Recycled concrete doped with short-cut basalt fibers and recycled coarse aggregate

A technology of regenerated coarse aggregate and basalt fiber, which is applied in the field of building materials, can solve problems such as limited scope of application, high cost, and corrosion resistance of steel fibers, and achieve the goals of reducing environmental pollution, reducing production costs, and improving tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

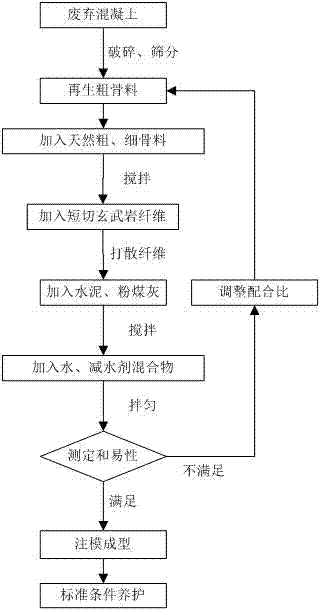

Method used

Image

Examples

Embodiment 1

[0028] Example 1 (strength of recycled concrete is C30):

[0029] A high-performance recycled concrete mixed with chopped basalt fiber and recycled coarse aggregate, which consists of the following raw materials in parts by weight: 205 parts of water, 337 parts of ordinary Portland cement, 648 parts of medium sand, and 576 parts of natural gravel , 576 parts of recycled coarse aggregate, 37 parts of fly ash, 2.52 parts of water reducing agent, and 2.65 parts of chopped basalt fiber.

[0030] The parameters of various materials are as follows:

[0031] The water reducer is a polycarboxylic acid liquid high-efficiency water reducer with an effective content of 25% and a water reducing rate of 25%.

[0032] Chopped basalt fiber density 2650kg / m³, fiber length 18mm, diameter 15μm, tensile strength 2.63×10 3 MPa, tensile modulus of elasticity 85 GPa.

[0033] The fly ash is a high-quality Class II fly ash with a fineness of 17.5%, a water requirement of 99%, a loss on ignition o...

Embodiment 2

[0046] Example 2 (recycled concrete strength is C35):

[0047] A high-performance recycled concrete mixed with chopped basalt fiber and recycled coarse aggregate, which consists of the following raw materials in parts by weight: 205 parts of water, 376 parts of ordinary Portland cement, 597 parts of medium sand, and 580 parts of natural crushed stone , 580 parts of recycled coarse aggregate, 42 parts of fly ash, 2.51 parts of water reducing agent, and 2.65 parts of chopped basalt fiber.

[0048] The parameters of various materials are as follows:

[0049] The water reducer is a polycarboxylic acid liquid high-efficiency water reducer with an effective content of 25% and a water reducing rate of 25%.

[0050] Chopped basalt fiber density 2650kg / m³, fiber length 18mm, diameter 15μm, tensile strength 2.63×10 3 MPa, tensile modulus of elasticity 85 GPa.

[0051] The fly ash is a high-quality Class II fly ash with a fineness of 17.5%, a water requirement of 99%, a loss on igniti...

Embodiment 3

[0064] Example 3 (recycled concrete strength is C40):

[0065] A high-performance recycled concrete mixed with chopped basalt fiber and recycled coarse aggregate, consisting of the following raw materials in parts by weight: 205 parts of water, 415 parts of ordinary Portland cement, 589 parts of medium sand, and 597 parts of natural crushed stone , 597 parts of recycled coarse aggregate, 46 parts of fly ash, 2.77 parts of water reducing agent, and 2.65 parts of chopped basalt fiber.

[0066] The parameters of various materials are as follows:

[0067] The water reducer is a polycarboxylic acid liquid high-efficiency water reducer with an effective content of 25% and a water reducing rate of 25%.

[0068] Chopped basalt fiber density 2650kg / m³, fiber length 18mm, diameter 15μm, tensile strength 2.63×10 3 MPa, tensile modulus of elasticity 85 GPa.

[0069] The fly ash is a high-quality Class II fly ash with a fineness of 17.5%, a water requirement of 99%, a loss on ignition o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com