Process for Producing Fiber Pulp Utilizing Bamboo and Pulp Produced Using the Same

a technology of fiber pulp and bamboo, which is applied in the direction of pulping with inorganic bases, pretreatment with water/steam, building rescue, etc., can solve the problems of increasing the emissions of greenhouse gases, increasing the cost of pulp production, so as to achieve low environmental pollution and high pulp production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

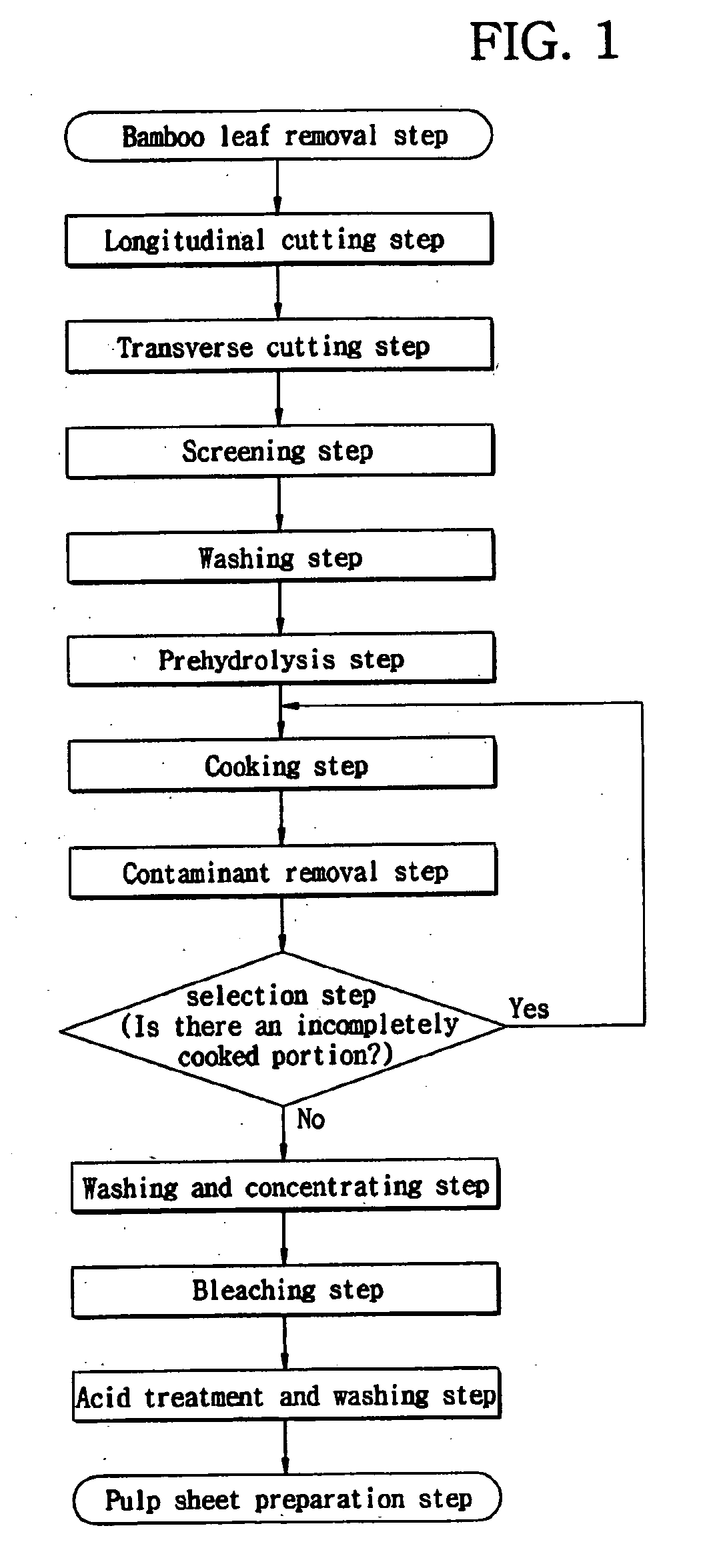

Method used

Image

Examples

example 1

[0118]A Myanmar bamboo was split to a width of about 2 mm and then cut to a length of 15-25 mm. The cut material was screened through a 60-mesh screen to remove contaminants and small bamboo fragments, followed by washing.

[0119]400 g (on a oven-dry weight-basis) of the washed bamboo was placed in a digester into which water was added to make a liquor ratio of 6:1. Then, a stainless weight is laid on the bamboo such that the bamboo could be sufficiently immersed in water.

[0120]After the digester was covered with a lid and screwed, the bamboo was subjected to prehydrolysis at 170° C. for 90 minutes.

[0121]After completion of the prehydrolysis, the content within the digester was washed and then placed again into the digester, into which 16% active alkali (calculated as Na2O) and 0.1% anthraquinone were added so as to adjust the liquor ratio to 4:1. Then, the bamboo was cooked at 170° C. for 120 minutes.

[0122]The cooked pulp was washed and subjected to a four-stage bleaching of DEDD, an...

example 2

[0123]The treatment of bamboo and most of conditions were the same as in Example 1, but the prehydrolysis and bleaching conditions were as follows:

[0124]The liquor ratio in the prehydrolysis Was adjusted to 4:1, and the prehydrolysis was conducted at 170° C. for 100 minutes.

[0125]The cooked and washed pulp was subjected to a four-stage bleaching of DEDP, and the properties of the resulting pulp are shown in Table 2 below.

TABLE 2Results of prehydrolysis and pulping tests of bambooYield of pulp before bleaching37.8Kappa number*9.8Yield of pulp after bleaching36.2Brightness (% ISO)86.2Alpha-cellulose95.4Viscosity (cps)5.1Degree of polymerization821

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com