Preparation method for basalt fiber conveying belt

A technology of basalt fiber and basalt fiber cloth, which is applied in the field of rubber products, can solve problems such as interface bonding, achieve the effects of increasing bonding strength and bonding amount, improving bonding performance, and reducing overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

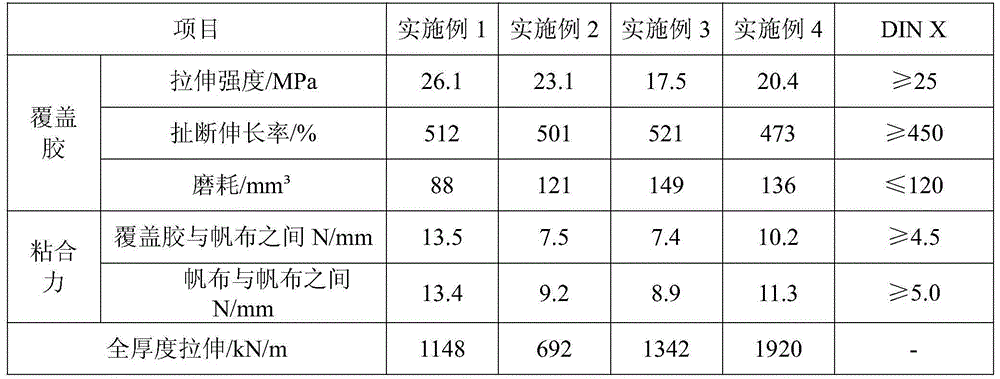

Examples

Embodiment 1

[0037] A method for preparing a basalt fiber conveyor belt, wherein the conveyor belt includes a skeleton, and the upper and lower surfaces of the skeleton are bonded with covering glue through adhesive glue; the feature is that the following process is used for preparation:

[0038] (1) Basalt fiber cloth is used as the skeleton material, and the basalt fiber cloth is treated with a hydrochloric acid solution with a concentration of 1mol / L for 5 minutes; then soaked in a KH570 coupling agent solution with a concentration of 5% for 1 hour, and then dried at 120°C for 0.5 hours; after drying Under the power of 100W, the basalt fiber cloth was treated with plasma for 6 minutes, put into the maleic anhydride solution with a concentration of 0.05mol / L, and 0.05mmol of benzoyl oxide (BPO) was used as the initiator. After soaking for 1 hour, it was taken out. Dried in a drying oven at 90°C, and finally processed in the dipped latex. The components of the dipped latex are: 3 parts by ...

Embodiment 2

[0044] A method for preparing a basalt fiber conveyor belt, wherein the conveyor belt includes a skeleton, and the upper and lower surfaces of the skeleton are bonded with covering glue through adhesive glue; the feature is that the following process is used for preparation:

[0045] (1) Basalt fiber cloth is used as the skeleton material, and the basalt fiber cloth is treated with a hydrochloric acid solution with a concentration of 2mol / L for 3 minutes; then soaked in a 2% KH792 coupling agent solution for 1.5 hours and then dried at 130°C for 0.6 hours; The final basalt fiber cloth was treated with plasma under 120W power for 8min, then put into the maleic anhydride solution with a concentration of 0.1mol / L, and took 0.08mmol benzoyl peroxide (BPO) as the initiator, soaked for 1.5h and then took it out , dried in a drying oven at 100°C, and finally processed in the dipped latex. The components of the dipped latex are: 4 parts by weight of resorcinol, 2.5 parts by weight of f...

Embodiment 3

[0051] A method for preparing a basalt fiber conveyor belt, wherein the conveyor belt includes a skeleton, and the upper and lower surfaces of the skeleton are bonded with covering glue through adhesive glue; the feature is that the following process is used for preparation:

[0052] (1) Basalt fiber cloth is used as the skeleton material, and the basalt fiber cloth is treated with a hydrochloric acid solution with a concentration of 4mol / L for 2 minutes; then soaked in a KH550 coupling agent solution with a concentration of 3% for 1.8 hours and then dried at 140°C for 0.8 hours; The final basalt fiber cloth was treated with plasma under 140W power for 7 minutes, then put into a solution of maleic anhydride with a concentration of 0.15mol / L, with 0.1mmol azobisisobutyronitrile (AIBN) as the initiator, soaked for 1.8h Take it out, dry it in a drying oven at 105°C, and finally process it in the dipped latex. The components of the dipped latex are: 5 parts by weight of resorcinol,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Weft breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com