Novel light-wave absorbing carbon fiber composite material preparation method

A composite material and carbon fiber technology, which is applied in the preparation of wave-absorbing materials and new-type wave-absorbing materials, can solve problems such as limited application, complicated process, and expensive price, and achieve good wave-absorbing effect, simple process, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

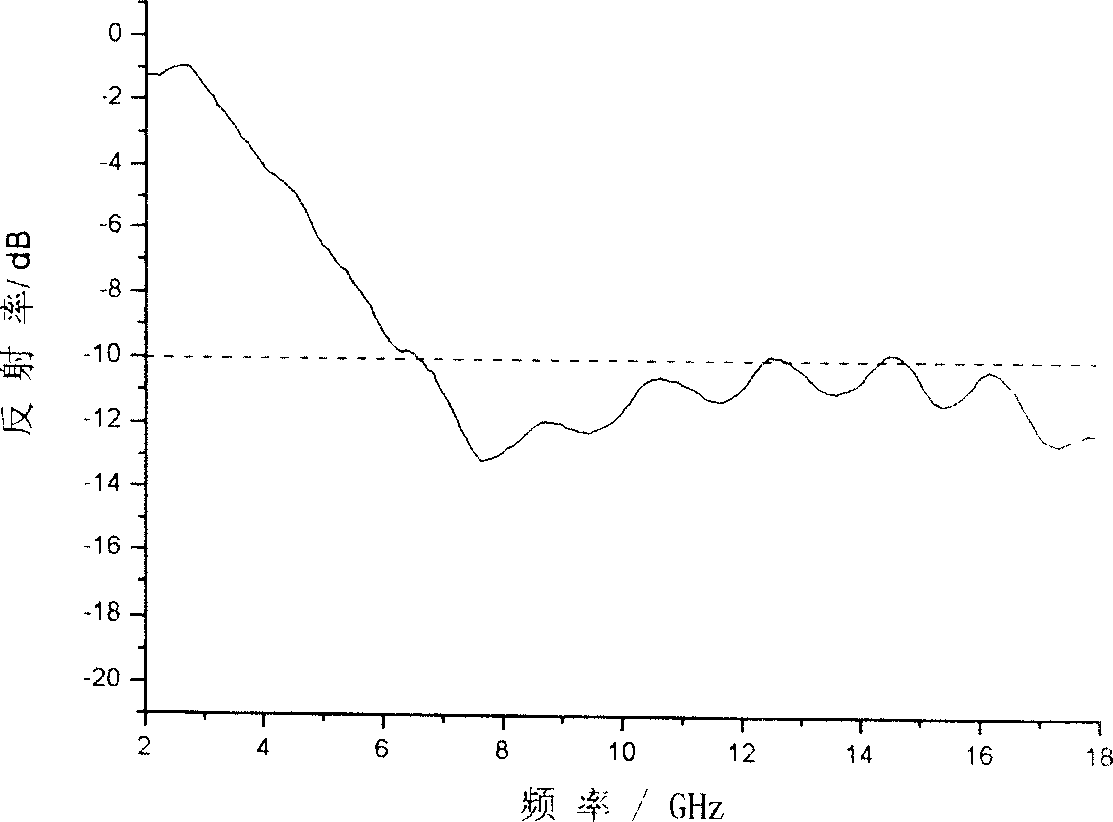

[0018] Get 100 grams of viscose-based fiber, with 2000 milliliters of 10% (NH 4 ) 2 SO 4 impregnated with the solution, dried at room temperature, and then carbonized in the air at 350-400°C; the carbonized fiber was placed in a rotary activation furnace, and heated at 10 -2 Pa low vacuum, 900 ~ 950 ℃, pass water vapor into the activation furnace and keep it warm for 10 minutes, take out the carbon fiber, and obtain the activated carbon fiber with special-shaped cross-section and high specific surface area, and make the obtained activated carbon fiber into a length of 20 mm for later use .

[0019] Weigh 100g of E-44 (6101) type epoxy resin and 1.1g of activated short carbon fiber, and stir thoroughly after mixing. Weigh 50 g of low-molecular-weight polyamide, add it to the aforementioned mixture, and stir again until it is evenly mixed, and use this mixture as the wave-absorbing layer in the wave-absorbing plate. Pour an appropriate amount of the mixture into the mold so ...

Embodiment 2

[0021] A composite material with a gradient distribution of carbon fiber content was prepared, in which the wave-absorbing layer was prepared in the form of layered casting, and the carbon fiber content of each layer decreased in turn. Using the same method as in Example 1, the short carbon fibers were fully mixed with epoxy resin and curing agent. A four-layer structure is adopted, and the content of short carbon fibers in each layer is 1%, 0.75%, 0.5% and 0.25%, respectively. Cast in layers in the mold, cure at 10MPa, 80°C for about three hours, and demould to obtain the gradient absorbing composite material.

Embodiment 3

[0023] Weigh 200g of E-44 type epoxy resin, mix it with 3g of active short carbon fiber and stir thoroughly. Weigh 100g of low-molecular-weight polyamide, add it to the original mixture, and stir again until the resin, curing agent and carbon wool are evenly mixed. Put this mixture into an appropriate mold, apply a pressure of about 10MPa, and cure it at 80°C for about three hours, and then demould to obtain a wave-absorbing composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com