Micro-structured mixer

A micro-structure mixer and fluid mixing technology, which is applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve problems such as blockage, limited popularization and use, and high requirements for cleanliness, and achieve easy processing and amplification , broad prospects for promotion and application, and low requirements for material cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

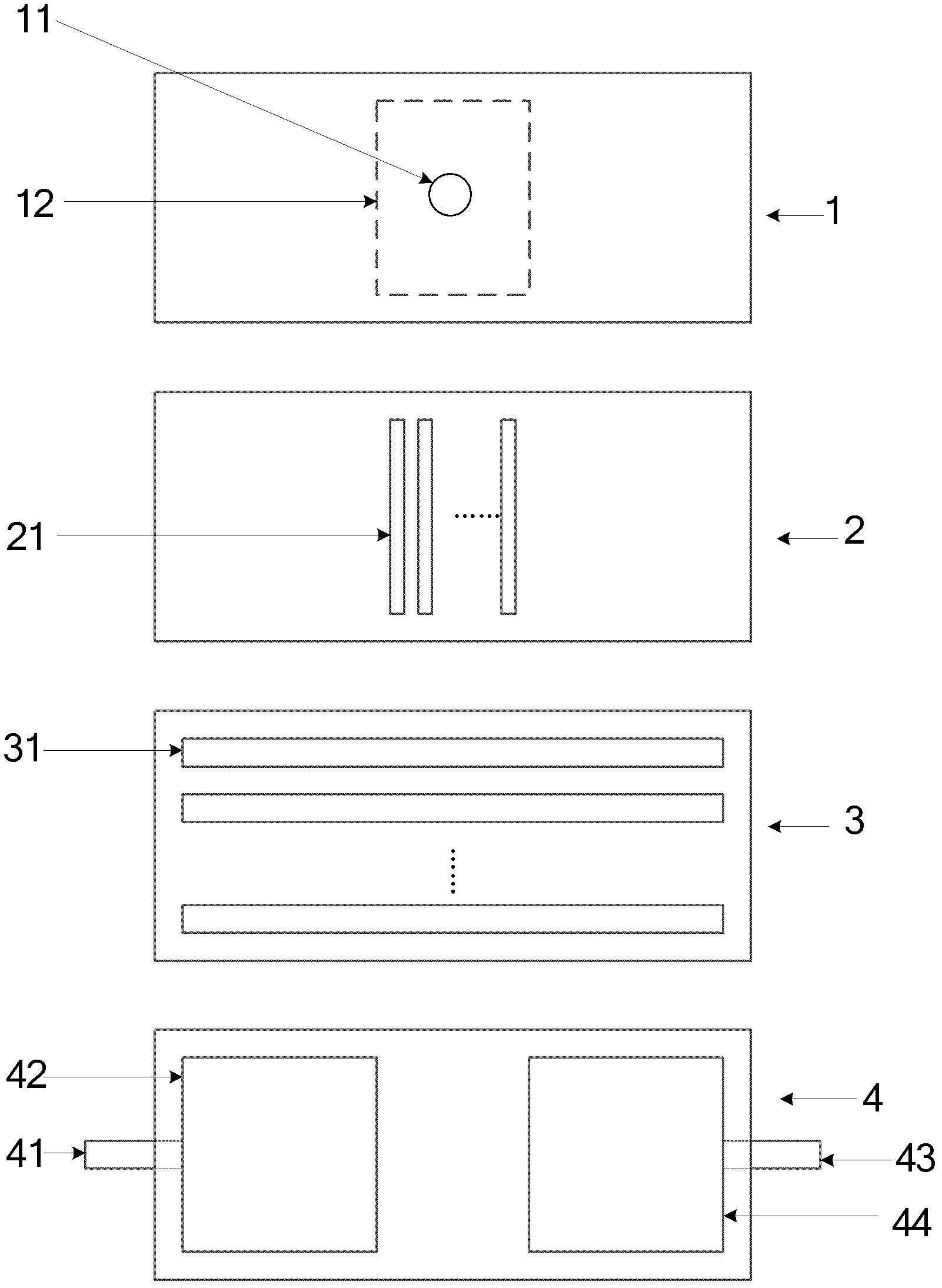

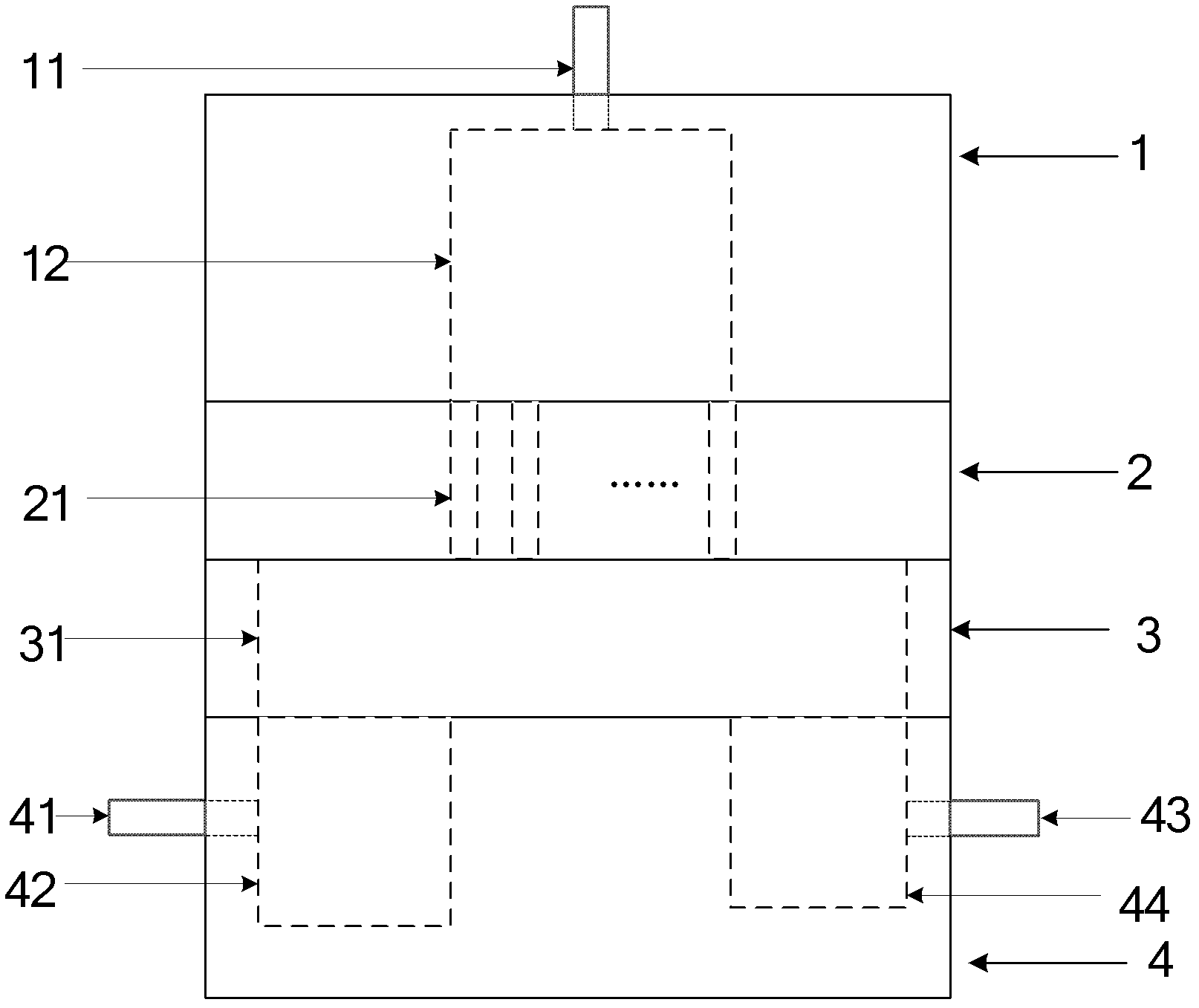

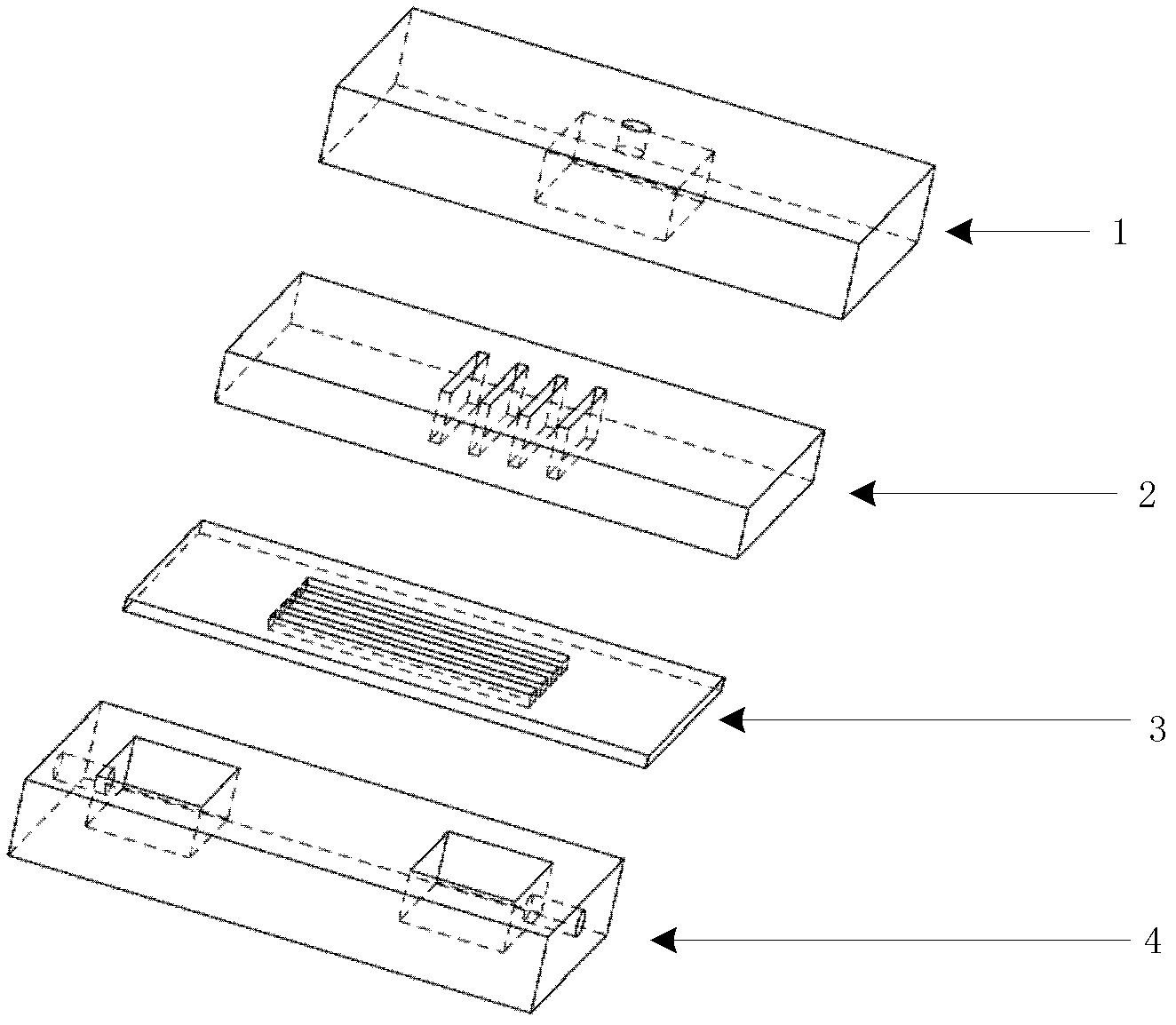

[0040] A microstructure mixer, the microstructure mixer is formed by sequentially stacking a first interface plate 1, a first fluid distribution plate 2, a fluid mixing plate 3 and a second interface plate 4; wherein,

[0041] The first interface plate 1 is provided with a first fluid inlet pipe 11 and a first fluid buffer chamber 12;

[0042] The first fluid distribution plate 2 is provided with at least one through groove 21;

[0043] The fluid mixing plate 3 is provided with at least one through groove 31;

[0044] The second interface plate 4 is provided with a second fluid inlet pipe 41, a second fluid buffer chamber 42, a mixed fluid buffer chamber 44 and a mixed fluid outlet pipe 43;

[0045] The channel 21 provided on the first fluid distribution plate 2 communicates with the first fluid buffer chamber 12 .

[0046] The through-groove 31 provided on the fluid mixing plate 3 and the through-groove 21 provided on the first fluid distribution plate 2 have micro-groove c...

Embodiment 2

[0052] A microstructure mixer, the number of through grooves on the first fluid distribution plate is 20, the width of each through groove is 0.4mm, and the aspect ratio is 1000. The number of through grooves on the fluid mixing plate is 20, the width of each through groove is 10mm, and the depth is 3mm.

[0053] The channel 21 provided on the first fluid distribution plate 2 is a parallel channel, and the channel 31 provided on the fluid mixing plate 3 is a parallel channel. All the other are identical with embodiment 1.

[0054] A solution flow rate is 20m 3 / h, the flow rate of solution B is 4m 3 / h, Xs was measured to be 0.003.

Embodiment 3

[0056] A microstructure mixer, the number of through grooves on the first fluid distribution plate is 5, the width of each through groove is 1 mm, and the aspect ratio is 100. The number of through grooves on the fluid mixing plate is 10, the width of each through groove is 5mm, and the depth is 2mm. All the other are identical with embodiment 2.

[0057] A solution flow rate is 2m 3 / h, the flow rate of solution B is 0.5m 3 / h, Xs was measured to be 0.002.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com