Basalt fiber concrete and preparation method thereof

A basalt fiber and concrete technology, applied in the field of concrete, can solve the problems of hindering the use of reinforcing fibers, unstable chemical properties, poor concrete toughness, etc., and achieve the effects of improving toughness and anti-cracking performance, low production cost, and improved impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the present embodiment, 100 kilograms is used as the total weight of the proportion, including 19 kilograms of cement, 33.79 kilograms of sand, 35 kilograms of stones, 2 kilograms of water-quenched blast furnace slag powder, 1.5 kilograms of fly ash, and 0.05 kilograms basalt short fiber, 0.06 kg of glass fiber, 8.5 kg of water, 0.05 kg of CTF synergist, 0.05 kg of water reducer.

[0025] The water reducer used in this embodiment and the following embodiments can be selected from ordinary water reducer, high efficiency water reducer, air entraining water reducer, retarding water reducing Water agent, high-efficiency early-strength superplasticizer and other types, or two or more can be selected to form a mixture and added to the concrete.

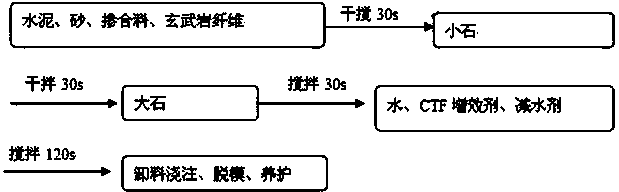

[0026] According to the above ratio, refer to figure 1 As shown, the concrete can be prepared according to the following steps:

[0027] Step 1. Add sand, cement, fly ash, water-quenched blast furnace slag powder, sand and basal...

Embodiment 2

[0035] One embodiment of the present invention is a kind of basalt fiber concrete, with 300 kilograms as proportioning total weight, including 52 kilograms of cement, 100 kilograms of sand, 111 kilograms of stones, 3 kilograms of volcanic ash, 3 kilograms of diatomite , 0.3 kg of basalt short fiber, 1 kg of aramid fiber, 20.4 kg of water, 0.24 kg of CTF synergist, 0.3 kg of water reducer, 6 kg of a mixture of zeolite powder and silica fume, 2.76 kg of calcined partial A mixture of kaolin powder and rice husk ash.

[0036] In this embodiment, in order to ensure the fluidity of the mixture, it is best to use granular raw materials in the selection of materials, for example, the particle size of the above-mentioned stones must be less than or equal to 31.5 mm.

[0037] According to the above ratio, refer to figure 1 As shown, the concrete can be prepared according to the following steps:

[0038] Step 1, adding the mixture of sand, cement, diatomaceous earth, volcanic ash, sand...

Embodiment 3

[0046] One embodiment of the present invention is a kind of basalt fiber concrete, with 500 kilograms as proportioning total weight, including 90 kilograms of cement, 180 kilograms of sand, 175 kilograms of stones, 7 kilograms of water-quenched blast furnace slag powder, 6 kilograms fly ash, 2.5 kg of short basalt fiber, 3 kg of glass fiber, 30 kg of water, 0.5 kg of CTF synergist, 0.75 kg of water reducer, 4.5 kg of a mixture of silica fume and tuff powder, 0.75 kg of A mixture of calcareous clay and calcined coal gangue.

[0047] In this embodiment, in order to ensure the fluidity of the mixture, it is best to use particle-grade raw materials in material selection. In addition to using stones with a particle size of 31.5 mm or less, the above-mentioned water-quenched blast furnace slag powder also needs to be finely ground And after adding the mixture of silica fume and tuff powder, and the mixture of limestone powder and calcined metakaolin, the fluidity of the mixture in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com