Hexamethylenediamine synthesis system

A technology of hexamethylenediamine and material mixing, which is applied in the preparation of amino compounds, the preparation of organic compounds, and the purification/separation of amino compounds. It can solve problems such as increasing misoperation, affecting production stability, and increasing bypasses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

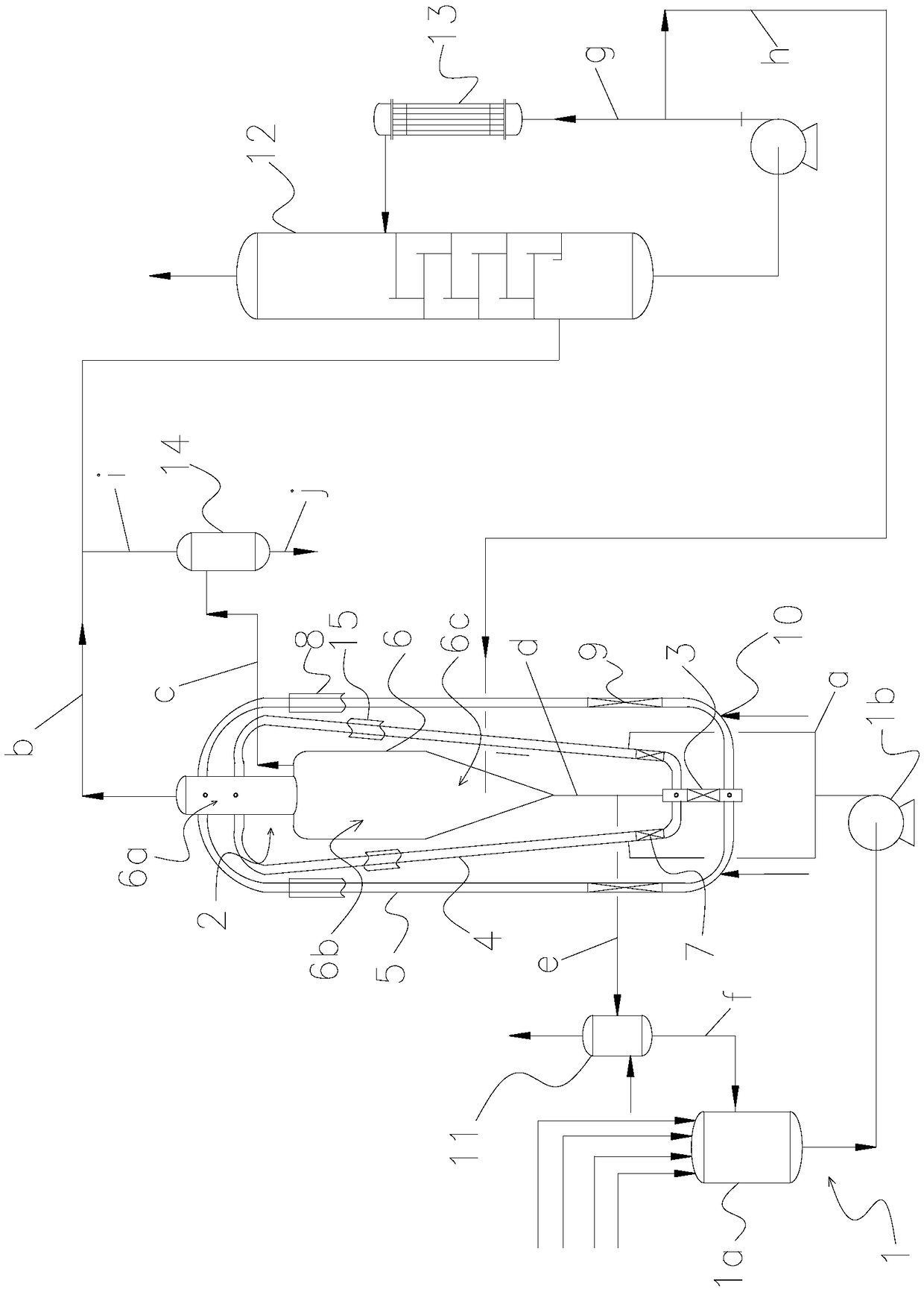

[0032] see figure 1 , is a specific example of a hexamethylenediamine synthesis system. The hexamethylenediamine synthesis system includes a feeder 1 and a reactor 2. In this embodiment, the feeder 1 includes a feed mixer 1a and a feed pump 1b. Both the feed mixer and the feed pump are conventional in the chemical industry. Commonly used feed mixing equipment. Wherein, the feeding end of feed mixer 1a is used to be respectively connected with catalyst source, adiponitrile source, ethanol source, sodium hydroxide solution source, wherein adiponitrile is one of addition raw materials, and sodium hydroxide solution provides The environmental carrier for the addition of adiponitrile and hydrogen, ethanol is mainly used as an additive to prevent pipeline blockage and promote the smooth and efficient addition reaction. The discharge end of the feed mixer 1a is connected with the material mixing pipeline 4 through the feed pump 1b. The reactor 2 includes a distributor 3, a number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com