The production method and pulp maked bamboos

A technology of cellulose pulp and bamboo, which is applied in the direction of pulping of cellulose raw materials, pulp bleaching, and fiber raw materials, and can solve problems such as fiber fragility, medicines, energy consumption, increased production costs, and durability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

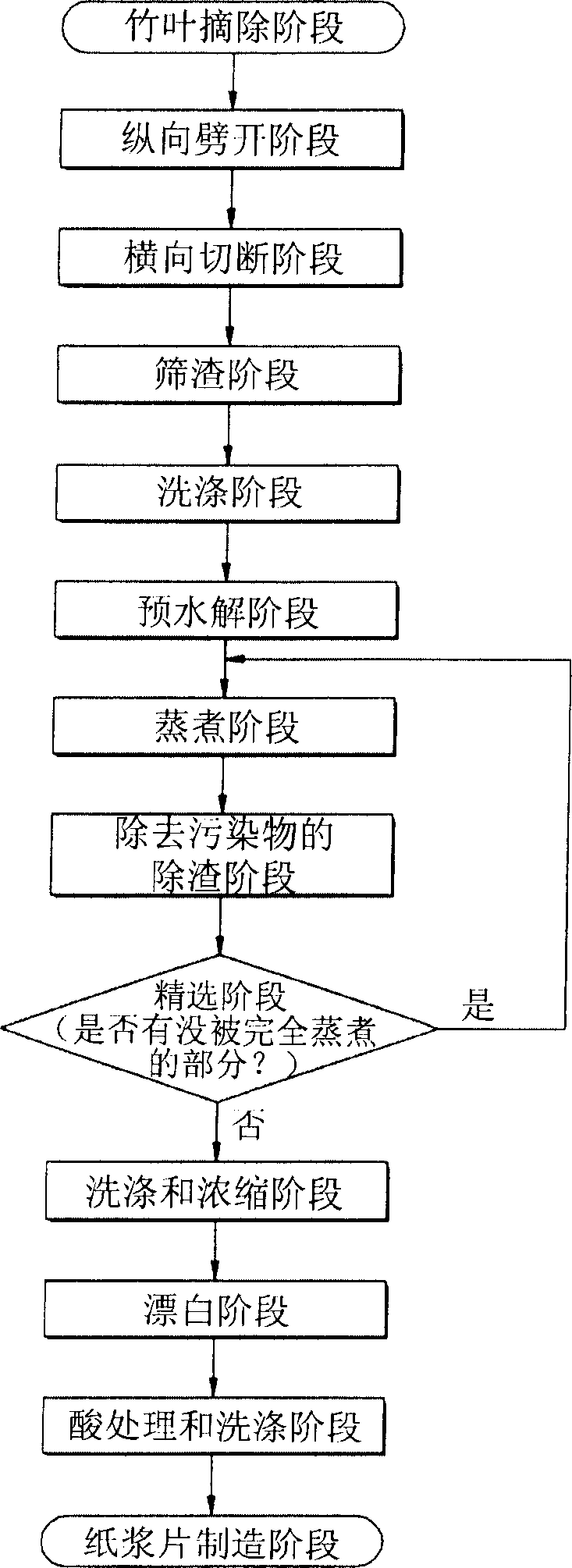

Method used

Image

Examples

Embodiment 1

[0057] Bamboo from Myanmar is finely cut to a width of approximately 2mm and cut to a length of 15-25mm, and is screened with a mesh drum with 60 meshes to remove pollutants and bamboo residue, followed by washing.

[0058]Take out the amount corresponding to 400g of dried bamboo slices from the washed bamboo and put it into the cooking section, and inject water to adjust the liquid ratio to 6:1, then place a stainless steel weight on it to fully immerse the bamboo in the water.

[0059] After closing the lid of the cooking section and screwing on the screws, pre-hydrolyze at 170°C for 90 minutes.

[0060] After washing the undissolved matter after pre-hydrolysis, put it into the cooking section again, and add 16% of active alkali (converted to Na 2 O), 0.1% of anthraquinone and after adjusting the liquid ratio to be 4: 1, cook at 170° C. for 120 minutes.

[0061] The washed and cooked pulp was bleached in four stages of DEDD, and the pulp characteristics obtained as a result...

Embodiment 2

[0065] The treatment of bamboo and most of the conditions are the same as in Example 1, while the prehydrolysis conditions and bleaching conditions are as follows.

[0066] During pre-hydrolysis, adjust the liquid ratio to 4:1, and pre-hydrolyze at 170° C. for 100 minutes.

[0067] The four stages of DEDP bleaching were performed on the cooked and washed pulp, and the pulp characteristics obtained as a result are shown in Table 2.

[0068] Yield of pulp before bleaching (%)

37.8

9.8

Yield of pulp after bleaching (%)

36.2

Whiteness (%ISO)

86.2

Alpha cellulose (%)

95.4

Viscosity (cps)

5.1

821

[0069] As mentioned above, the present invention is easy to carry out pre-hydrolysis and cooking by splitting longitudinally and cutting transversely, so that cellulose (dissolving) pulp can be produced under milder conditions, and bamboo pulping is adopted i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com