Composite material containing modified basalt fiber and polymer and preparation method thereof

A technology of basalt fiber and composite material, which is used in building thermal insulation materials, building structures, building components, etc., can solve the problems of difficulty in uniform dispersion of modified basalt fibers, high surface energy of specific surface area, easy agglomeration, etc., and achieves easy molding. , the effect of high output and wide distribution of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

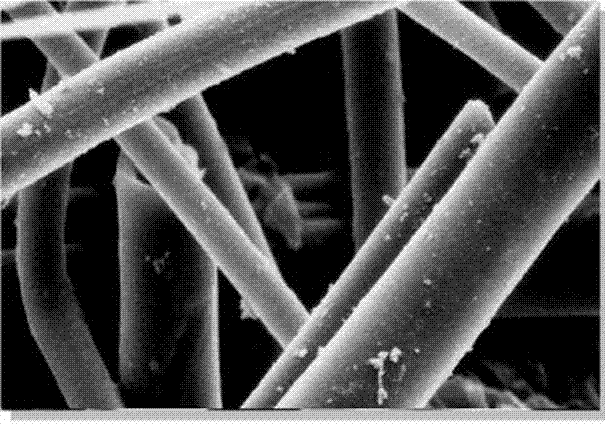

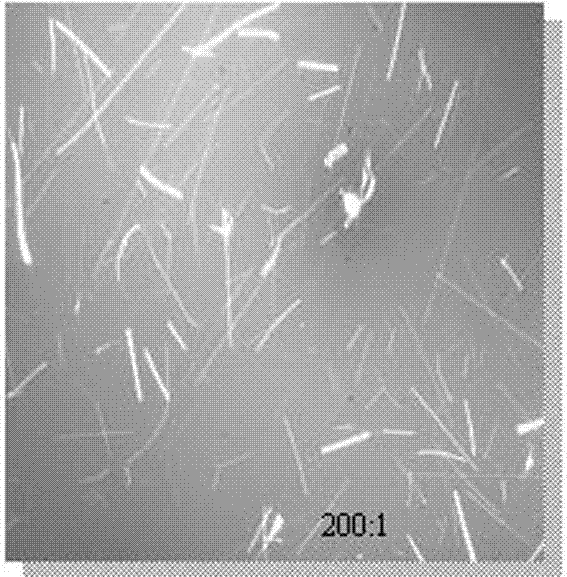

[0057] Preparation of modified basalt fiber: Intermittent flocculent basalt fiber is made by multi-axis centrifugation under the action of electromagnetic effect after melting basalt as the main raw material at 1350 ℃ ~ 1680 ℃. The modified basalt fiber is Al 2 o 3 The mass content is 6%-18%, the mass content of ferrous oxide and ferric oxide is 9%-16%, the acidity coefficient is 1.2-4.8; and the average diameter is 1 micron-8 microns﹑length / diameter≥ 8. The fiber content is ≥ 65%, the bulk density is 70 g / L-380 g / L, and the particle size is 3 mm-8 mm flocculent fiber clusters;

[0058] Preparation method of composite material:

[0059] 1295 grams of polycarbonate, 50 grams of sodium lauryl sulfate and 713 grams of the above-mentioned modified basalt fiber with an acidity coefficient of 2.3 are made into a uniform mixture in 5600 grams of N-methyl-2 pyrrolidone by means of stirring and ultrasonic waves , then add 260 grams of deionized water to the above mixture, the compou...

Embodiment 2

[0064] First 1295 grams of polymethyl methacrylate, 5 grams of sodium lauryl sulfate and 780 grams of acidity coefficient are the modified basalt fibers described in embodiment 1 of 1.2 under the effect of stirring and ultrasonic waves in N-methyl- 2. Make a uniform mixed solution in 5600 grams of pyrrolidone, then add 260 grams of methanol in the above mixed solution, and the polymethyl methacrylate / modified basalt fiber composite will be separated out, and it will be separated from the solvent and processed at 60 Drying in a vacuum oven at ℃-90℃ is the polymethyl methacrylate composite material with a modified basalt fiber content of 60%. Recorded as BMF / NT836 composite material. Result is with embodiment 1.

[0065] Application of composite materials:

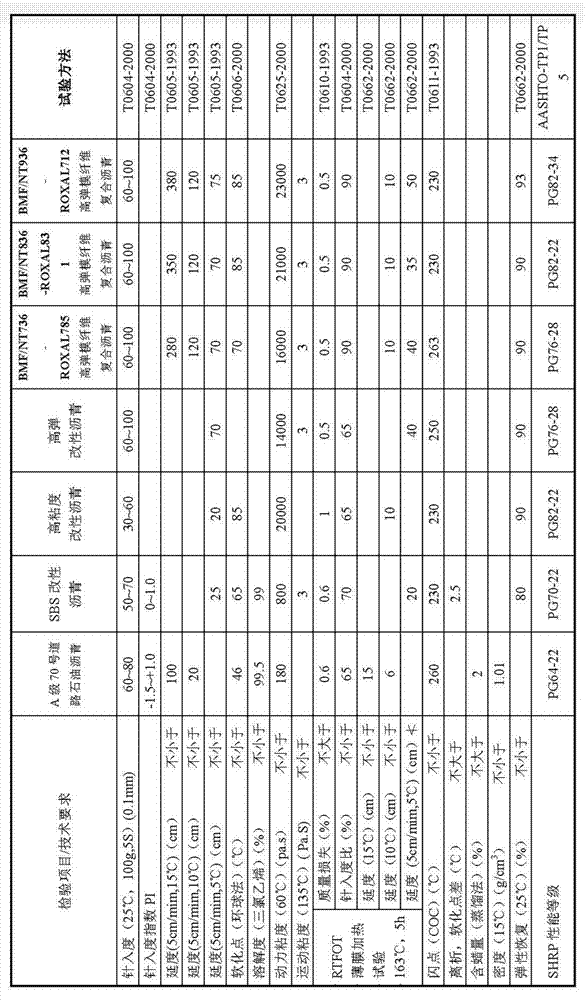

[0066] Heat 1000 grams of No. 70 road traffic asphalt to 165 ° C, spray the asphalt into 120 grams of the BMF / NT836 composite material prepared in Example 2, and add 65 grams of polyethylene at the same time; It is melted...

Embodiment 3

[0068] First utilize stirring and ultrasonic wave to make 1295 grams of polystyrene, 5 grams of KH-550 silane coupling agent and embodiment 1 described 780 grams of modified basalt fibers with an acidity coefficient of 3.6 in 5600 grams of chloroform to make a uniform mixed solution , and then add 260 grams of absolute ethanol to the above mixture, and the polystyrene / modified basalt fiber composite will be precipitated, and the composite and the solvent will be separated and dried in a vacuum oven at 60°C-90°C to obtain the modified The polystyrene composite material with basalt fiber content of 60% is recorded as BMF / NT936 composite material. Result is with embodiment 1.

[0069] Application of composite materials:

[0070] Heat 1,000 grams of No. 70 road traffic asphalt to 165°C, spray the asphalt into 180 grams of the BMF / NT936 composite material prepared in Example 3 above, and continue heating to 185°C through high shear and kneading. During this period, 43 grams of meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com