mixing omit this step for polymers);

[0051] 3) Pour the polycarboxylate high-efficiency water reducer into the water, start the mixer, pour the water evenly into the working mixer, and stir for 3 minutes;

[0052] 4) Pour the polymer with an amount of 10% of the total mass of the cementitious material (Portland cement + fly ash) into the working mixer evenly, and stir for 3 minutes, (ignore this step when only mixing fibers);

[0053] 5) After the mixing is completed, turn off the power, pour out the freshly mixed concrete, and pour it into the steel mold. The numbers of eac...

Embodiment 2

[0069] 1. Preparation method:

[0070] 1) Pour gravel, sand, cement, and fly ash into the mixer, and stir evenly for 30 seconds;

[0071] 2) Disperse the fiber, and then slowly sprinkle the fiber with a volume content of 0.08% into the working mixer. After the fiber is completely sprinkled, mix it with the dry material for 30 seconds (the time can be adjusted according to the speed of the fiber) (single mixing omit this step for polymers);

[0072] 3) Pour the polycarboxylate high-efficiency water reducer into the water, start the mixer, pour the water evenly into the working mixer, and stir for 3 minutes;

[0073] 4) Pour the polymer with an amount of 10% of the total mass of the cementitious material (Portland cement + fly ash) into the working mixer evenly, and stir for 3 minutes, (ignore this step when only mixing fibers);

[0074] 5) After the mixing is completed, turn off the power, pour out the freshly mixed concrete, and pour it into the steel mold.

[0075] 2. Main...

Embodiment 3

[0085] 1. Preparation method:

[0086] 1) Pour gravel, sand, cement, and fly ash into the mixer, and stir evenly for 30 seconds;

[0087] 2) Disperse the fiber, and then slowly sprinkle the fiber with a volume content of 0.08% into the working mixer. After the fiber is completely sprinkled, mix it with the dry material for 30 seconds (the time can be adjusted according to the speed of the fiber) (single mixing omit this step for polymers);

[0088] 3) Pour the polycarboxylate high-efficiency water reducer into the water, start the mixer, pour the water evenly into the working mixer, and stir for 3 minutes;

[0089] 4) Pour the polymer with an amount of 10% of the total mass of the cementitious material (Portland cement + fly ash) into the working mixer evenly, and stir for 3 minutes, (ignore this step when only mixing fibers);

[0090] 5) After the mixing is completed, turn off the power, pour out the freshly mixed concrete, and pour it into the steel mold.

[0091] 2. Main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com