Surface treatment method for basalt fibre

A basalt fiber and surface treatment technology, which is applied in the field of basalt fiber surface modification treatment, can solve the problems of high energy consumption, high environmental pollution, and poor effect, and achieve good treatment effect, less environmental pollution, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

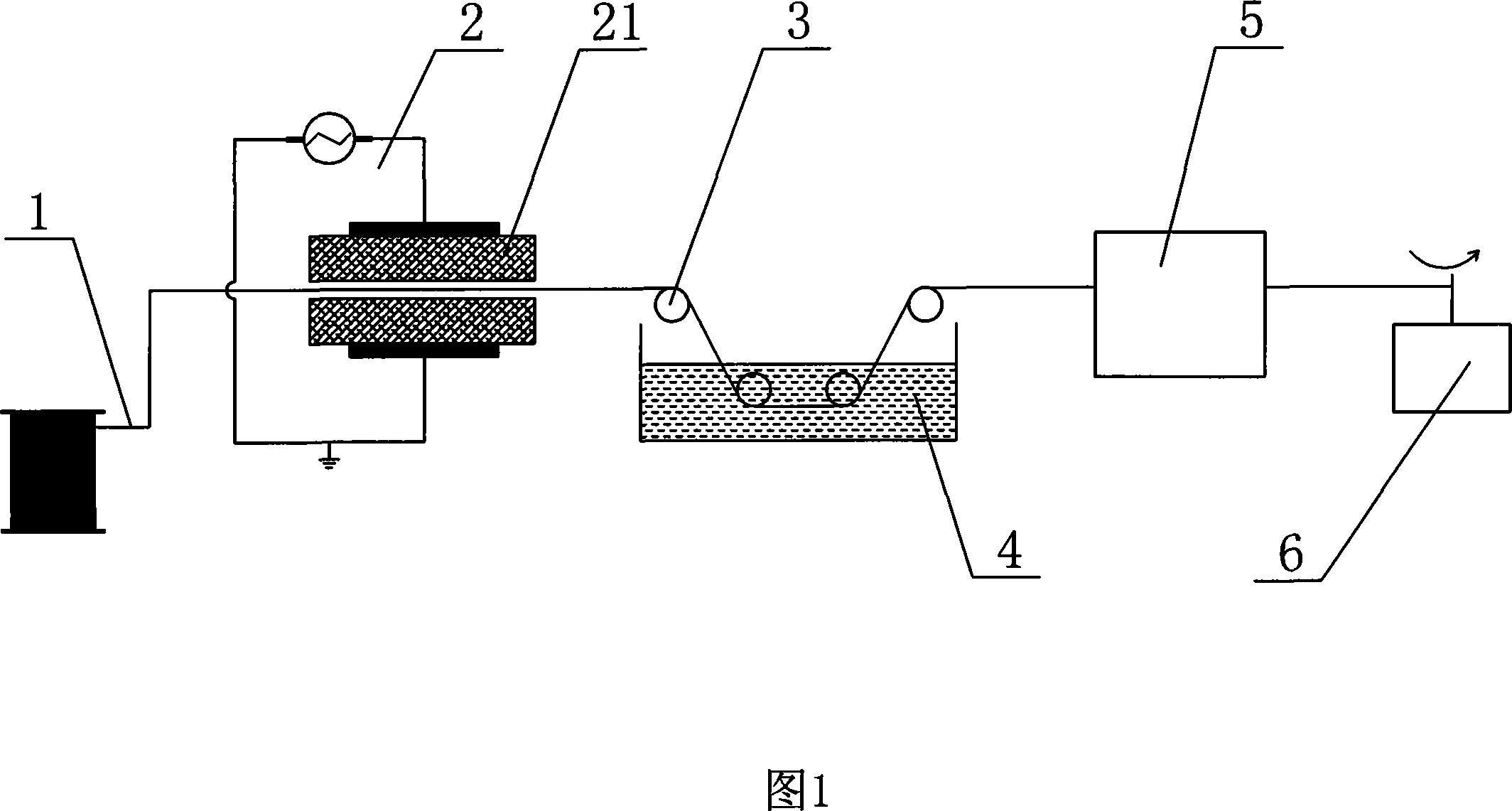

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0014] Referring to shown in Fig. 1, the basalt fiber 1 to be treated is passed between the discharge electrodes 21 in the radio frequency plasma generator 2 in the axial direction, and a sample pool for containing resin solution is arranged at the back of the radio frequency plasma generator 2 4. The resin is selected from the group consisting of ethylene-vinyl acetate, polyvinyl butyral, styrene-isoprene-styrene block copolymer, polymethyl methacrylate, thermoplastic polyurethane resin, polyester elastic resin, epoxy resin, phenolic resin, urea-formaldehyde resin, etc., during work, dissolve the resin with gasoline, absolute ethanol, acetone and other solvents to prepare a solution with a concentration of 2 to 15%, and put the resin solution in the sample pool 4 . After the plasma treatment, the basalt fiber 1 is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com