Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111 results about "Thiosulfuric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thiosulfuric acid is a sulfur oxoacid. The acid cannot be made by acidifying aqueous thiosulfate salt solutions as the acid readily decomposes in water. The decomposition products can include sulfur, sulfur dioxide, hydrogen sulfide, polysulfanes, sulfuric acid and polythionates, depending on the exact reaction conditions.

Electroless gold plating liquid

ActiveUS20060269761A1Low toxicityHigh bonding strengthAnti-corrosive paintsLiquid/solution decomposition chemical coatingAlkaline earth metalCyanide

A cyanide-free immersion type electroless gold plating solution that is less toxic, that can be used at near neutrality, and that gives an excellent and improved solder adhesion and plated film adhesion is provided. An electroless gold plating solution, comprising a cyanide-free water-soluble gold compound, a pyrosulfurous acid compound and a thiosulfuric acid compound. This plating solution preferably further contains a sulfurous acid compound and an aminocarboxylic acid compound. Pyrosulfurous acid and alkali metal salts, alkaline-earth metal salts, ammonium salts and other salts thereof can be used as the pyrosulfurous acid compound.

Owner:JX NIPPON MINING& METALS CORP

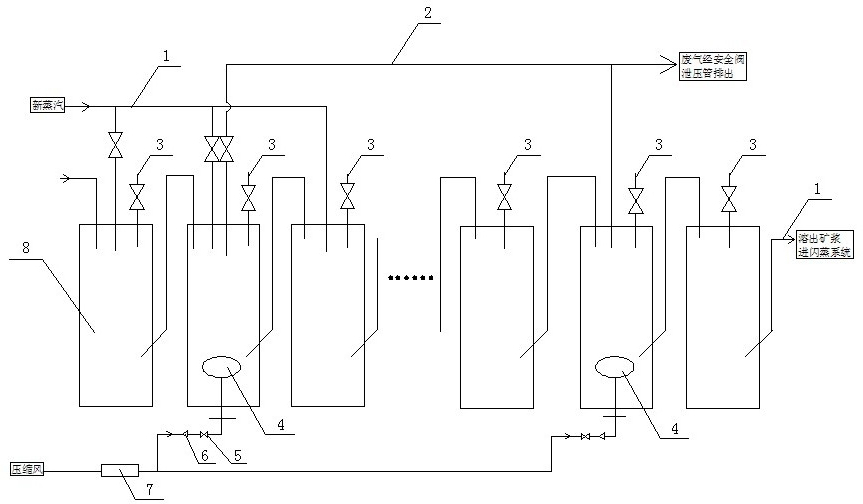

Method for producing aluminum oxide by high sulfur bauxite

InactiveCN102616821AReduce manufacturing costNegative divalent sulfur concentration decreasedAluminium oxide/hydroxide preparationSulfate radicalsAluminium hydroxide

The invention discloses a method for producing aluminum oxide by high sulfur bauxite, which comprises the processes of raw material preparation, high-pressure digestion, settling separation and washing, aluminum hydroxide seed decomposition, aluminum hydroxide washing and calcination, and mother liquor evaporation. The high-pressure digestion process comprises a low-temperature section, a medium-temperature section and a high-temperature section; compressed air is fed into a high-temperature section reaction kettle in the high-pressure digestion process, so as to finally oxidize S2- in pulp into SO42-; and SO42- is combined in sodium-silicon slag in red mud and discharged with the red mud. By adopting the technical scheme, the concentration of negative bivalent sulfur in dissolution pulp liquid phase is obviously reduced, the concentration of thiosulfate in the dissolution pulp liquid phase is not increased obviously, the concentrations of negative bivalent sulfur and ferric oxide in circulating mother liquor are obviously reduced, the concentration of negative bivalent sulfur in fine liquor is obviously reduced, the concentration of thiosulfate is not increased obviously, the content of ferric oxide in the fine liquor is reduced, the contents of ferric oxide in aluminum hydroxide and aluminum oxide meet the primary standard of the national standard, and all production links return to normal.

Owner:洛阳香江万基铝业有限公司

Thiosulfuric acid derivant preparation

The invention relates to a novel process for preparing salts of S-alkyl esters of thiosulphuric acid by reacting organic dihalides with thiosulphates in water.

Owner:LANXESS DEUTDCHLAND GMBH

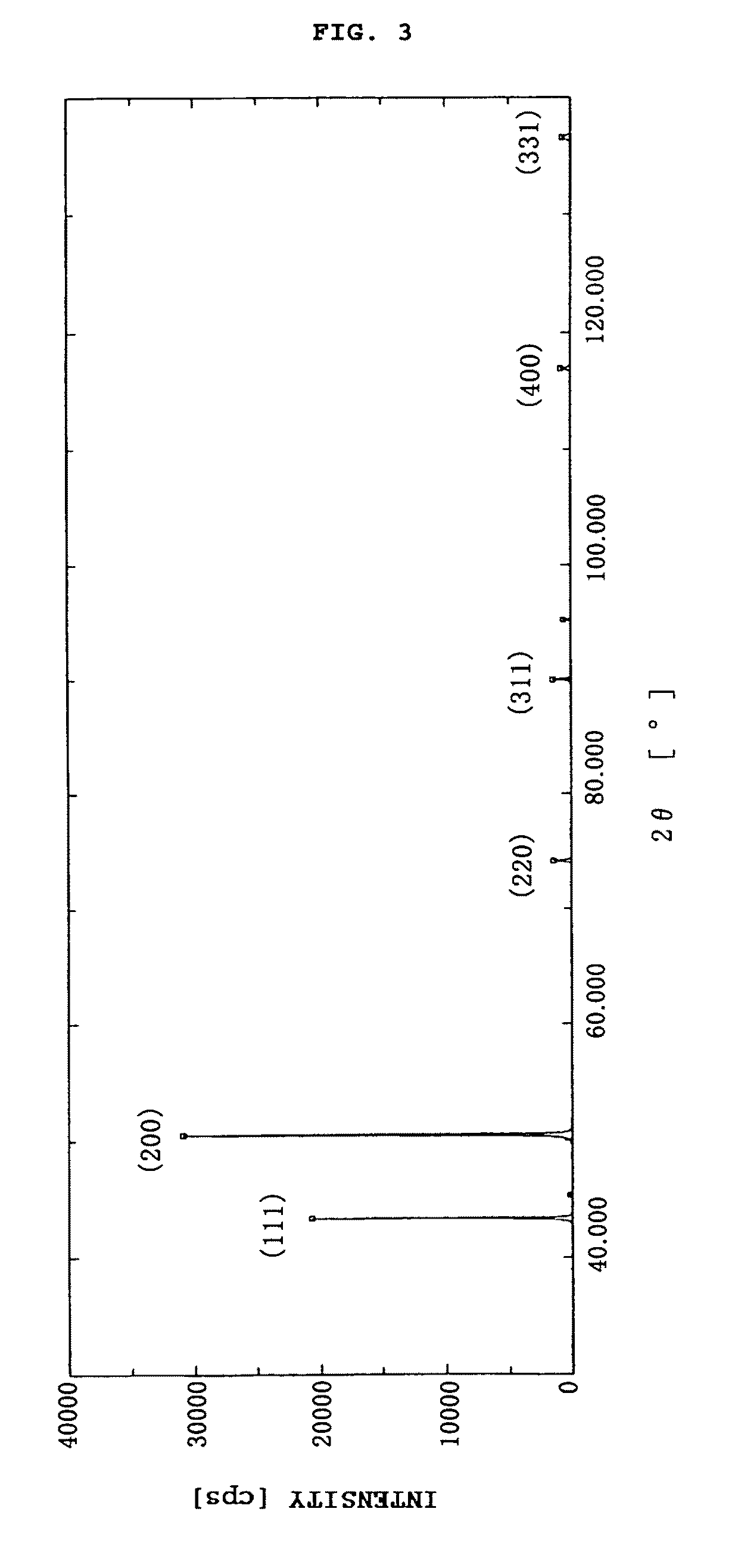

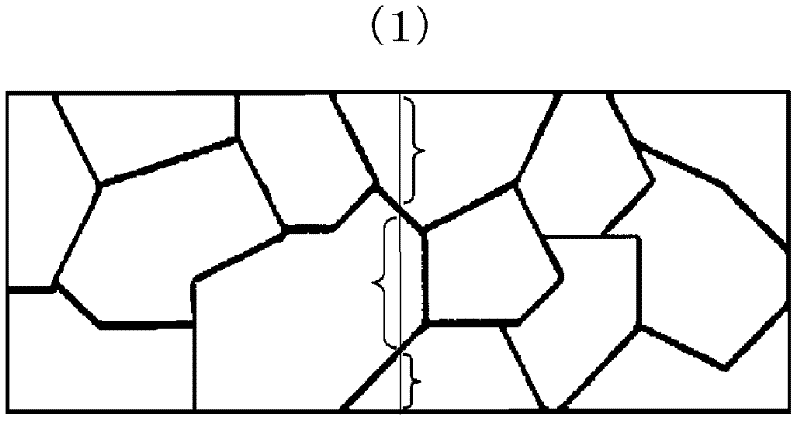

Two-layer flexible substrate, and copper electrolytic solution for producing same

InactiveUS20110311834A1Polycrystalline material growthFrom normal temperature solutionsFolding enduranceThiourea

It is an object of the invention to provide a two-layer flexible substrate that excels in folding endurance and free from occurrence of Kirkendall voids or the like even when lead portions of COF are plated with tin and heat treatment is performed. The present invention is directed to a two-layer flexible substrate in which a copper layer is provided on one or both faces of an insulating film by using a copper electrolytic solution, wherein an average size of copper crystal grains constituting the copper layer is equal to or greater than 1 μm and equal to or less than a thickness of the copper layer, and a ratio of peak intensity of (200) to a sum total of intensities of six principal peaks {[peak intensity of (200)] / [sum total of peak intensities of (111), (200), (220), (311), (400), (331)]} in the X-ray diffraction of the copper layer is equal to or greater than 0.4. The above copper electrolytic solution for forming the copper layer contains a chloride ion and one or more of thiourea, thiourea derivatives, and thiosulfuric acid as additives.

Owner:JX NIPPON MINING& METALS CORP

Two-layered flexible substrate, and copper electrolyte for producing same

InactiveCN102348835ANo porosityPolycrystalline material growthFrom normal temperature solutionsChip on filmThiourea

Disclosed is a two-layered flexible substrate which has excellent bending endurance, and furthermore, wherein Kirkendall voids do not arise even if a chip-on-film lead section is tin plated and heat treatment is performed. The disclosed two-layered flexible substrate is provided with a copper layer using a copper electrolyte on one or both faces of an insulating film, and is characterized by the copper crystal grains forming the aforementioned copper layer having a grain size of at least 1 [mu]m and no more than the thickness of the copper layer, and by X-ray diffraction of the aforementioned copper layer having a ratio of the (200) peak strength to the sum of the main six peak strengths { (200) peak strength / ( sum of (111), (200), (220), (311), (400), and (331) peak strengths) } of at least 0.4. Furthermore, the copper electrolyte for forming the aforementioned copper layer is characterized by including as an additive at least one of chloride ions, thiourea, a thiourea derivative, and thiosulfuric acid.

Owner:JX NIPPON MINING & METALS CORP

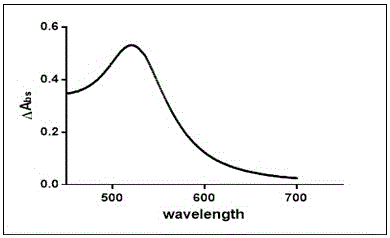

Test paper film based on nanogold and method for detecting lead ion by test paper film

ActiveCN104990918ANot prone to aggregationEasy to fixMaterial analysis by observing effect on chemical indicatorSulfate radicalsFilm base

The invention relates a test paper film based on nanogold and a method for detecting lead ion by the test paper film; a nano-titanium dioxide coating is coated on a basement membrane of the test paper film, and the nano-titanium dioxide coating is adhered with the nanogold and thiosulfuric acid root shell which are fixed by sulfydryl and amidogen. The invention also provides a method for detecting the lead ion in water by the test paper film based on the nanogold, the pre-treatment process for a sample to be detected is not needed, and large-scale equipment is not needed either; the method provided by the invention has the advantages of fast detection speed, low cost, strong anti-interference and low limit of detection; the detection lower limiting value of the lead ion can reach 5nM.

Owner:CHONGQING UNIV

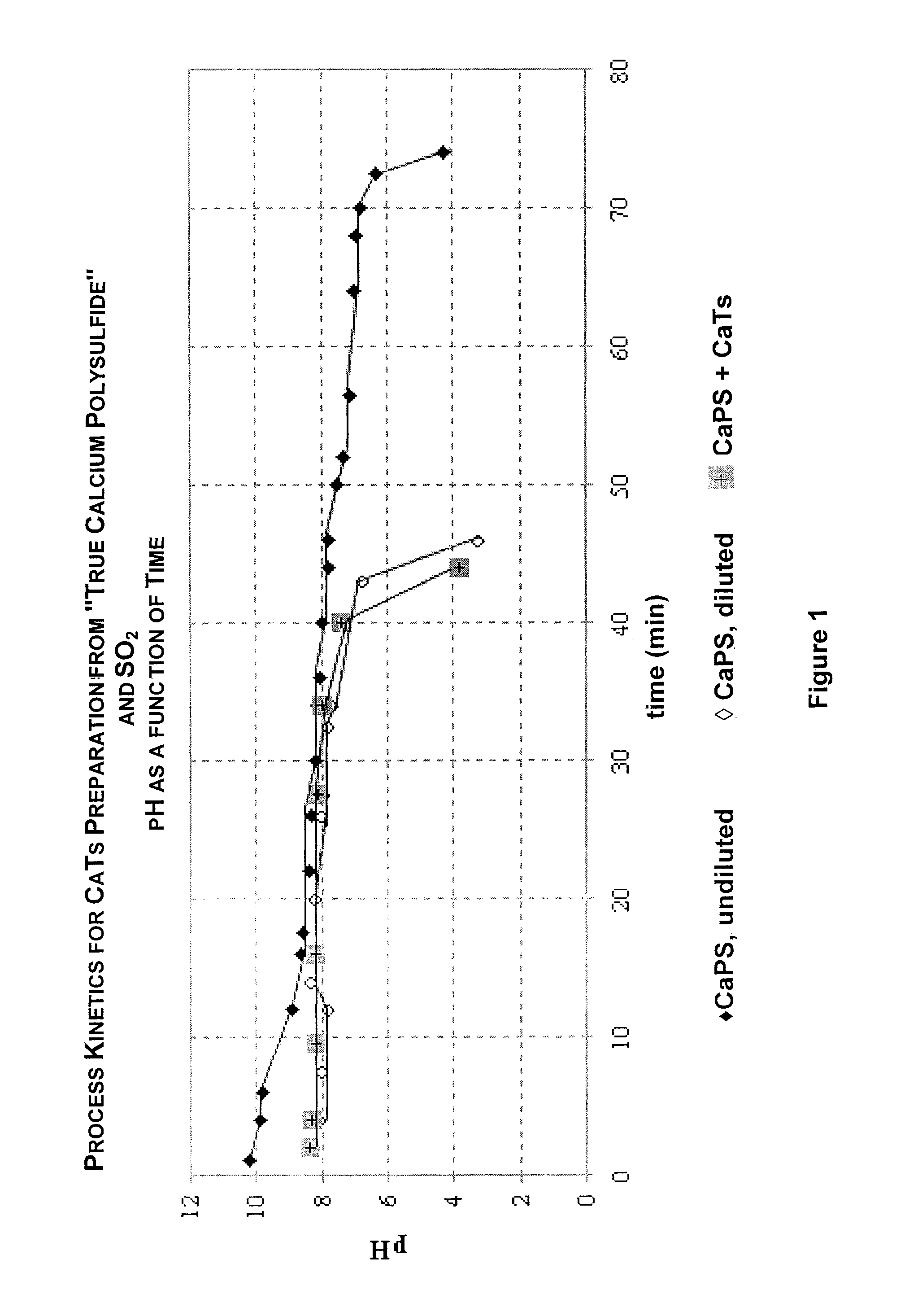

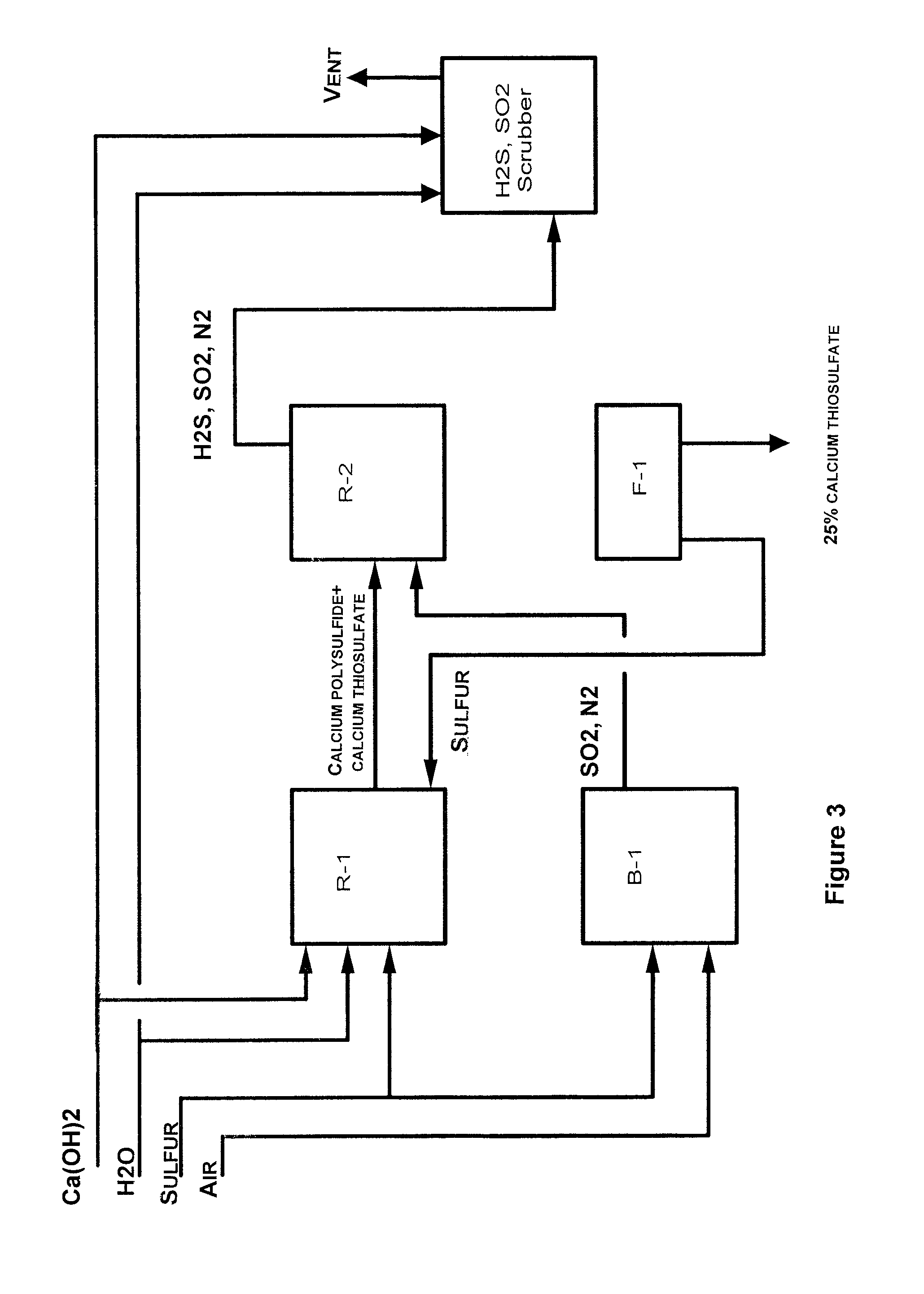

Process for preparation of calcium thiosulfate liquid solution from lime, sulfur, and sulfur dioxide

ActiveUS8034318B1Reduces formation of undesirableIncrease concentrationThiosulfates/dithionites/polythionitesDispersed particle separationHigh concentrationEmulsion

An efficient batch or semi-continuous method of production of relative high concentration, low byproduct-containing, calcium thiosulfate (CaS2O3) from lime, sulfur or calcium polysulfide, and sulfur dioxide under elevated reaction temperature conditions is described. The product is an emulsion of liquid calcium thiosulfate and solid byproducts. Under the conditions of the art, including the mole ratios of lime to sulfur, the temperature of the reaction process and the sulfur dioxide reaction conditions, including rate and duration, the byproducts are reduced to about 2% by weight.

Owner:TESSENDERLO KERLEY INC

Method for leaching sulfide gold concentrate by virtue of combination of acid pressure leaching and alkali pressure leaching

InactiveCN104805281AImprove leaching rateFully exposedProcess efficiency improvementReaction temperatureSulfide

The invention relates to a method for leaching sulfide gold concentrate by virtue of combination of acid pressure leaching and alkali pressure leaching. The method comprises an acid pressure leaching pretreatment stage and an alkali pressure leaching stage; firstly, in an acid pressure leaching process, reaction conditions are controlled, so that sulfides are oxidized, part of elemental sulfur is converted into a simple substance sulphur and thus gold is dissociated and exposed. Acid pressure leaching residues are subjected to alkali pressure leaching stage after being washed; in the alkali leaching process, the dosage of alkali substances is controlled, and the reaction temperature and the oxygen partial pressure are kept at a relatively low level, so that the sulphur in the acid pressure leaching residues is oxidized into ligands, namely thiosulfate ions and polysulfide ions, which are coordinated with gold, so that efficient gold leaching is realized under a condition of no additional leaching agent. The method is environmentally friendly and low in production cost.

Owner:CENT SOUTH UNIV

Preparation method of sodium gold sulfide solution for cyanide-free gold plating

ActiveCN106637314AConducive to promoting the process of industrializationIncrease profitGold compoundsSulfite saltActivated carbon filtration

The invention provides a preparation method of a sodium gold sulfide solution for cyanide-free gold plating. The method comprises the following steps: firstly, dissolving and nitrating elemental gold by aqua regia to obtain a chlorate gold solution; secondly, adding sodium thiosulfate in the chlorate gold solution and reacting to generate a sodium gold thiosulfate; thirdly, adding ethanol and separating out sodium gold thiosulfate precipitation; fourthly, adding a sodium sulfide solution for complexing; and finally, carrying out filtering by using activated carbon to remove sulfur, thus obtaining the sodium gold sulfide solution. The preparation method provided by the invention is simple in process and convenient to operate; the yield of the sodium gold thiosulfate generated by reacting gold chlorate with the sodium thiosulfate is high, and the loss is less; in addition, the sodium gold thiosulfate is stable and is easy to separate; the complexing conversion rate of the sodium gold thiosulfate and the sodium sulfide is high, so that a product obtained by the method provided by the invention is high in purity; and in addition, the utilization rate of precious metal gold is also high, and the prepared sodium gold sulfide solution is more stable.

Owner:GUANGDONG GUANGHUA SCI TECH

Process for preparation of calcium thiosulfate liquid solution from lime, sulfur, and sulfur dioxide

ActiveUS20110262343A1Reduce formationIncrease concentrationThiosulfates/dithionites/polythionitesHigh concentrationEmulsion

An efficient batch or semi-continuous method of production of relative high concentration, low byproduct-containing, calcium thiosulfate (CaS2O3) from lime, sulfur or calcium polysulfide, and sulfur dioxide under elevated reaction temperature conditions is described. The product is an emulsion of liquid calcium thiosulfate and solid byproducts. Under the conditions of the art, including the mole ratios of lime to sulfur, the temperature of the reaction process and the sulfur dioxide reaction conditions, including rate and duration, the byproducts are reduced to about 2% by weight.

Owner:TESSENDERLO KERLEY INC

Chemical gold plating liquid

ActiveCN1842616ALow toxicityHigh bonding strengthLiquid/solution decomposition chemical coatingAlkaline earth metalCyanide

A cyanide-free transposing type chemical gold plating solution that is less toxic, that can be used at near neutrality, and that gives an excellent and improved solder adhesion and plated film adhesion is provided. A chemical gold plating solution, comprising a cyanide-free water-soluble gold compound, a pyrosulfurous acid compound and a thiosulfuric acid compound. This plating solution preferably further contains a sulfurous acid compound and an aminocarboxylic acid compound. Pyrosulfurous acid and alkali metal salts, alkaline-earth metal salts, ammonium salts and other salts thereof can be used as the pyrosulfurous acid compound.

Owner:JX NIPPON MINING & METALS CO LTD

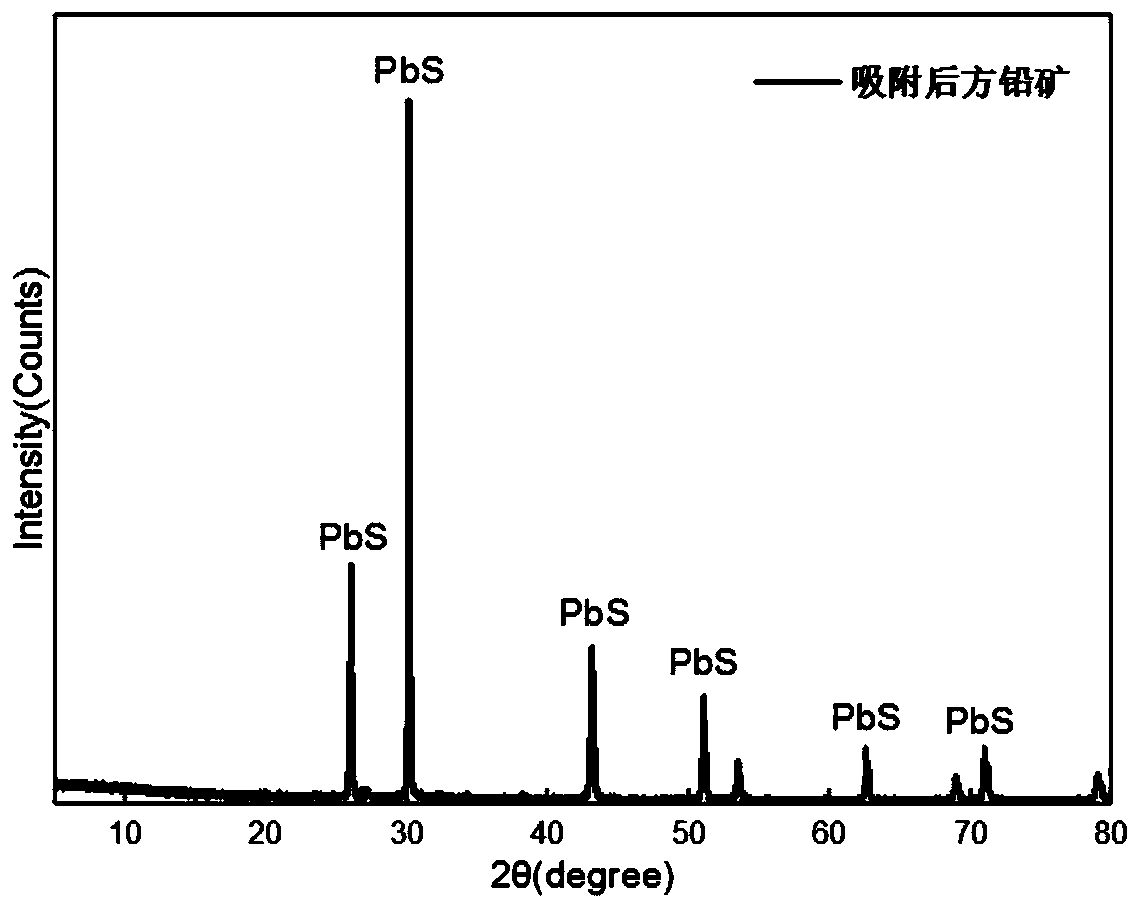

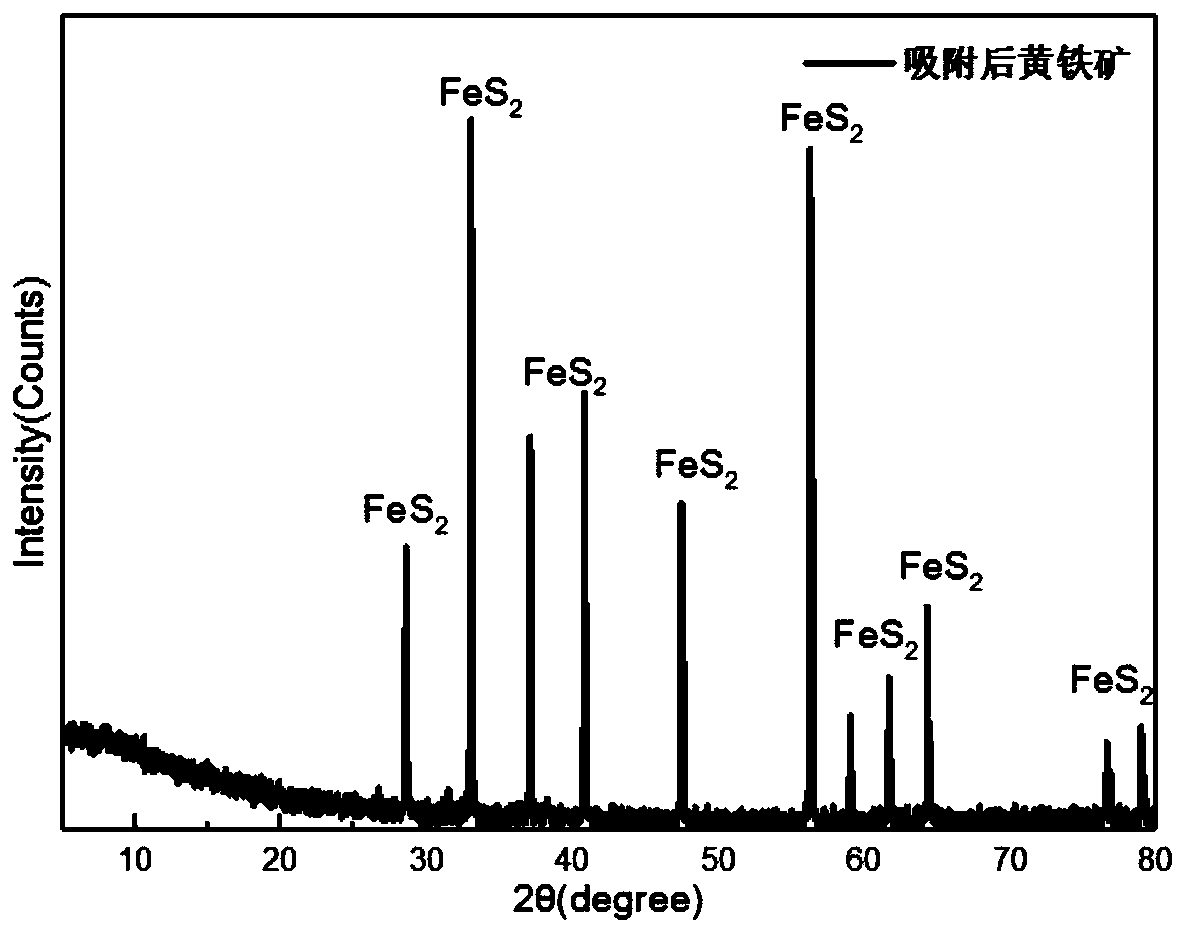

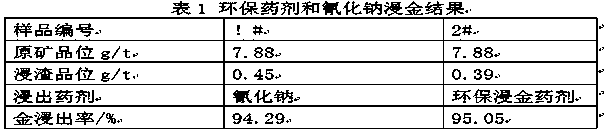

Process for recovering precious metal from sulphide ore based on thiosulfate leaching method

ActiveCN109797281AImprove adsorption capacityEfficient desorptionPhotography auxillary processesProcess efficiency improvementPregnant leach solutionSorbent

The invention discloses a process for recovering precious metal from sulphide ore based on a thiosulfate leaching method. The process comprises the following steps: ore containing the precious metal is selected and placed in a thiosulfate solution to be ground, and ore pulp after ore grinding is leached; leaching liquid is obtained, and the sulphide ore is placed into the leaching liquid to adsorbthiosulfuric acid complexes of the precious metal; a solution after adsorption is filtered and dewatered, and the sulphide ore loaded with the precious metal thiosulfuric acid complexes is obtained;the precious metal thiosulfuric acid complexes are desorbed from the sulphide ore, and precious liquid containing precious metal complex ions is obtained; and the obtained precious liquid is electrolyzed, and a precious metal simple substance is obtained. Through the sulphide ore, the adsorption quantity on Au / Ag can reach the situation that an adsorbent adsorbs tens of milligrams of Au / Ag per gram, and the adsorption quantity is much larger than that of an existing adsorbent; meanwhile, Au / Ag is desorbed from the adsorbent through a NaOH solution or a Na2S solution; and the method is easy tooperate, the adsorbent is simple and easy to obtain, the adsorption effect on Au / Ag is good, and meanwhile Au / Ag is efficiently desorbed.

Owner:WUHAN UNIV OF TECH

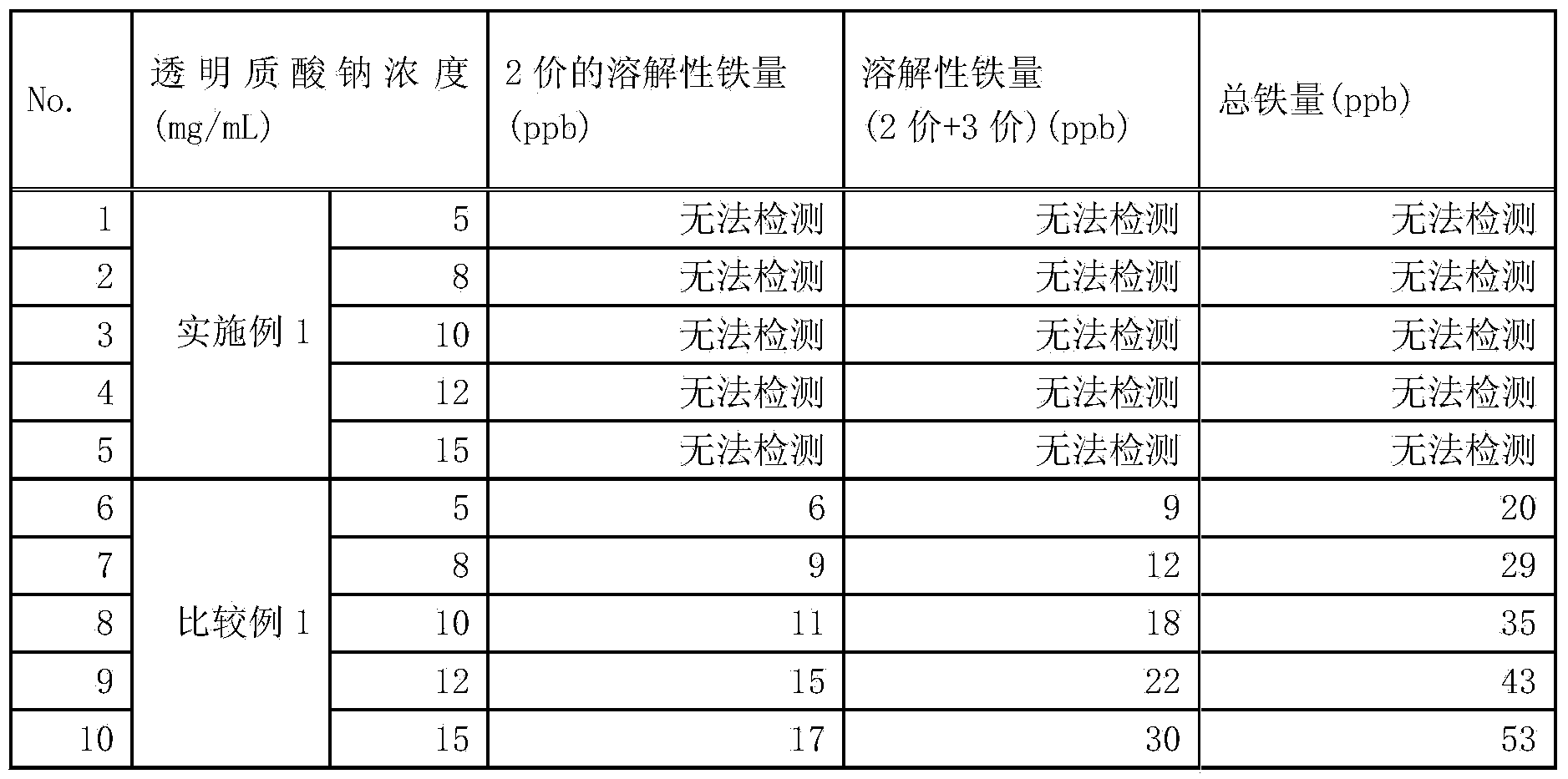

Pre-filled syringe filling syringe having resin barrel with aqueous solution containing hyaluronic acid or salt thereof

Provided is a pre-filled syringe that can stably store a highly-pure sodium hyaluronate aqueous solution that fills the inside of a resin barrel. Provided is a pre-filled syringe that fills a syringe having a resin barrel with an aqueous solution containing hyaluronic acid or a salt thereof. Moreover, the aqueous solution containing hyaluronic acid or a salt thereof contains a divalent soluble iron content of no greater than 5 ppb, and contains at least one additive selected from the group consisting of a metal thiosulfate, a metal thiocyanate, a thiourea, a thiosemicarbazide, a thioketone, and a sulfide.

Owner:DENKA CO LTD

Reverse osmosis membrane cleaning agent and preparation and cleaning method thereof

InactiveCN109971555AEasy to cleanShorten cleaning timeInorganic/elemental detergent compounding agentsSemi-permeable membranesDaily operationSulfite salt

The invention discloses a reverse osmosis membrane cleaning agent and a preparation and cleaning method. The landfill leachate secondary RO membrane cleaning agent comprises the following raw materials in percent by mass: 7.6%-9.6% of thiosulfuric acid, 3.5%-5.5% of sodium sulfite, 0.04%-0.06% of sodium hydroxide, 0.005-0.015% of a surfactant, and the balance deionized water. Deionized water is injected into a corrosion-resistant mixing vessel, each component is weighed for standby application according to the mass percentage, the surfactant, thiosulfuric acid and sodium sulfite are successively added, the inorganic alkali is added, even mixing is performed by stirring at room temperature until all the components are dissolved, and the secondary RO membrane cleaning agent is obtained. Thestorage of a secondary RO membrane module is as follows: the secondary RO membrane module is steadily placed in a pressure vessel of a conventional cleaning system, and the cleaning is performed by using the secondary RO membrane cleaning agent according to the correct steps. The cleaning and restoring effect of the secondary RO membrane fouling blockage is relatively good, the cleaning time is shortened by more than 50% compared with the conventional cleaning time, the water flux of the membrane is restored by more than 98%, and the daily operation efficiency is greatly improved.

Owner:水发合众清源(北京)环境科技有限公司

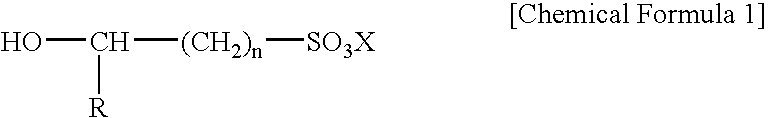

Electroless gold plating liquid

ActiveUS20070095249A1Adequate deposition speedExcellent liquid stabilityAnti-corrosive paintsLiquid/solution decomposition chemical coatingPhenyl groupAlkali metal

The object is to provide an electroless plating liquid which has an adequate deposition speed for practical use without containing any thallium or other heavy metal ions, and which has excellent stability of the plating liquid. An electroless gold plating liquid comprising a non-cyanide gold salt as a gold salt, an alkali metal salt or an ammonium salt of sulfurous acid and thiosulfuric acid as a metal complexing agent, a hydroxyalkylsulfonic acid or a salt thereof represented by the following general formula as a reducing agent, and an amine compound. (wherein R represents hydrogen, a carboxyl group, or any of a phenyl group, a tolyl group, a naphthyl group, a saturated or unsaturated alkyl group, an acetyl group, an acetonyl group, a pyridyl group and a furyl group which may have a substitutional group, X represents any of hydrogen, Na, K, and NH4, and n is an integer between 0 and 4.)

Owner:JX NIPPON MINING & METALS CORP

Preparation method of dithiocarbamic acid sulfurized cross-linking agent

The invention discloses a preparation method of a dithiocarbamic acid sulfurized cross-linking agent, and particularly relates to a preparation method of 1,6 bis(N,N-bisbenzothiazole carbamyl disulfide)-hexane. The sulfurized cross-linking agent 1,6 bis(N,N-bisbenzothiazole carbamyl disulfide)-hexane is obtained by taking hexamethylene-1,6-bis- thiosulfuric acid disodium salt dihydrate and dibenzyl dithiocarbamic acid sodium salt as reactants and generating double decomposition reaction in an organic solvent, and the organic solvent is dioxane, methanol, tetrahydrofuran, ethanol, dichloromethane or methylbenzene. The preparation method disclosed by the invention has the advantages of easiness for operation, short time, high productivity and less pollution; according to the preparation method, obtained by-product sodium sulfate can be industrially utilized.

Owner:JIANGSU QIXIANG HIGH NEW MATERIAL

Method for treating sodium hydrosulfite production wastewater

ActiveCN106830581AReduce sulfur contentReduce CODTreatment using aerobic processesWater treatment compoundsFiltrationWastewater

The invention provides a method for treating sodium hydrosulfite production wastewater. The method comprises feeding oxidizing gas into sodium hydrosulfite production wastewater at a temperature of 25-180 DEG C so that a sulfur-containing inorganic substance in the sodium hydrosulfite production wastewater is oxidized and primary oxidized wastewater is obtained, adding sulfuric acid into the primary oxidized wastewater so that the thiosulphate anion in the primary oxidized wastewater is decomposed, carrying out filtration to obtain acidification wastewater, mixing the acidification wastewater and an oxidizing agent for oxidation so that a sulfur-containing organic substance in the acidification wastewater is transformed into a sulfur-containing inorganic substance and secondary oxidation wastewater is obtained, mixing the secondary oxidation wastewater and quicklime, carrying out precipitation, carrying out filtration, and carrying out anaerobic and aerobic treatment on the filtrate to obtain wastewater to be discharged. The method has the advantages of mild conditions, operation simpleness, low cost and wide application prospect.

Owner:河南安翼环保科技有限公司

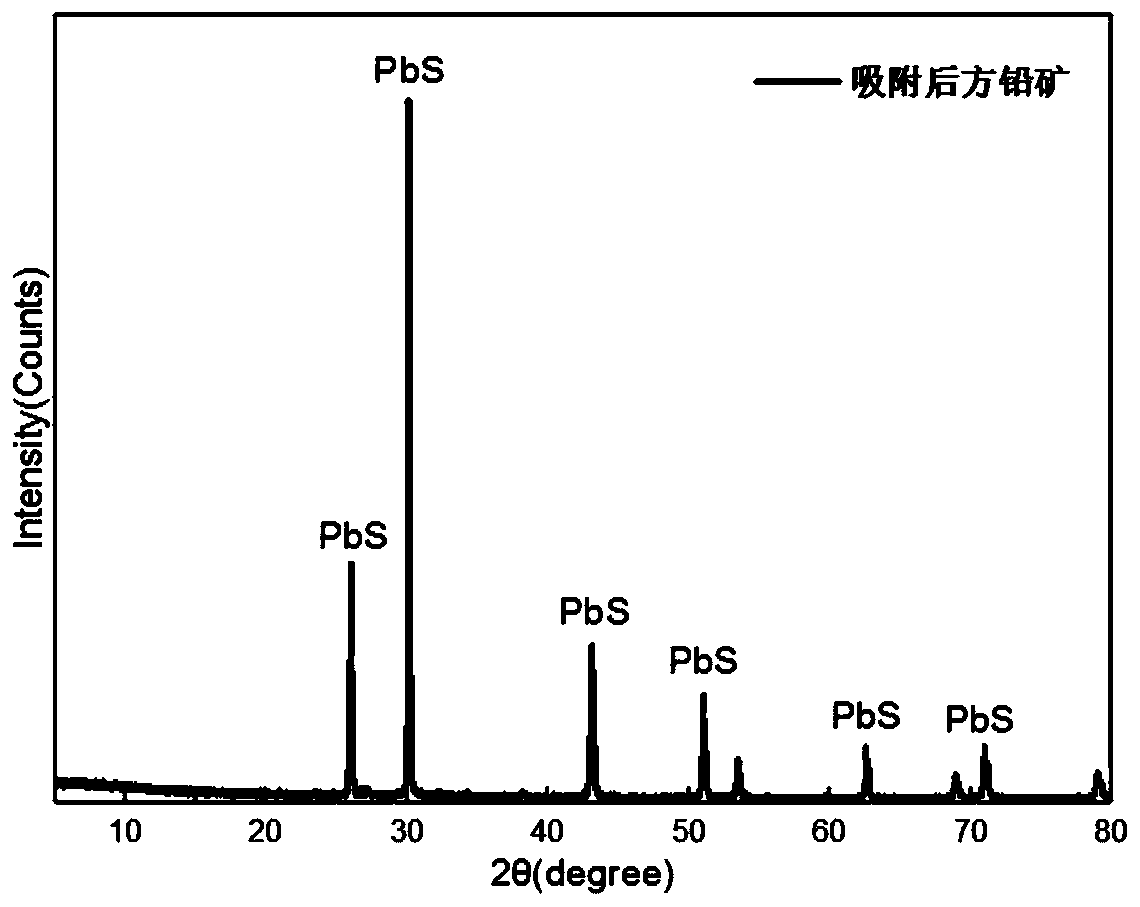

Method for adsorbing precious metal complex ions in thiosulfate leaching agent through sulphide ore

ActiveCN109852816AReduce recycling costsNo need for complex processing modificationProcess efficiency improvementActive siteMachining

The invention discloses a method for adsorbing precious metal complex ions in a thiosulfate leaching agent through sulphide ore. The method comprises the steps that the sulphide ore is placed in precious metal thiosulfuric acid complex solution to carry out adsorbing; the adsorbed solution is subjected to filtering and water removal, and the sulphide ore carried with precious metal thiosulfuric acid complex is obtained. Through sulphide ore surface hydrophobicity and S active sites, Au(S2O3)2<3-> / Ag(S2O3)2<3-> is adsorbed, according to the adsorption amount of gold / silver, dozens of mg of Au / Ag can be adsorbed by per g of an adsorbent, and the adsorbing amount is far larger than the adsorbing amount of the existing Au(S2O3)2<3-> / Ag(S2O3)2<3-> adsorbent. The adsorbent is simple and easy toobtain, complex machining modification is not needed, and the recycling cost of Au / Ag in the thiosulfate leaching agent can be reduced.

Owner:WUHAN UNIV OF TECH

Environment-friendly gold extraction agent and preparation method thereof

InactiveCN108441648AReduce manufacturing costSimple production methodAdditive ingredientSodium thiocyanate

The invention relates to an environment-friendly gold extraction agent and a preparation method for the environment-friendly gold extraction agent and belongs to the technical field of gold production. The technical scheme of the environment-friendly gold extraction agent and the preparation method for the environment-friendly gold extraction agent is that the environment-friendly gold extractionagent is compounded of sodium carbonate, carbamide, sodium chloride, sodium sulphide, iodine, potassium ferricyanide, sodium thiocyanate, sodium bromide and sodium thiosulfate by thermal reaction, themass ratio of all the ingredients is 20-50% of sodium carbonate, 10-50% of carbamide, 1-10% of sodium chloride, 1-5% of sodium sulphide, 1-5% of iodine, 1-5% of potassium ferricyanide, 1-5% of sodiumthiocyanate, 1-5% of sodium bromide and 1-5% of sodium thiosulfate, the ingredients are heated to 700-800 DEG C in an airtight container to perform thermal reaction after being mixed evenly by a mixer, heat preservation is performed for 1-5 h, and the product after reaction is poured out to an open container and cooled to room temperature naturally to form the environment-friendly gold extractionagent. The environment-friendly gold extraction agent and the preparation method for the environment-friendly gold extraction agent have the positive effects that the environment-friendly gold extraction agent can completely replace sodium cyanide and is suitable for recovery and utilization of gold in gold-bearing oxidized ore and gold-bearing tail ore, and compared with other agents, the environment-friendly gold extraction agent has the characteristics of being low in production cost, simple in production method, high in applicability, environmental friendly, good in economic benefit and the like.

Owner:韩志永

Method for manufacturing metallic vanadium

The invention provides a method by which high-purity metallic vanadium is manufactured inexpensively and energy efficiently. [Solution] Provided is a method for manufacturing metallic vanadium in which a portion of an inorganic molten salt for forming a molten salt electrolytic bath in a reaction vessel is electrolyzed to generate calcium, and a vanadium compound is thermally reduced by the calcium to manufacture metallic vanadium, wherein at least one of the following conditions is met in the method for manufacturing metallic vanadium: the portion of the inorganic molten salt contains one ormore compounds selected from the group consisting of sulfides and sulfate compounds of calcium; and the vanadium compound is a mixed vanadium compound containing one or more compounds selected from the group consisting of vanadium sulfide, vanadium sulfate compounds, vanadium thiosulfate compounds, ammonium metavanadate, and vanadyl sulfate.

Owner:HOKKAIDO UNIVERSITY +1

Preparation method of calcium thiosualfate

InactiveCN105692565AEfficient governanceLow costThiosulfates/dithionites/polythionitesAlkali metal chloridesEconomic benefitsImpurity

The invention is applicable to the field of preparation of compounds and provides a preparation method of calcium thiosulfate. The preparation method comprises the following steps: taking oxidized filtrate of a sulfide dye and a hydrochloric acid diluted solution to react in a corrosion-resisting container at the mass ratio of 1 to 0.54; filtering a thiosulfuric acid and sodium chloride mixed solution generated at a low-temperature condition to obtain filter cake impurities and clarified filtrate; taking the clarified filtrate and calcium chloride to react in the corrosion-resisting container at the mass ratio of 1 to 0.97; filtering a mixed solution of the calcium thiosulfate generated by the clarified filtrate and the calcium chloride, hydrochloric acid and previous sodium chloride to obtain filtrate containing the calcium thiosulfate and the sodium chloride; putting the filtrate containing the calcium thiosulfate and the sodium chloride into a decompression distiller to obtain the calcium thiosulfate, the sodium chloride and distilled liquid. By reutilizing the oxidized filtrate of the sulfide dye, the oxidized filtrate of the sulfide dye is effectively managed and the environment is protected; the equipment cost is reduced and economic benefits are created.

Owner:王嘉兴

Purpose of by-product ammonium thiosulfate generated in steel-making waste water treatment process as complexing agent for leaching silver and its application method

InactiveCN102560098AImprove leaching rateLow leaching rateProcess efficiency improvementSilver ionMaterials science

The invention discloses a purpose of a by-product ammonium thiosulfate generated in a steel-making waste water treatment process as a complexing agent for leaching silver and its application method. According to the invention, the by-product ammonium thiosulfate generated in the steel-making waste water treatment process as the complexing agent are reacted with the silver-containing solution for leaching silver; the by-product ammonium thiosulfate generated in the steel-making waste water treatment process is taken as the complexing agent for leaching silver, because thiosulfate radical ion and silver ion can form a stable complex, ammonia ion and silver ion can form stable silver-ammonia complex ion, therefore a better leaching effect is provided to silver chloride, silver oxide, silver sulfide and metal silver, and the ammonium thiosulfate solution possesses high leaching rate to silver under low concentration, the invention has the advantages of short leaching time, high leaching rate, good selectivity, low base metal leaching rate, small environment damage and small hidden trouble in safety production.

Owner:苏州久王环保科技股份有限公司

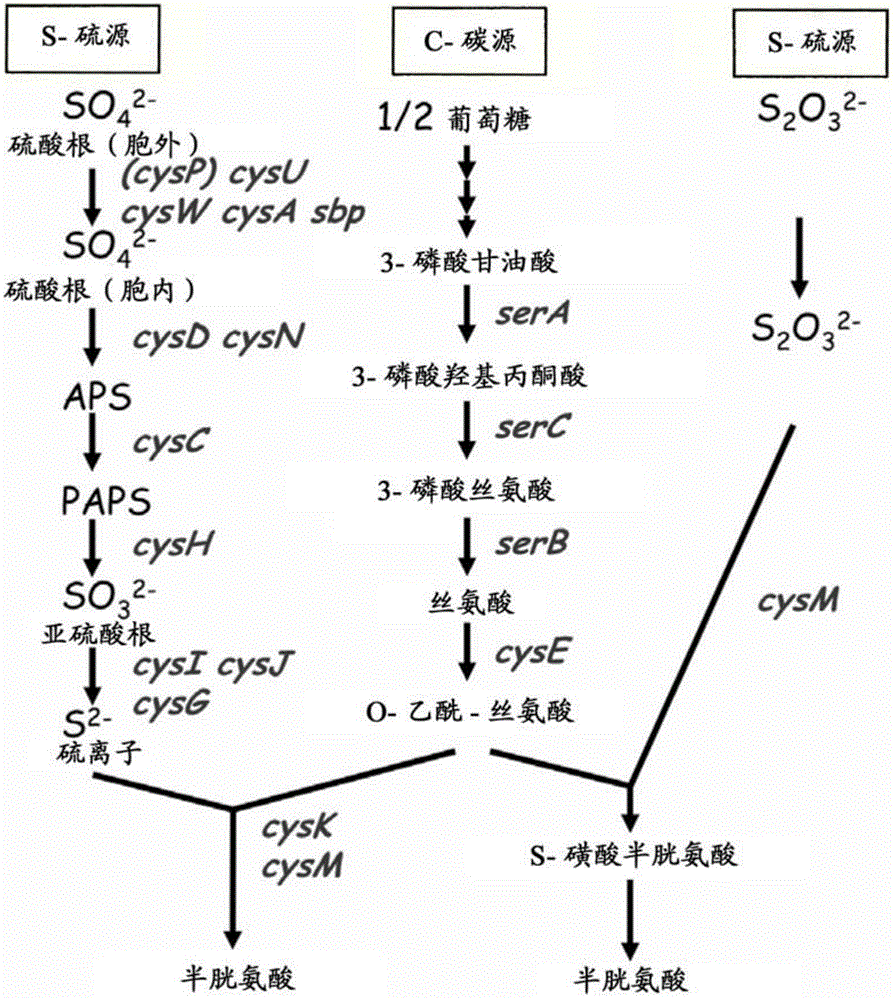

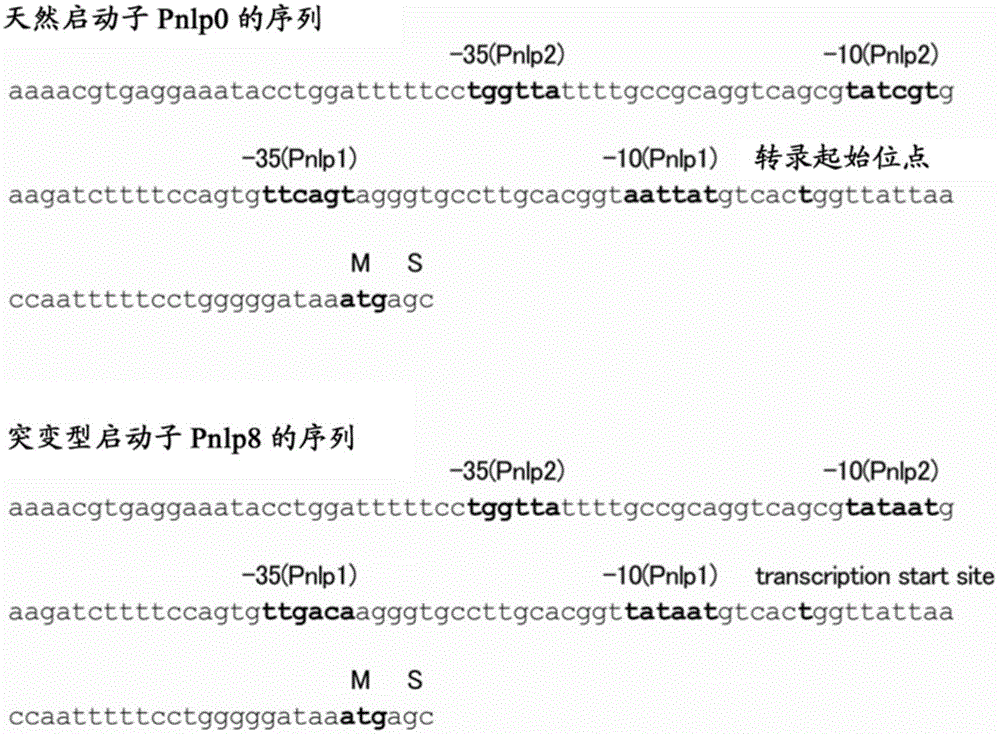

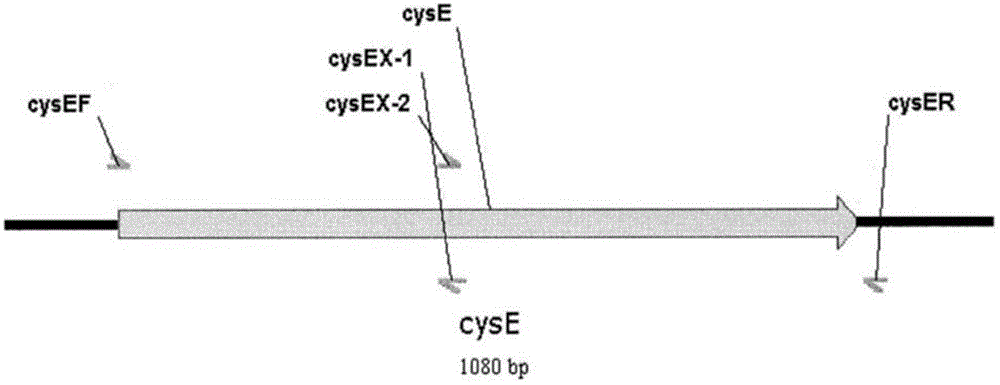

Method for producing l-cysteine

A method for producing L-cysteine and the like is provided by developing a novel technique for improving bacterial L-cysteine-producing ability. By culturing a bacterium belonging to the family Enterobacteriaceae and having L-cysteine-producing ability, of which expression of a gene involved in sulfite reduction is enhanced, in a medium containing thiosulfate and collecting L-cysteine, a related substance thereof, or a mixture thereof accumulated in the medium, these compounds are produced.

Owner:AJINOMOTO CO INC

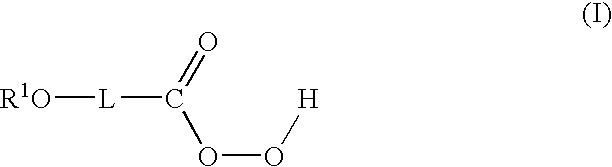

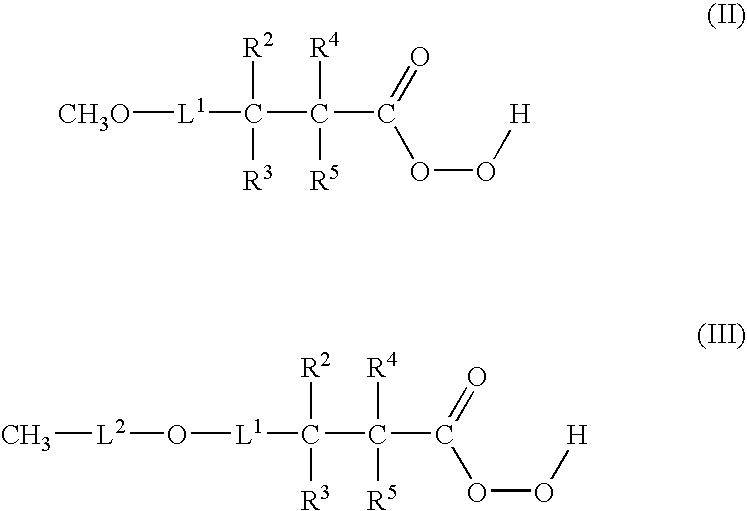

Checker for aqueous composition for sterilization

A checker which comprises potassium iodide, thiosulfate ion, and starch, wherein a weight ratio of the potassium iodide and the thiosulfate ion (potassium iodide / thiosulfate ion) is 0.70 to 0.3; and a kit comprising two or more of the aforementioned checkers, wherein the aforementioned weight ratio is different between said checkers are provided. The checker or the kit easily and precisely determines whether or not the concentration of an organic carboxylic acid peroxide such as peracetic acid in an aqueous composition for sterilization comprising the organic carboxylic acid peroxide as an active ingredient is an effective concentration.

Owner:FUJIFILM CORP

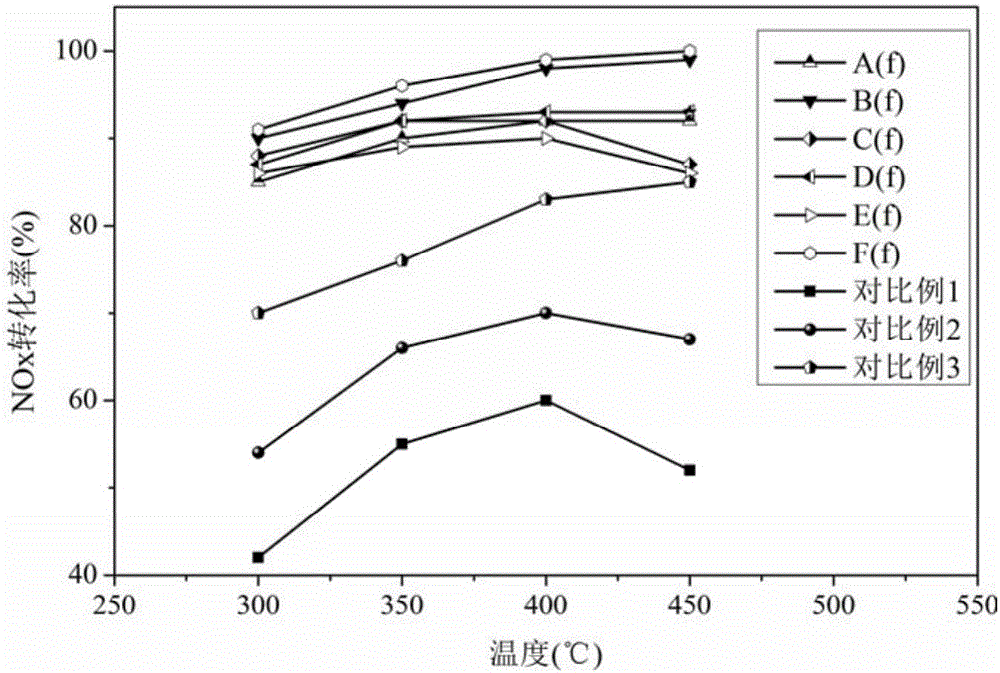

Regenerated liquid capable of effectively recovering activity of sintered vanadium-based SCR catalyst

ActiveCN105921182AReduce oxidation rateRestore catalytic activityCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsProcessing costSulfur dioxide

The invention discloses a regenerated liquid capable of effectively recovering the activity of a sintered vanadium-based SCR catalyst. The regenerated liquid is characterized by being prepared from, by mass, 0.1-2 parts of organic dispersant, 1-8 parts of ammonium thiosulfate, 0.5-4 parts of ammonium fluoride, 0-40 parts of titanic oxide, 0-20 parts of binder, 0.1-10 parts of tungsten salt, 0.1-3 parts of vanadium salt and 100 parts of deionized water. Due to the fact that the regenerated liquid contains a redispersing agent composed of the organic dispersant, ammonium thiosulfate and ammonium fluoride, sintered and agglomerated vanadium and tungsten species in the sintered vanadium-based SCR catalyst can be well dispersed in a carrier material again through complexation, dispersion and readsorption, catalysis activity can be recovered, sulfur dioxide oxidation rate can be reduced, and service life can be prolonged; meanwhile, consumption of newly added active components can be reduced, and processing cost can be reduced.

Owner:陕西万里蓝环保科技有限公司

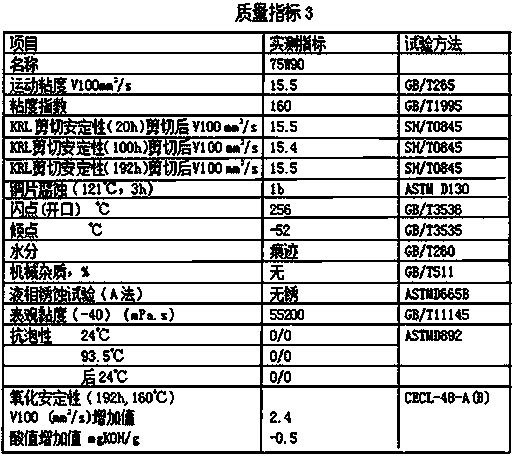

Special oil for 75W-90 viscosity grade vehicle gear, and preparation method thereof

InactiveCN110819426AImprove shear resistanceImprove detergencyLubricant compositionFatty amineAlpha-olefin

The invention provides special oil for a 75W90 vehicle gear, wherein the special oil comprises, by weight, base oil and an additive, the addition amount of the additive is 3.631-13.108% of the addition amount of the base oil, the base oil comprises three components of 25-50% of poly alpha-olefin, 15-25% of alkyl naphthalene and 25-60% of metallocene poly alpha-olefin, and the additive comprises eight components of 0.1-0.5% of an anti-rust agent amide anti-rust agentm 0.3-1.5% of an antioxidant octyl / butyl liquid-state diphenylamine, 0.5-4% of a corrosion inhibitor molybdenum dialkyl dithiosulfate, 0.2-2% of an antiwear agent tricresyl phosphate, 2-4% of an extreme pressure agent sulfurized isobutylene, 0.03-1% of a friction modifier benzotriazole fatty amine salt, 0.1-0.5% of a dispersingagent synthetic calcium sulfonate with a medium base number, and 0.001-0.008% of a composite antifoaming agent. According to the invention, the viscosity index improver is not added, and the high-viscosity poly alpha olefin is used for increasing the viscosity, so that the anti-shearing performance is excellent, the oxidation resistance is greatly improved, the service life of the product is prolonged, and the service life is prolonged and can reach more than 100000 kilometers.

Owner:YANTAI HENGBANG CHEM

Tire member and method for manufacturing the same

ActiveUS20140128525A1Excellent abrasion resistanceHigh tear strengthSpecial tyresVulcanizationThiosulfuric acid

A method for manufacturing a tire member, containing a step (A) for producing a mixture containing a diene rubber component, an inorganic filler, a peptizer and a thiosulfuric acid compound containing an amino group, and a step (B) for mixing the mixture, a sulfur component and a vulcanization accelerator, wherein a tire member having improved abrasion resistance, tear strength and flex fatigue resistance is obtained, and the tire member are provided. A premix containing 100 parts by mass of the diene rubber component, from 0.1 to 0.5 parts by mass of the peptizer and 0.2 parts by mass or more of the thiosulfuric acid compound containing an amino group, obtained under a condition in which a temperature during mixing is maintained within a range of from 145 to 170° C. for 20 seconds or more and a temperature at completion of the mixing is 170° C. or lower.

Owner:TOYO TIRE & RUBBER CO LTD

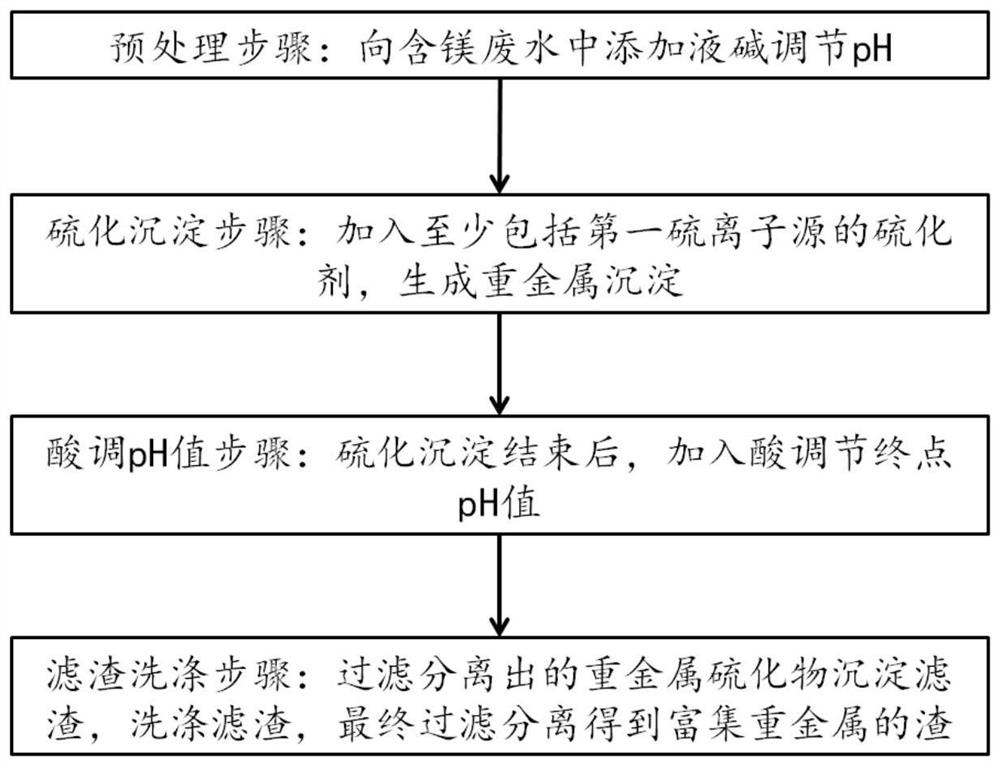

Heavy metal recovery method and sulfide precipitation method for magnesium-containing wastewater

PendingCN113025828ANot easy to double-teamAvoid overreactionWater contaminantsProcess efficiency improvementThio-Sulfidation

The invention discloses a heavy metal recovery method and precipitation method for magnesium-containing wastewater. The heavy metal recovery method comprises a sulfide precipitation step, wherein a sulfuration agent is added into the wastewater to achieve sulfide precipitation, and the sulfuration agent comprises a first sulfur ion source, and the first sulfur ion source comprises at least one kind selected from the combination consisting of a thiosulfate source, hydrogen sulfide and elemental sulfur. According to the heavy metal recovery method and the precipitation method, by using the sulfuration agent comprising the first sulfur ion source (slow-release sulfur ion source) selected from the thiosulfate source, hydrogen sulfide or elemental sulfur, and introducing the slow-release sulfuration process, sulfur ion release is buffered, the overreaction caused by the generation of a large number of sulfur ions is avoided, the sulfuration reaction is carried out controllably, magnesium is not prone to being clamped in sulfide precipitation particles, and therefore the effect of reducing magnesium-containing impurities of precipitate is achieved.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

Method for recovering mercury from mercury-contained tailings in form of selenide

ActiveCN104032137ASafe storageReduce pollution hazardsProcess efficiency improvementSolubilityNon-ferrous extractive metallurgy

The invention belongs to the field of environmental protection; and aiming at problems of complex components and no proper method for treatment of mercury-contained tailings produced in a nonferrous metal smelting process, the invention discloses a method for recovering mercury from the mercury-contained tailings in a form of selenide. The mercury contained in the mercury-contained tailings is leached out by adopting thiosulfate; and alkali metal selenide is added in solution containing the mercury and thiosulfuric acid radical complex ions, so that the mercury is converted to mercury selenide precipitates with stability, low solubility and low toxicity. The method is simple in operation; after the complex leaching treatment is performed with the thiosulfate solution, the transfer-state mercury in the mercury-contained tailings is largely decreased; and the mercury is finally converted to the precipitates in the form of stored and stable mercury selenide, so that the pollution harm of the mercury in the mercury-contained tailings to the environment is eliminated.

Owner:NORTHEASTERN UNIV

Plating solution, conductive material, and surface treatment method of conductive material

ActiveCN1873058AGood adhesionGood lookingLiquid applicationMagnetic materialsCarboxylic acidConductive materials

A plating solution including a copper salt, an organic phosphonic acid compound, and at least one compound or ions selected from an amine, alpha-amino acid, ammonium ions, carbonic acid ions, carboxylic acid ions, dicarboxylic acid ions, sulfuric acid ions, and thiosulfuric acid ions and a method of treating the surface of a conductive material using this plating solution.

Owner:TDK CORPARATION

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com