Building external wall insulation board laying device

A laying device and a technology for building exterior walls, which can be used in thermal insulation, construction, building components, etc., and can solve problems such as the inability to quickly lay insulation boards outside the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

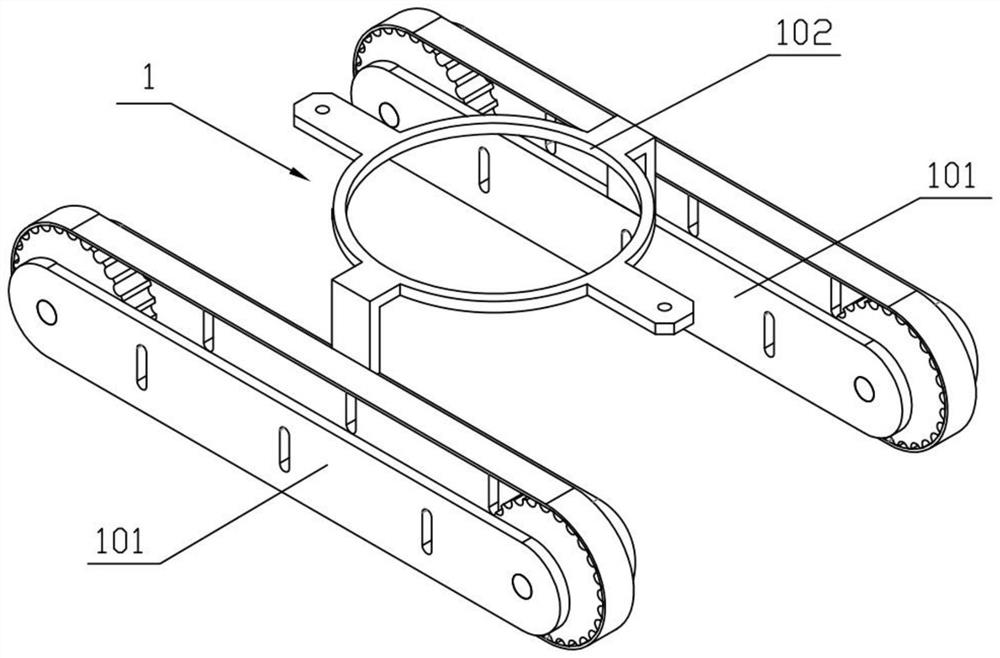

[0036] Combine below Figures 1 to 12 Describe this embodiment, a device for laying thermal insulation boards on building exterior walls, including a moving mechanism 1, a rotating mechanism 2, a retractable mechanism 3, a laying bracket 4, a power mechanism 5, a refueling mechanism 6, a material pushing mechanism 7, and a feeding mechanism 8 and a spraying mechanism 9, the moving mechanism 1 is connected with a rotating mechanism 2, the rotating mechanism 2 is connected with a retractable mechanism 3, the retractable mechanism 3 is fixedly connected with a laying support 4, and the laying support 4 is fixedly connected with a power mechanism 5. A refueling mechanism 6 is rotatably connected to the laying support 4. The refueling mechanism 6 and the power mechanism 5 are connected in transmission. The feeding mechanism 8 is slidingly connected to the laying support 4, the compression spring I is fixedly connected between the feeding mechanism 8 and the laying support 4, and th...

specific Embodiment approach 2

[0038] Combine below Figures 1 to 12 Describe this embodiment, this embodiment will further explain Embodiment 1, the moving mechanism 1 includes a crawler mechanism 101 and an installation swivel 102, two crawler mechanisms 101 are provided, and an installation swivel is fixedly connected between the two crawler mechanisms 101 Ring 102.

specific Embodiment approach 3

[0040] Combine below Figures 1 to 12 Describe this embodiment, this embodiment will further explain the second embodiment, the rotating mechanism 2 includes a rotating pulley 201, a rotating motor 202, a rotating bracket 203 and a limit ring 204, and the rotating pulley 201 is rotatably connected to the installation swivel 102, the rotating motor 202 is fixedly connected to the installation swivel 102, the rotating pulley 201 is connected with the output shaft of the rotating motor 202, the rotating pulley 201 is fixedly connected with a rotating bracket 203, and the rotating bracket 203 is fixedly connected with two Limiting ring 204; during use, the device is placed on the upstairs where the insulation board needs to be laid, and the crawler mechanism 101 is started, and the crawler mechanism 101 can drive the device to move, and the rotation motor 202 is started, and the output shaft of the rotation motor 202 drives the rotation pulley 201 to carry out Rotate, the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com