High-iron ground steel slag lightweight high-toughness wave absorption concrete and preparation method thereof

A high-toughness, concrete technology, applied in the interdisciplinary field of the combination of electromagnetics and material science, can solve the problems of restricting construction engineering, low absorption efficiency, and poor environmental adaptability, so as to improve bearing capacity, improve wave-absorbing performance, reduce reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

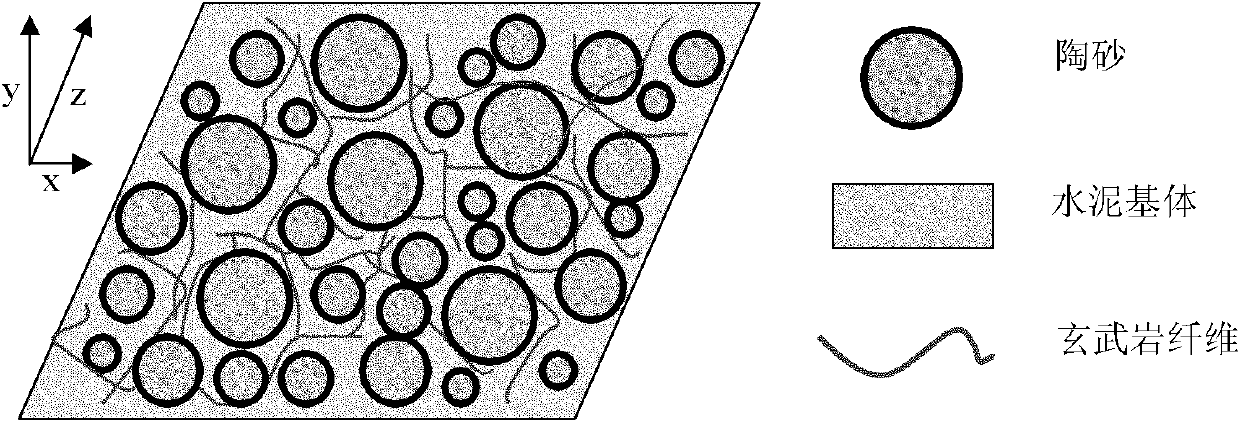

Method used

Image

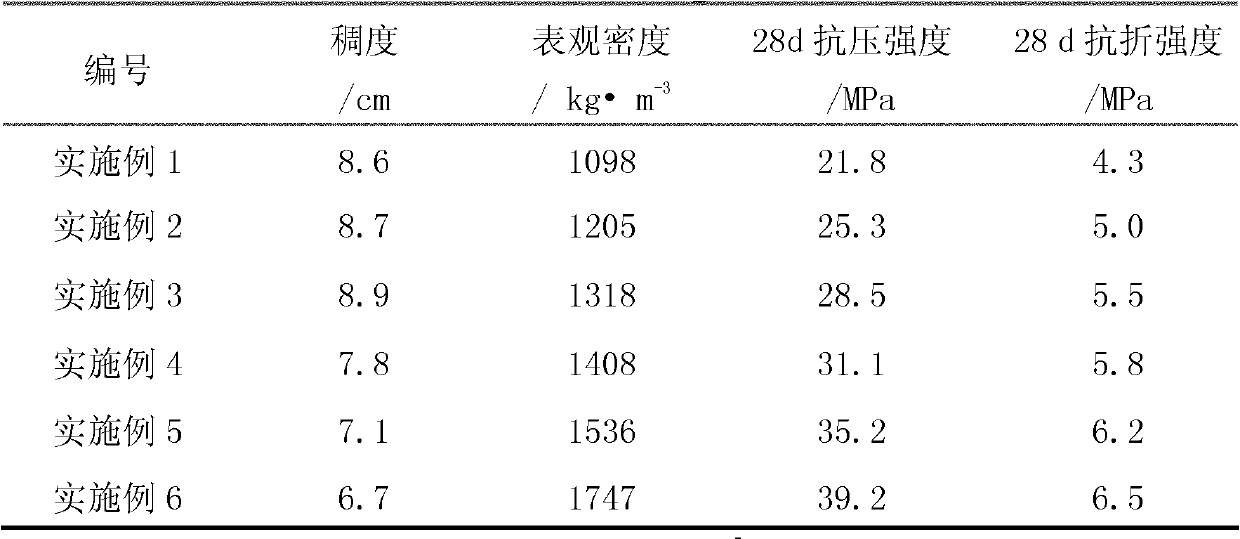

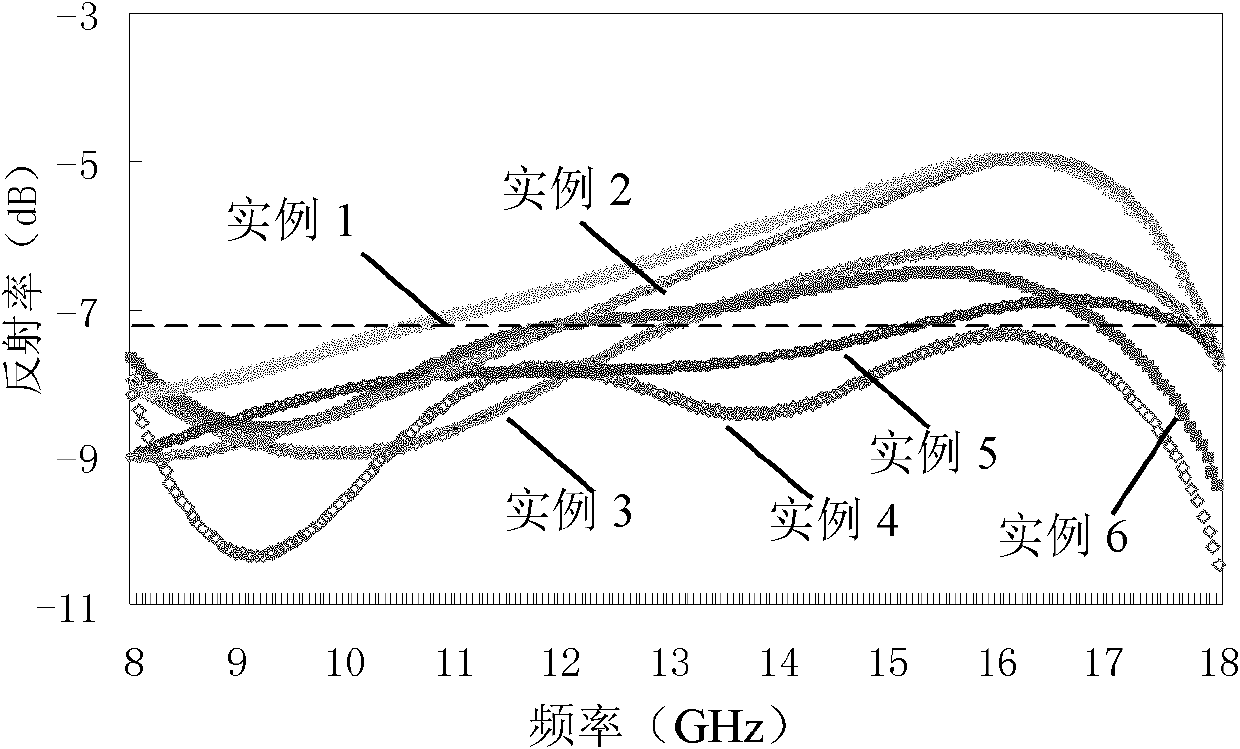

Examples

Embodiment 1

[0022] A method for preparing light-weight high-toughness wave-absorbing concrete with high-speed iron-ground steel slag, comprising the following steps:

[0023] 1) Selection of raw materials: according to the ratio of each raw material (kg / m 3 ) is: Portland cement: 110, fly ash: 120, high-speed iron milled steel slag: 70, ceramic sand: 600, superplasticizer: 3.0, basalt fiber 50, water: 154.

[0024] The strength grade of the Portland cement is 42.5MPa, and the specific surface area is greater than 350m 2 / kg; said fly ash is Class II fly ash with a density of 2.6-2.8g / cm 3 , the specific surface area is greater than 400cm 2 / g; The iron component mass content (Fe 2 o 3 ) is greater than 30%, and the specific surface area is greater than 600m 2 / kg; the bulk density of the pottery sand is less than 500m3 3 / kg, with a particle size of 0.6-4.75mm; the high-efficiency water-reducer is a polycarboxylate high-efficiency water-reducer with a water-reducing rate of 20%-25%,...

Embodiment 2

[0028] A method for preparing light-weight high-toughness wave-absorbing concrete with high-speed iron-ground steel slag, comprising the following steps:

[0029] 1) Selection of raw materials: according to the ratio of each raw material (kg / m 3 ) is: Portland cement: 130, fly ash: 90, high-speed iron milled steel slag: 90, ceramic sand: 620, superplasticizer: 3.2, basalt fiber 50, water: 160.

[0030] The strength grade of the Portland cement is 42.5MPa, and the specific surface area is greater than 350m 2 / kg; said fly ash is Class III fly ash with a density of 2.6-2.8g / cm 3 , the specific surface area is greater than 400cm 2 / g; The iron component mass content (Fe 2 o 3 ) is greater than 30%, and the specific surface area is greater than 600m 2 / kg; the bulk density of the pottery sand is less than 500m3 3 / kg; the particle size is 0.6-4.75 mm; the high-efficiency water-reducer is a polycarboxylate high-efficiency water-reducer with a water-reducing rate of 20%-25%, a...

Embodiment 3

[0034] A method for preparing light-weight high-toughness wave-absorbing concrete with high-speed iron-ground steel slag, comprising the following steps:

[0035]1) Selection of raw materials: according to the ratio of each raw material (kg / m 3 ) is: Portland cement: 150, fly ash: 90, high-speed iron milled steel slag: 110, pottery sand: 700, superplasticizer: 3.5, basalt fiber 50, water: 171.

[0036] The strength grade of the Portland cement is above 32.5MPa, and the specific surface area is greater than 350m 2 / kg; said fly ash is Class II fly ash with a density of 2.6-2.8g / cm 3 , the specific surface area is greater than 400cm 2 / g; The iron component mass content (Fe 2 o 3 ) is greater than 30%, and the specific surface area is greater than 600m 2 / kg; the bulk density of the pottery sand is less than 500m3 3 / kg; the particle size is 0.6-4.75 mm; the high-efficiency water-reducer is a polycarboxylate high-efficiency water-reducer with a water-reducing rate of 20%-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com