Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Restore catalytic activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

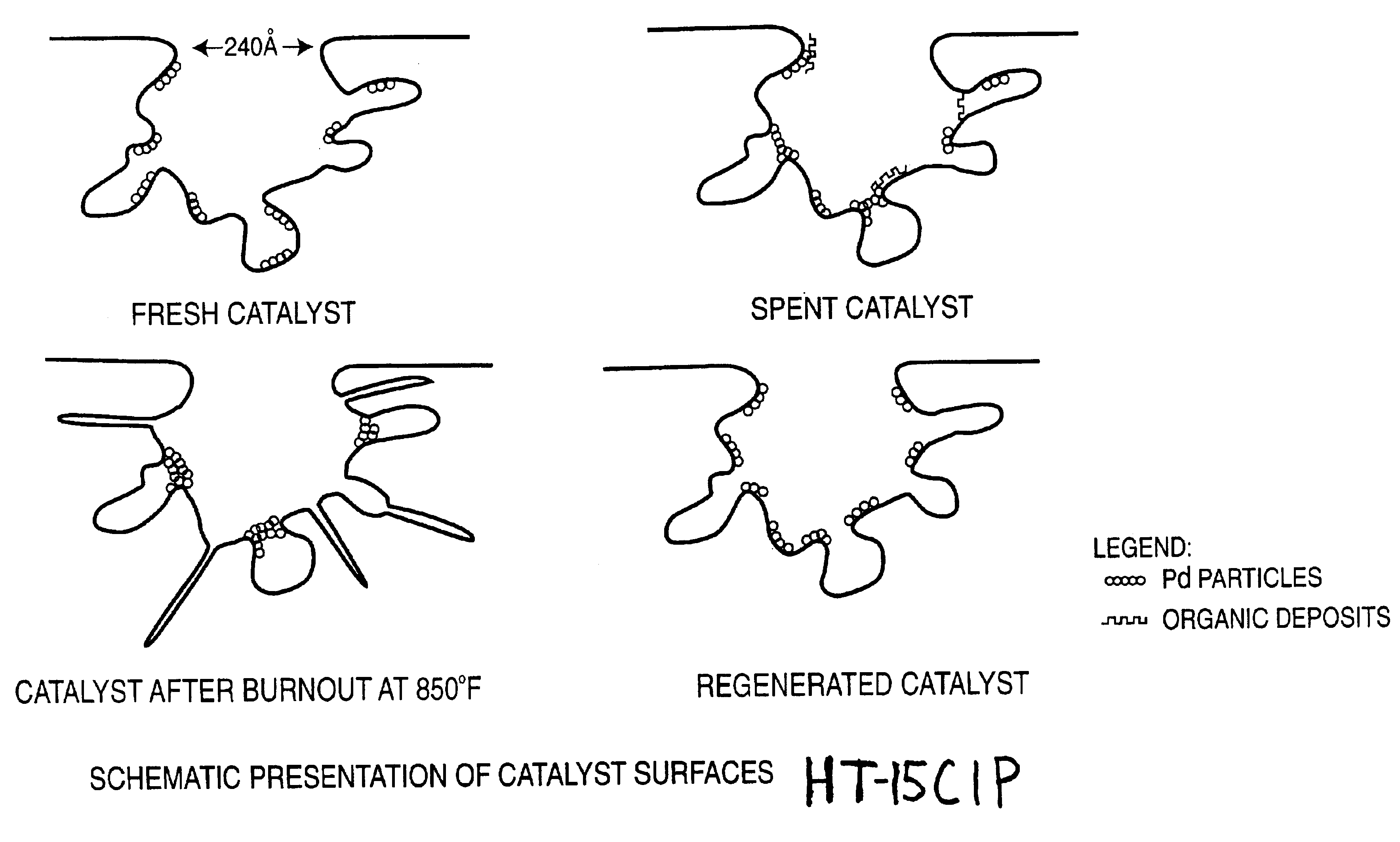

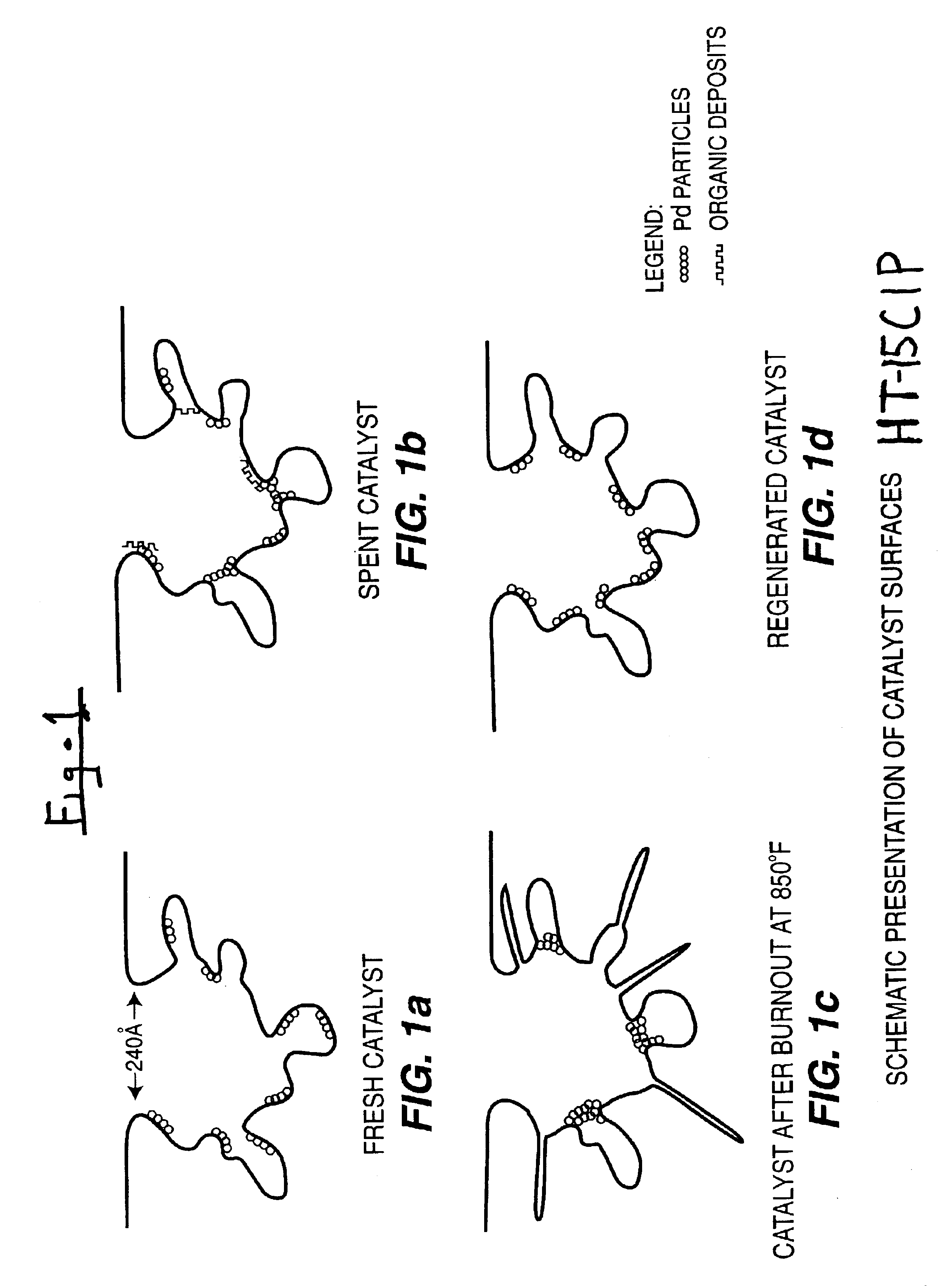

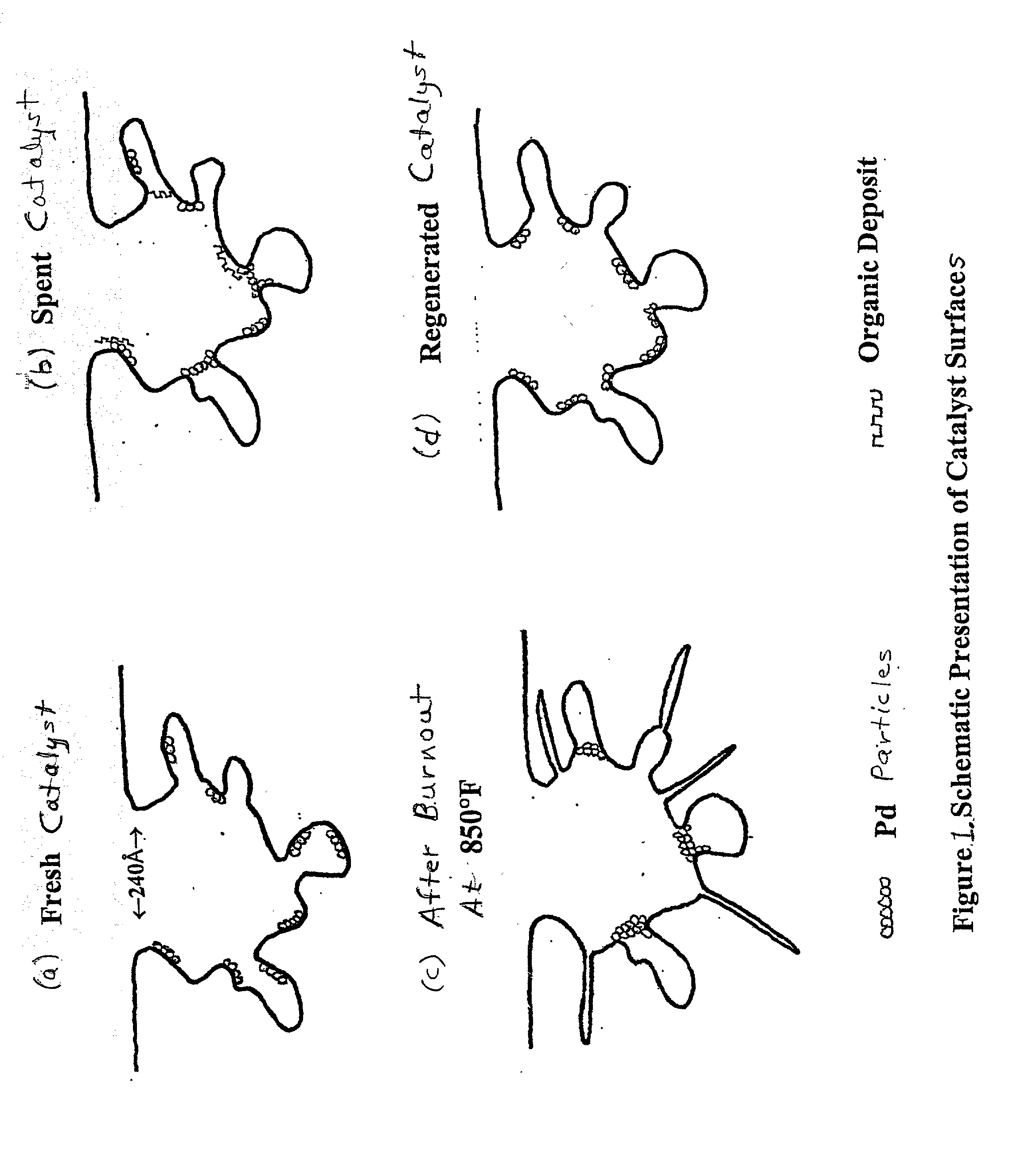

Regeneration of used supported noble metal catalysts

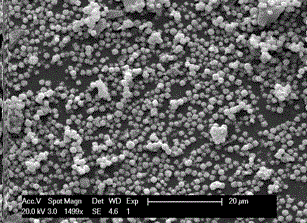

InactiveUS6740615B2Efficient removalImproves expositionHydrogen peroxideOther chemical processesPalladium catalystMetal particle

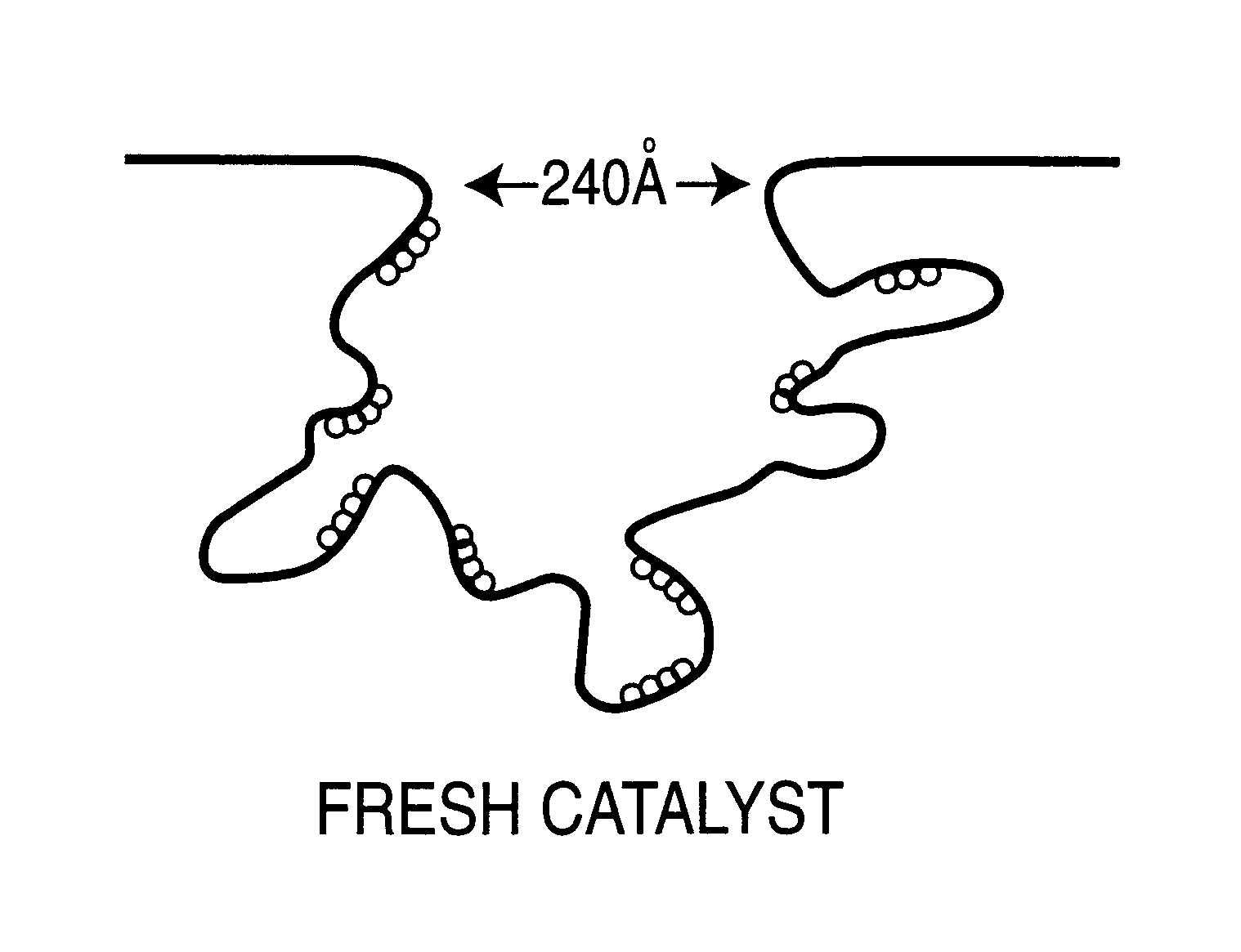

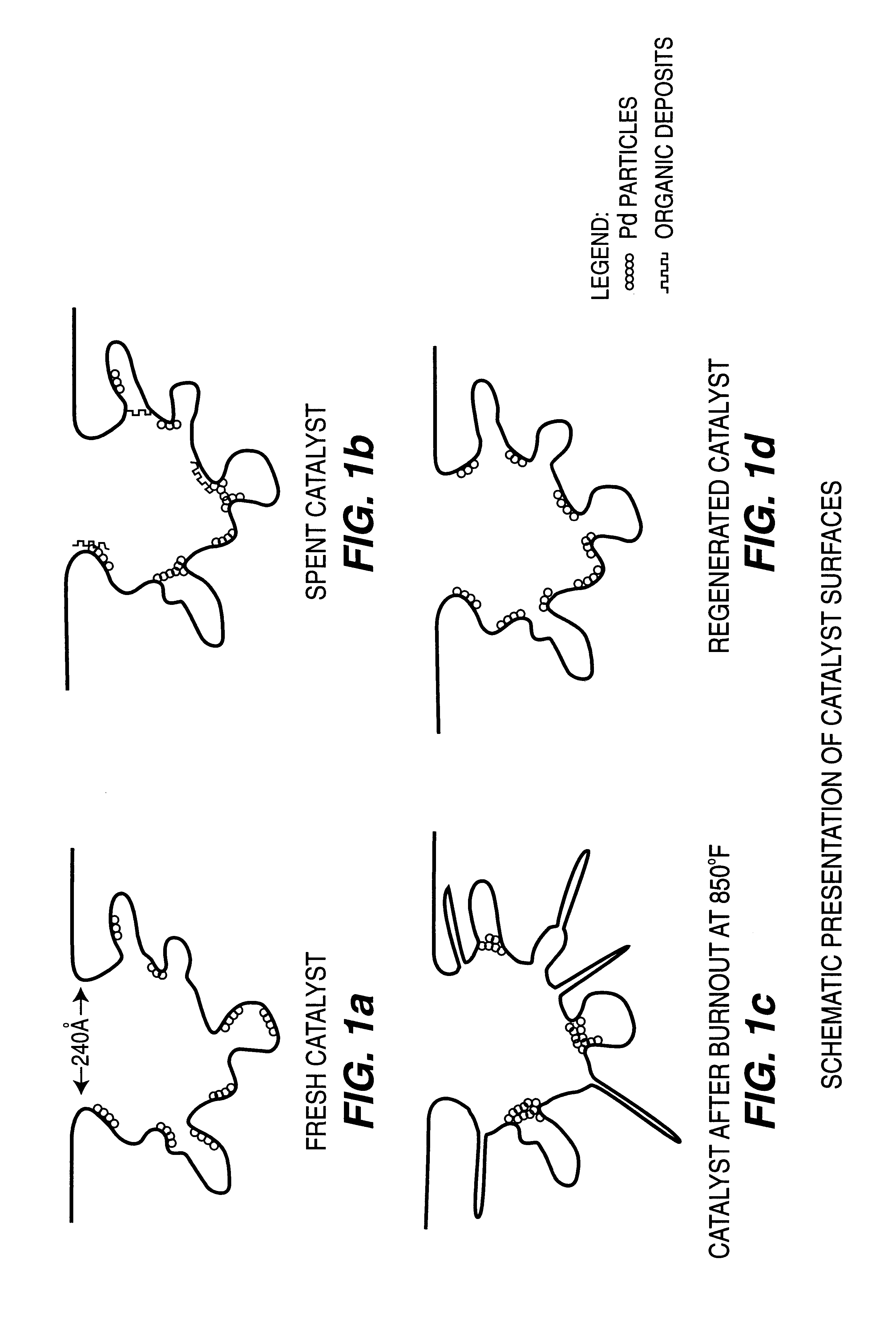

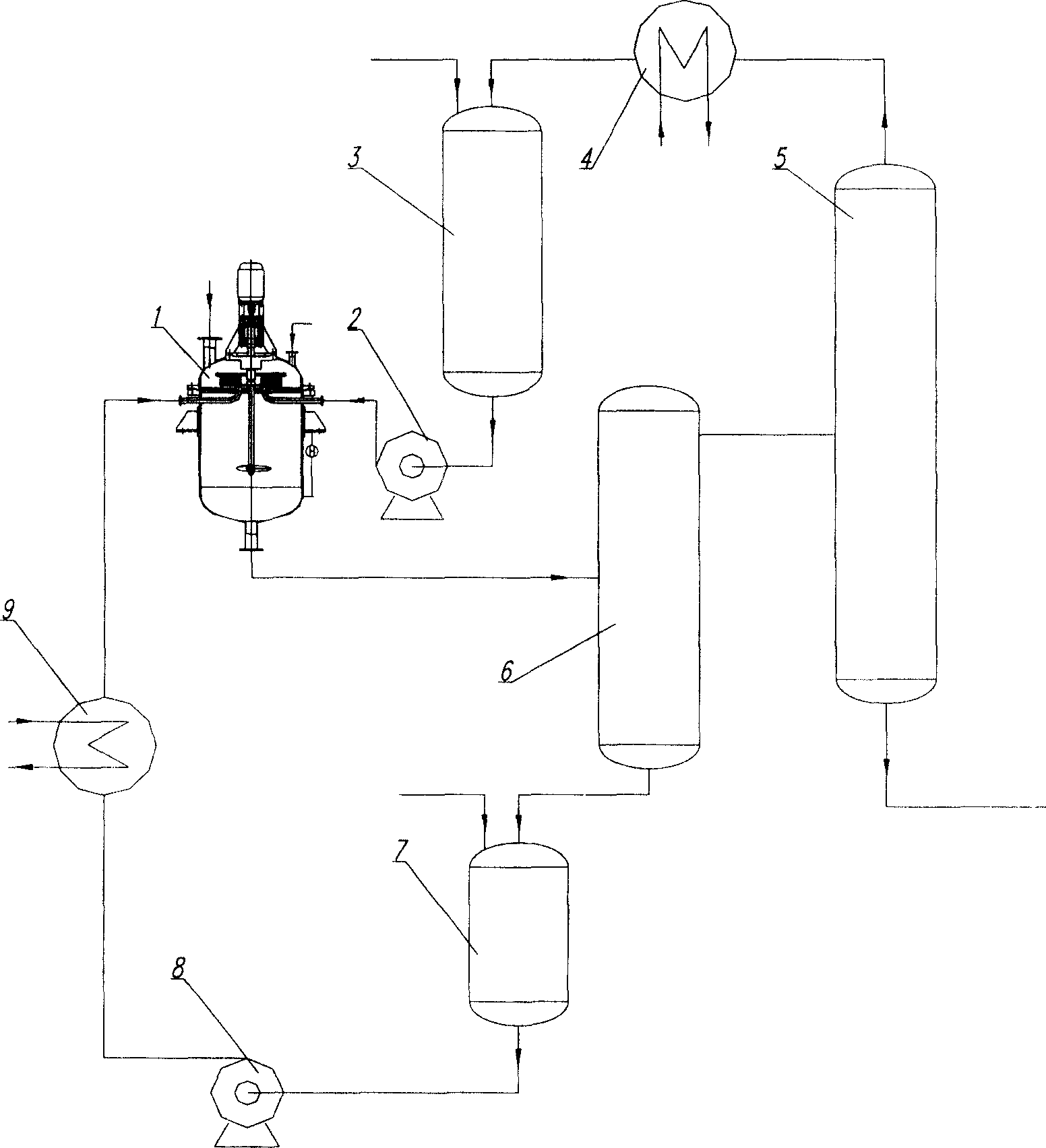

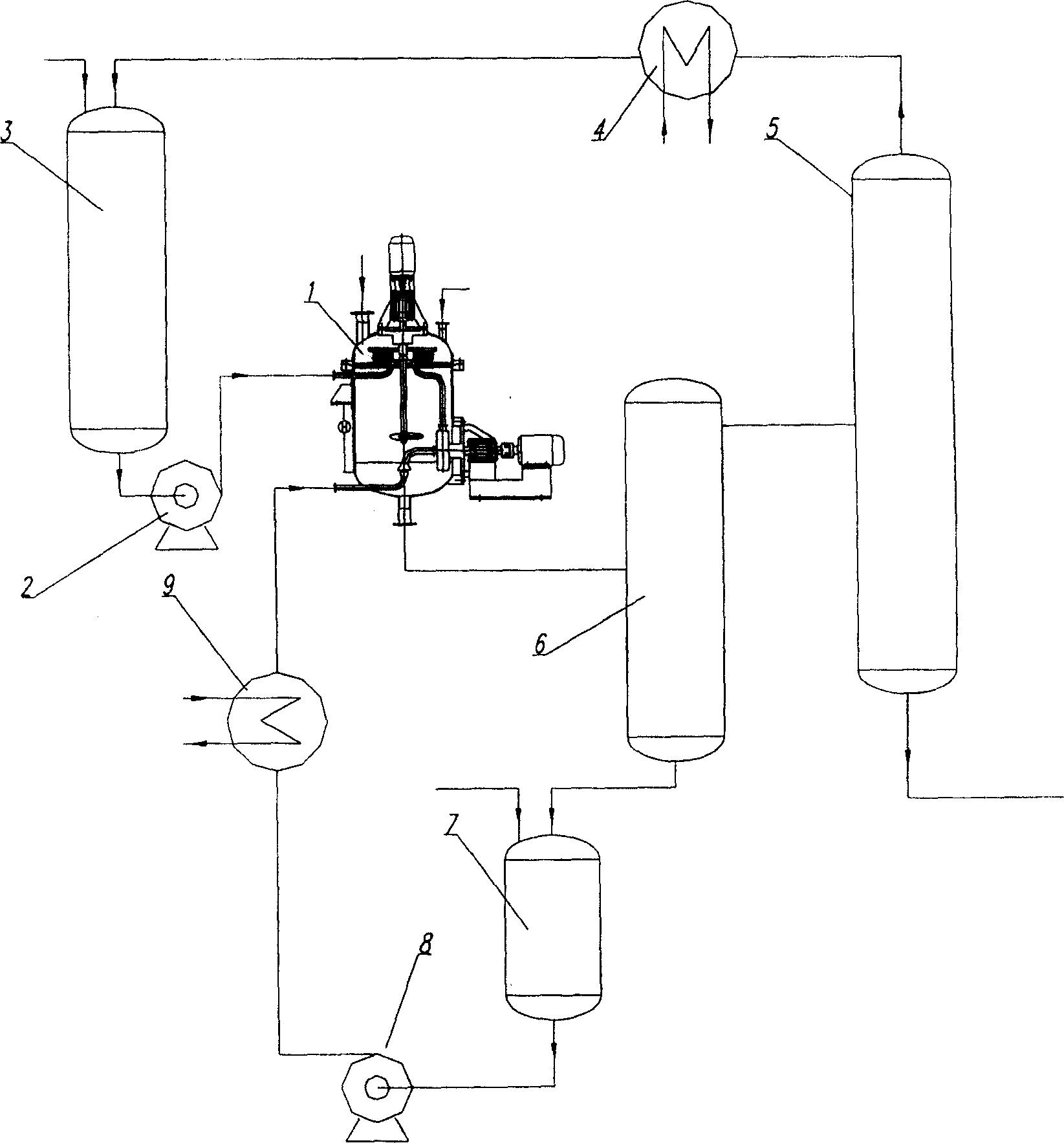

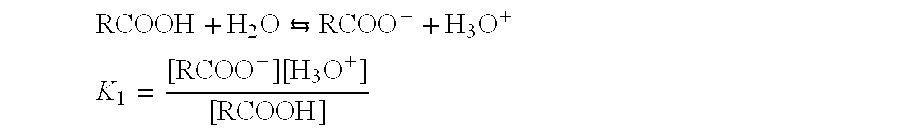

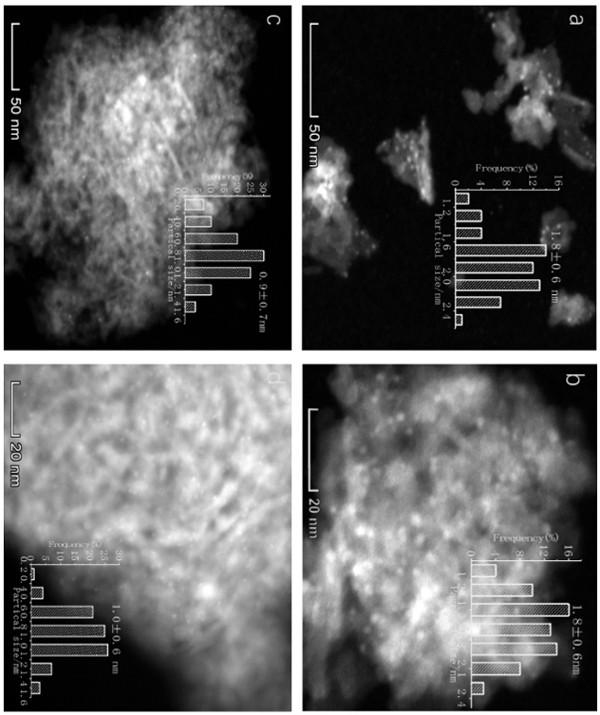

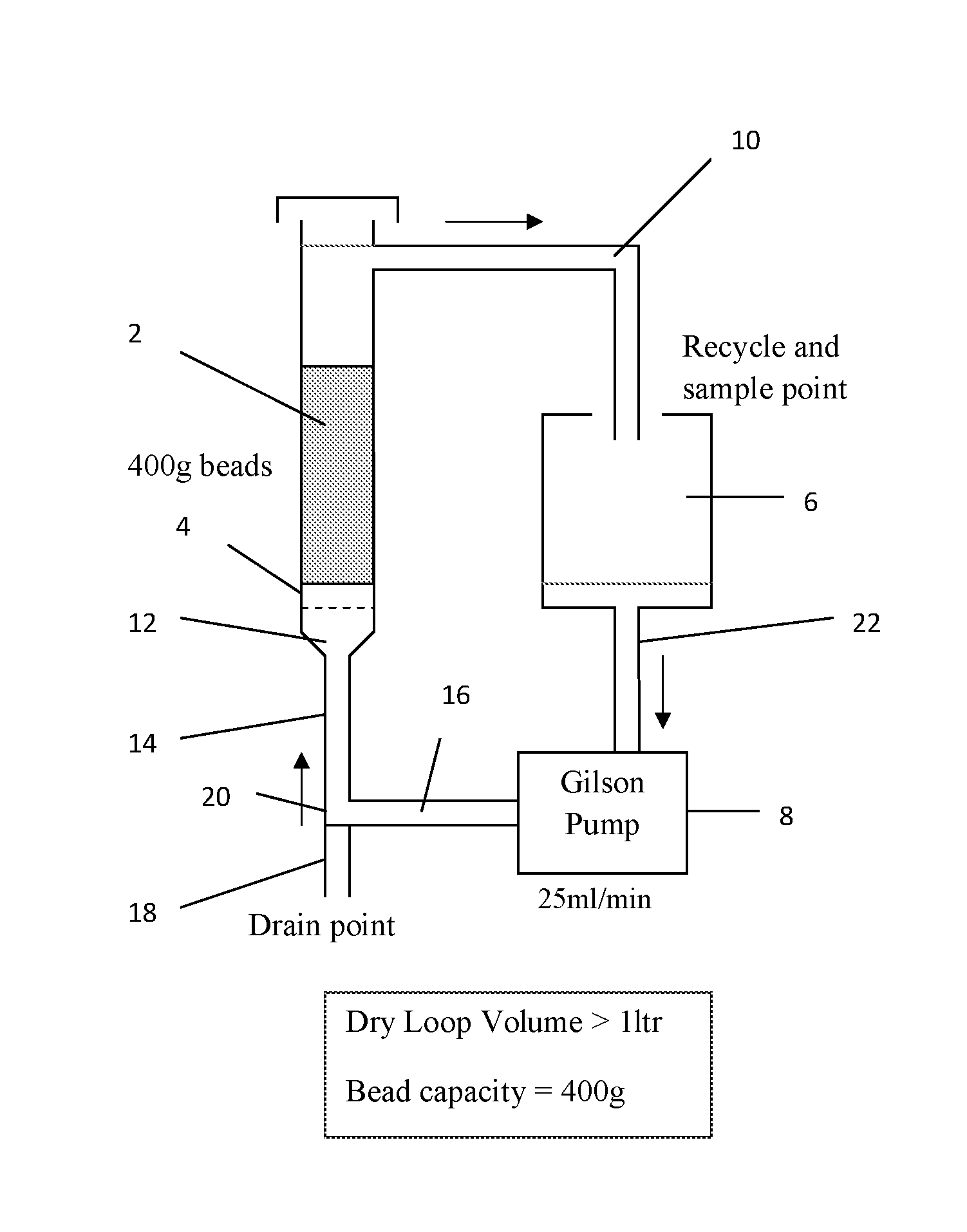

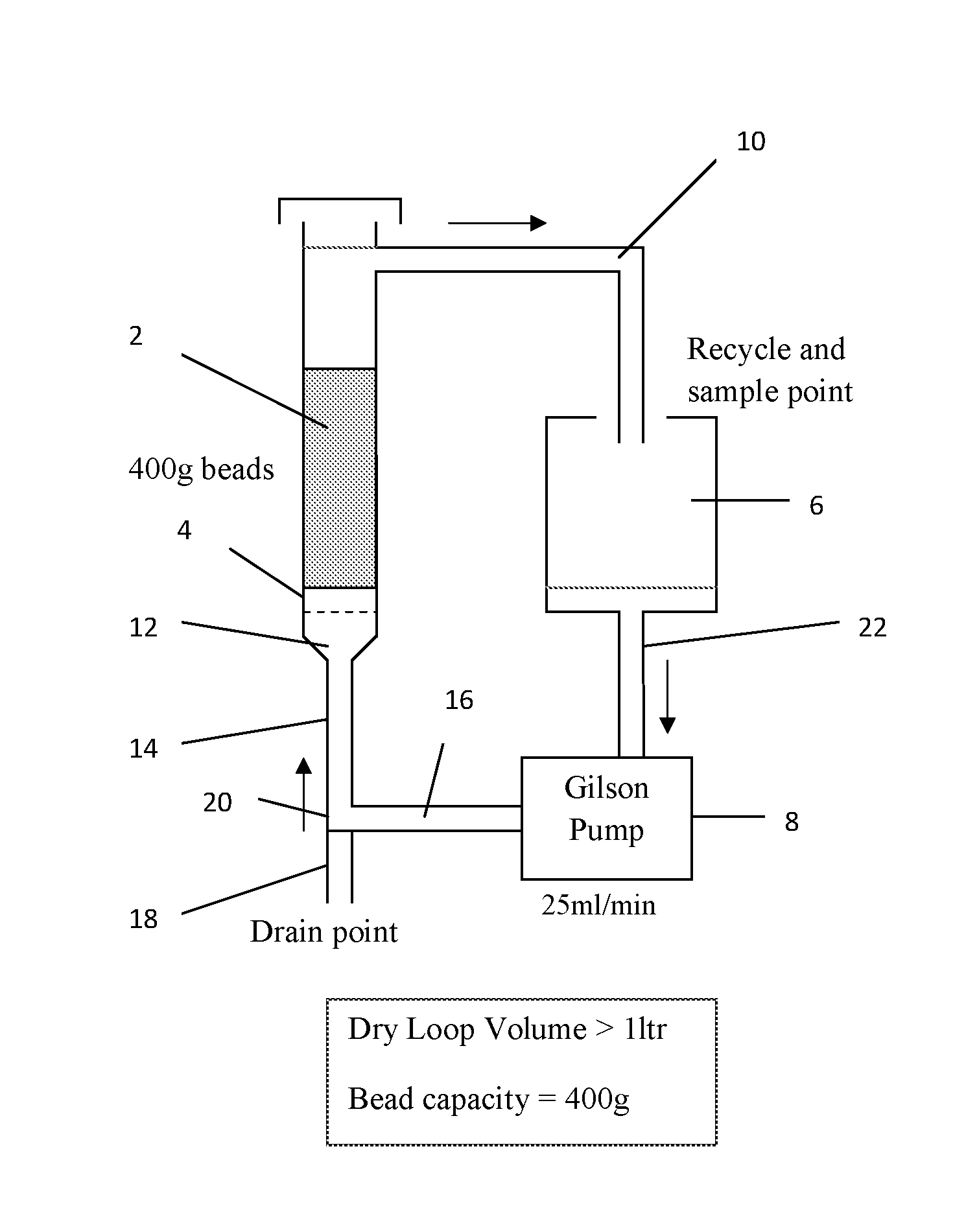

A method for regenerating used supported noble metal catalysts, which method includes solvent cleaning the used catalyst by contact with a suitable organic liquid cleaning solvent such as alcohols, ketones and such to remove organic deposits from the catalyst, followed by drying and calcining at elevated temperature to remove any remaining organic deposits from the catalyst, then treating the catalyst with an organo-metallic complex forming agent having ionization constant pK1 greater than about 2.5, such as glycolic acid and the like. The organic-metallic complex forming agent acts to break down large clusters of noble metal particles such as palladium (Pd) and redistributes the metal particles on the catalyst support such as alumina (Al2O3) in the same or other larger pores, so as to increase catalyst surface area and catalytic activity to provide a catalytic activity level at least 80% or even exceeding that of the fresh catalyst. This regeneration method is particularly useful for regenerating used supported palladium catalysts utilized for hydrogenation of ethyl anthraquinone (EAQ) for producing hydrogen peroxide (H2O2) product.

Owner:POROCEL INT LLC +1

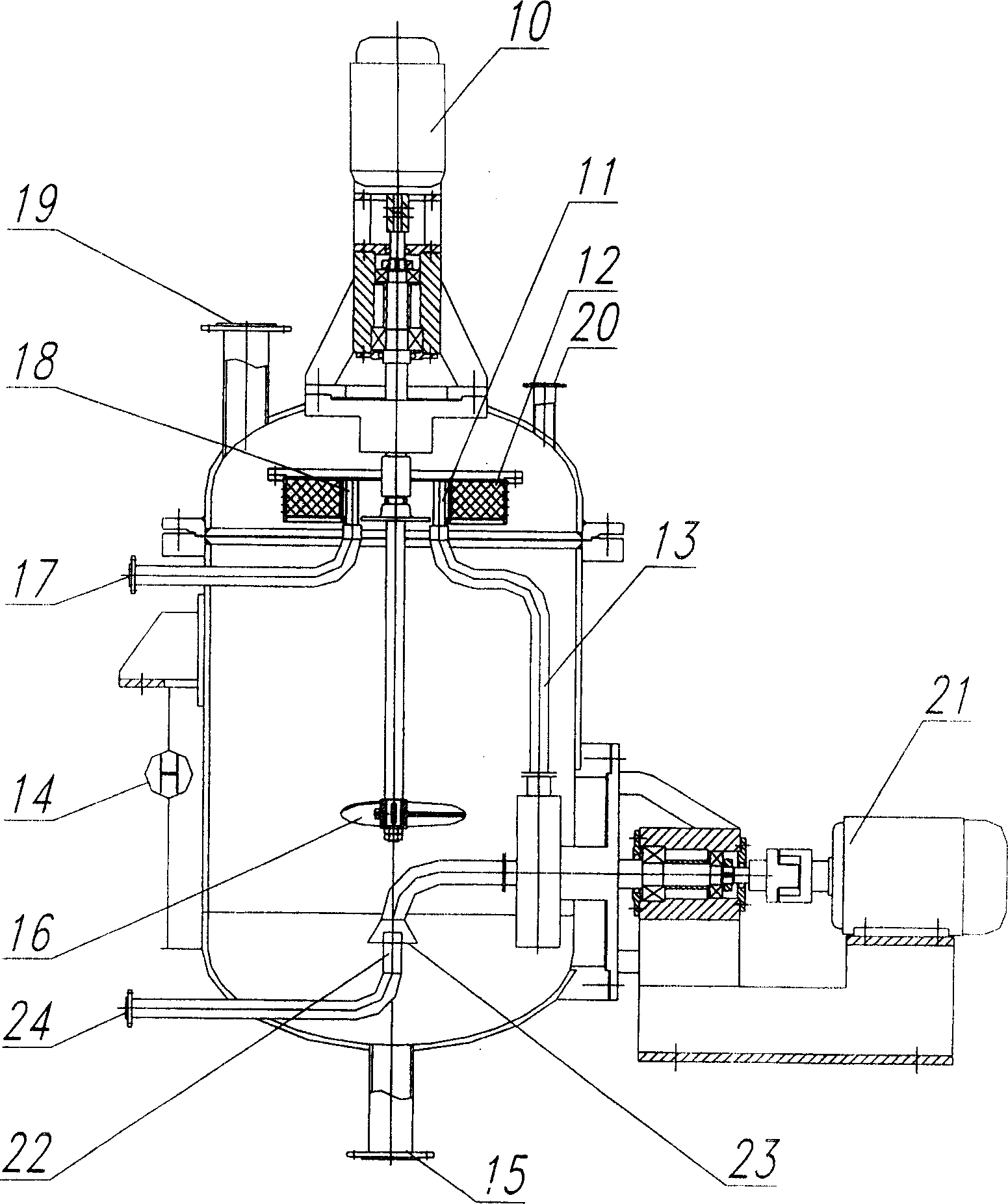

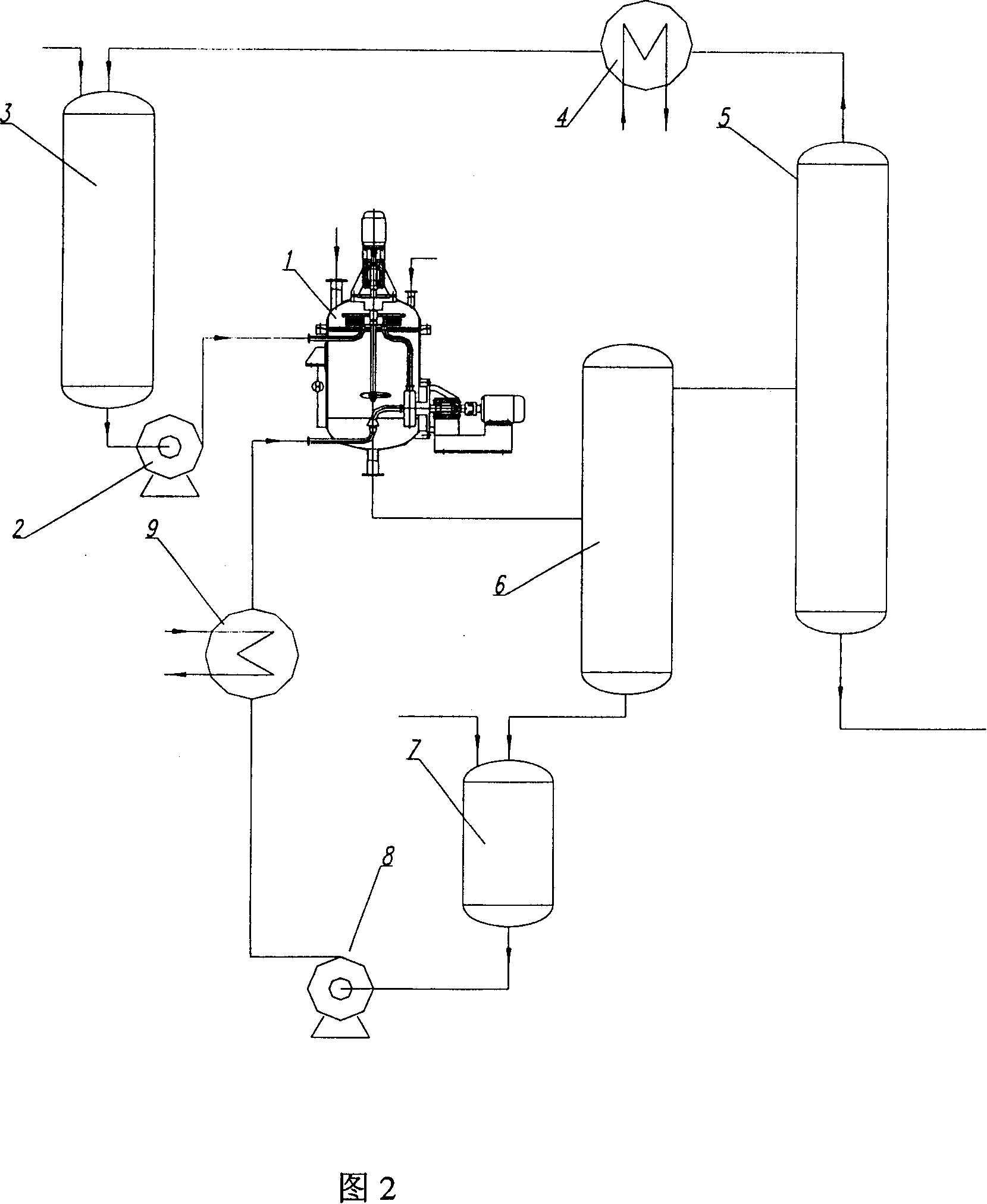

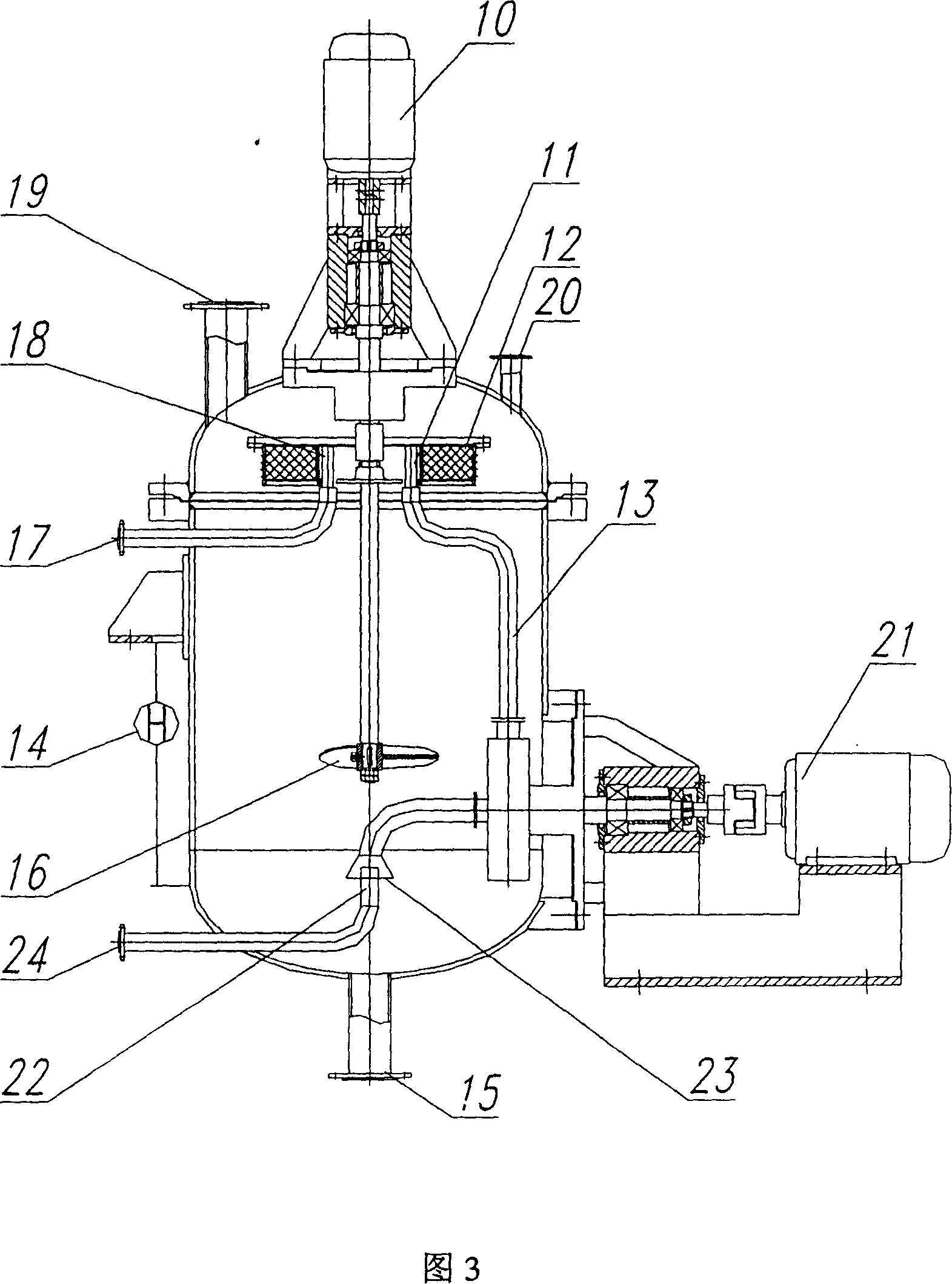

Alkylation reaction technique catalyzed by ion liquid and reactor apparatus

InactiveCN1907924AEasy to separateRestore catalytic activityHydrocarbon from saturated and unsaturated hydrocarbon additionHydrocarbon oils refiningIonAlkane

This invention involves an ion liquid catalytic alkylation process and a responsing reactor. The process comprises carrying out a reaction of isobutene, C3-C5 olefins and ionic liquid catalyst in a rotating bed reactor with reaction temperature of 8~40DEG C, pressure of 0.3~1.0 MPa and rotor speed of 100~2500 rpm, wherein the volume ratio of ion liquid feed to alkanes-olefins is 0.1~1.5:1 and the molar ratio of alkanes to olefins is 10~300, and controlling the reaction time less than 1~10min. The invention improved alkylation reaction selectivity, and the octane value of alkylation product can reach to 94-100. The operation is simple and low-cost, and has no pollution to environment and beneficial to environment protection.

Owner:BEIJING UNIV OF CHEM TECH

Regeneration of spent supported metal catalysts

InactiveUS6908873B2Efficient removalImproves expositionOther chemical processesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal catalystPalladium catalyst

Owner:EVONIK OPERATIONS GMBH

Regeneration of used supported noble metal catalysts

InactiveUS20020115554A1Easy to cleanHigh activityHydrogen peroxideOther chemical processesPtru catalystPalladium catalyst

A method for regenerating used supported noble metal catalysts, which method includes solvent cleaning the used catalyst by contact with a suitable organic liquid cleaning solvent such as alcohols, ketones and such to remove organic deposits from the catalyst, followed by drying and calcining at elevated temperature to remove any remaining organic deposits from the catalyst, then treating the catalyst with an organo-metallic complex forming agent having ionization constant pK1 greater than about 2.5, such as glycolic acid and the like. The organic-metallic complex forming agent acts to break down large clusters of noble metal particles such as palladium (Pd) and redistributes the metal particles on the catalyst support such as alumina (Al2O3) in the same or other larger pores, so as to increase catalyst surface area and catalytic activity to provide a catalytic activity level at least 80% or even exceeding that of the fresh catalyst. This regeneration method is particularly useful for regenerating used supported palladium catalysts utilized for hydrogenation of ethyl anthraquinone (EAQ) for producing hydrogen peroxide (H2O2) product.

Owner:POROCEL INT LLC +1

Method of restoring catalytic activity to a spent hydrotreating catalyst, the resulting restored catalyst, and a method of hydroprocessing

ActiveUS20050159295A1Carbon concentration can be reducedRestore catalytic activityOther chemical processesCatalyst regeneration/reactivationSulfurSolvent

A method of restoring catalytic activity to a spent hydroprocessing catalyst that has a first carbon concentration. The concentration of carbon on the spent hydroprocessing catalyst is reduced to provide a carbon-reduced catalyst having a second carbon concentration that is less than the first carbon concentration. The carbon-reduced catalyst is exposed to a solution, comprising a chelating agent and a solvent, for an aging time period sufficient to provide for a restored catalytic activity thereby resulting in an aged catalyst having incorporated therein the chelating agent and the solvent. The aged catalyst is exposed to conditions, including a drying temperature, so as to remove from the aged catalyst a portion of the solvent without removing a significant portion of the chelating agent from the aged catalyst thereby resulting in a dried aged catalyst. The dried aged catalyst is then sulfur treated to thereby provide a restored catalyst. The restored catalyst and those catalysts made by the treatment method can be used in a hydroprocessing process comprising contacting the restored catalyst with a hydrocarbon feedstock under hydroprocessing conditions.

Owner:SHELL USA INC

Alkylation reaction technique catalyzed by ion liquid and reactor apparatus

InactiveCN100348559CEasy to separateRestore catalytic activityHydrocarbon from saturated and unsaturated hydrocarbon additionHydrocarbon oils refiningAlkanePtru catalyst

This invention involves an ion liquid catalytic alkylation process and a responsing reactor. The process comprises carrying out a reaction of isobutene, C3-C5 olefins and ionic liquid catalyst in a rotating bed reactor with reaction temperature of 8~40DEG C, pressure of 0.3~1.0 MPa and rotor speed of 100~2500 rpm, wherein the volume ratio of ion liquid feed to alkanes-olefins is 0.1~1.5:1 and the molar ratio of alkanes to olefins is 10~300, and controlling the reaction time less than 1~10min. The invention improved alkylation reaction selectivity, and the octane value of alkylation product can reach to 94-100. The operation is simple and low-cost, and has no pollution to environment and beneficial to environment protection.

Owner:BEIJING UNIV OF CHEM TECH

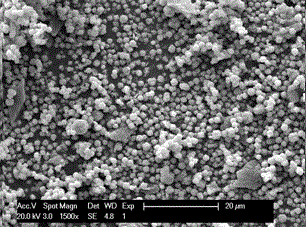

Efficient catalyst for decomposition of N2O and preparation method and application thereof

ActiveCN105363451AEconomicalHigh catalytic activityNitrous oxide captureDispersed particle separationDecompositionAdipic acid

The present invention provides an efficient catalyst for decomposition of N2O and a preparation method and application thereof. The catalyst comprises an active center and a carrier; the active center includes quantum dot oxide and spinel-type structural compound, and the carrier is a Al2O3 carrier; and the catalyst has a molecular formula L IIxO / M II1-xNIII2O4 / Al2O3, wherein: L II and M II are divalent metal cations, N III is a trivalent metal cation, and x equals to 0.01-1.0. The efficient catalyst for decomposition of N2O has high activity, good stability and low N2O decomposition temperature, is conducive to the purification of industrial waste gas from adipic acid plant; and the catalyst for decomposing N2O can significantly reduce the N2O concentration in industrial emission, reduce air pollution and protect the environment.

Owner:CHINA TIANCHEN ENG +1

Preparation method and application of iron-sulfur heterogeneous Fenton-like catalyst

ActiveCN105562036AEasy to makeIncrease contactPhysical/chemical process catalystsWater treatment compoundsSulfurPersulfate

The invention relates to a preparation method and application of an iron-sulfur heterogeneous Fenton-like catalyst. The preparation method comprises the following steps of adding a dispersing agent into a ferrous solution, and performing uniform stirring; sequentially and slowly pouring solutions of hydrosulfide and sulfide into the solution, keeping the pH of the solution to be 5.0 to 5.5, and performing stirring for 10 to 20min; slowly adding a solution of sulfite into the solution, keeping the pH value to be 5.0 to 5.5, and performing stirring for 5 to 10min to obtain precursor sol; transferring the precursor sol into a sealed glass bottle, and performing constant temperature (25 DEG C) aging reaction in dark to obtain black precipitates, i.e. the final catalyst. The pH of wastewater is regulated to 7.0 to 11.0, a mixed solution of hydrogen peroxide / persulfate and the synthesized heterogeneous fenton-like catalyst are added into the wastewater, and stirring reaction is performed for 10 to 120min to finish the degrading of organic pollutants in the wastewater. A preparation process of the prepared iron-sulfur heterogeneous Fenton-like catalyst is simple, conditions are mild, and when being used, the prepared iron-sulfur heterogeneous Fenton-like catalyst is large in applicable pH range, and has a good deep treatment effect on industrial wastewater.

Owner:TONGJI UNIV

Method for catalyzing butene oligomerization by using ionic liquid as catalyst

InactiveCN101190861AImprove conversion rateControl degree of aggregationHydrocarbons from unsaturated hydrocarbon additionButeneEconomic benefits

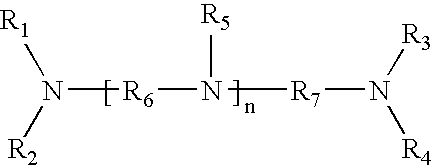

The invention discloses a method of producing medium and mid-high olefines, such as C8, C12, C16 and C20, etc. with ionic liquid as catalyst to catalyze butylene to carry out butylene oligomerization. The method adopts the butylene as raw material; cation of the ionic liquid catalyst comes from hydrohalide of amine with alkyl, and anion of the ionic liquid catalyst is produced by a metallic compound that has one or two metals. In the technique of the invention, volume ratio of catalyst to butylene is low; conversion efficiency of butylene is high; selectivity of oligomerized product is high; distribution of oligomerized product is improved, and the invention has good social and economic benefits.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

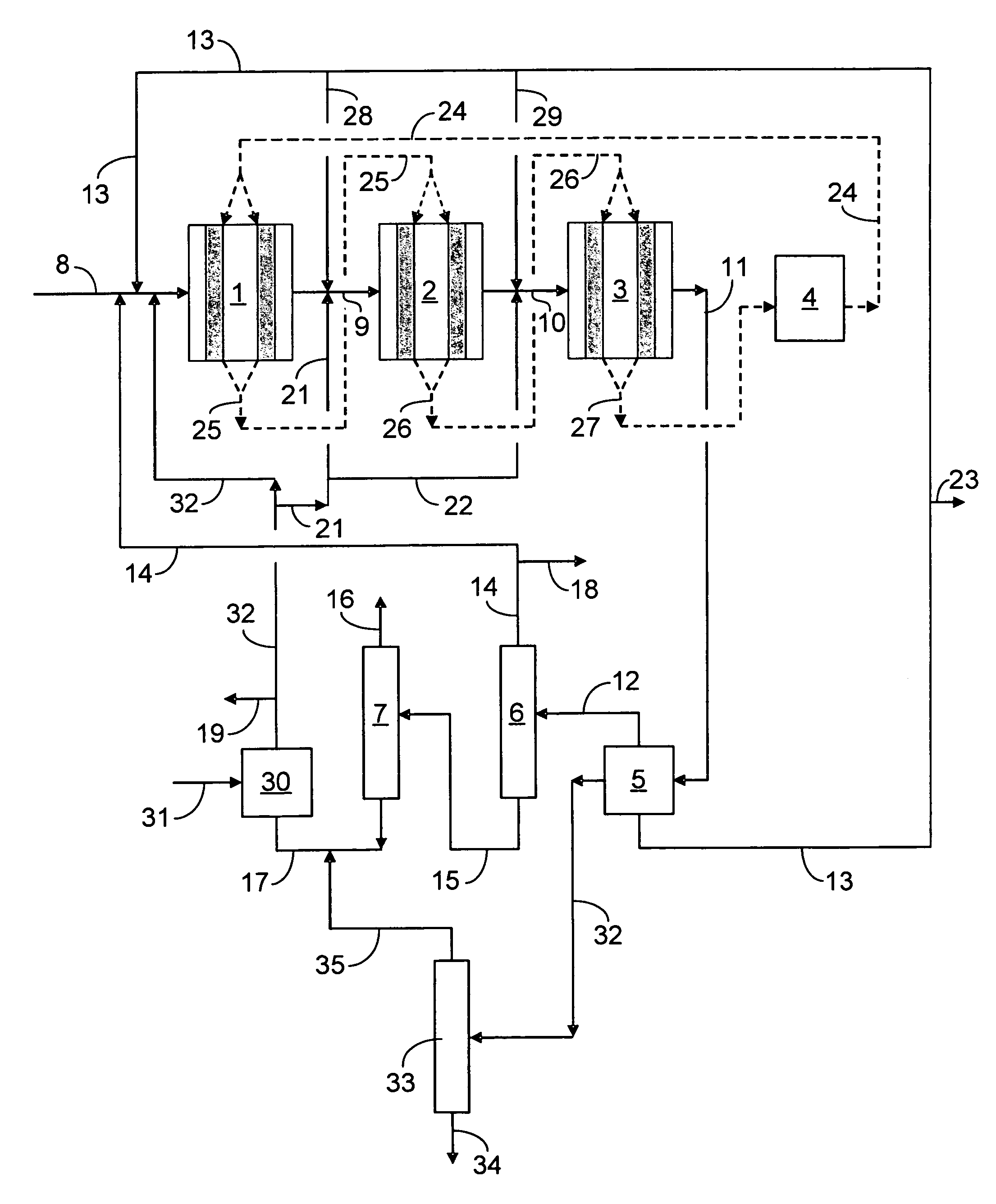

Conversion of oxygenate to propylene with selective hydrogen treatment of heavy olefin recycle stream

ActiveUS7405337B2Improve economyMinimize severityMolecular sieve catalystHydrocarbons from unsaturated hydrocarbon additionOxygenateHydrogen treatment

The average cycle propylene selectivity of an oxygenate to propylene (OTP) process using one or more fixed or moving beds of a dual-function oxygenate conversion catalyst with recycle of one or more C4+ olefin-rich fractions is substantially enhanced by the use of selective hydrotreating technology on these C4+ olefin-rich recycle streams to substantially eliminate detrimental coke precursors such as dienes and acetylenic hydrocarbons. This hydrotreating step helps hold the build-up of detrimental coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling a substantial improvement in propylene average cycle yield. The propylene average cycle yield improvement enabled by the present invention over that achieved by the prior art using the same or a similar catalyst system but without the use of the hydrotreating step on the C4+ olefin-rich recycle stream is of the order of about 1.5 to 5.5 wt-% or more.

Owner:UOP LLC

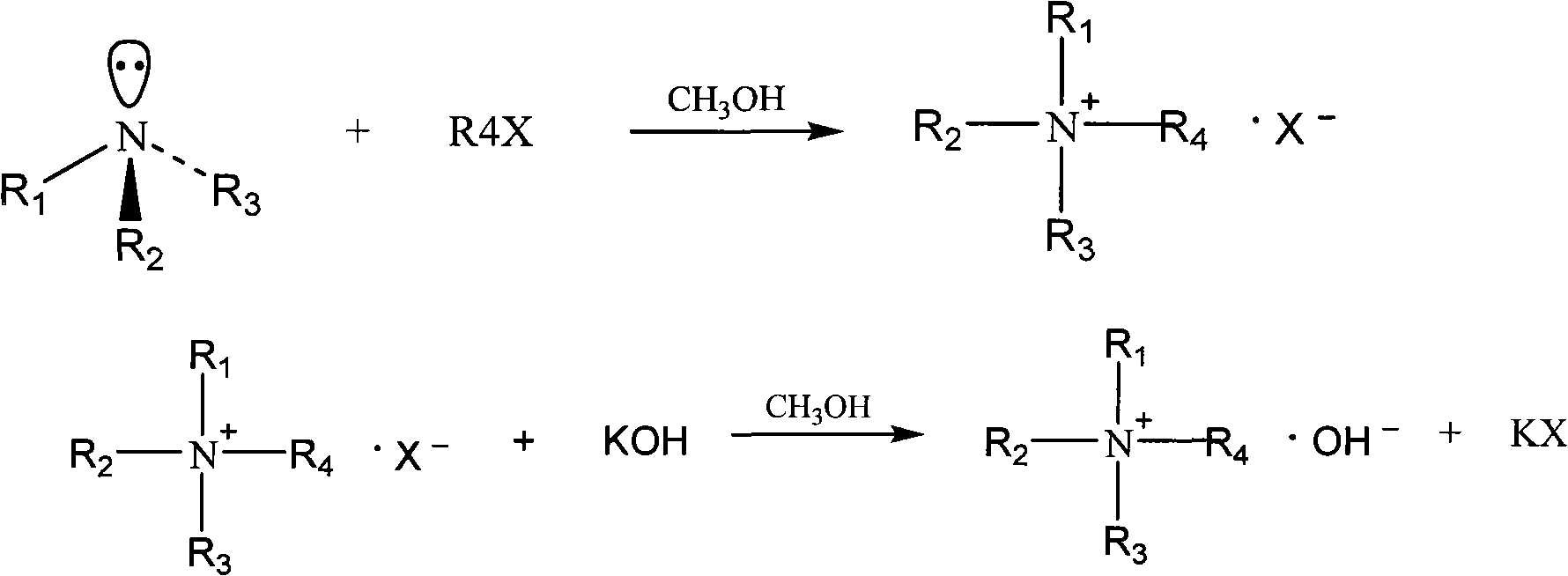

Preparation method for tetra-alkyl ammonium hydroxide and application

InactiveCN101870659ALow costReduce energy consumptionAmino preparation from aminesOrganic compound preparationTetramethylammonium hydroxideAlkaline earth metal

The invention discloses a preparation method for tetra-alkyl ammonium hydroxide. The preparation method is implemented by the following technical scheme: performing a reaction on trialkylamine and alkyl halide in a single organic solvent to obtain tetra-alkyl ammonium halide; performing ion exchange on the tetra-alkyl ammonium halide and an oxide or a hydroxide of an alkali metal or an alkaline earth metal in the presence of an organic solvent; and obtaining the aqueous solution of the tetra-alkyl ammonium hydroxide by after-treatment. The method has the advantages of convenient raw material source, low cost, simple preparation process, high halide ion-exchange rate and the like. The tetra-alkyl ammonium hydroxide prepared by adopting the method is particularly suitable to be used as a base catalyst, which is used for the condensation of nitrobenzene and aniline for generating 4-nitrodiphenylamine and / or 4-nitrosodiphenylamine and the reduction for generating 4-aminodiphenylamine by hydrogenating. Therefore, the conversion rate of the nitrobenzene is greater than or equal to 99.5 percent and the selectivity is up to over 92 percent.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Ionic-like liquid and preparation method and application thereof in preparation of alkylated oil

ActiveCN105536866AStrong water resistanceHigh Lewis acidityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsAlkaneIonic liquid

The invention provides an ionic-like liquid and a preparation method and an application thereof in preparation of alkylated oil. An amide compound undergoes a reaction with a first metal compound and more than one second metal compound to obtain the ionic-like liquid. With the ionic-like liquid as a catalyst, isoparaffin and olefin are subjected to an alkylation reaction, the ionic-like liquid is separated, and thus the alkylated oil is prepared. The ionic-like liquid has the advantages of easily obtained synthetic raw materials, simple synthetic method and cheap price, the alkylation reaction with the ionic-like liquid as the catalyst has high selectivity, and the proportion of C8 components and trimethyl pentane and the octane number of the alkylated oil are both greatly improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

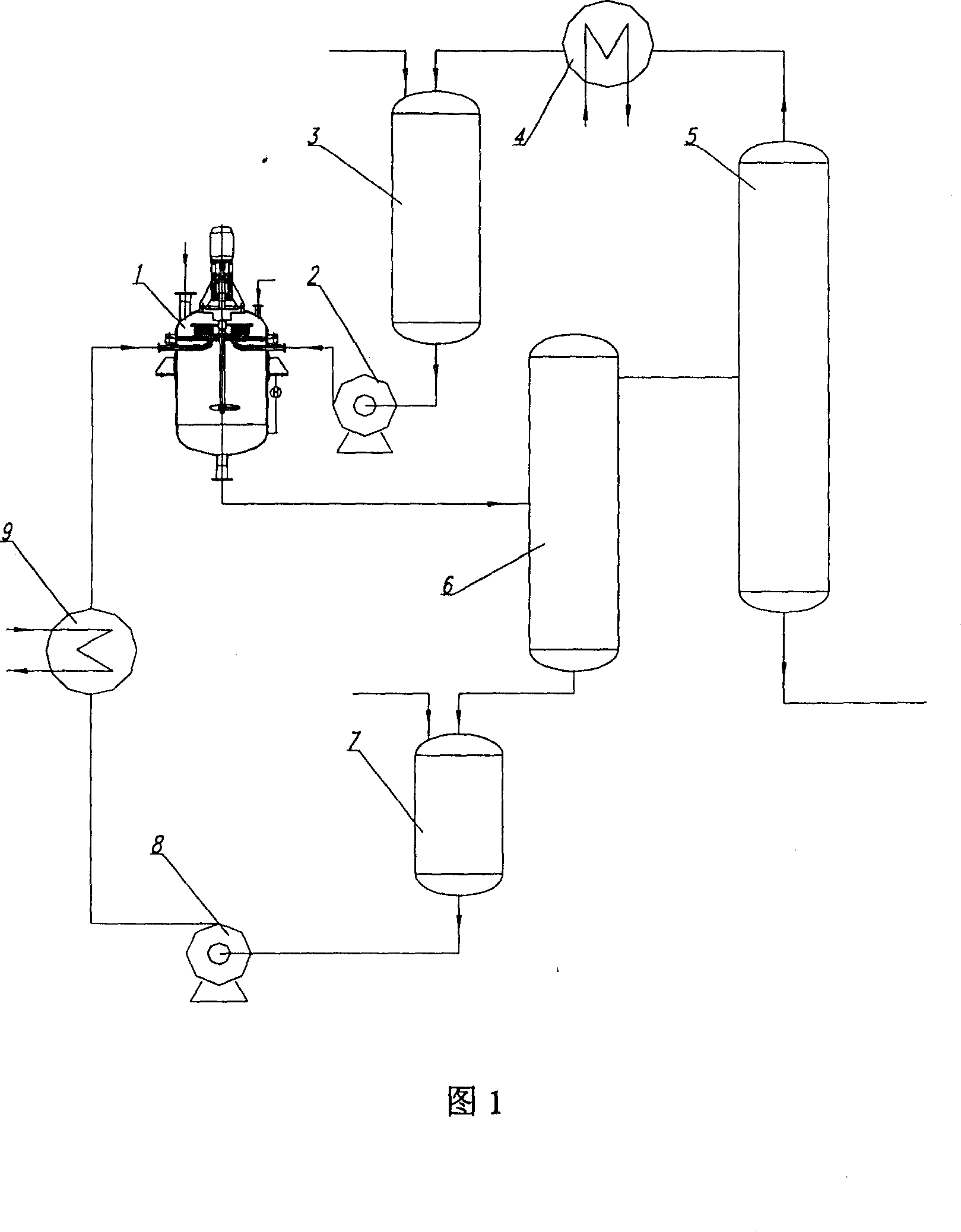

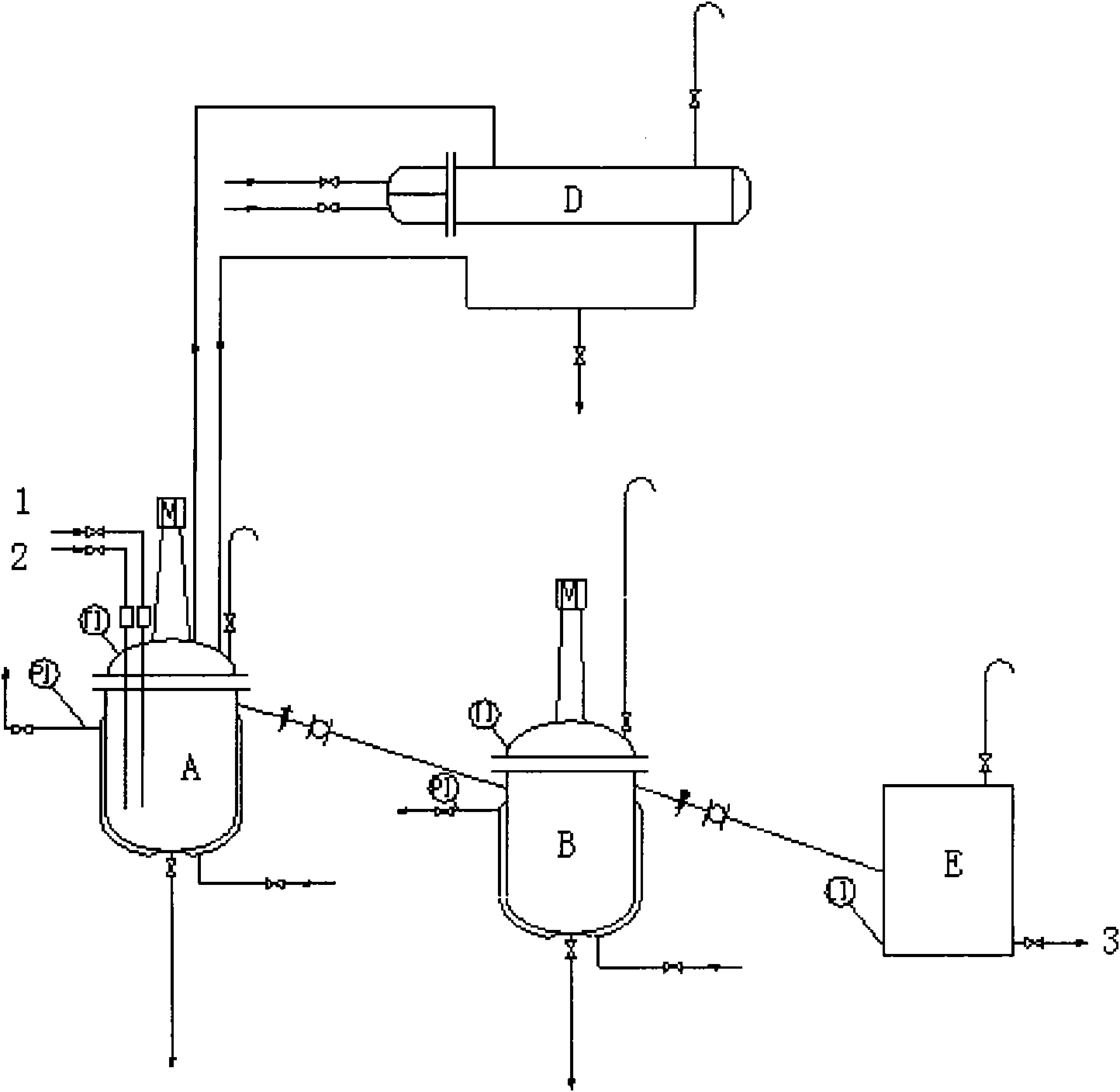

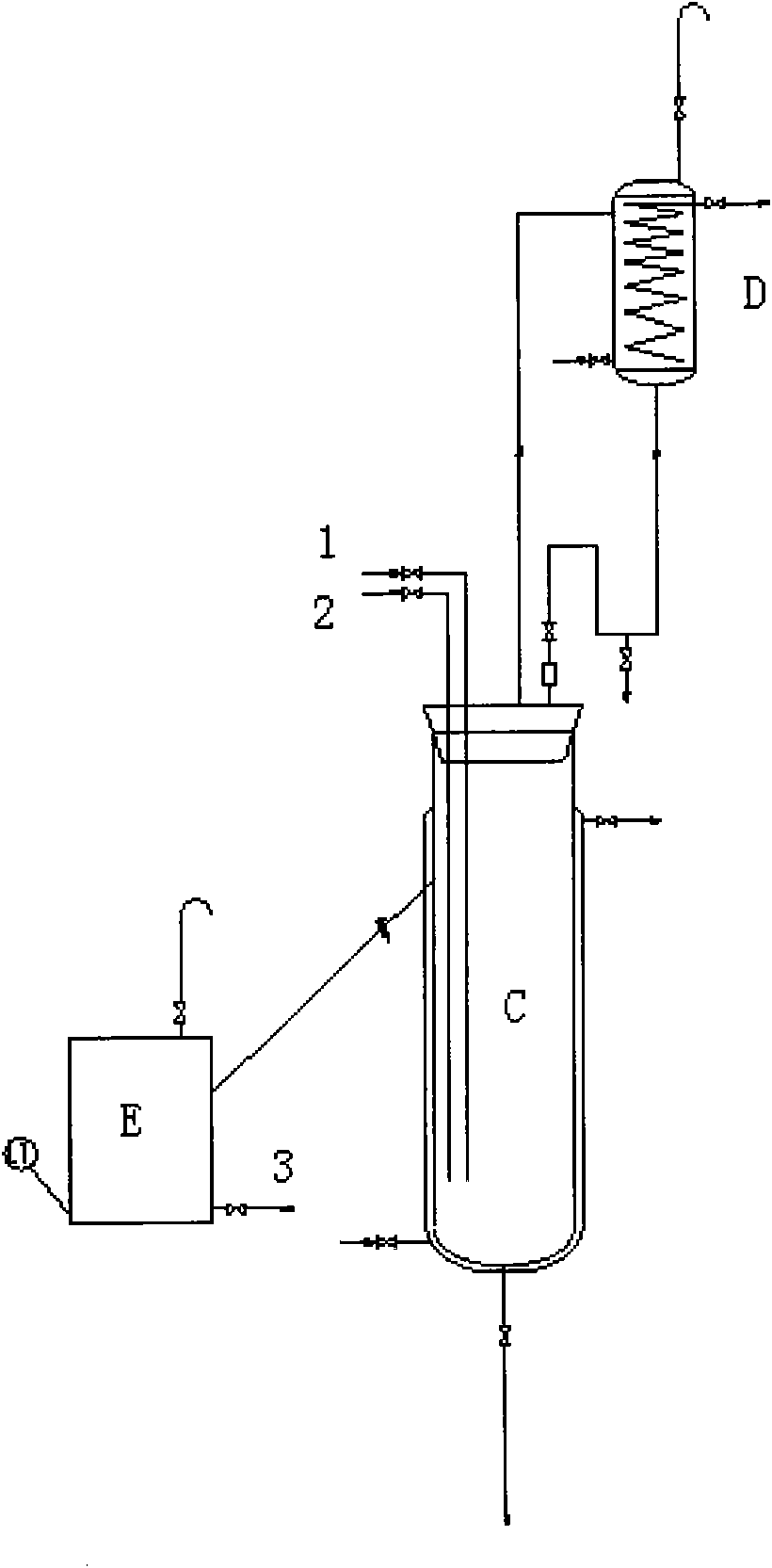

Process for preparing n-hexylic acid by oxidation of sec- octyl alcohol with nitric acid and its special device

InactiveCN1699324AReduce NO contentReduce processing workloadCarboxylic preparation by oxidationImpurityNitric acid

The disclosed method includes a capryl alcohol oxidation step and a crude oxidation liquid purification step, wherein in the capryl alcohol oxidation step, a downward injection type reactor is employed to use the closed injection cycle of the reaction liquid for charging nitric acid, air and nitroxides gases produced in the reaction into the reactor for mixing and reacting with capryl alcohol, in the crude oxidation liquid purification step, a non-washing physical method, i.e. an air blowing method is employed to remove the inorganic acidic impurity in the oxidation liquid, the processing time being 0.5-2.0 hours.

Owner:HENAN UNIVERSITY

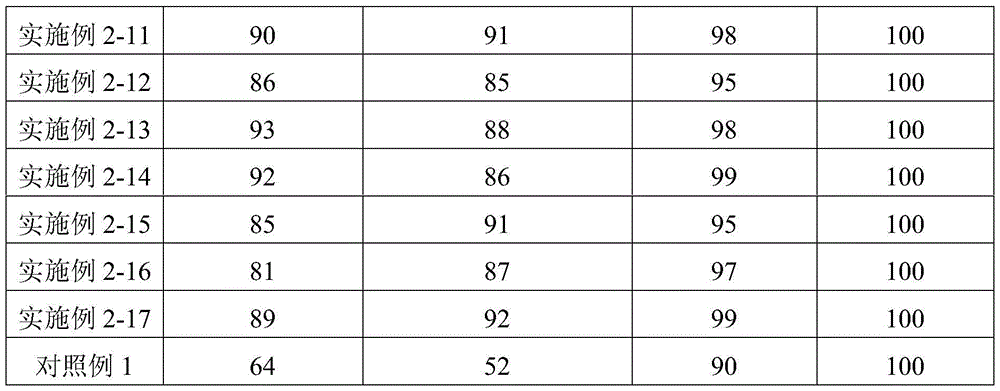

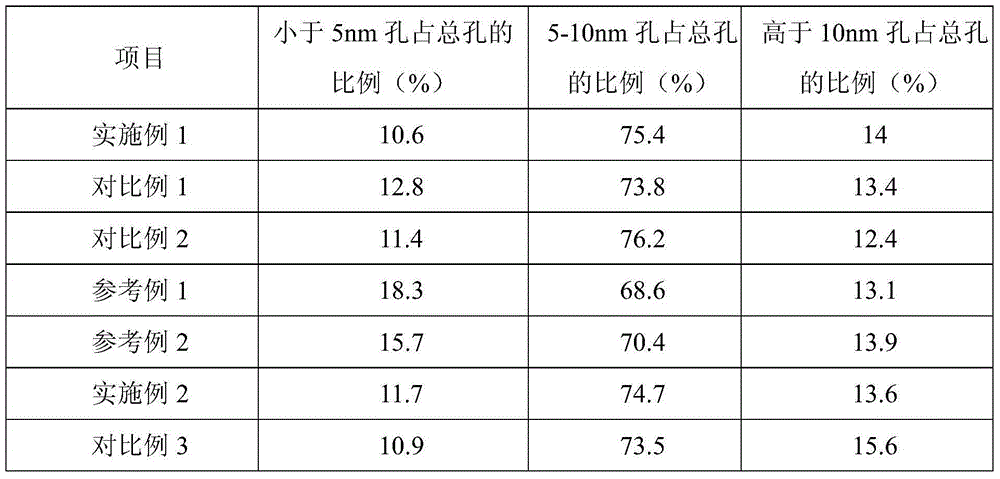

Acrylic acid catalyst regeneration method

InactiveCN103551161AStrong anti-coking abilityExtended service lifeOrganic compound preparationCarboxylic compound preparationPore distributionNitrogen atmosphere

The invention relates to an acrylic acid catalyst regeneration method. An acrylic acid catalyst has a concentrated pore distribution and a moderate total pore volume, the amount of medium-sized pores of about 5-10nm accounts for above 70% of the amount of total pores, and the medium-sized pores of about 5-10nm form short and thick tunnel structures, so the catalyst has the characteristics of strong carbon deposit resistance, difficult agglomeration and long service life. The two-step calcining regeneration method for regenerating an inactivated acrylic acid catalyst comprises the following steps: heating the inactivated acrylic acid catalyst to 280-320DEG C at a speed of 1-2DEG C / h, and carrying out constant temperature calcining for 1-10h; and heating to 330-370DEG C at a speed of 1-2DEG C / h, calcining in an oxidizing gas for 1-3d, heating to 380-410DEG C, and calcining in nitrogen atmosphere for 1-3d to obtain a regenerated acrylic acid catalyst having an equivalent activity with the fresh catalyst.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Regeneration method for flue gas SCR de-nitration catalyst filtering element

ActiveCN104826494ARestoring Filtration FluxImprove filtration efficiencyDispersed particle separationEngineeringFlue gas

The present invention discloses a regeneration method for a flue gas SCR de-nitration catalyst filtering element. By means of the method, the filtering efficiency and the catalytic activity of an SCR de-nitration catalyst filtering element are recovered. The method comprises the steps of (1) purging the surface of the SCR de-nitration catalyst filtering element by means of the compressed gas, and then reversely purging the SCR de-nitration catalyst filtering element from the inside to the outside; (2) dipping the above SCR de-nitration catalyst filtering element in a dilute acid solution; (3) after the dipping process of the above SCR de-nitration catalyst filtering element in the dilute acid solution, dipping the SCR de-nitration catalyst filtering element in an activated solution so as to realize the replenishment of catalytic active ingredients on the surface of the SCR de-nitration catalyst filtering element; (4) after the fully dipping process of the SCR de-nitration catalyst filtering element in the activated solution, taking the SCR de-nitration catalyst filtering element out of the activated solution, roasting the SCR de-nitration catalyst filtering element and finally obtaining a regenerated SCR de-nitration catalyst filtering element. The above activated solution is used for the replenishment of catalytic active ingredients on the surface of the SCR de-nitration catalyst filtering element and is in the form of a saline solution containing an SCR de-nitration catalyst.

Owner:CHENGDU INTERMENT TECH

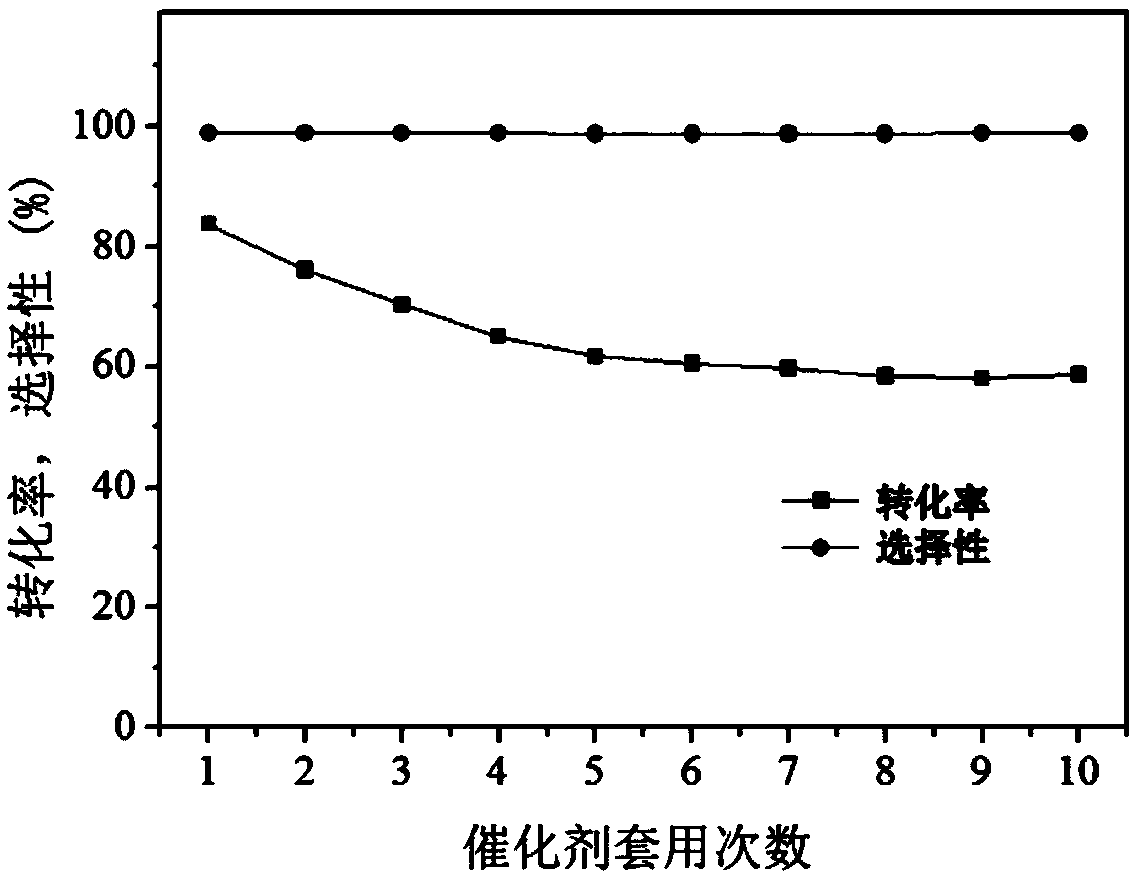

Regeneration method for Pd@CN catalyst for phenol hydrogenation

ActiveCN108927203AExperimental stabilityRestore catalytic activityCatalyst regeneration/reactivationCyclohexanoneFiltration

The invention relates to a regeneration method for a Pd@CN catalyst for phenol hydrogenation. The regeneration method comprises the following steps: after the Pd@CN catalyst is used to catalyze the phenol hydrogenation, the catalyst is recovered by filtration, the recovered catalyst is placed into a reaction kettle, a solvent is added, washing is performed under certain conditions to regenerate the catalyst, and after secondary filtration is performed, the obtained catalyst is used for a next application experiment. The regeneration method provided by the invention can effectively regenerate the deactivated catalyst, realize the recycling of the catalyst, reduce a use amount of the catalyst, improve economic efficiency of the process, and provide a guarantee for the green production process of preparing cyclohexanone by the phenol hydrogenation.

Owner:NANJING MEMBRANE IND TECH RES INST CO LTD +1

Method of regeneration of titanium-containing molecular sieve catalyst

InactiveUS20090018291A1Efficient removalRestore catalytic activityMolecular sieve catalystsOther chemical processesMolecular sieveAlcohol

Disclosed herein is a method of regenerating a titanium-containing molecular sieve catalyst. Particularly, this invention provides a method of regenerating a titanium-containing molecular sieve catalyst used in epoxidation of olefin through simple treatment using a mixture solvent comprising aqueous hydrogen peroxide and alcohol. According to the method of this invention, when the catalyst having decreased activity is regenerated, the activity of the regenerated catalyst is equal to that of new catalyst and can be maintained stable for a long period of time.

Owner:SK INNOVATION CO LTD

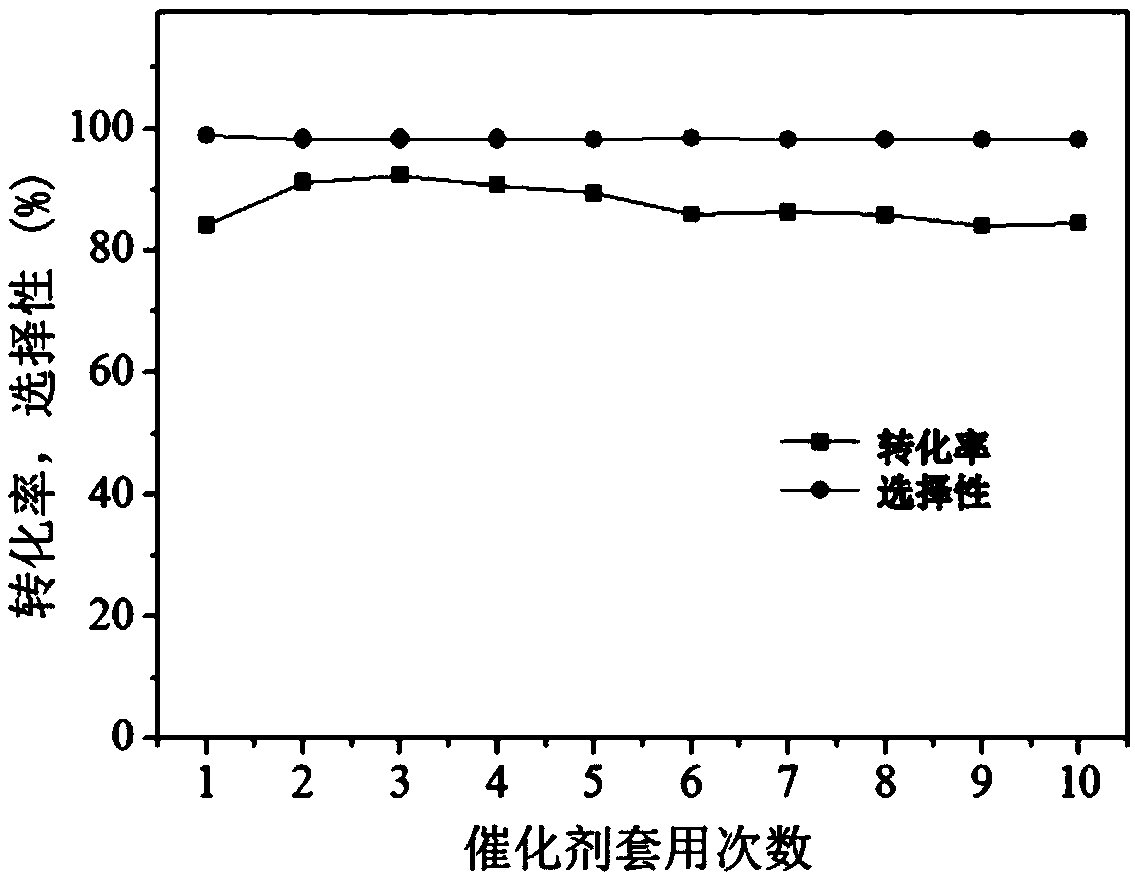

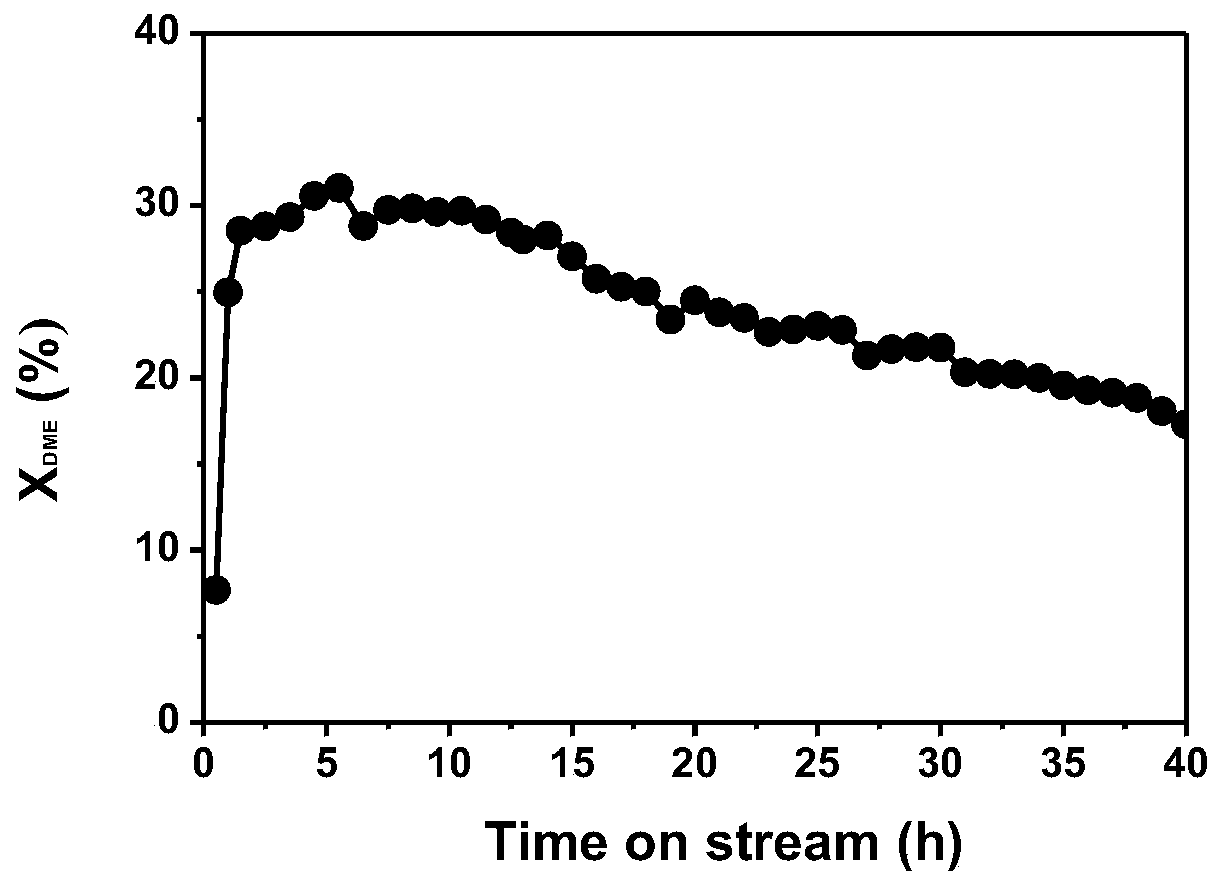

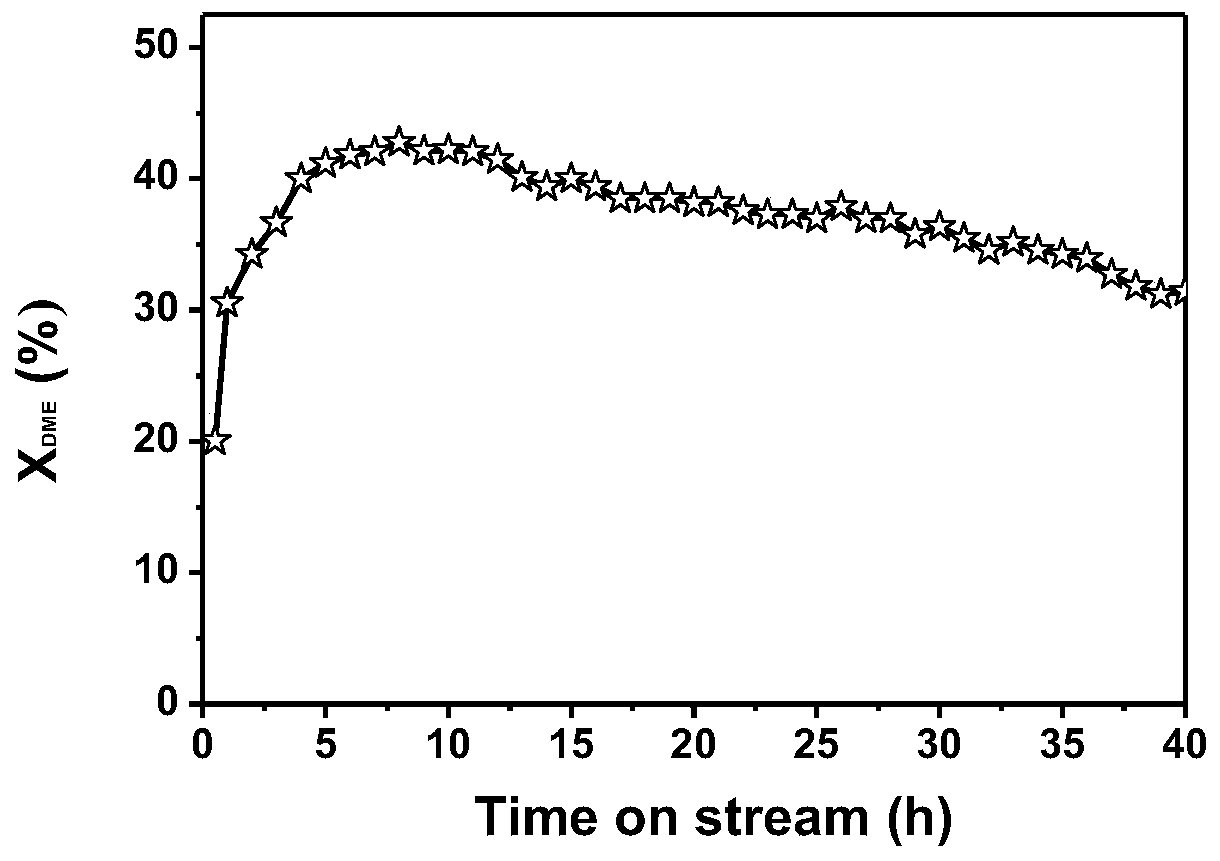

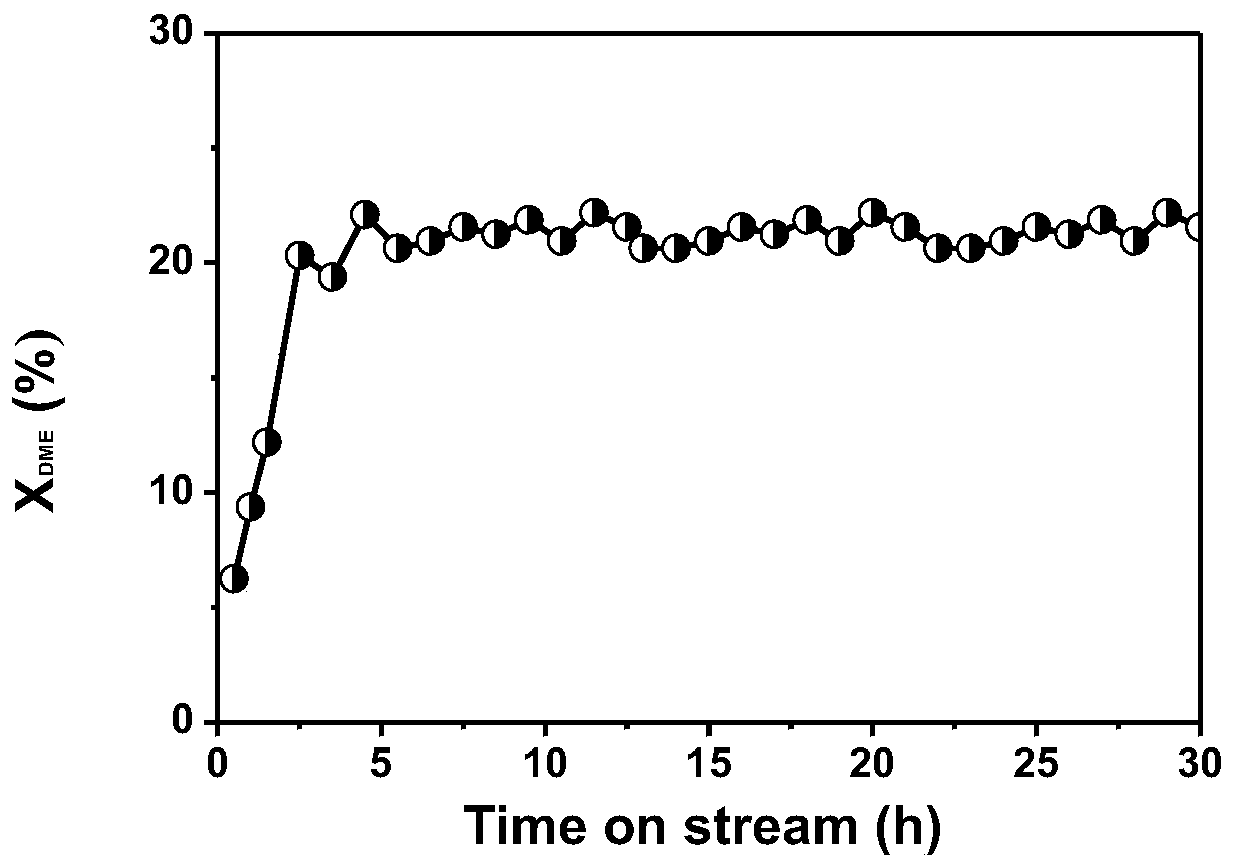

Modification method of hydrogen type mordenite molecular sieve for dimethyl ether carbonylation reaction

ActiveCN109985658AEasy to operateRestore catalytic activityCatalyst protectionMolecular sieve catalystsProtein carbonylMolecular sieve

The invention discloses a modification method of a hydrogen type mordenite molecular sieve for dimethyl ether carbonylation reaction. The modification method comprises the following steps: under the condition of one or a mixed atmosphere of inert atmosphere or H2 gas, drying a hydrogen type mordenite molecular sieve at a temperature of 300 to 600 DEG C to obtain a dried hydrogen type mordenite molecular sieve; introducing a mixed gas of pyridine or methylpyridine and an inert atmosphere at a temperature of 250 to 400 DEG C to the dried hydrogen type mordenite molecular sieve, so as to enable the mordenite molecular sieve to pre-adsorb pyridine or methylpyridine until the pyridine or methylpyridine absorbed by the molecular sieve is saturated; carrying out heating desorption treatment on the mordenite molecular sieve with saturated adsorbed pyridine or methylpyridine, introducing an inert atmosphere, and desorbing weakly adsorbed pyridine or methylpyridine under the conditions that thedesorption temperature is higher than the adsorption temperature by 50-250 DEG C. A catalyst provided by the invention is used for preparing methyl acetate by carbonylation of dimethyl ether, and methyl acetate is obtained at a high and stable yield.

Owner:TIANJIN UNIV

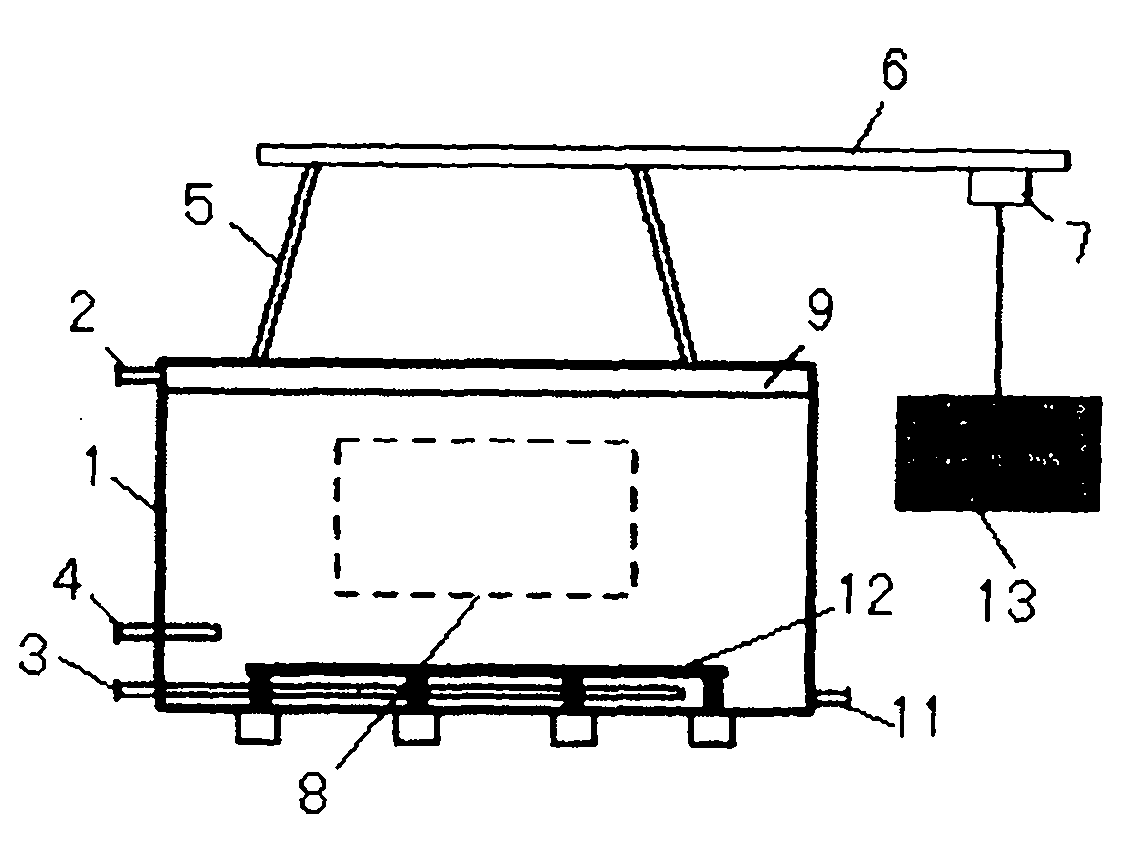

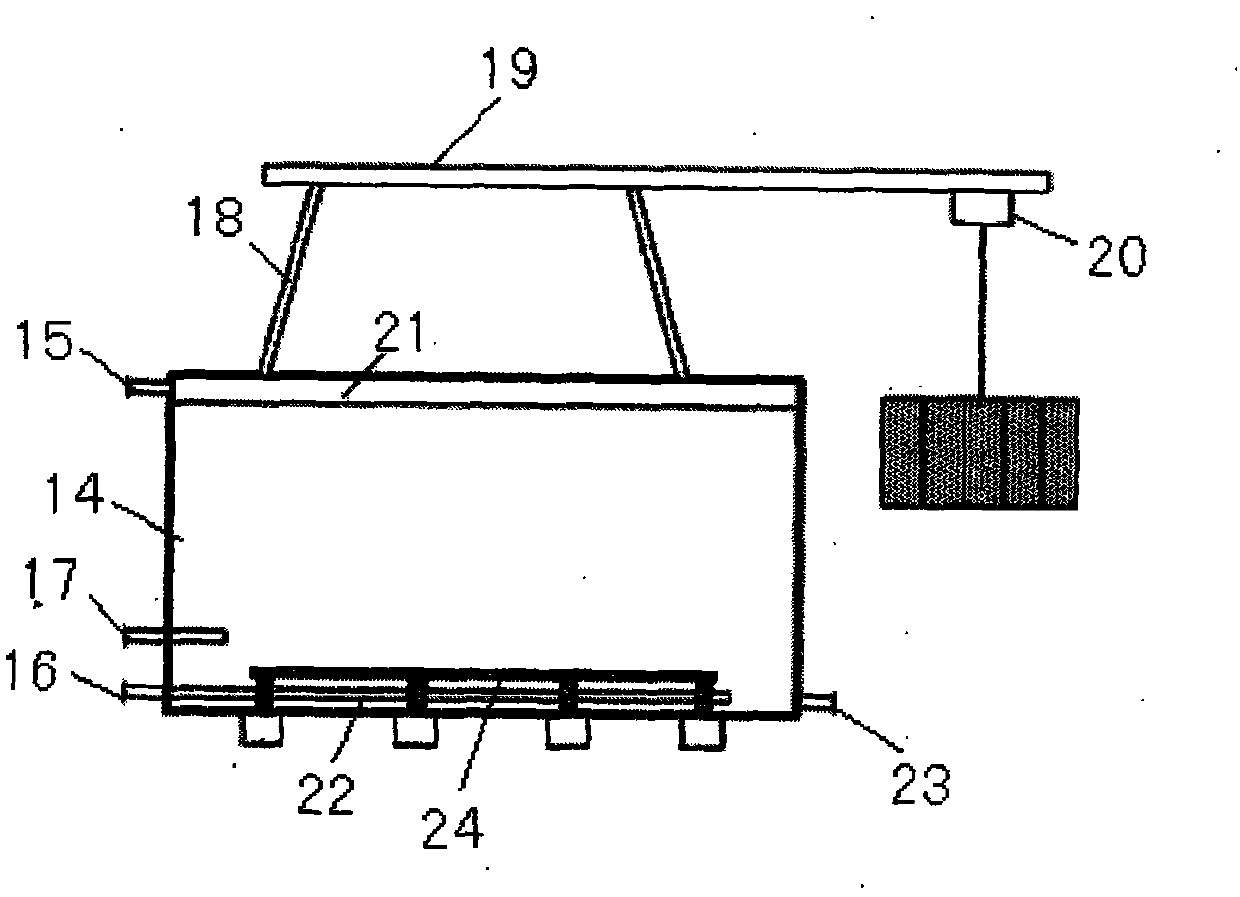

Movable type denitration catalyst cleaning device

InactiveCN101947414ARestore catalytic activityHigh catalytic efficiencyDispersed particle separationCleaning using liquidsAlkaline earth metalMetal

The invention relates to a movable type denitration catalyst cleaning device, composed of a cleaning tank and a rinsing tank. The invention has the advantages that: catalyst (especially denitration catalyst) is cleaned, soluble pollutants such as catalyst hole tamper, alkalis and alkaline earth are effectively removed, catalytic activity of catalyst is recovered, catalytic efficiency of catalyst is improved, and service life of catalyst is prolonged; the catalyst lifting appliances which are arranged in an ultrasonic cleaning tank and the rinsing tank are dismountable, thus being beneficial to suspension cleaning and rinsing of catalyst module; an overflow slot is arranged in the ultrasonic cleaning tank and the rinsing tank, so as to realize automatic outflow of dirt foam produced in thecleaning process, thus avoiding manual cleaning and improving cleaning efficiency; a compressed air bubbling device is arranged in the rinsing tank, thus being beneficial to clearing dirt remained after the catalyst module is cleaned; and the ultrasonic cleaning tank and the rinsing tank can be transported by utilizing vehicles such as a car and a ship, thus being beneficial to in-place cleaning of catalyst.

Owner:NANJING KAITUO ENVIRONMENTAL PROTECTION TECH CO LTD

Method of regeneration of titanium-containing molecular sieve catalyst

InactiveUS7838455B2Efficient removalRestore catalytic activityMolecular sieve catalystsOther chemical processesMolecular sieveAlcohol

Disclosed herein is a method of regenerating a titanium-containing molecular sieve catalyst. Particularly, this invention provides a method of regenerating a titanium-containing molecular sieve catalyst used in epoxidation of olefin through simple treatment using a mixture solvent comprising aqueous hydrogen peroxide and alcohol. According to the method of this invention, when the catalyst having decreased activity is regenerated, the activity of the regenerated catalyst is equal to that of new catalyst and can be maintained stable for a long period of time.

Owner:SK INNOVATION CO LTD

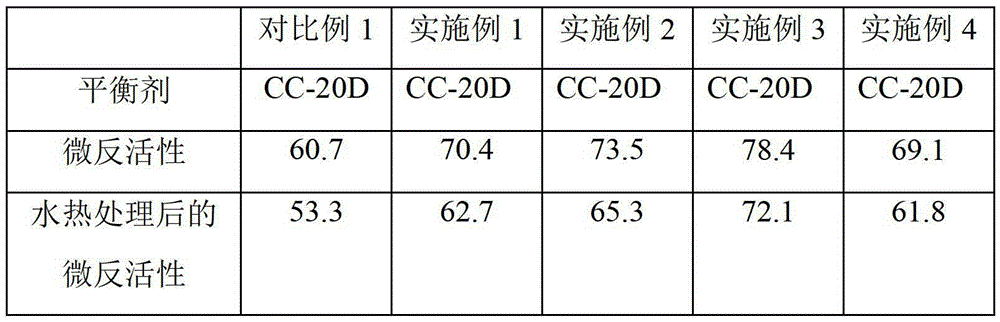

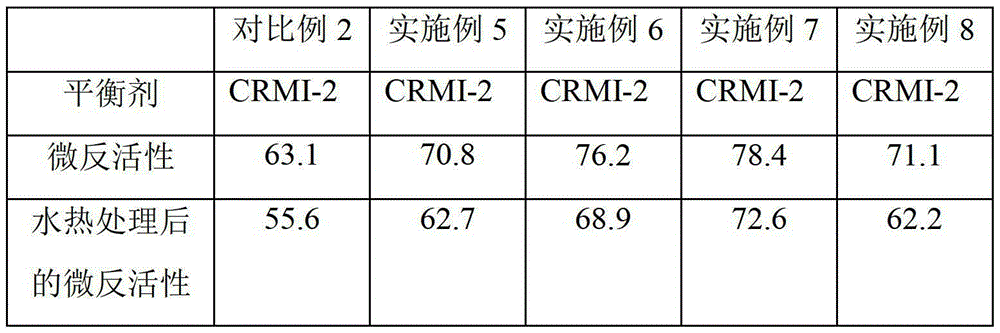

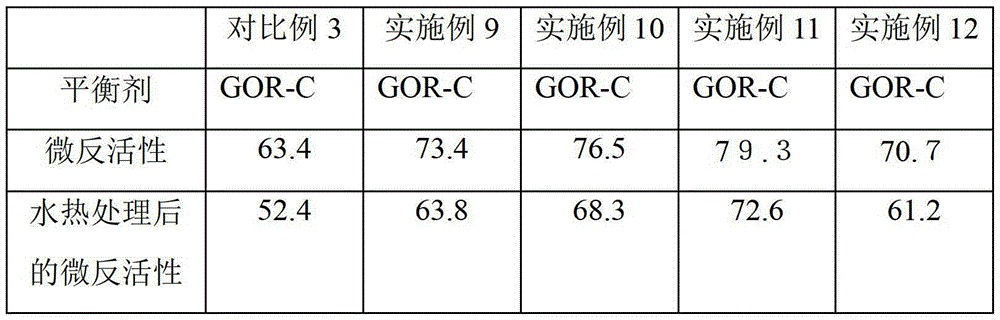

Method for modifying catalytic cracking equilibrium agent

InactiveCN106622398AEnhanced Surface AcidityRestore catalytic activityCatalyst regeneration/reactivationRoom temperatureWater soluble

The invention relates to a method for modifying a catalytic cracking equilibrium agent. The method comprises the following steps: 1) roasting the catalytic cracking equilibrium agent at the temperature of 250-900 DEG C; 2) dumping the roasted catalytic cracking equilibrium agent obtained in the step 1) in an acid solution, processing the materials at the temperature between room temperature and 100 DEG C for 10min-5h, and drying the materials after processing; 3) mixing the catalytic cracking equilibrium agent obtained in the step 2) and a solution of water-soluble metal salt at the temperature between room temperature and 100 DEG C and exchanging for 10min-5h, then drying the materials, and roasting the material; wherein the mass ratio of the metal ions to the catalytic cracking equilibrium agent is 0.05-20%. The micro-activity of the catalytic cracking equilibrium agent processed by the method is increased by 5-16 units, and the hydro-thermal stability is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

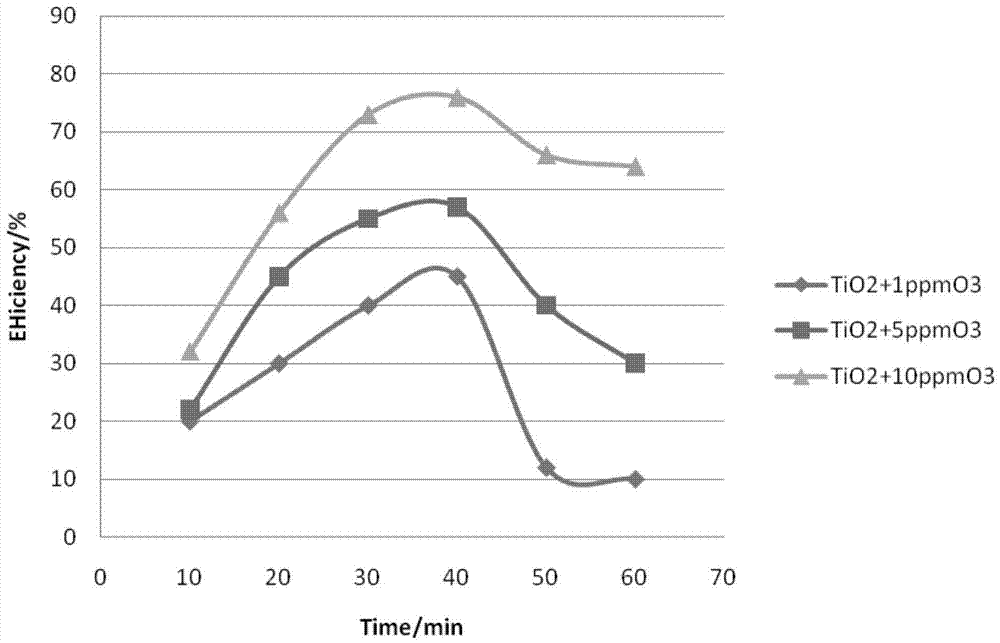

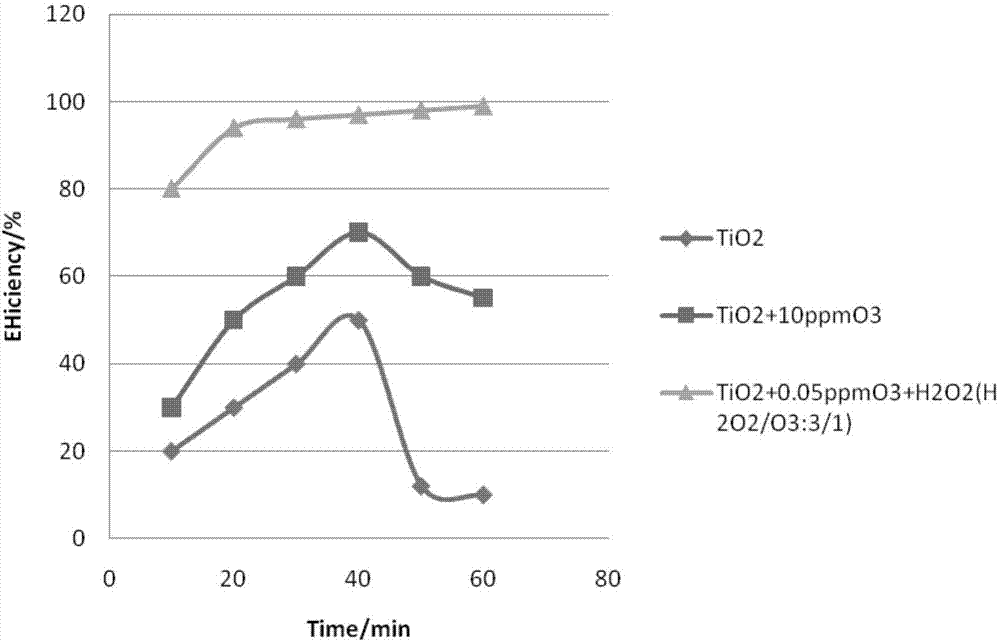

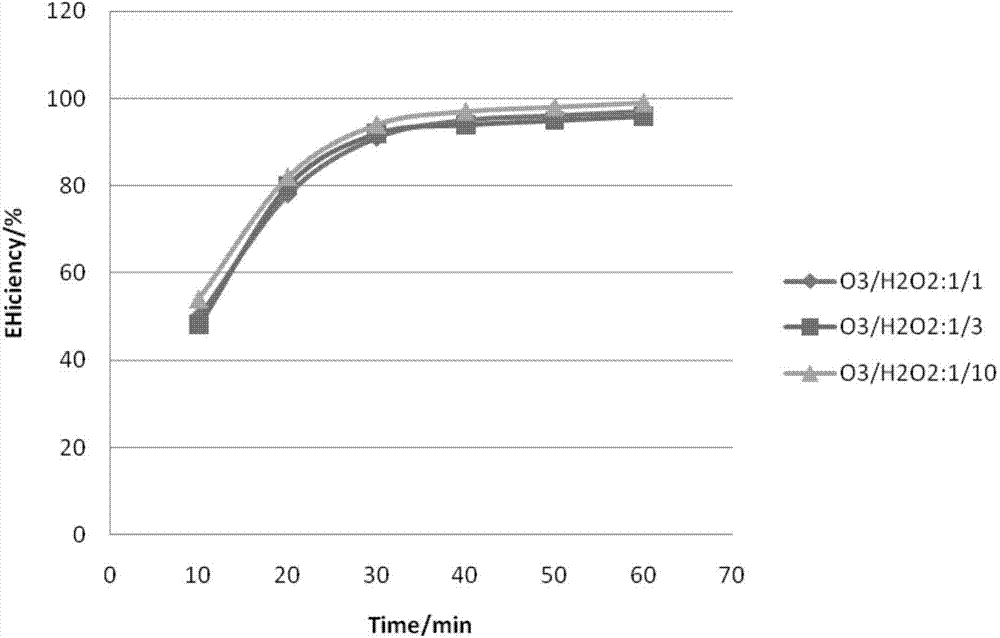

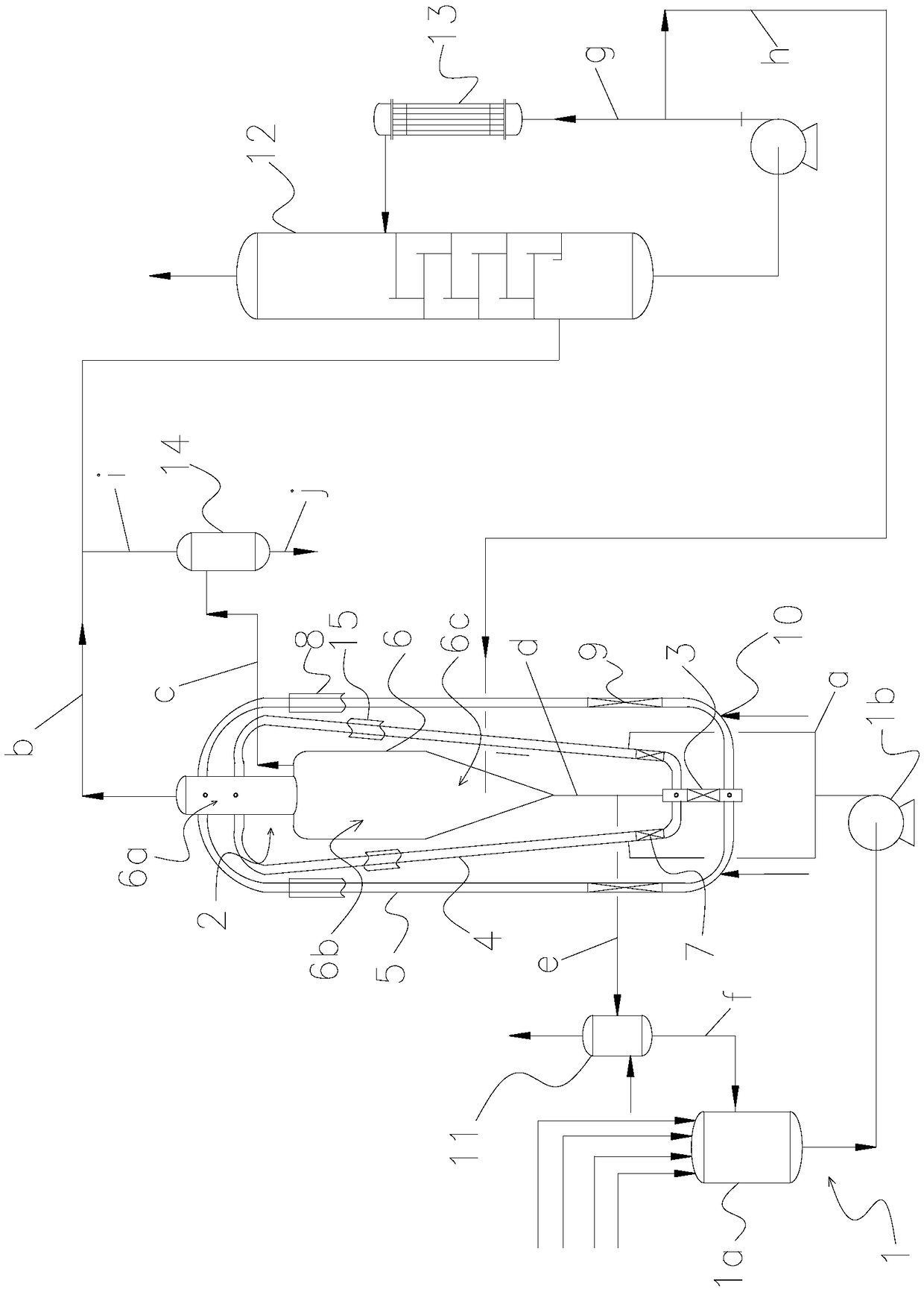

Method and device for purifying indoor harmful volatile organic compounds

ActiveCN104707478AQuick clearEfficient removalDispersed particle separationHigh concentrationPhotocatalytic reaction

The invention relates to a method and device for purifying indoor harmful volatile organic compounds. The method for purifying the indoor harmful volatile organic compounds comprises the steps: an air purifier loaded with a photocatalyst is provided; the air purifier is internally filled with a mixed oxidizing agent composed of ozone and hydrogen peroxide; and air containing the harmful volatile organic compounds is allowed to flow through the air purifier, so as to degrade the harmful volatile organic compounds under the action of the photocatalyst. The method not only can effectively inhibit gradual disappearing of the photocatalyst activity during the photocatalytic reaction process, but also avoids secondary pollution brought by use of high-concentration O3 and after-treatment required for O3.

Owner:珠海圣邦科技有限公司

Reproduction method for synthesizing carbonic allyl(ethene) ester by carbamide and propylene(ethylene) glycol

InactiveCN1762599AMaintain and Improve Crystalline MorphologyRestore catalytic activityOrganic compound preparationCatalyst regeneration/reactivationUreaPropylene carbonate

This invention relates to a regenerating method for compounding propylene carbonate catalyst with aquacare and methyl ethylene glycol, which comprises the following steps: a, separating the catalyst with the centrifuge; b, scouring with the organic solvent, filtering and drying; c, baking the dried catalyst in the cave, then can get the regenerated catalyst. This invention can preserve and improve the present crystallization shape of the catalyst without destroying the catalyst structure, recovering its catalyst effort. The effective component of the catalyst is not separate with the carrier, and does not create acid pickle.

Owner:PETROCHINA CO LTD +1

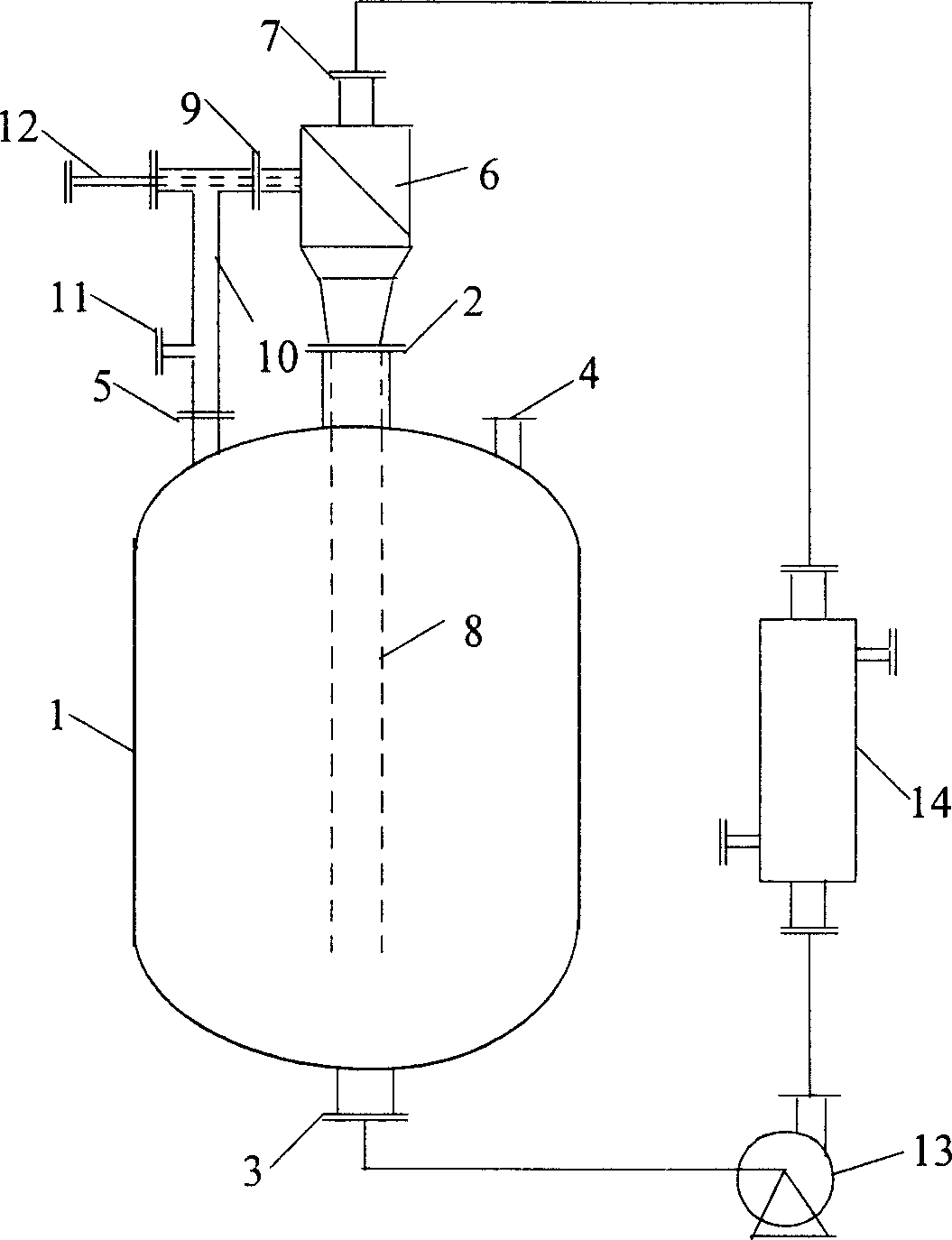

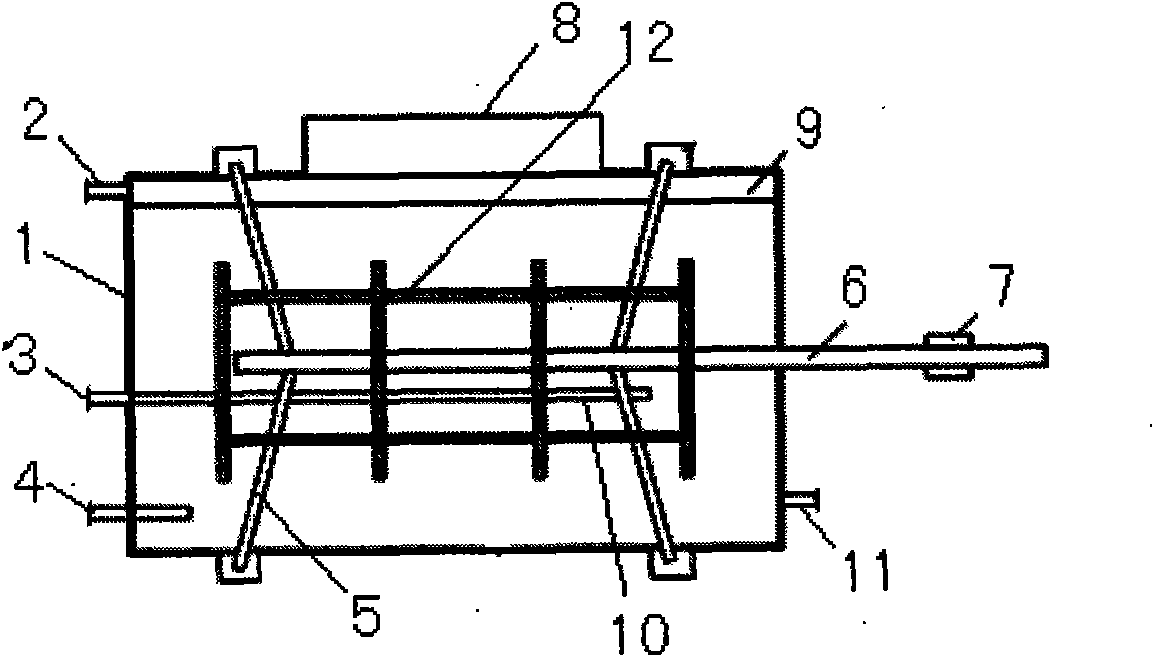

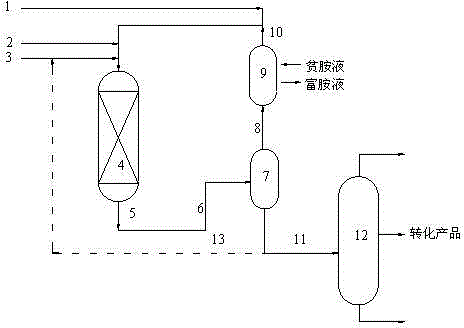

Hexamethylenediamine synthesis system

ActiveCN109261085AGuaranteed mixing effectRadial temperature difference is smallAmino compound purification/separationOrganic compound preparationHydrogenHexamethylenediamine

A hexamethylenediamine synthesis system comprises a feeder, a reactor and a distributor, wherein the reactor comprises a plurality of material mixing pipelines, a plurality of material synthesis pipelines and a separator, an inner cavity of the separator comprises a gas-liquid separation zone, a liquid-solid separation zone and a conical sedimentation zone, a material mixing device is arranged ineach material mixing pipeline, and the feeder is connected with the material mixing pipelines. The upper end of each material mixing pipeline is communicated with the gas-liquid separation zone, the lower end of each material mixing pipeline is communicated with the feeding end of the distributor, and each material synthesis pipeline is wrapped with a cooling medium jacket. A spiral mixing deviceis arranged in each material synthesis pipeline, the upper end of each material synthesis pipeline is communicated with the gas-liquid separation zone and located above the corresponding material mixing pipeline, and the lower end of each material synthesis pipeline is communicated with the discharging end of the distributor. A hydrogen inlet is formed in each material synthesis pipeline, an exhaust pipeline is arranged at the top of the gas-liquid separation zone, the liquid-solid separation zone is provided with a hexamethylenediamine discharge pipeline, and the conical sedimentation zone iscommunicated with the feeding end of the distributor through a return pipeline.

Owner:CHONGQING HUAFON CHEM +2

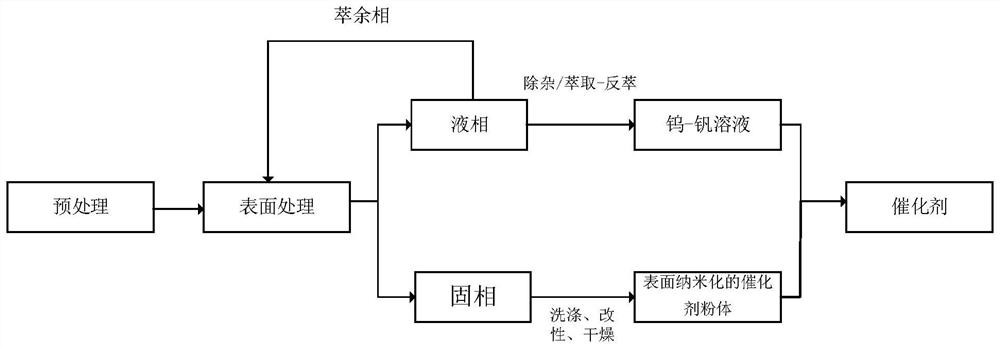

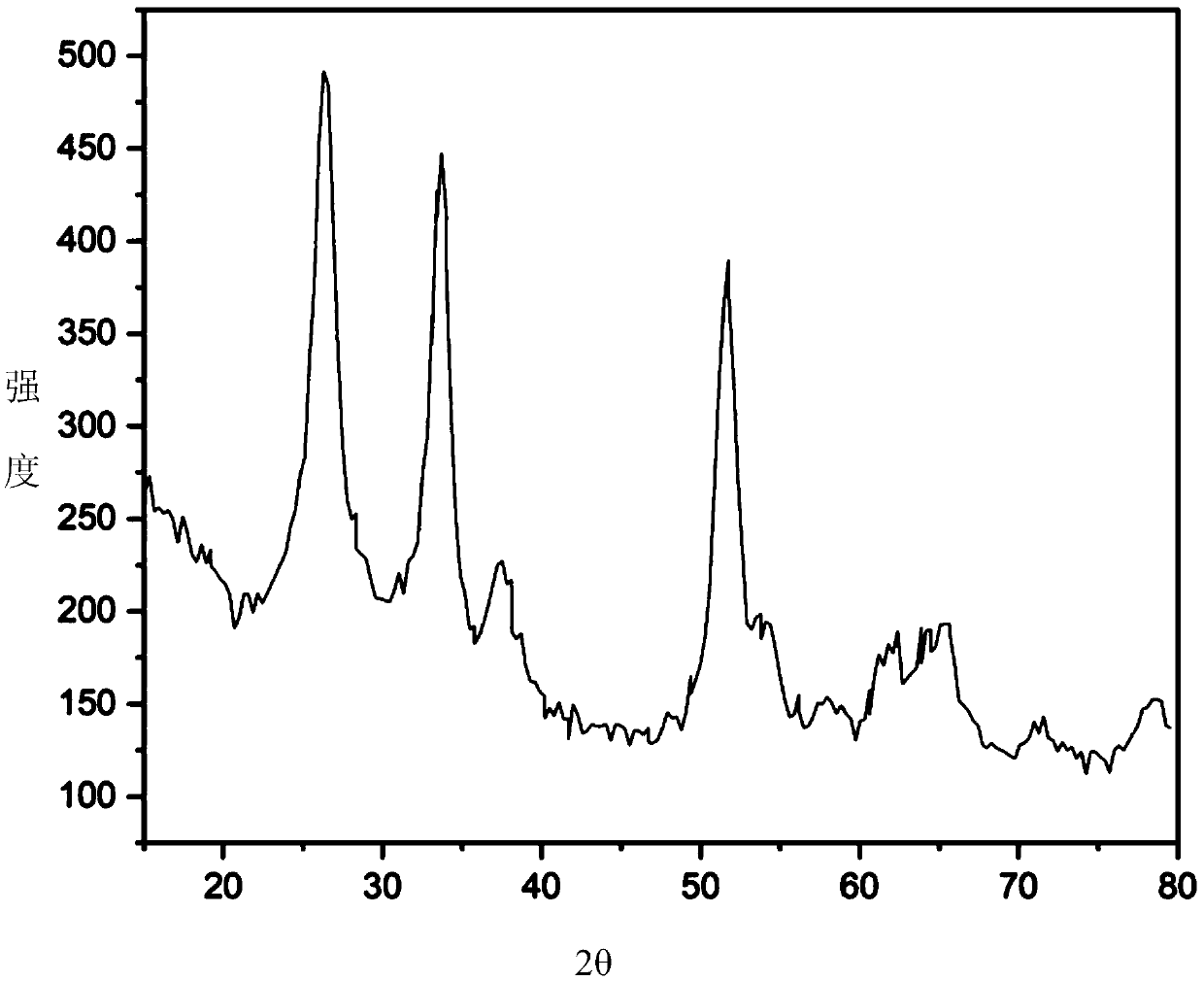

Denitration catalyst and preparation method thereof

ActiveCN111974378AImprove denitrification effectLarge specific surface areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention relates to the field of waste catalyst disposal, and discloses a denitration catalyst, a preparation method of the denitration catalyst and the denitration catalyst prepared by the method. The denitration catalyst comprises a titanium oxide carrier material, a metal active component and an auxiliary agent, wherein the carrier material comprises titanium oxide and nanocrystallized titanium oxide whiskers coating at least part of the outer surface of the titanium oxide, and based on the total weight of the carrier material, the content of the nanocrystallized titanium oxide whiskers is 5-30wt%. According to the denitration catalyst provided by the invention, the titanium oxide of which at least part of the outer surface is coated with the nanocrystallized titanium oxide whiskers is adopted as the carrier material, the denitration catalyst provided by the invention has excellent denitration catalytic activity, and meanwhile, the carrier material is obtained by recycling thewaste denitration catalyst, so that the cost of the denitration catalyst is obviously reduced, and the environmental pollution is reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

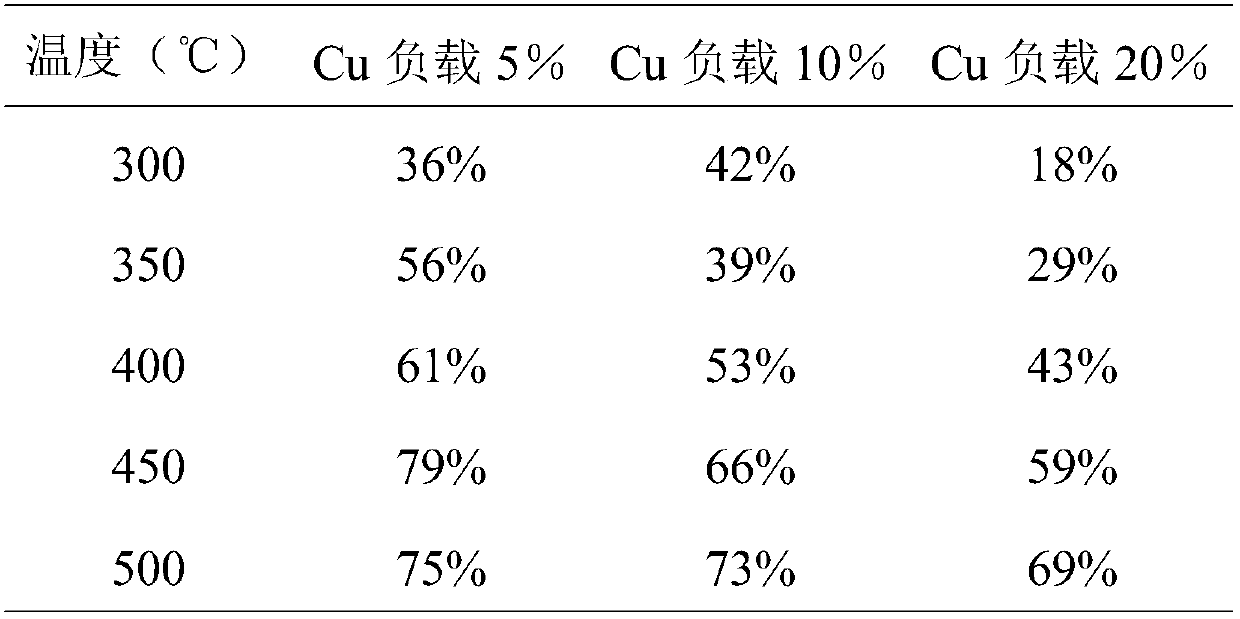

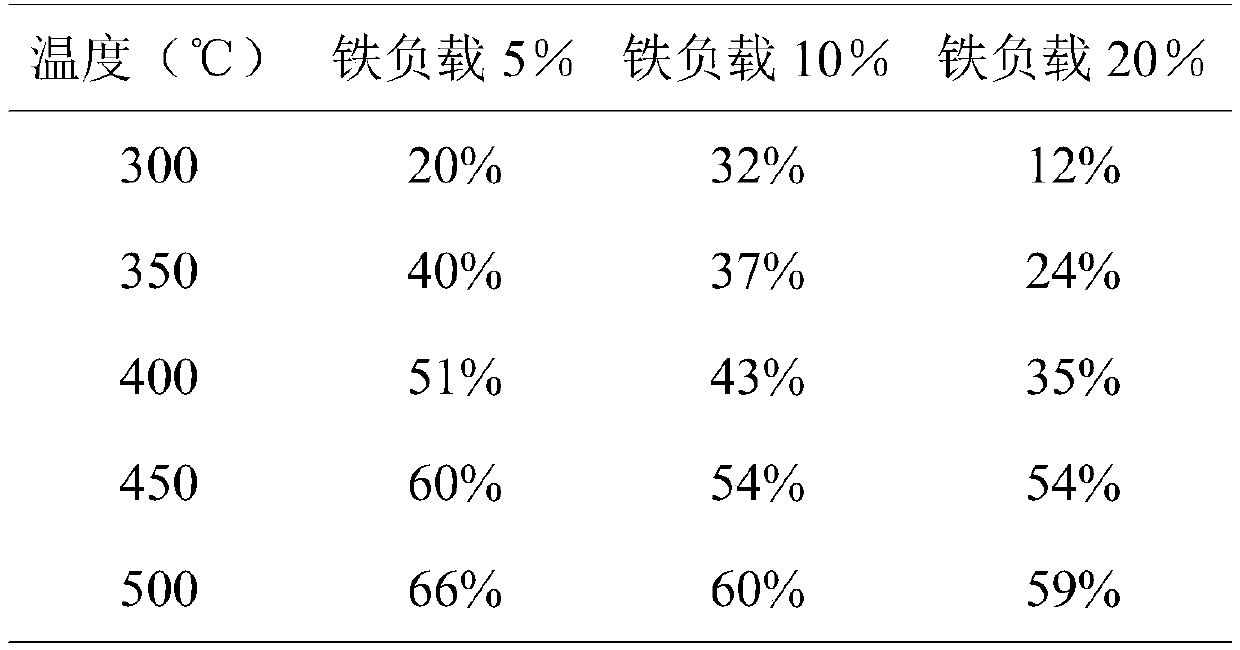

X-Sn-Zr reduction catalyst, and preparation method and application thereof

InactiveCN109529860ASolve the problem of secondary pollution caused by desulfurizationImprove desulfurization efficiencyGas treatmentHeterogenous catalyst chemical elementsSulfurOxygen

The invention discloses an X-Sn-Zr reduction catalyst, and a preparation method and an application thereof. The catalyst has a structure with a formula of XnOm-SnO2-ZrO2, wherein X is selected from the group consisting of Cu and group metals thereof, and Fe; the ratio of n to m is 1: 1, or 2: 3; the catalyst is used to reduce SO2 to elemental sulfur; and the mass of XnOm in the catalyst accounts for 5% to 20% of the total mass of the catalyst. The catalyst provided by the invention can catalytically desulfurizes mixed gas containing oxygen and sulfur dioxide at 300 to 500 DEG C through prevulcanization of mixed gas of N2, CO and SO2, and has high desulfurization efficiency.

Owner:YUNNAN UNIV

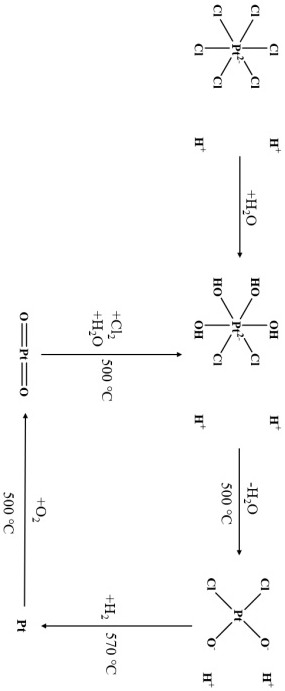

Activity regeneration method for Pt-based catalyst for preparing propylene through propane dehydrogenation

The invention discloses an activity regeneration method of a Pt-based catalyst for preparing propylene through propane dehydrogenation. According to the regeneration method, mixed gas of eight regeneration gases including HBr, C2H5Br, HCl, Cl2, NH3, C2HCl3, CCl4 and CH2Cl2 and air is adopted for carrying out regeneration treatment on an inactivated catalyst, wherein the regeneration temperature ranges from 300 DEG C to 400 DEG C, and the regeneration process is carried out in a fixed bed reactor. According to the regeneration method of the catalyst, three regeneration gases react with a metalcomponent sintered on an inactivated catalyst to generate a compound capable of moving on the surface of a catalyst carrier, so that the sintered metal component is re-dispersed on the catalyst carrier, and the activity of the catalyst is recovered again; and the catalytic activity of the catalyst regenerated by the method can be almost completely recovered to the activity level of a fresh catalyst, and theoretical basis knowledge and technical support are provided for developing a new industrial catalyst regeneration process.

Owner:FUZHOU UNIV

Carbon deposition deactivated noble metal loading type catalyst regeneration method

InactiveCN1233617CPrevent sinteringGood regeneration performanceOrganic compound preparationCatalyst activation/preparationCarbon depositCarbon deposition

A process for regenerating the carried noble metal catalyst deactivated by carbon deposit, in order to use it in preparing 2,6-biisopropyl phenylamine features that the H2, CO, or their mixture is used to eliminate the carbon deposit from said catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for prolonging running period of hydrotreatment device

ActiveCN102876373BReduce surface tensionEasy to take outTreatment with hydrotreatment processesTreatment apparatus corrosion/fouling inhibitionHydrogenVulcanization

The invention discloses a method for prolonging the running period of a hydrotreatment device. According to the method, during the steady-state inactivation stage of a hydrotreatment catalyst, a reactor is cooled, raw oil is switched to cleaning oil, low hydrogen-oil ratio is maintained, and the largest amount of inlet oil is used to flush a catalyst bed; the temperature of the catalyst bed is raised, and a certain proportion of a scale inhibitor is poured into the cleaning oil, and cyclic operation doesn't start until there is no solid char particles in oil generated at the tower bottom of a fractionate tower; and the temperature is adjusted, and supplementary vulcanization of the catalyst is carried out by pouring a vulcanizing agent into the cleaning oil so as to raise the activity of the catalyst. By the adoption of the method, decoking and supplementary vulcanization are simultaneously realized during the cleaning process of the catalyst, thus greatly reducing pressure drop of the catalyst bed, alleviating rising tendency of the pressure drop and prolonging the operating life of the catalyst. Therefore, the running period of the device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for production of a silica-supported alkali metal catalyst

ActiveUS9504991B2Restore catalytic activityLow heat generationOrganic compound preparationCatalyst regeneration/reactivationOrganic solventCatalytic metal

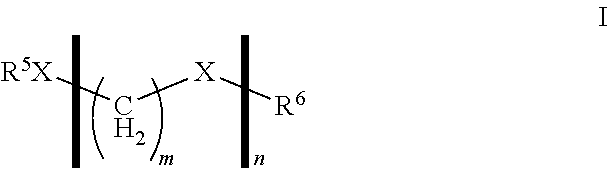

A process for regenerating a silica-supported depleted alkali metal catalyst is described. The level of alkali metal on the depleted catalyst is at least 0.5 mol % and the silica support is a zero-gel. The process comprises the steps of contacting the silica supported depleted alkali metal catalyst with a solution of a salt of the alkali metal in a solvent system that has a polar organic solvent as the majority component. A re-impregnated catalyst prepared by the process of the invention any comprising a silica zero-gel support and a catalytic metal selected from an alkali metal in the range 0.5-5 mol % on the catalyst, wherein the surface area of the silica support is <180 m2 / g is also described. The invention is applicable to a process for preparing an ethylenically unsaturated acid or ester comprising contacting an alkanoic acid or ester of the formula R1—CH2—COOR3, with formaldehyde or a suitable source of formaldehyde.

Owner:MITSUBISHI CHEM UK LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com