Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Reduce cycle ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

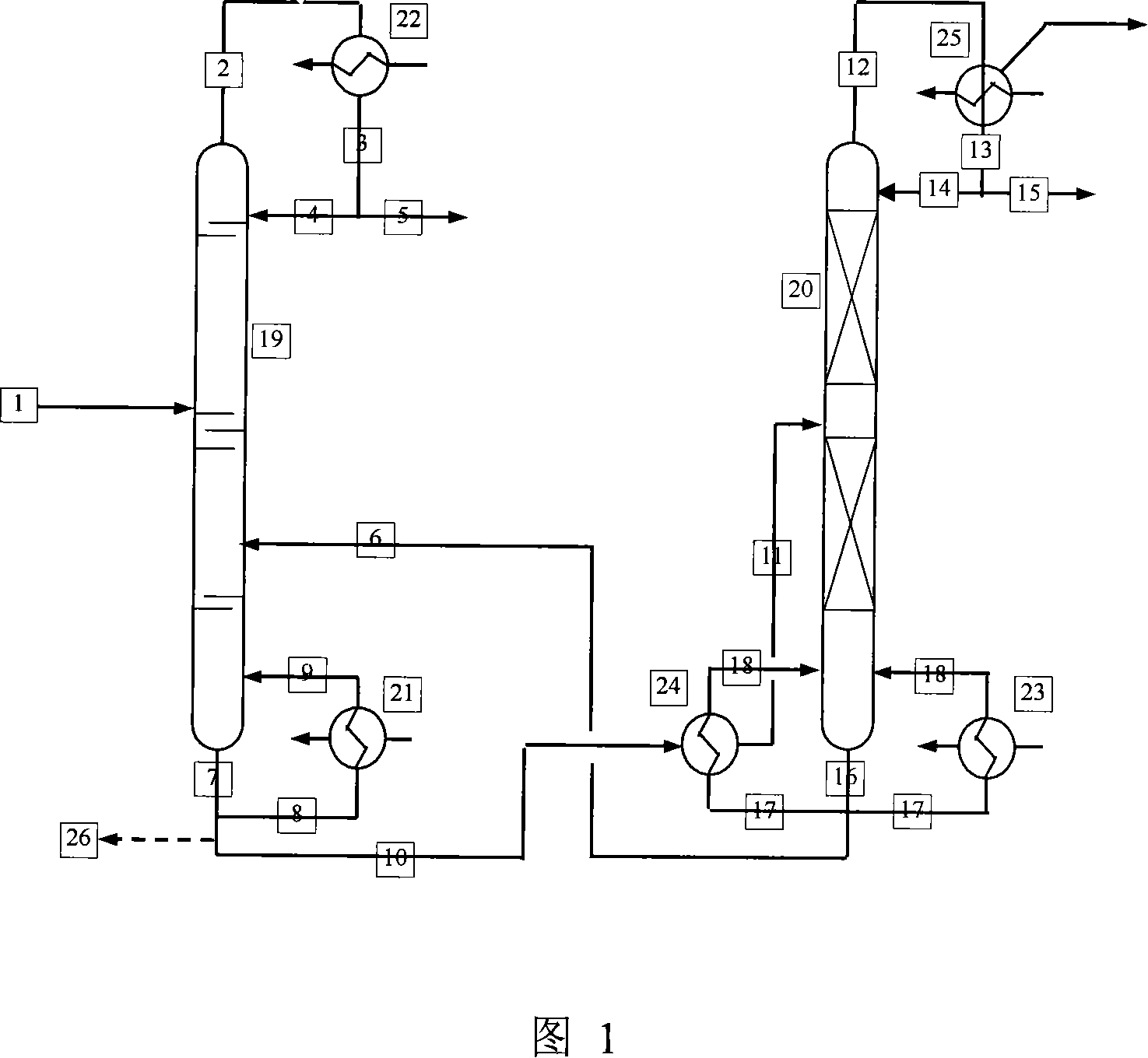

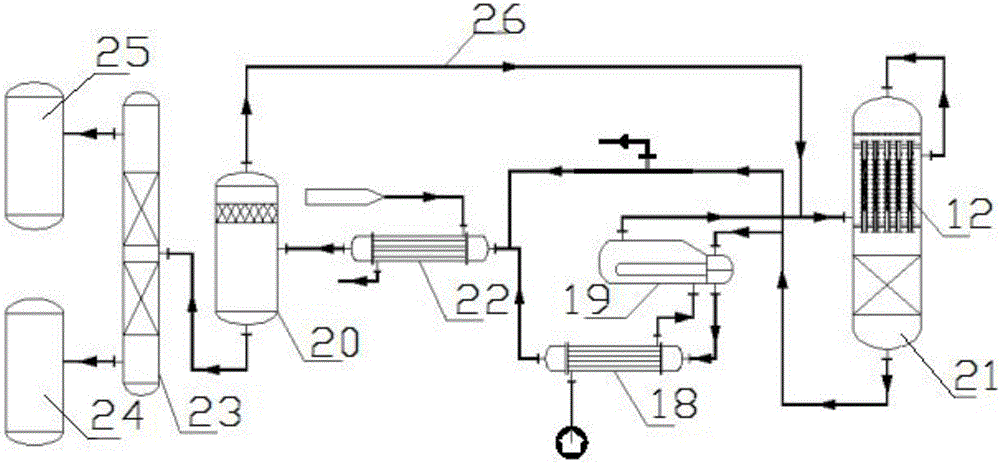

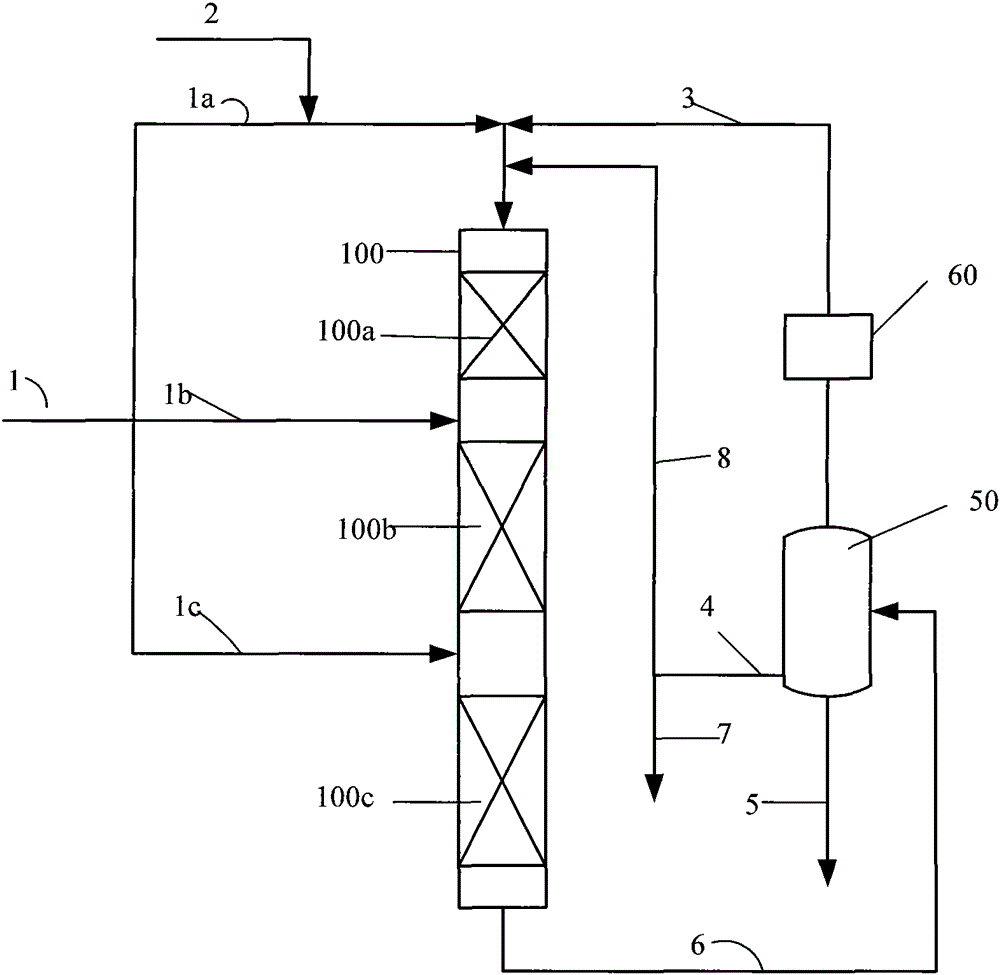

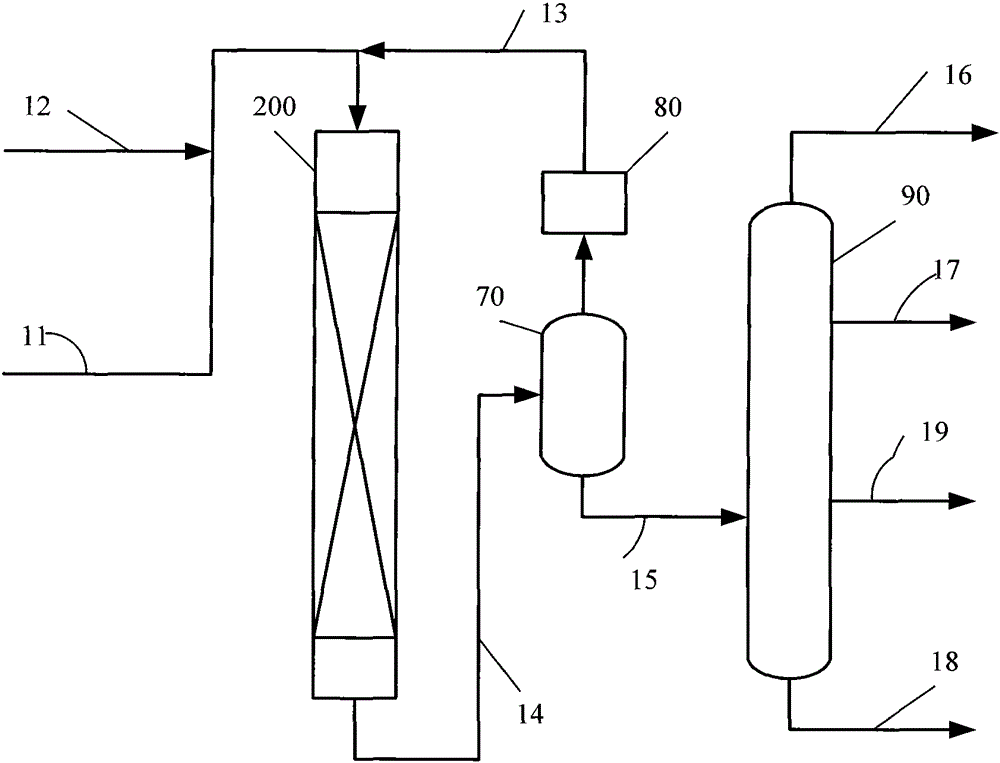

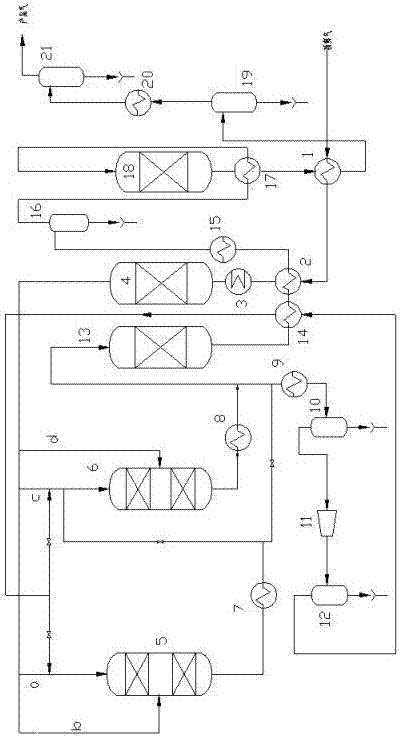

Method for preparing diesel oil component or jet fuel component by using animal and plant oil

ActiveCN103059901AHigh yieldHigh calorific valueLiquid hydrocarbon mixture productionBio-feedstockOil and greaseAlkane

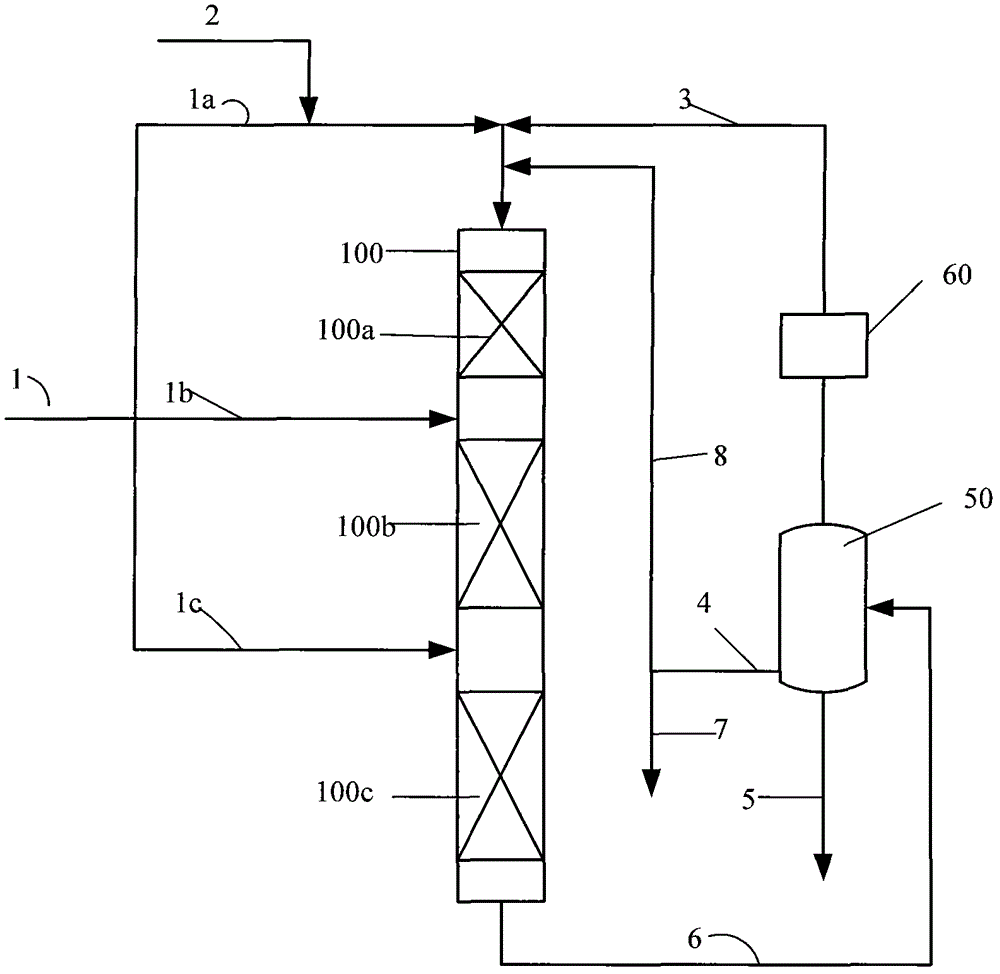

The invention provides a method for preparing a diesel oil component or jet fuel component by using animal and plant oil. The method comprises the following steps of: (1) dividing the animal and plant oil into at least two parts, introducing the at least two parts of animal and plant oil to a plurality of catalyst beds of a first hydrogenation reactor, and enabling the at least two parts of animal and plant oil and a hydrodeoxygenation catalyst to contact and react to obtain n-alkanes with the carbon number of 8-24; (2) filling an isomerization catalyst in a second hydrogenation reactor, introducing a reaction product obtained in the step (1) to the second hydrogenation reactor, and reducing a condensation point after isomerization reaction to obtain a diesel oil component; or, (3) filling a selective cracking catalyst in the second hydrogenation reactor, introducing the reaction product obtained in the step (1) to the second hydrogenation reactor, and then, carrying out selective hydrocracking and isomerization to obtain a jet fuel blending component. The method provided by the invention is high in jet fuel yield; and the prepared jet fuel blending component is good in quality and can be mixed with the traditional petroleum-based jet fuel according to any proportion so as to be an excellent blending component.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkylation reaction technique catalyzed by ion liquid and reactor apparatus

InactiveCN100348559CEasy to separateRestore catalytic activityHydrocarbon from saturated and unsaturated hydrocarbon additionHydrocarbon oils refiningAlkanePtru catalyst

This invention involves an ion liquid catalytic alkylation process and a responsing reactor. The process comprises carrying out a reaction of isobutene, C3-C5 olefins and ionic liquid catalyst in a rotating bed reactor with reaction temperature of 8~40DEG C, pressure of 0.3~1.0 MPa and rotor speed of 100~2500 rpm, wherein the volume ratio of ion liquid feed to alkanes-olefins is 0.1~1.5:1 and the molar ratio of alkanes to olefins is 10~300, and controlling the reaction time less than 1~10min. The invention improved alkylation reaction selectivity, and the octane value of alkylation product can reach to 94-100. The operation is simple and low-cost, and has no pollution to environment and beneficial to environment protection.

Owner:BEIJING UNIV OF CHEM TECH

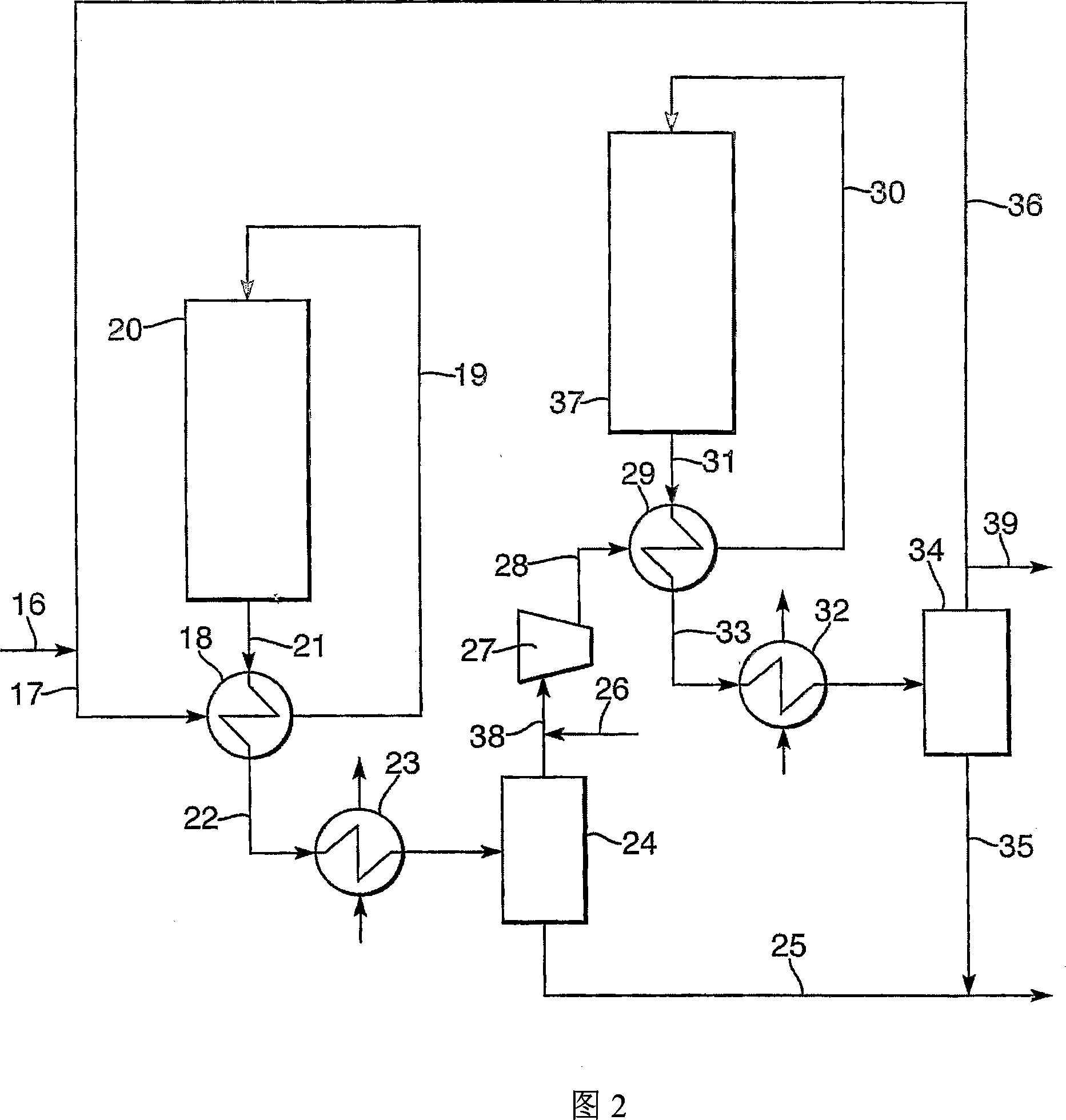

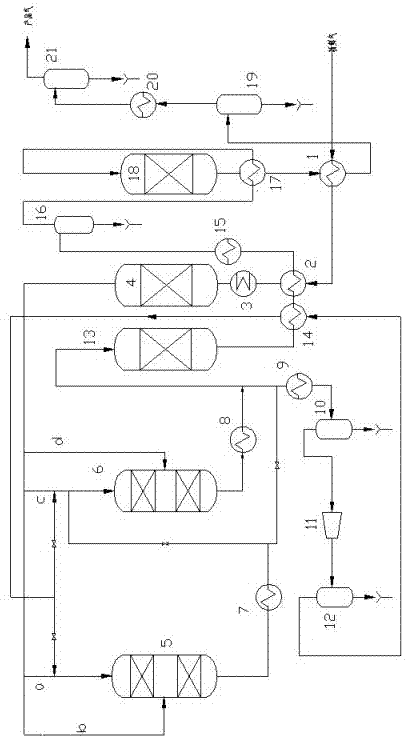

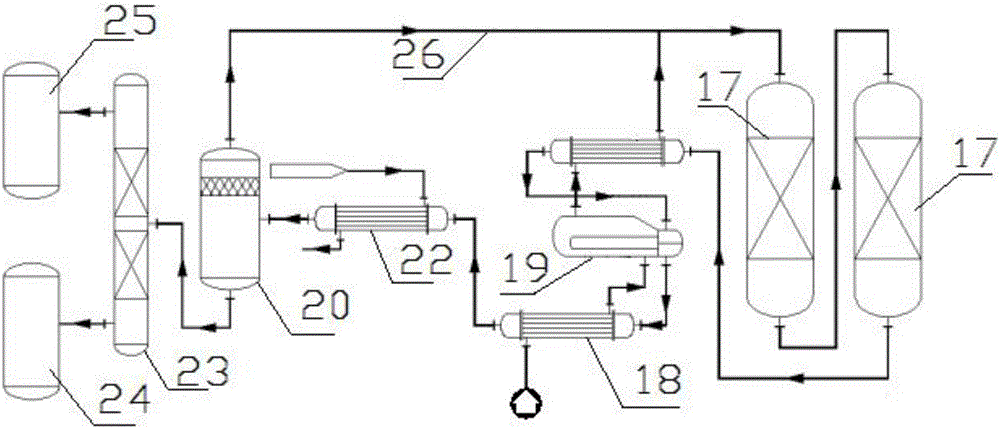

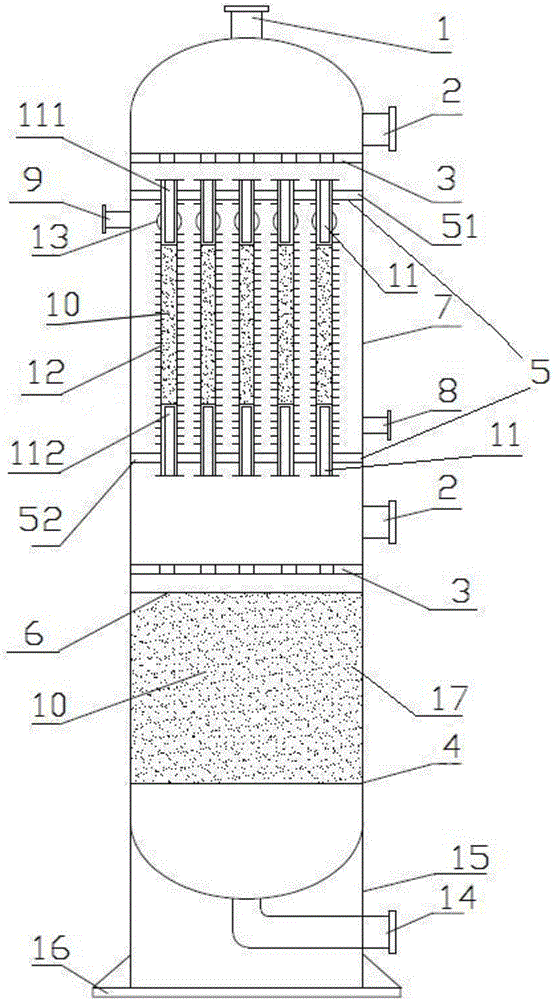

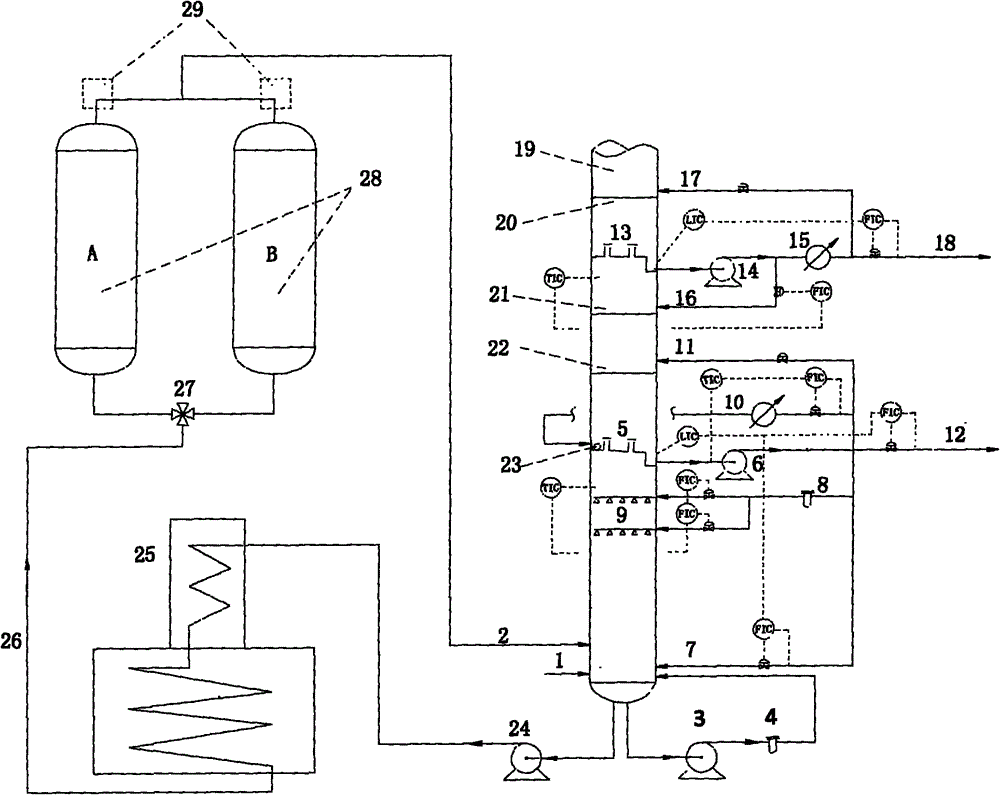

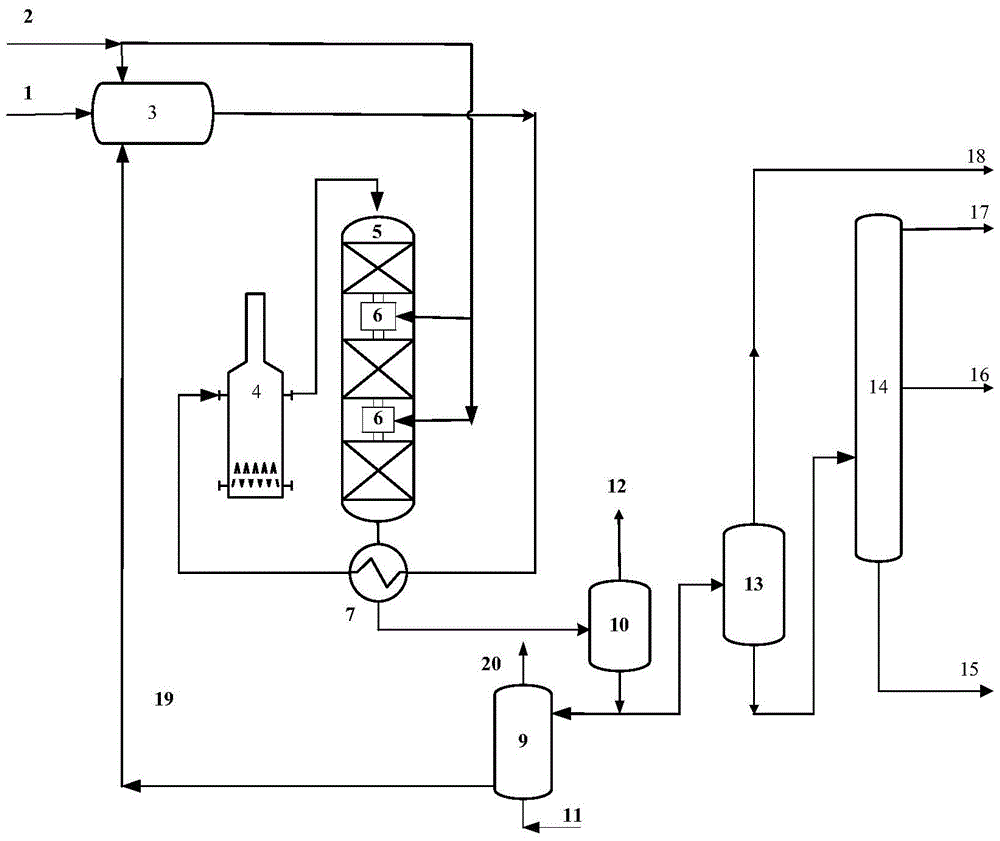

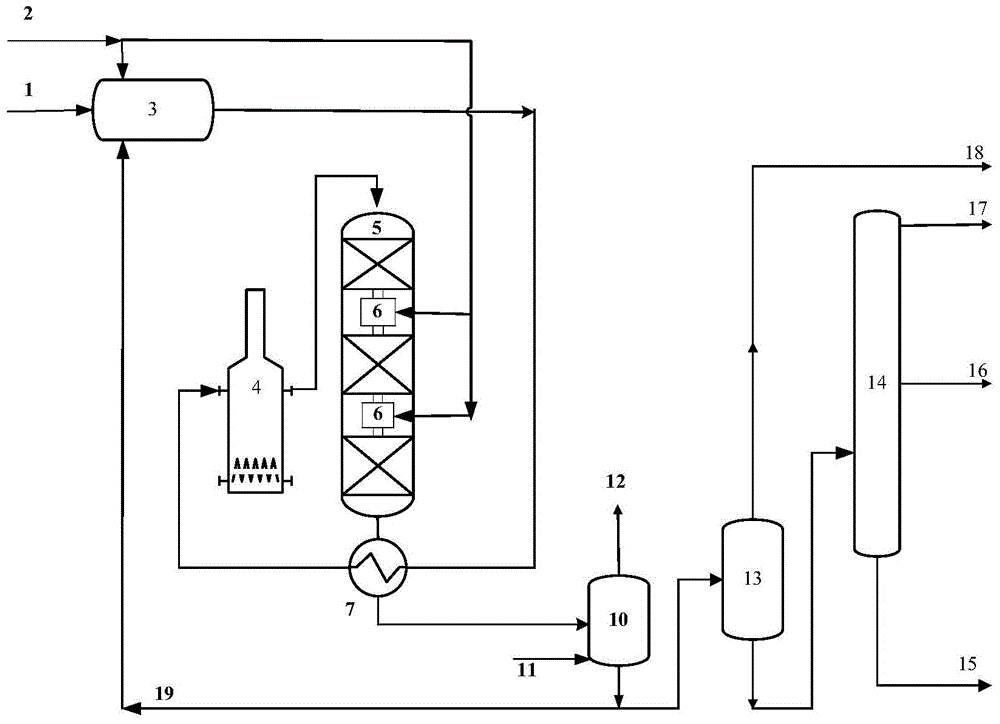

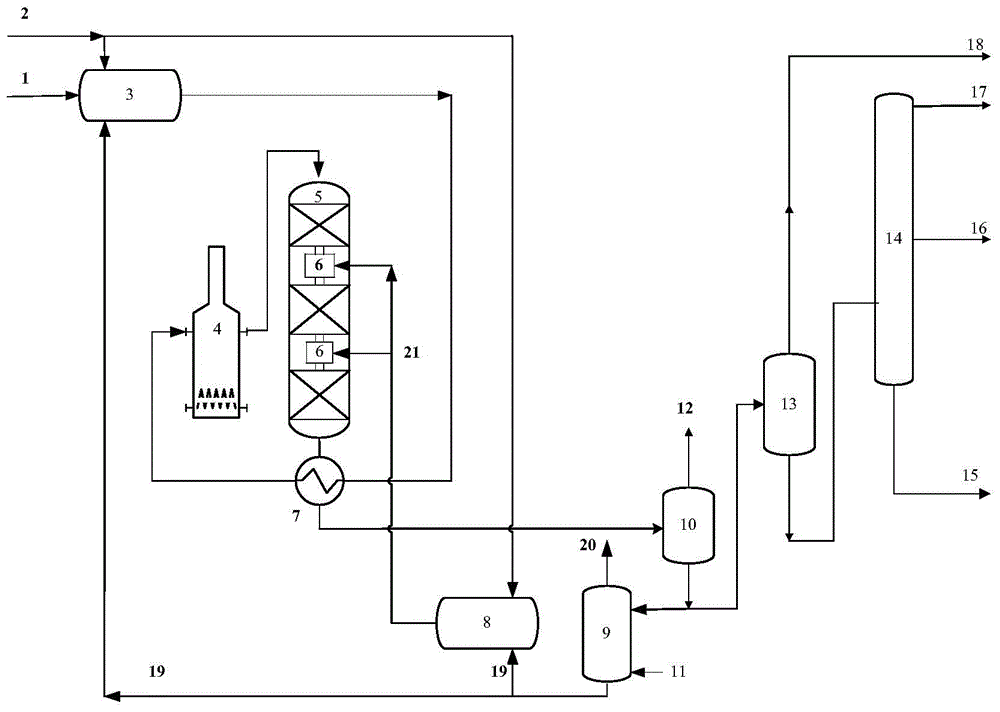

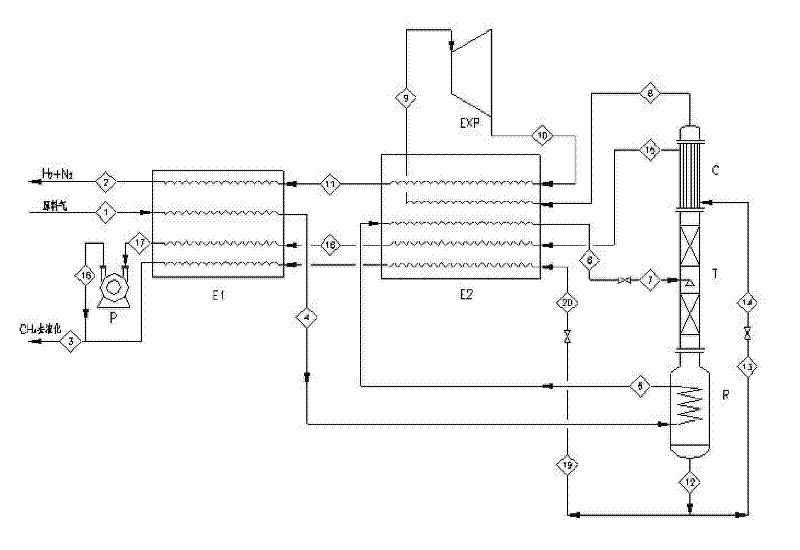

Energy-efficient super-large scale methanol-synthesizing method with production of steam of different grades and apparatus thereof

ActiveCN105399604AIncrease concentrationIncrease conversion rate per passOrganic compound preparationHydroxy compound preparationSyngasProduct gas

The invention discloses an energy-efficient super-large scale methanol-synthesizing method with production of steam of different grades. Virgin gas is compressed and mixed with circulation gas for forming a gas mixture, the gas mixture is heated and simultaneously enters two parallelly arranged first methanol reactors for carrying out methanol synthesis reactions, and incompletely reacted synthetic gas and a methanol steam mixture are formed; the incompletely reacted synthetic gas and the methanol steam mixture are cooled and enter a second methanol reactor for carrying out a methanol synthesis reaction to obtain a final product; the final product is cooled and separated, and parts of the separated gas is used as circulation gas; and liquid crude methanol enters a downstream rectification unit. The invention also discloses an apparatus for realizing the method. A reasonably configured heat exchanger network is used for improving conversion per pass and concentration of methanol at the outlet of the reactor maximally, and reducing recycle ratio and energy consumption, and producing steam of different grades; the low pressure steam can meet low pressure steam demands of the downstream methanol rectification unit.

Owner:SHANGHAI INT ENG CONSULTING

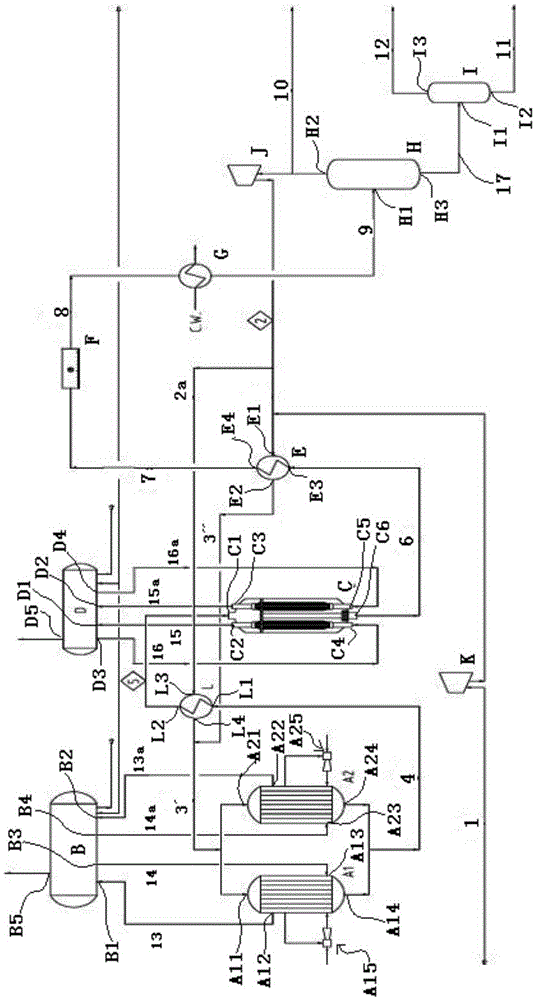

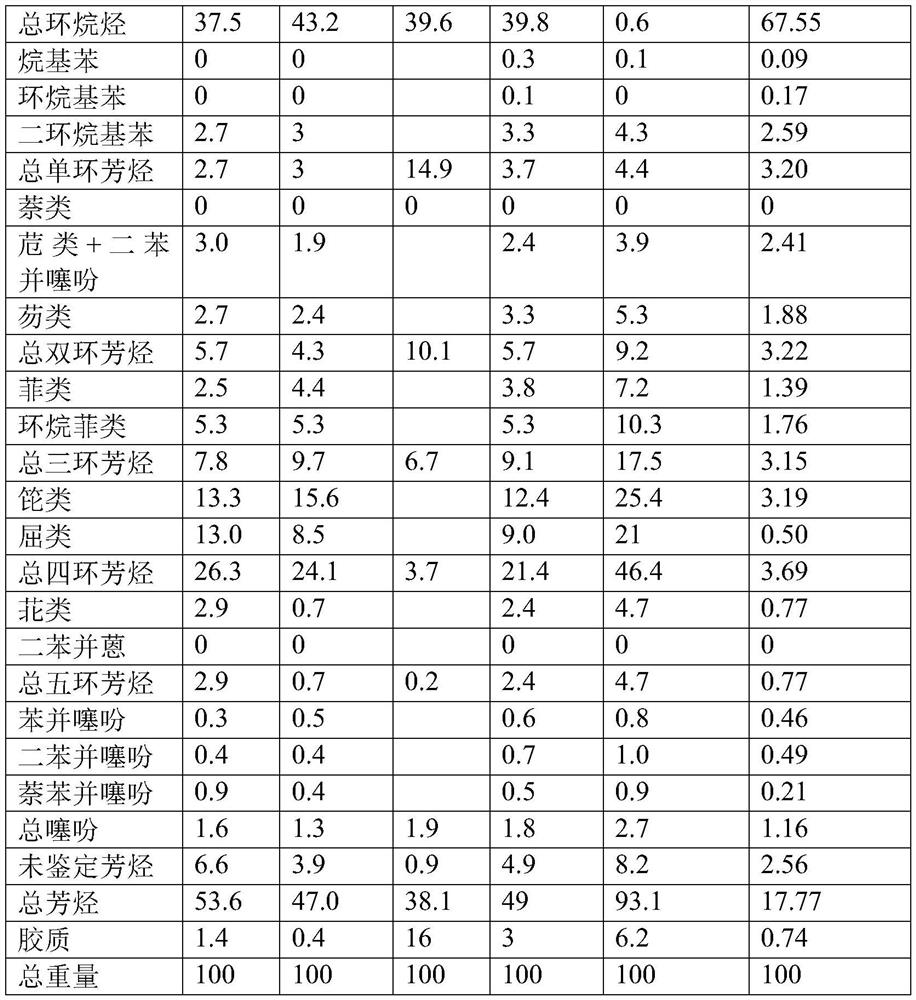

Process for use in gas phase reactions

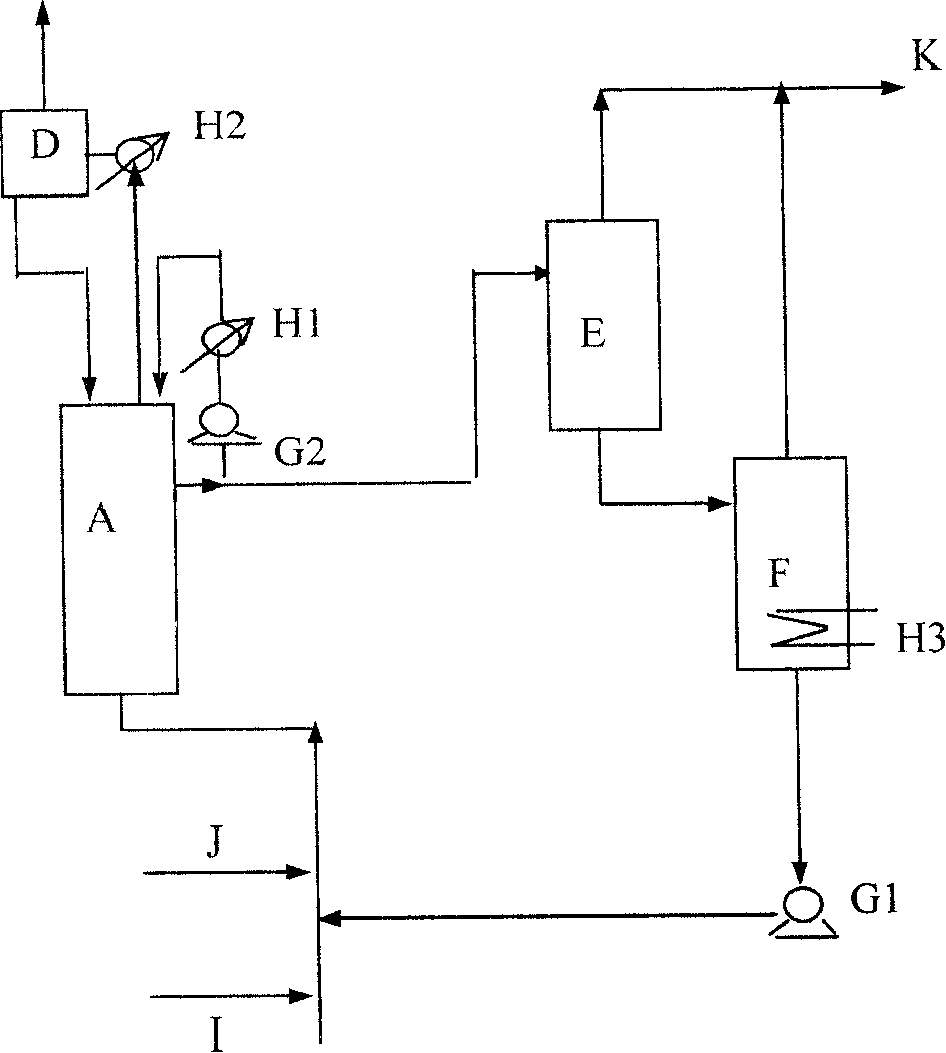

ActiveCN1989092AReduce cycle ratioTemperature controlOrganic compound preparationHydroxy compound preparationGas phaseLiquid phase

A process for use in equilibrium exothermic gas phase reactions comprising the steps of (a) providing a recycle stream with the addition of make-up gas, to form a feed gas stream; (b) heating the feed gas stream; (c) passing the heated feed gas stream to a first reactor containing a catalyst for the exothermic gas phase reactions at conditions suitable for the reaction; (d) removing a product stream comprising product and unreacted gases from the first reactor; (e) cooling and partially condensing the product stream to form a gas phase and a liquid phase; (f) separating the liquid phase containing the desired product from the product stream and removing said liquid phase; (g) separating the gas phase from the product stream to form a gas stream; (h) optionally mixing the gas stream from the product stream with additional make-up gas; (i) heating the gas stream; (j) passing the heated gas stream to a final reactor containing a catalyst for the exothermic gas phase reactions at conditions suitable for the reaction; (k) removing a final product stream comprising product and unreacted gases from the final reactor; (l) cooling and partially condensing the final product stream to form a final gas phase and a mal liquid phase; (m) separating the final liquid phase containing the desired product from the final product stream and removing said final liquid phase; and (n) separating the gas phase from the final product stream and recycling the gas to step (a); and in which the gas stream from step (g) is compressed prior to heating in step (i).

Owner:JOHNSON MATTHEY DAVY TECH LTD

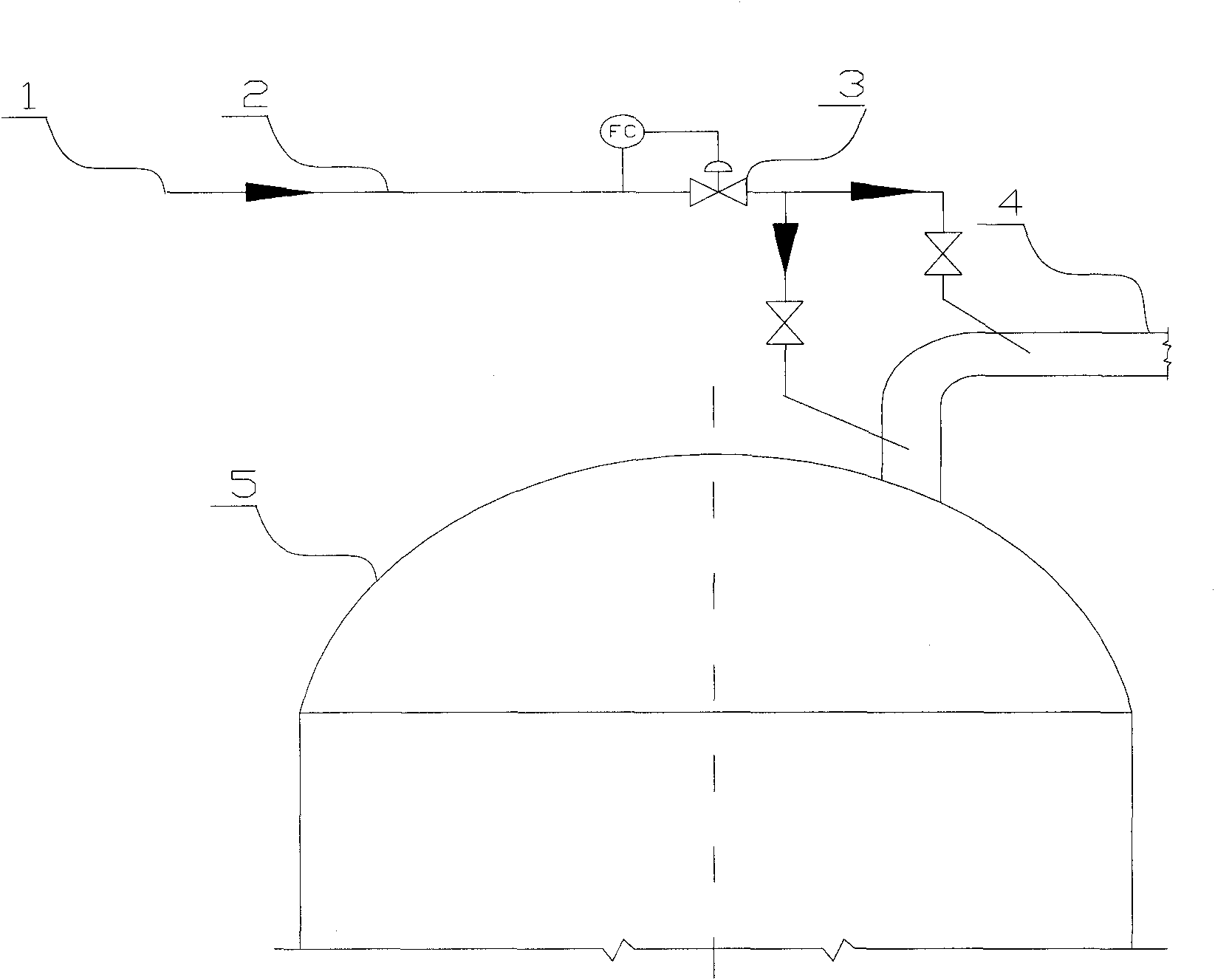

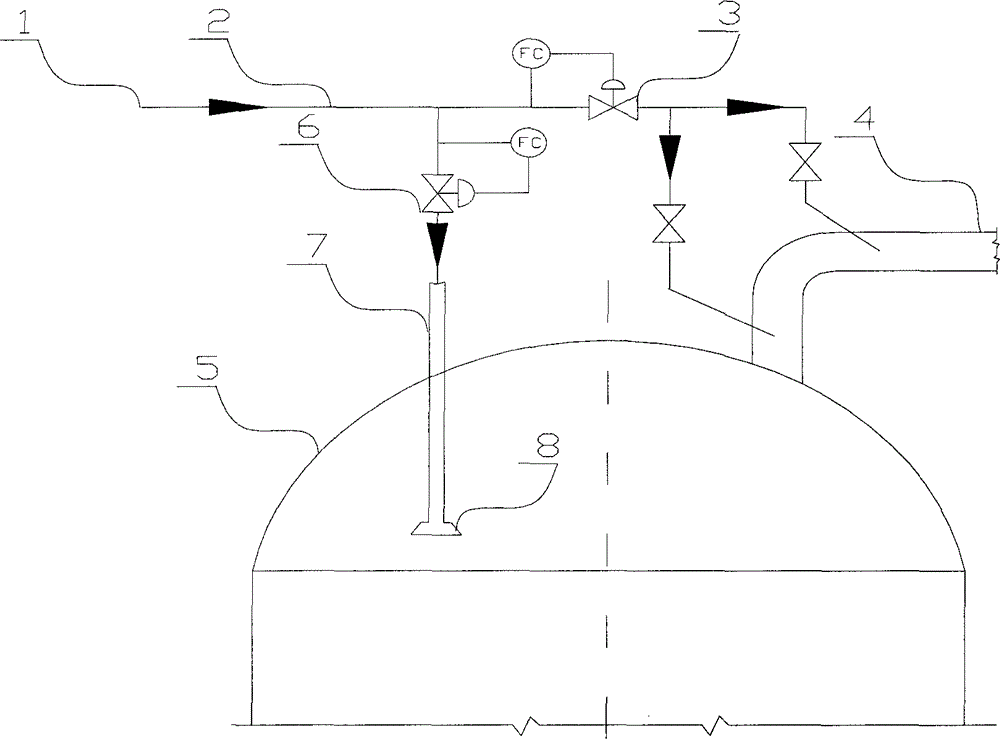

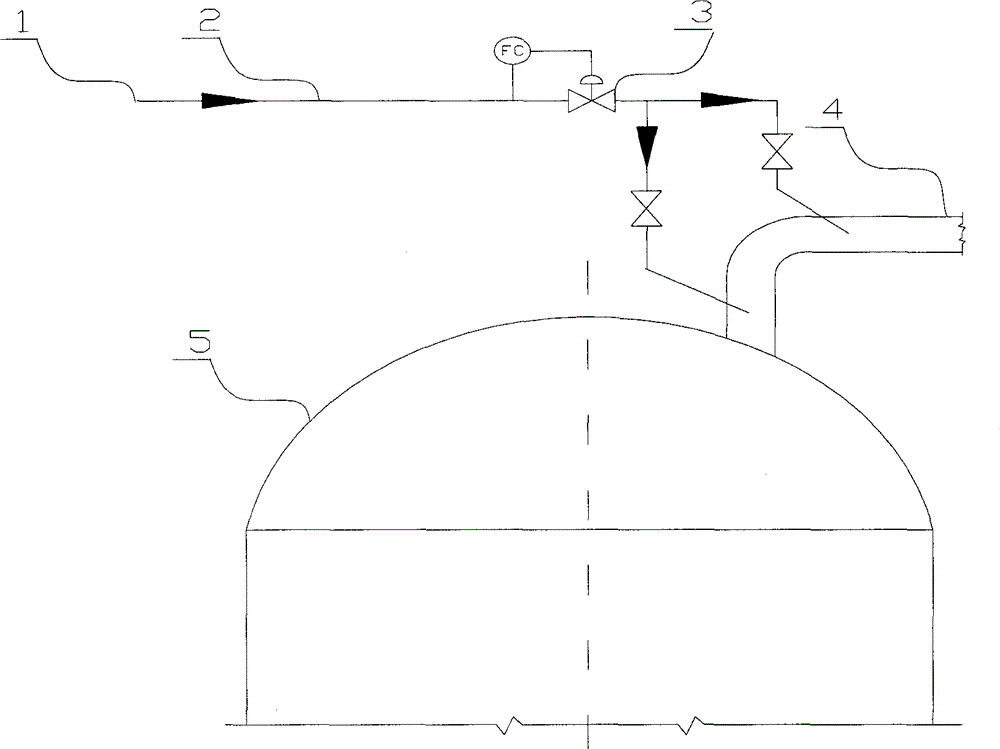

Method for alleviating coking of coke tower top oil gas pipeline

The invention provides a method for alleviating coking of a coke tower top oil gas pipeline. The method comprises the following steps: 1, spraying parts of quenching oil into a coke tower from the upper part or the top of the coke tower, and pre-quenching a coke tower top oil gas; and 2, spraying the other parts of the quenching oil in a tower outlet oil gas pipeline into the pipeline, and quenching the high temperature oil gas in the tower outlet oil gas pipeline. The method allows the temperature of the coke tower top oil gas to be effectively reduced and a secondary reaction to be timely inhibited, so the coking of the coke tower top oil gas pipeline can be effectively alleviated, and the on-stream period of a coking delay apparatus is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

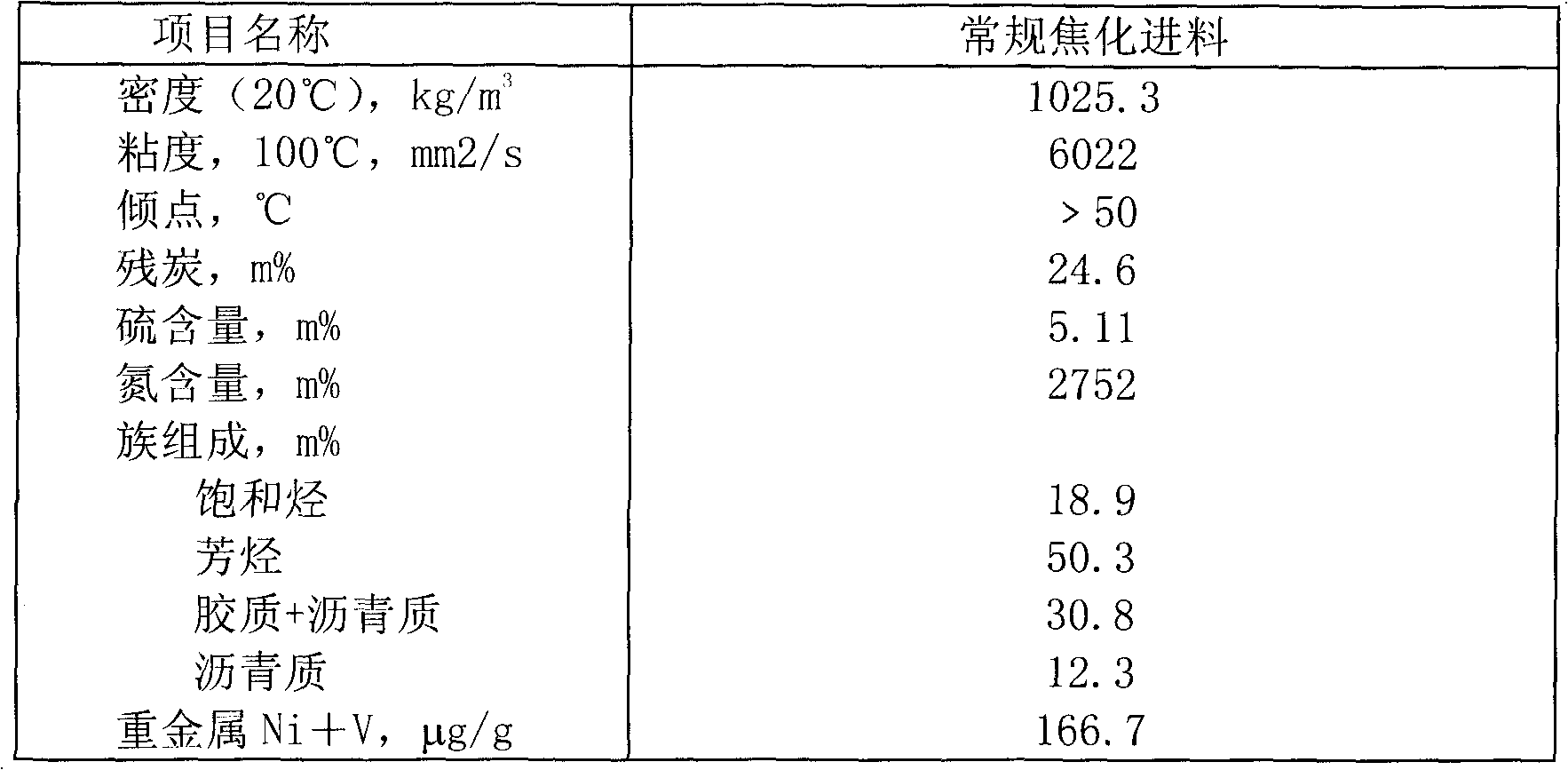

Anti-coking agent for delaying coking and preparation method of anti-coking agent

InactiveCN106479555AFacilitates homolysisReduce generationThermal non-catalytic crackingPentaerythritolAntioxidant

The invention discloses an anti-coking agent for delaying coking and belongs to the field of petrochemical engineering. The anti-coking agent for delaying coking is prepared from components in percentage by mass as follows: 10%-30% of a thermal cracking accelerative activator, 20%-40% of a free radical chain reaction inhibitor, 1%-15% of an anti-scorching agent, 1%-15% of an antioxidant and the balance of a solvent, wherein the thermal cracking accelerative activator is block polyether, the free radical chain reaction inhibitor is pentaerythritol ether, and the anti-scorching agent is a sulfonamide agent. The anti-coking agent for delaying coking can effectively prevent and inhibit cokes from settling in a furnace tube of a heating furnace and can inhibit a free radical chain reaction, reduce production of dry gas, prevent aromatic hydrocarbon from condensation, reduce coke production, improve the thermal cracking reaction activity and improve the selectivity of a coking reaction; coking and scale depositing caused by high-temperature oxidation of raw materials in the furnace tube can be prevented, the scale inhibiting ratio reaches 92% or above, and the device running cycle is prolonged by one time or more.

Owner:JIANGSU KECHUANG PETROCHEM

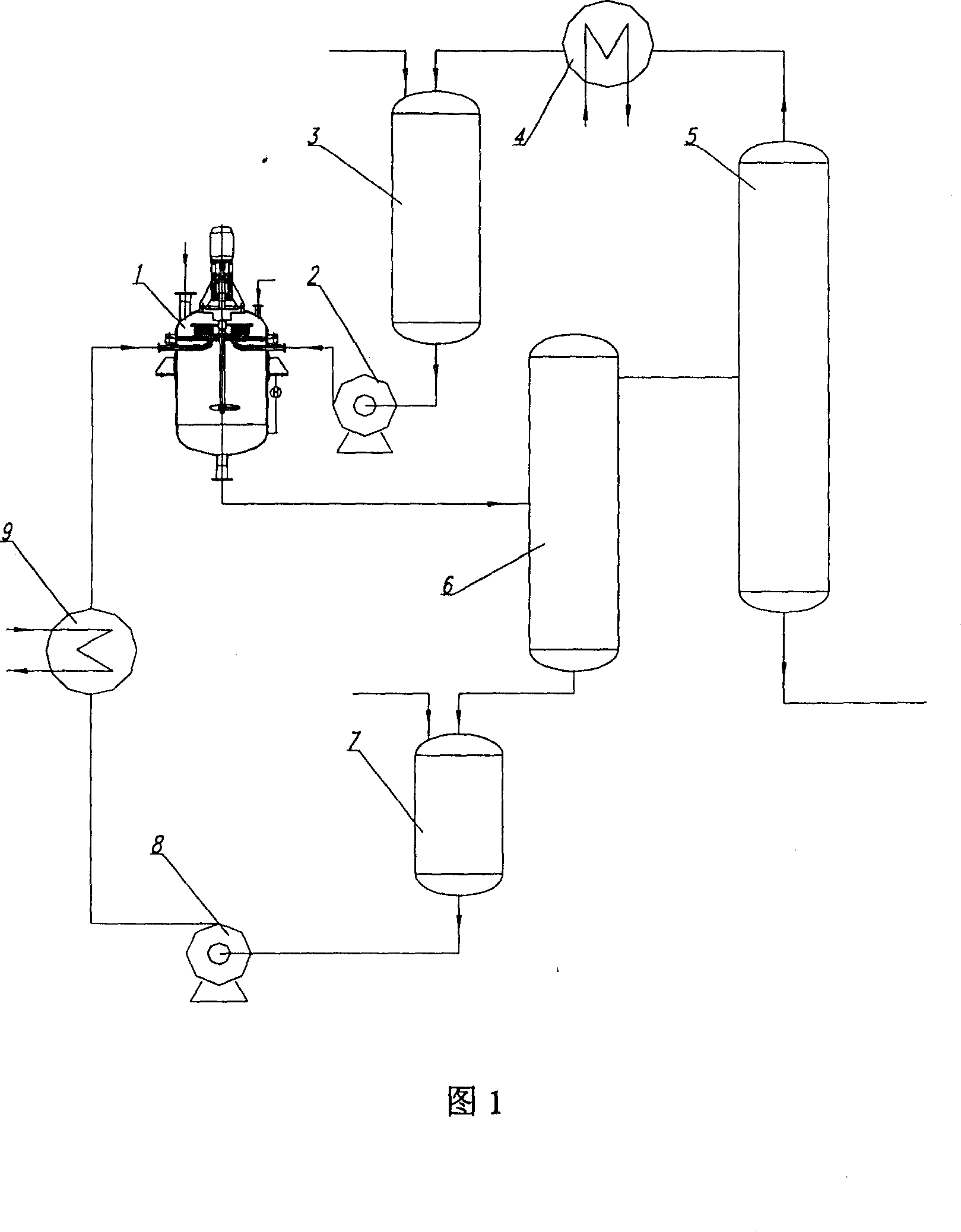

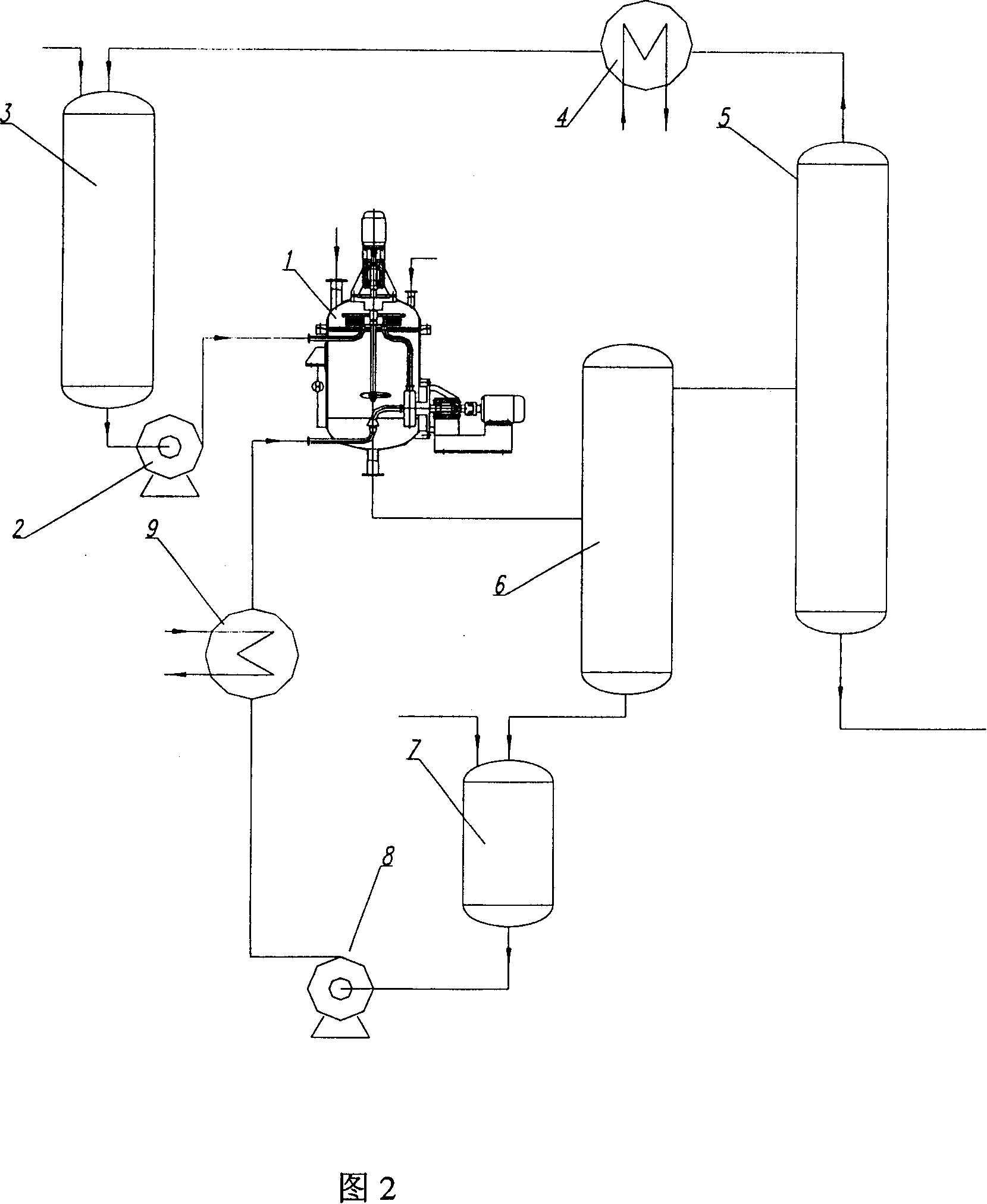

Low pressure methanol carboxylating process to synthesize acetic acid

ActiveCN1740131AIncrease concentrationIncrease production capacityCarboxylic preparation from carbon monoxide reactionAcetic acidMorpholine

The low pressure methanol carboxylating process to synthesize acetic acid includes acetic acid synthesis inside reaction liquid in the presence of rhodium-iodine catalyst system, adding morphinone compound, morphinone salt derivative or other additive to stabilize the catalyst system, and separating the coarse product through flash evaporation-evaporation process. The present invention has specific component added to constitute high activity and high stability catalyst system and has greatly raised production capacity of the reactor.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method for preparing formic acid

ActiveCN101125795AControl incidenceFull recoveryOxygen-containing compound preparationOrganic compound preparationDecreased energyFormate Esters

The invention discloses a preparation method of methanoic acid, main steps of which are that: (1) compound containing water, methanoic acid, methanol and methyl formate is produced by hydrolyzing methyl formate; (2) methanol, water and methyl formate are separated from the compound containing water, methanoic acid, methanol and methyl formate by pressurizing and distilling, and then methanoic acid containing water is taken out of tower bottom. The method for preparing methanoic acid can effectively prevent reversing esterification, increase hydrolyzing reaction, reduce recycle ratio of materiel, improve manufacturing ability of hydrolyzing system equipment and greatly decrease energy consumption.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Production method for 1-butylene

ActiveCN101121630AIncrease conversion rate per passShort regeneration periodHydrocarbon by isomerisationChemical recyclingIsomerizationTower

The present invention relates to a preparation method for butylene-1; the method is to overcome the shortcoming in the prior technology that: the selectivity of the produced butylene-1 is lower; the benefit ratio is lower; the regeneration period for the catalyzer is much shorter; and the energy consumption is much higher. The steps in turn include: (1) the raw material including butylenes is contacted with a molecule screen catalyzer to produce the first reaction flow with the molar ratio between butylene-2 and butylene-1 closing to the thermodynamics balance value; (b) the first reaction flow enters a separated tower for separating to obtain butylene-1 in the tower top and the second reaction flow including butylene-2 is obtained in the tower bottom; (c) the second reaction flow used as butylene-2 directly or turned back to the difference reaction device to be reacted continually; the method can solve the problem greatly, which can be uses in the industrial production of butylene-1.

Owner:CHINA PETROLEUM & CHEM CORP +1

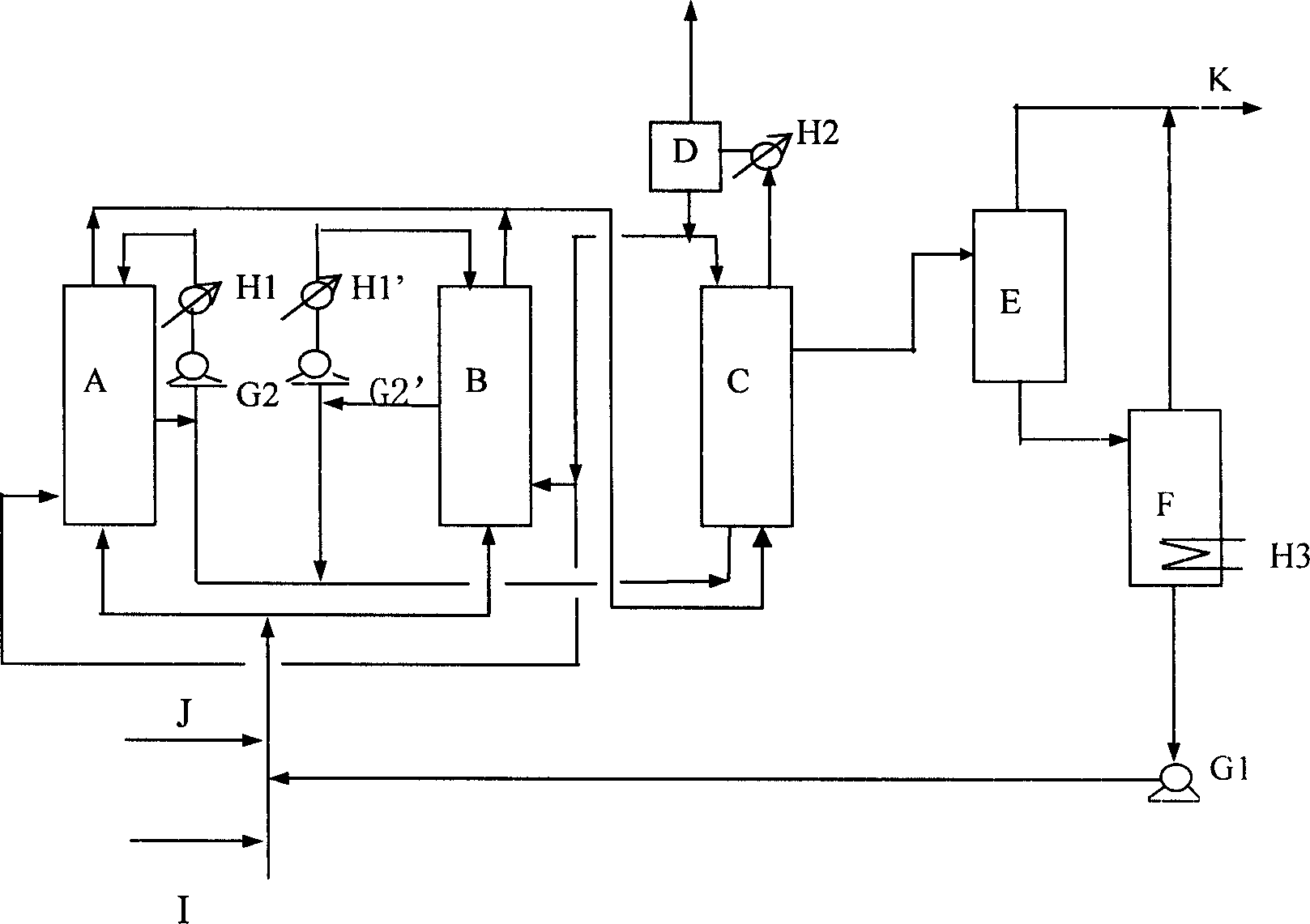

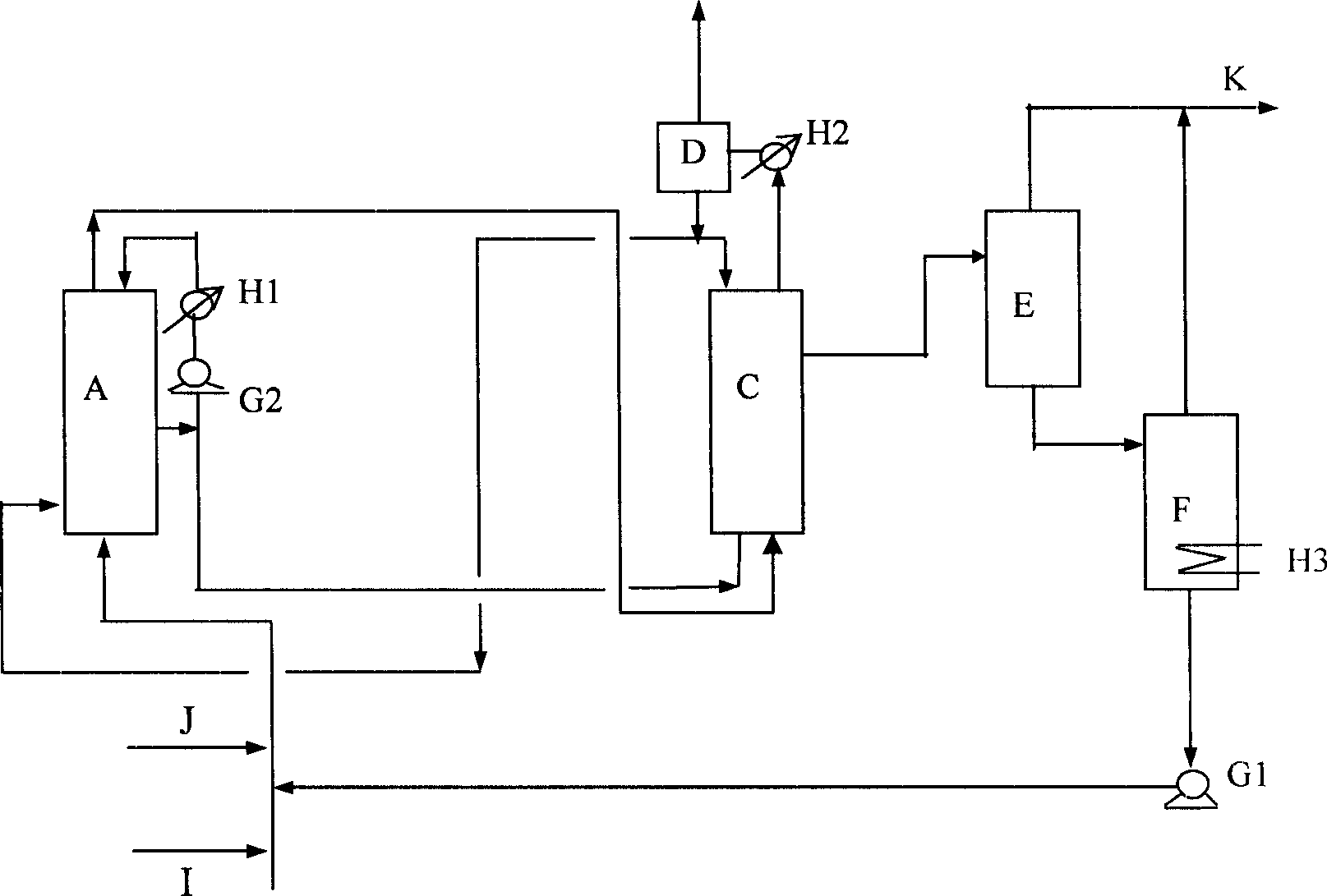

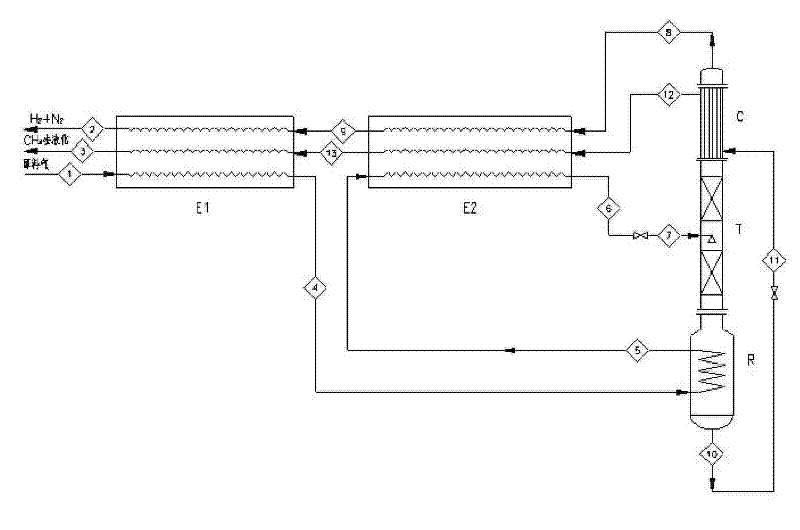

Technology for preparing synthetic natural gas through methanation of coal-based synthetic gas

A technology for preparing synthetic natural gas through methanation of coal-based synthetic gas belongs to the technical filed of coal gasification comprehensive application. The technology comprises a high temperature methanation reaction process, a medium temperature methanation reaction process and a low temperature methanation reaction process. The high temperature methanation reaction process is realized through two heat insulation reactors, the two heat insulation reactors respectively adopt a series-parallel two stage gas feeding mode to meet requirements of replacement of a high temperature catalyst, and the two reactors can be respectively isolated from a system without influencing normal running. The medium temperature methanation process and the low temperature methanation process are respectively realized by respectively arranging a heat insulation reactor. The outlet of the medium temperature reactor is provided with a water division heat exchanger, outlet gas is refined by the low temperature reactor to prepare the synthetic natural gas according with pipeline transportation requirements. The technology has the characteristics of low cycle ratio, long continuous running period of the system, short flow of the refining reaction process, and high product gas quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

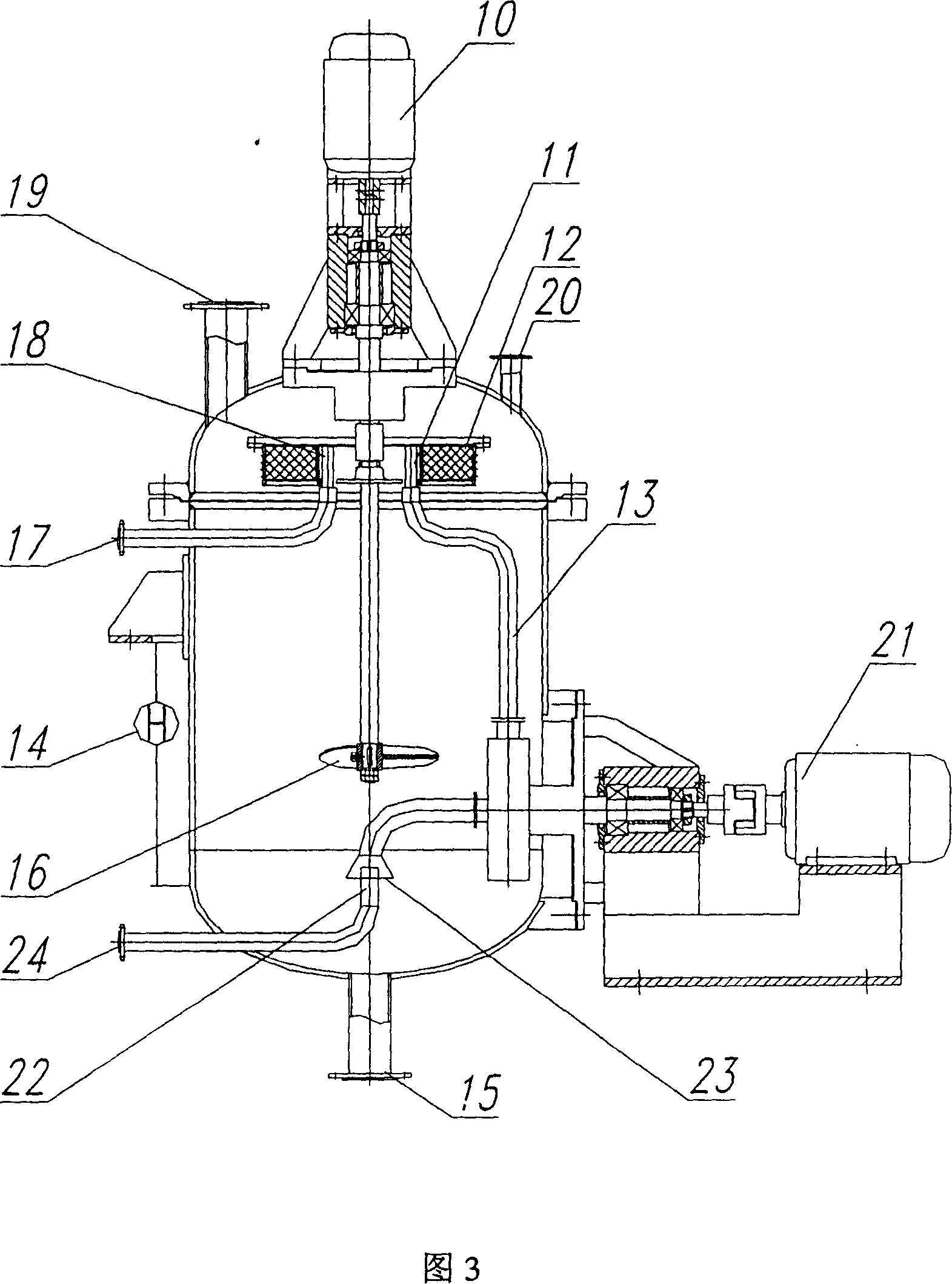

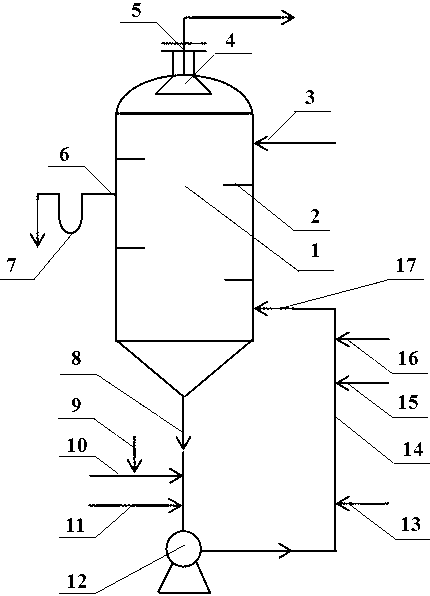

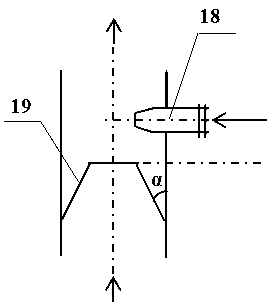

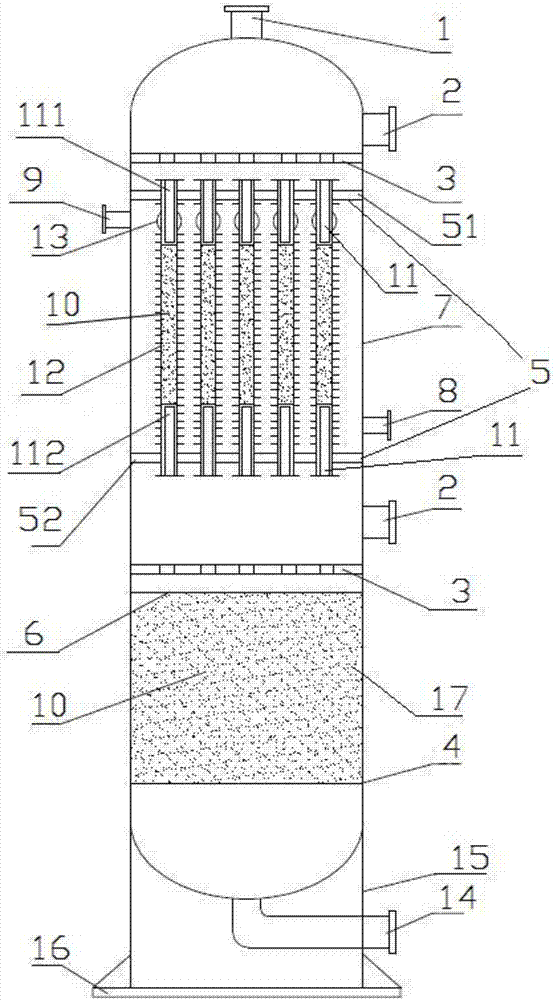

Neutralization apparatus for nitric phosphate fertilizer production mother liquid ammonia neutralization process

ActiveCN102924128AEmission reductionImprove absorption efficiencyPhosphate fertilizerCirculating pump

The invention relates to a neutralization apparatus for a nitric phosphate fertilizer production mother liquid ammonia neutralization process. The neutralization apparatus comprises a first segment neutralization device, a second segment neutralization device and a neutralization tail gas washing device, wherein the second segment neutralization device is a forced circulation tubular reactor, a flash evaporation separation chamber, a descending pipe, a circulation pump and a reaction pipe are sequentially communicated to form a reaction system having an annular closed structure, and reaction system is provided for solving phenomena of material agglomeration and scab caused by increased mother liquid ammonia neutralization slurry viscosity during the nitric phosphate fertilizer production process. According to the neutralization apparatus, the multi-point material feeding structure is arranged, and the forced circulation tubular reaction is performed, such that a viscous region of the neutralization process is avoided, the material is uniformly mixed, the slurry has good fluidity, and NH3 loss is low.

Owner:TIANJI COAL CHEM IND GROUP +1

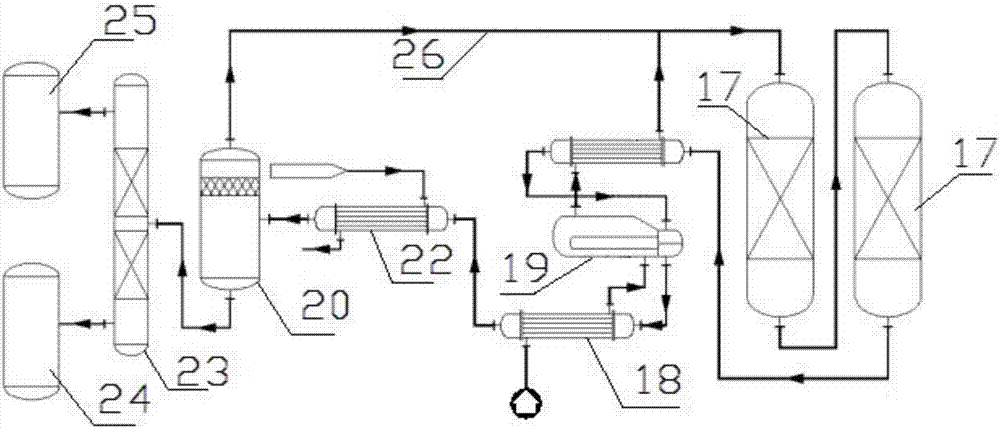

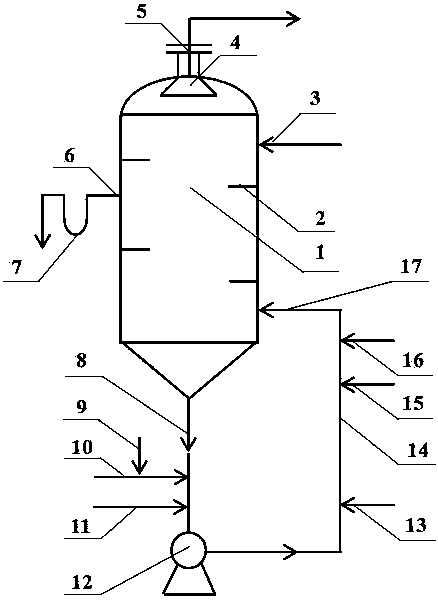

Technique for preparing gasoline from methyl alcohol through combined bed

ActiveCN105925301AOptimal response pressureLower reaction conditionsLiquid hydrocarbon mixture productionBio-feedstockVapor–liquid separatorAlcohol

The invention discloses a technique for preparing gasoline from methyl alcohol through a combined bed. The technique comprises the following steps of: preheating the raw material methyl alcohol through a preheater; inputting the preheated raw material methyl alcohol into an evaporator and completely gasifying; causing the gasified raw material methyl alcohol and recycling gas enter into a combined constant temperature reactor from a mixed gas inlet pipe and draining from an outlet of the combined constant temperature reactor; outputting the product from the discharging port, and then inputting to a condenser in two paths, condensing and then entering into a gas-liquid separator; outputting the separated gas as circulating gas, outputting liquid into an oil water separator for separating, thereby acquiring the required end products of oil and water. The technique is used for overcoming the defects of high operation pressure, high feeding temperature, large recirculating ratio, much more generated invalid low-temperature heat, inconvenience in reutilization, and inconvenience in large-scale industrial production.

Owner:鲁盈 +2

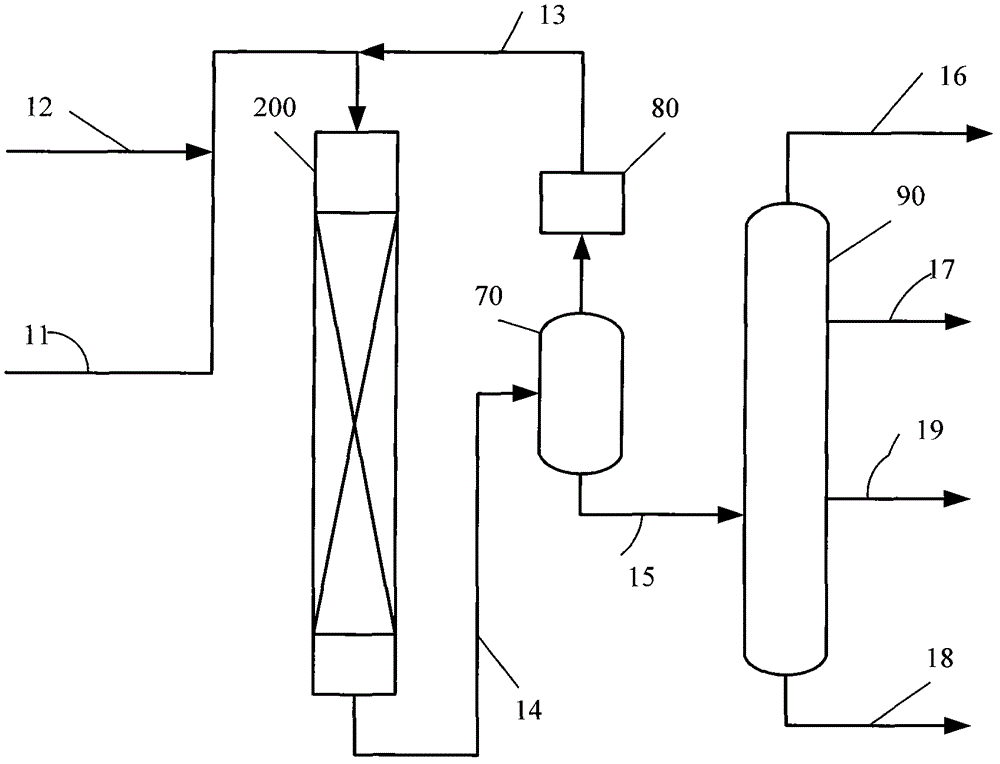

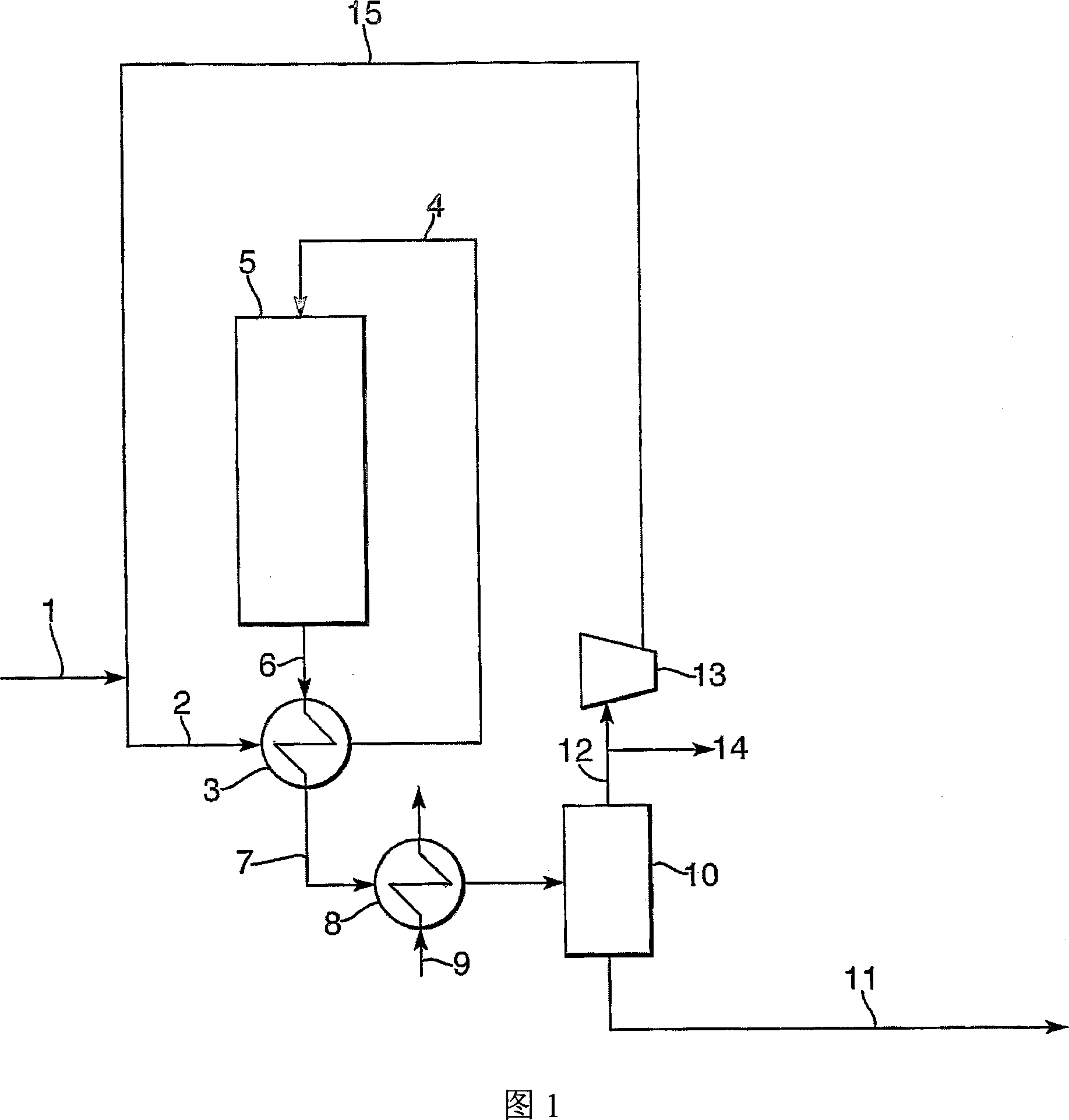

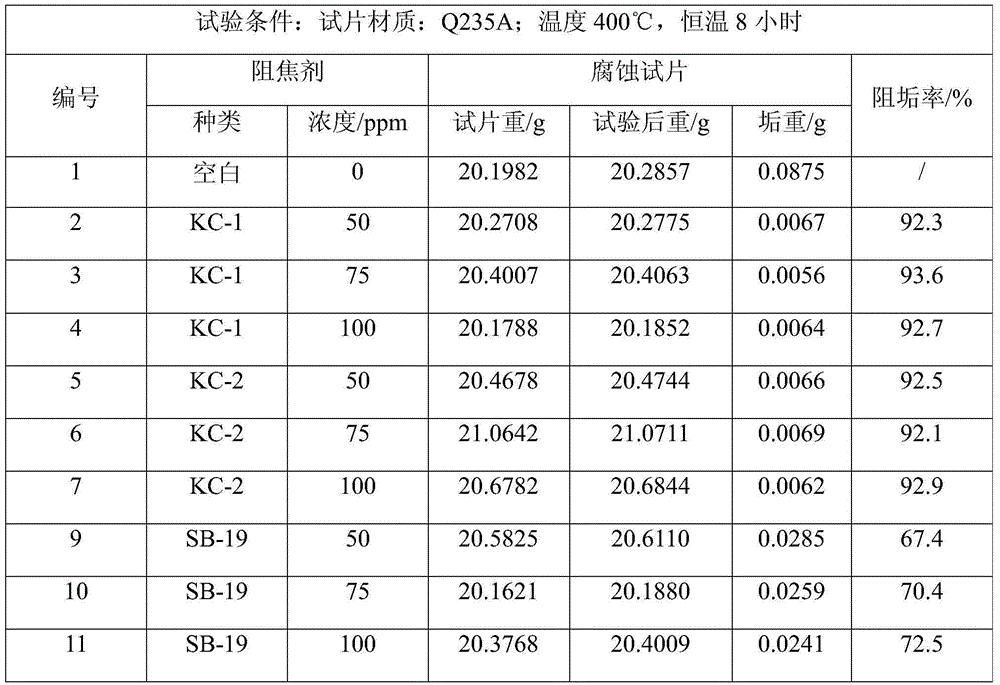

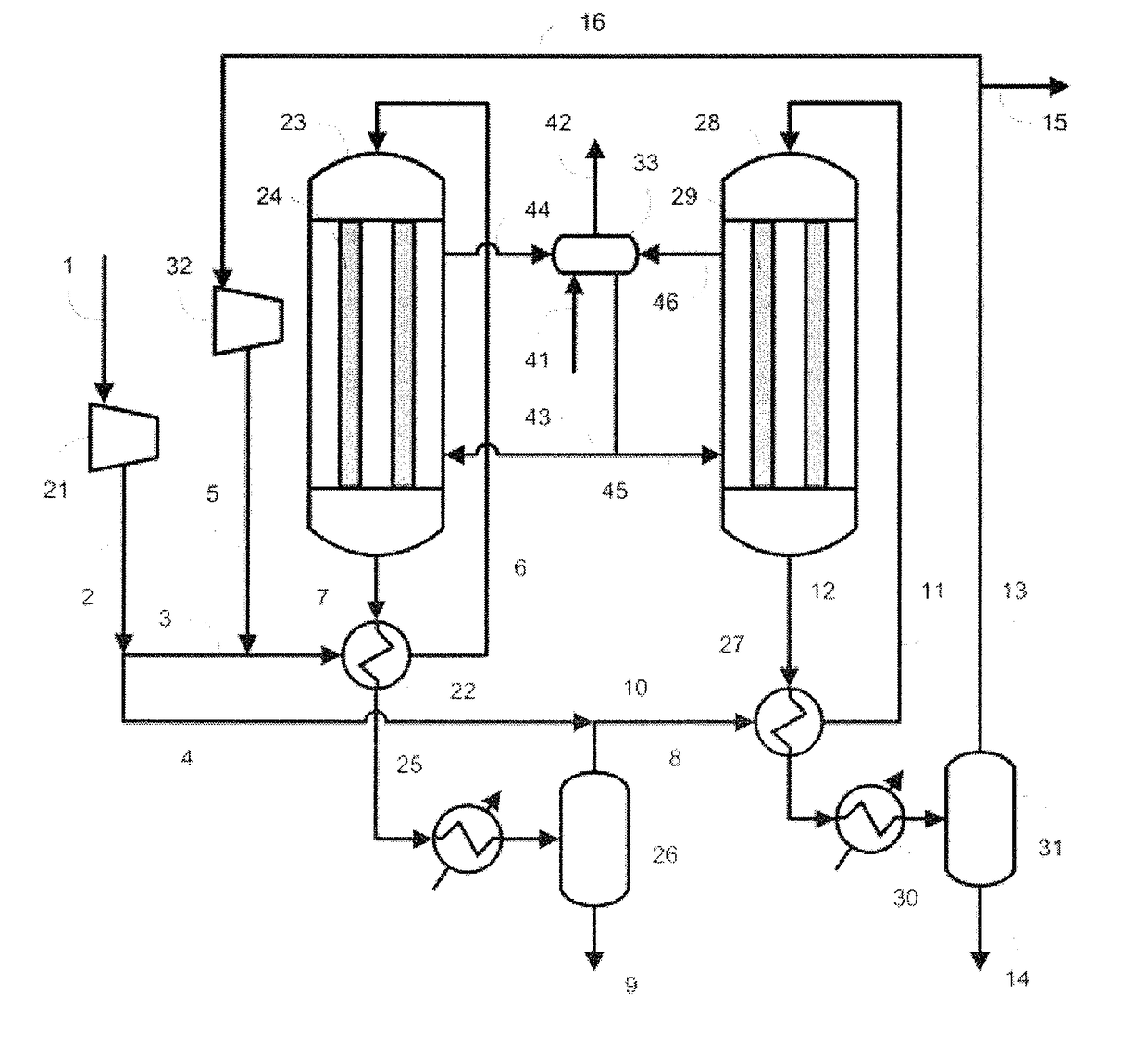

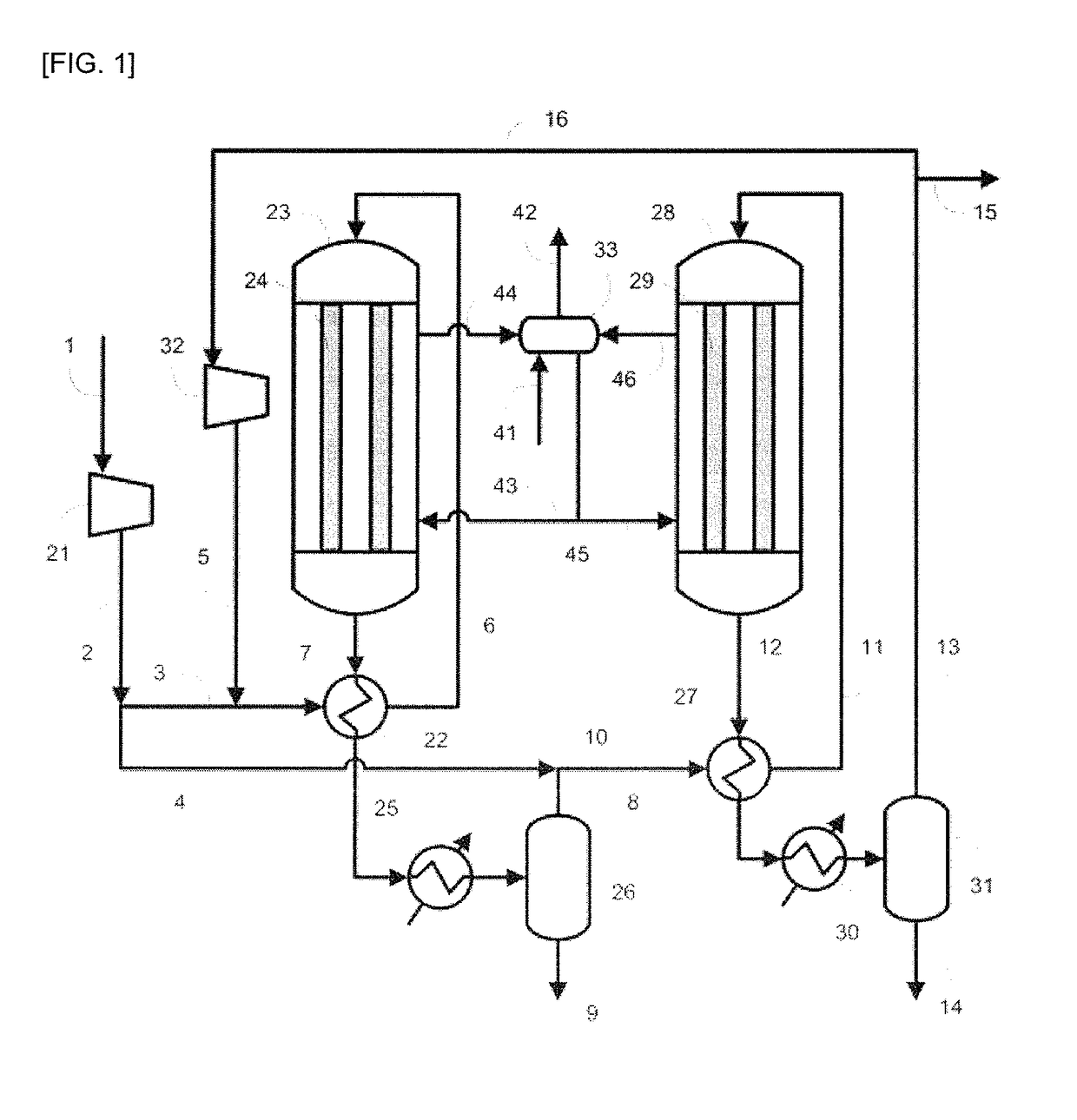

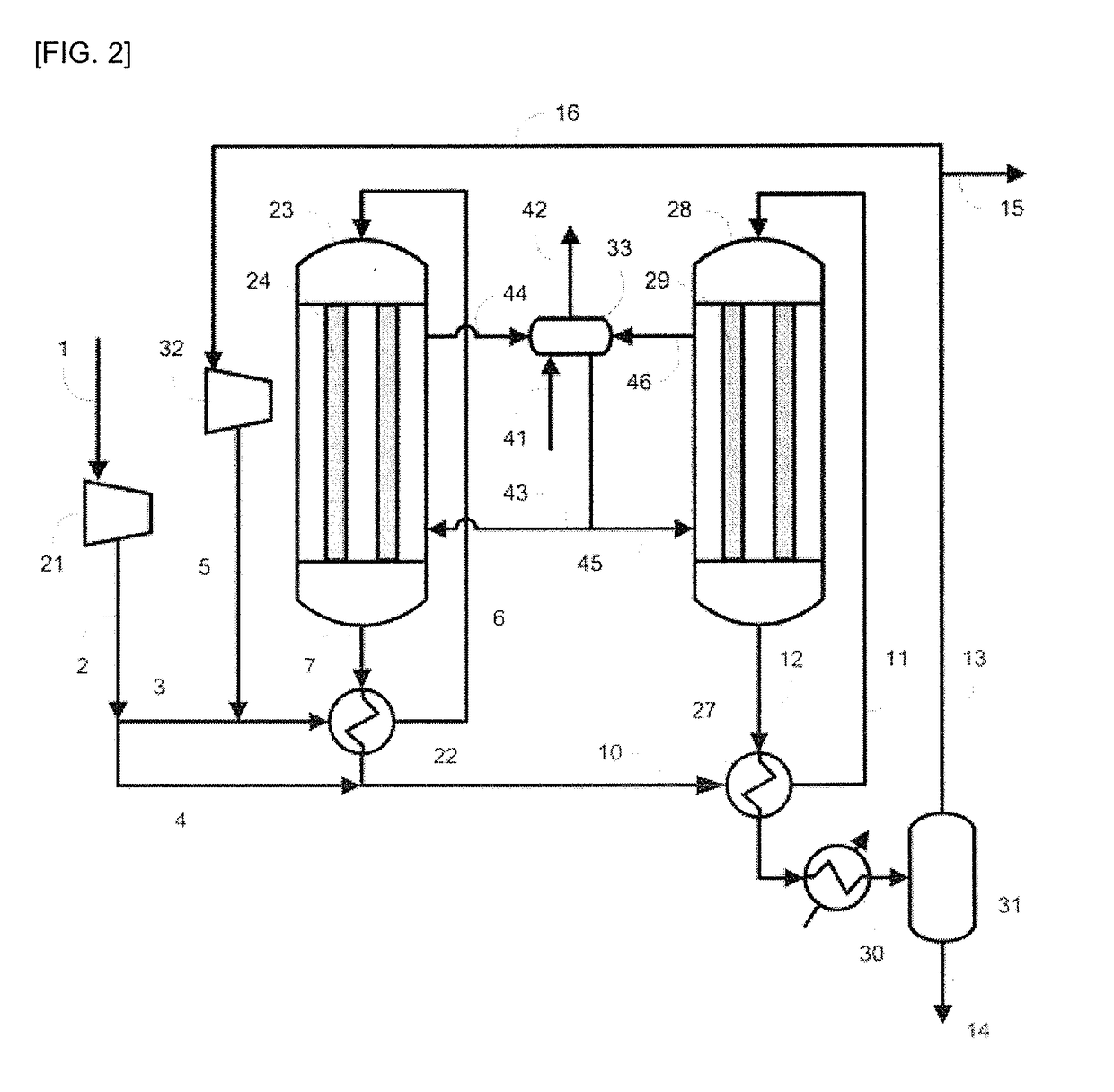

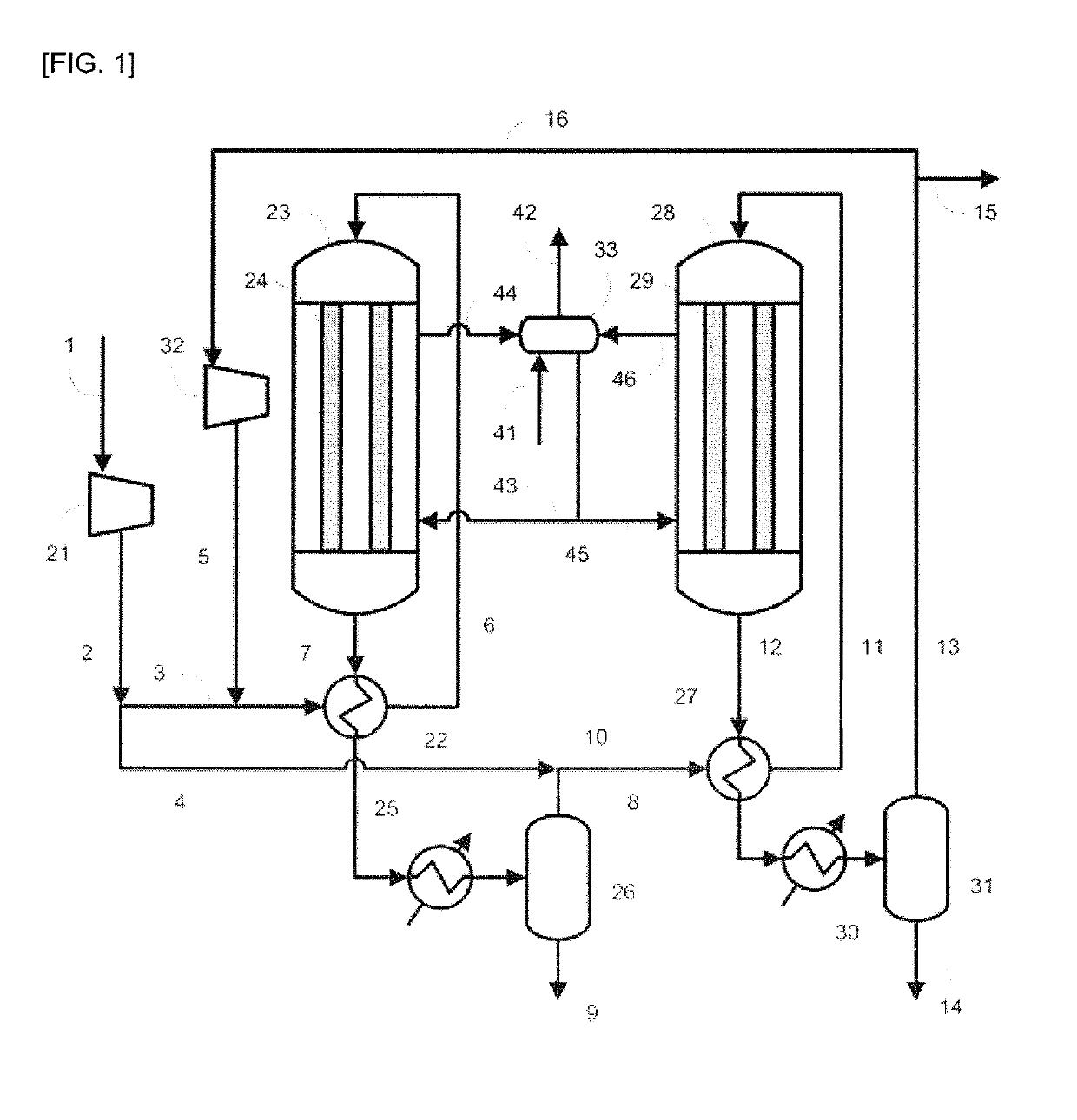

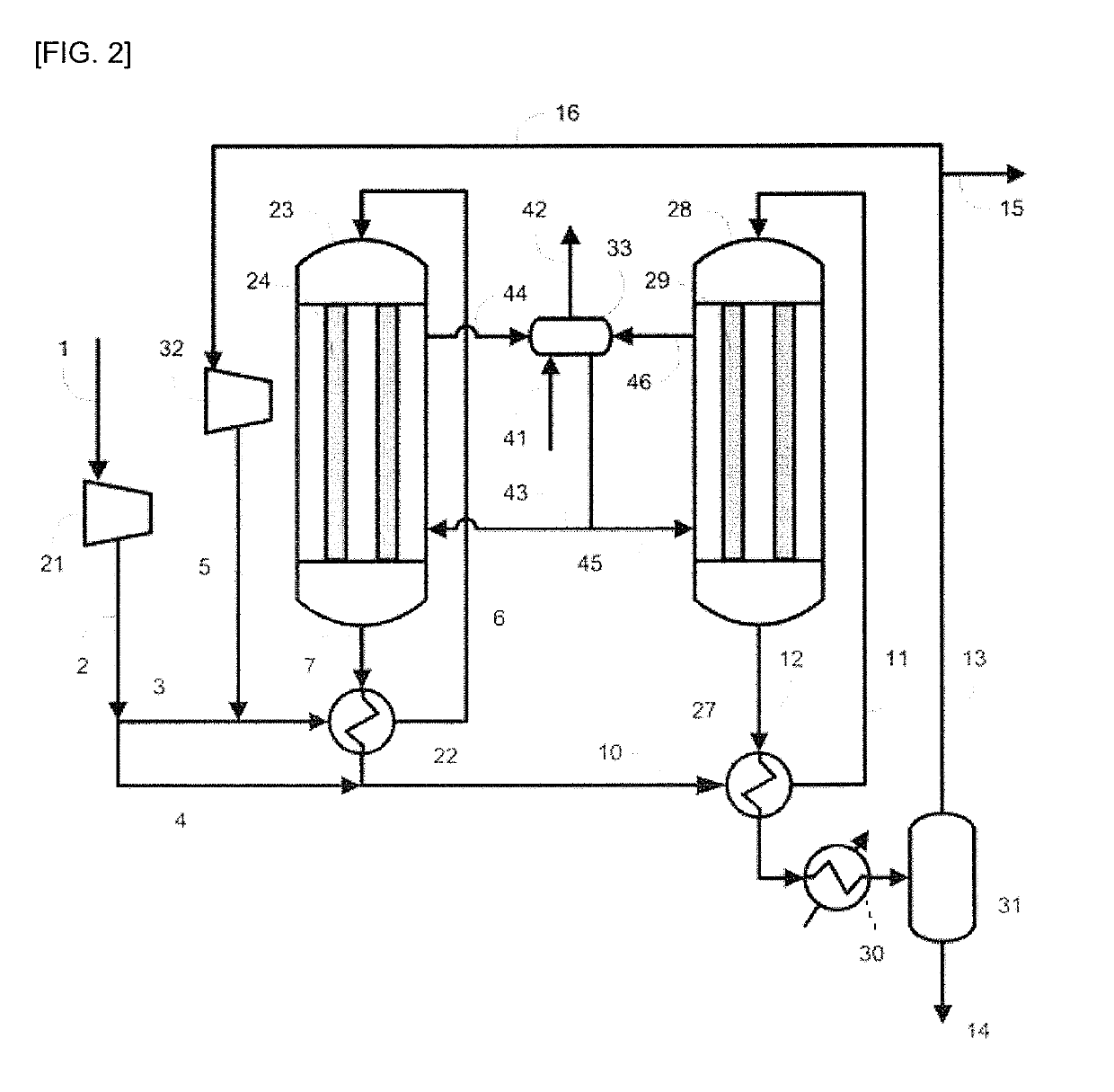

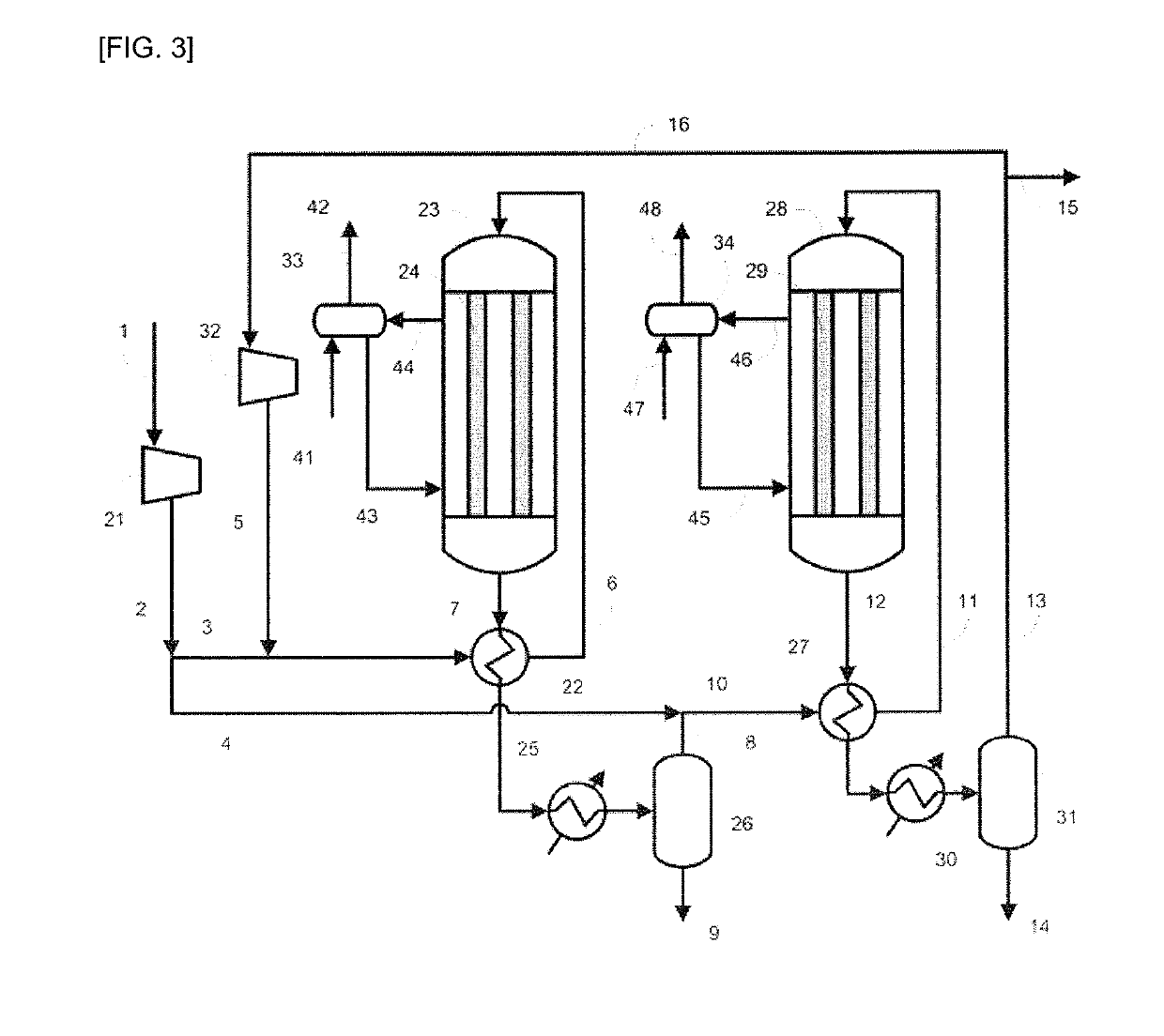

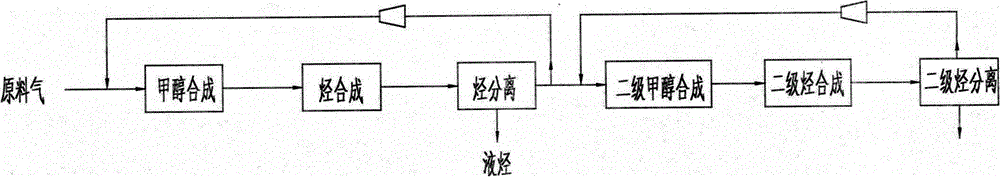

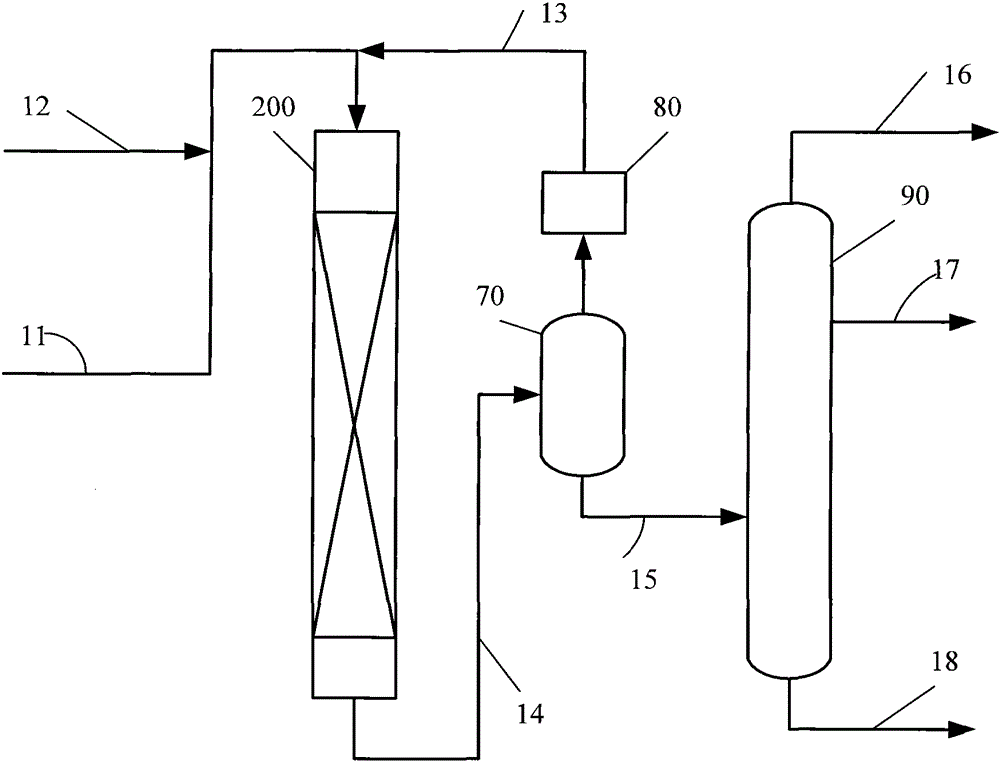

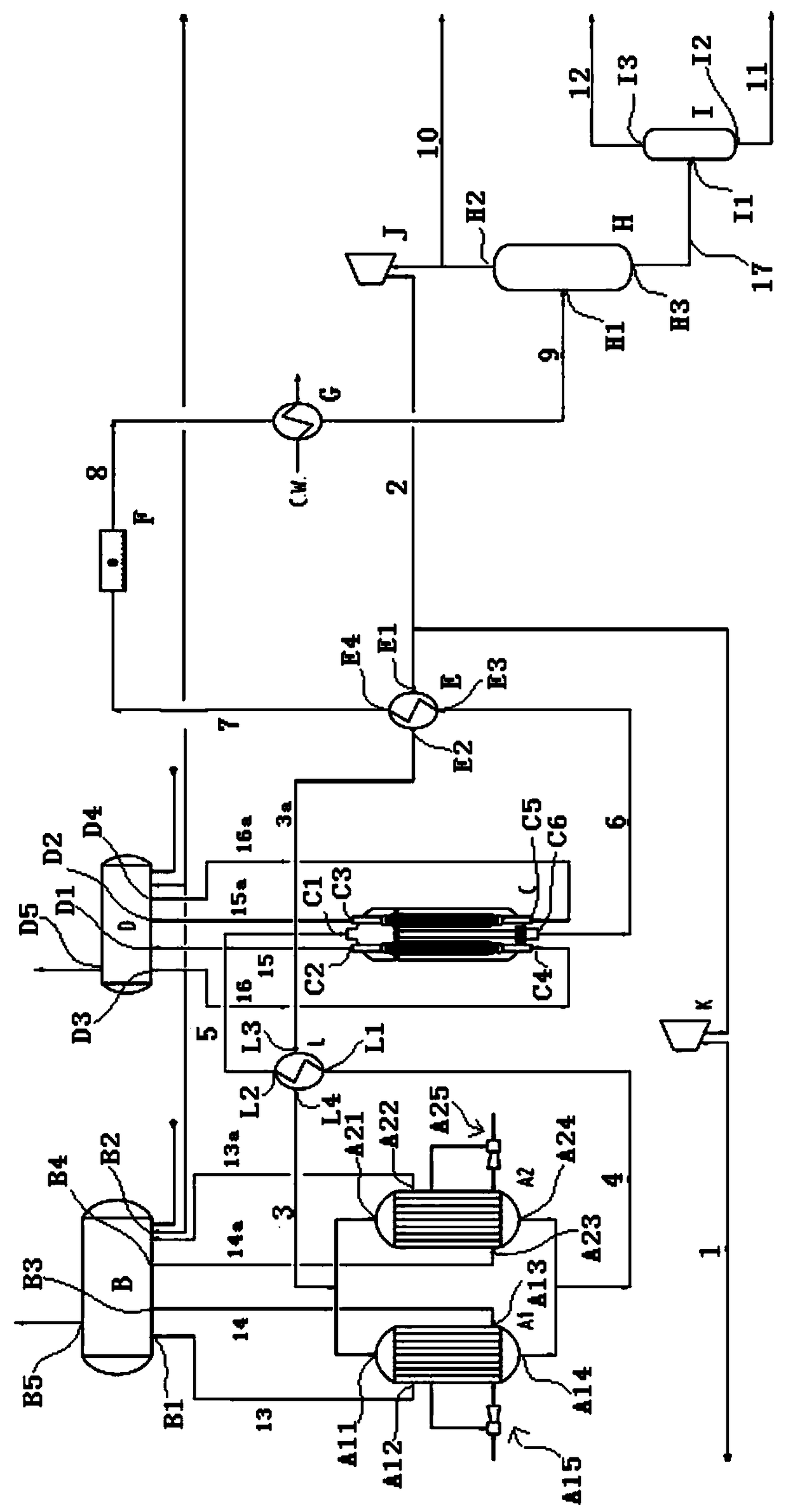

Methanol production method and methanol production apparatus

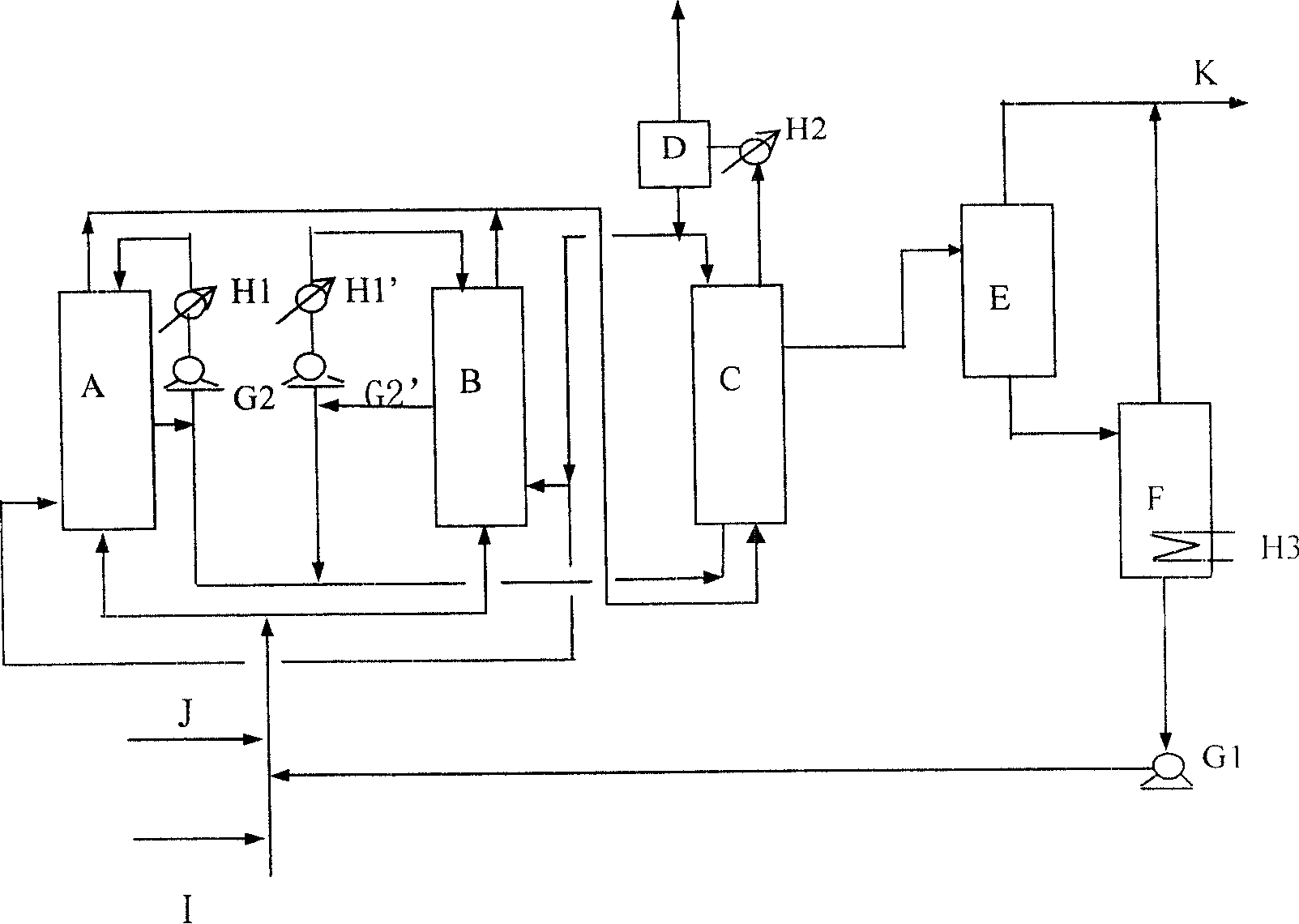

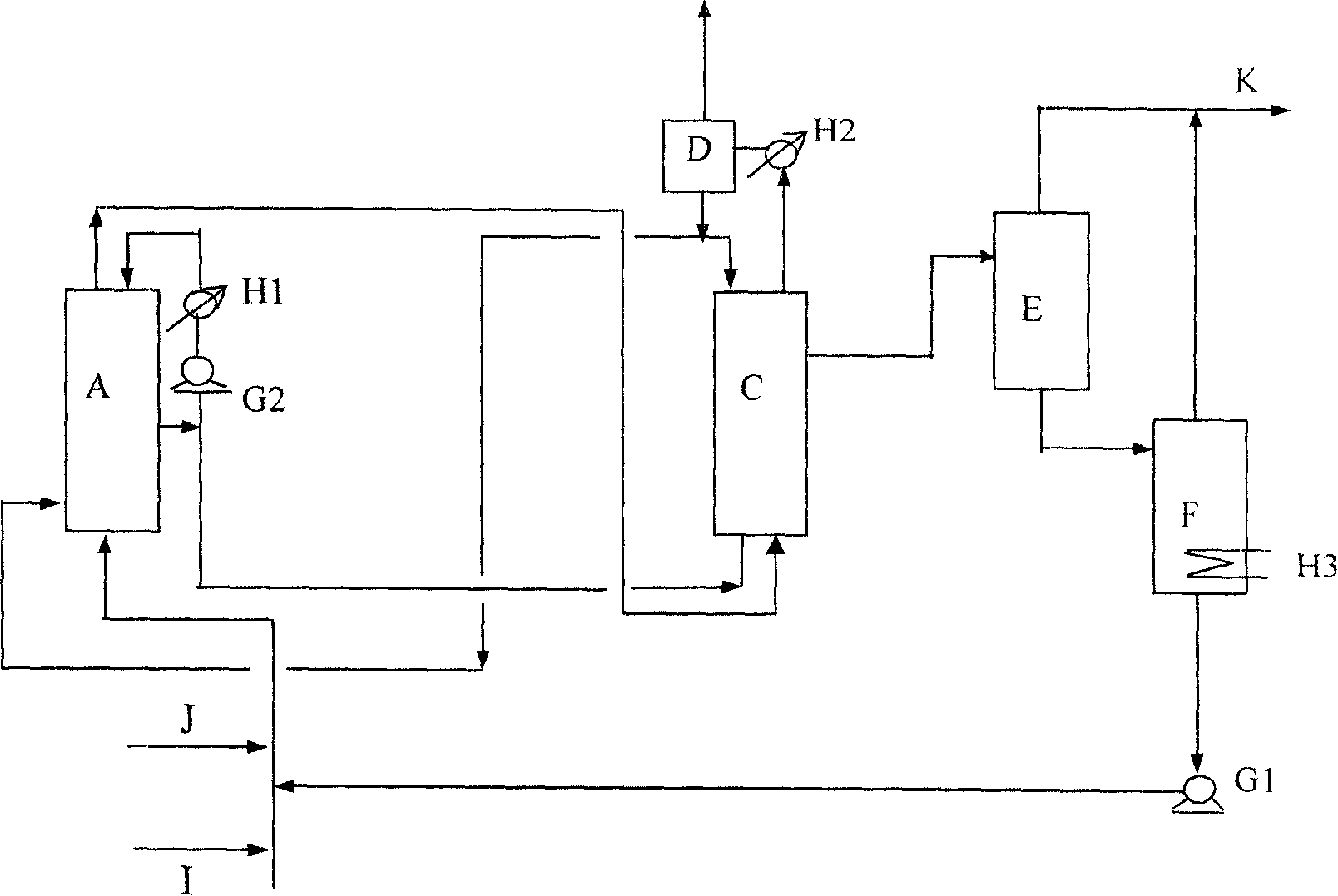

ActiveUS20170240492A1High carbon yieldWeaken energyOrganic compound preparationOrganic chemistry methodsProduct gasMixed gas

Synthesizing methanol from a synthesis gas and separating an unreacted gas from a reaction mixture obtained by passing through the synthesis step, the method including a synthesis loop having at least two synthesis steps and at least two separation steps; obtaining a first mixed gas by increasing through a circulator a pressure of a residual gas, obtained by removing a purge gas from the final unreacted gas separated from the final reaction mixture subsequent to the final synthesis step, and by mixing the residual gas with a fraction of a make-up gas; synthesizing methanol; separating a first unreacted gas from the first reaction mixture obtained in the synthesizing step; obtaining a second mixed gas by mixing the first unreacted gas and a fraction of the make-up gas; finally synthesizing methanol; and separating the final unreacted gas from the final reaction mixture obtained in the final synthesis step.

Owner:MITSUBISHI GAS CHEM CO INC

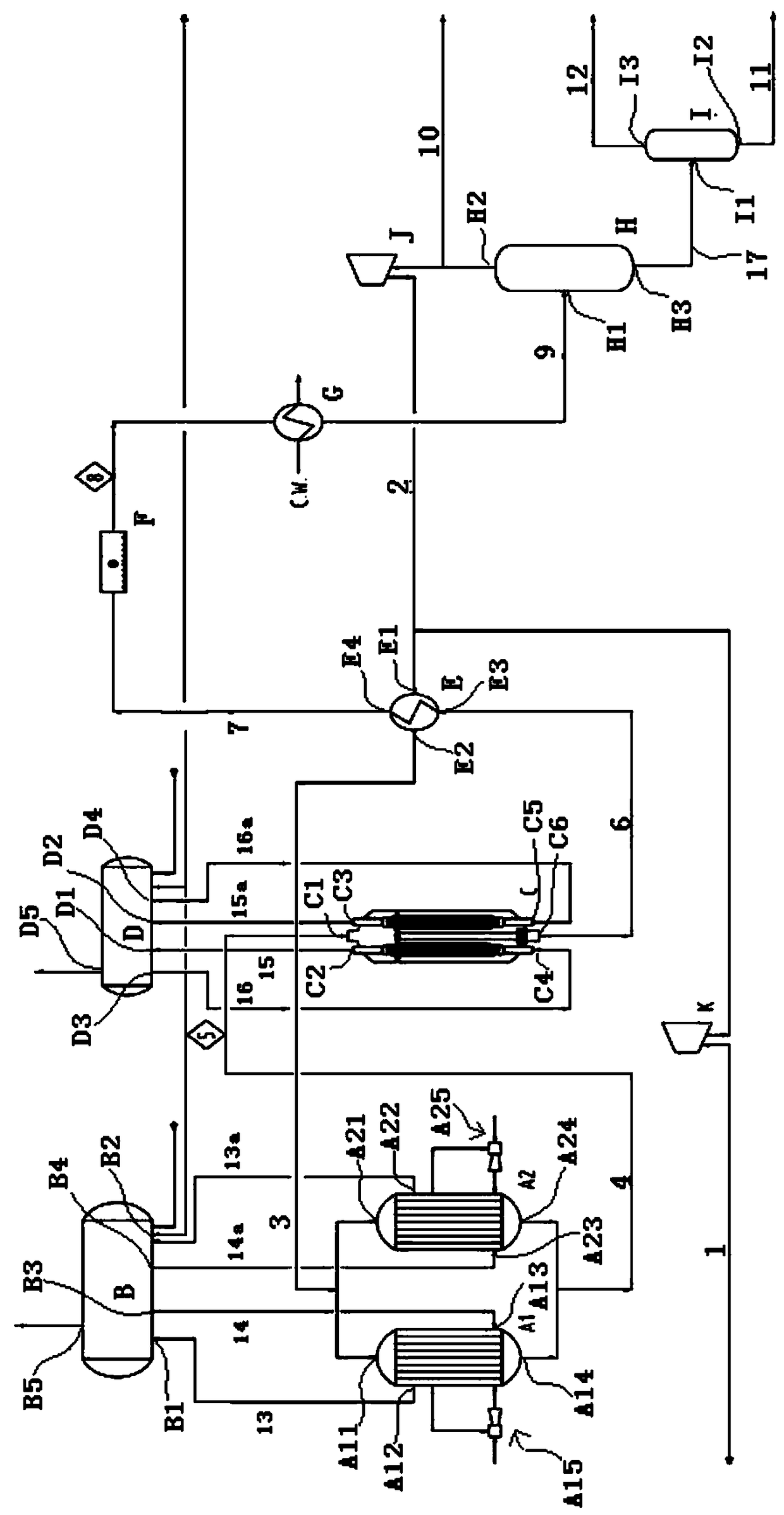

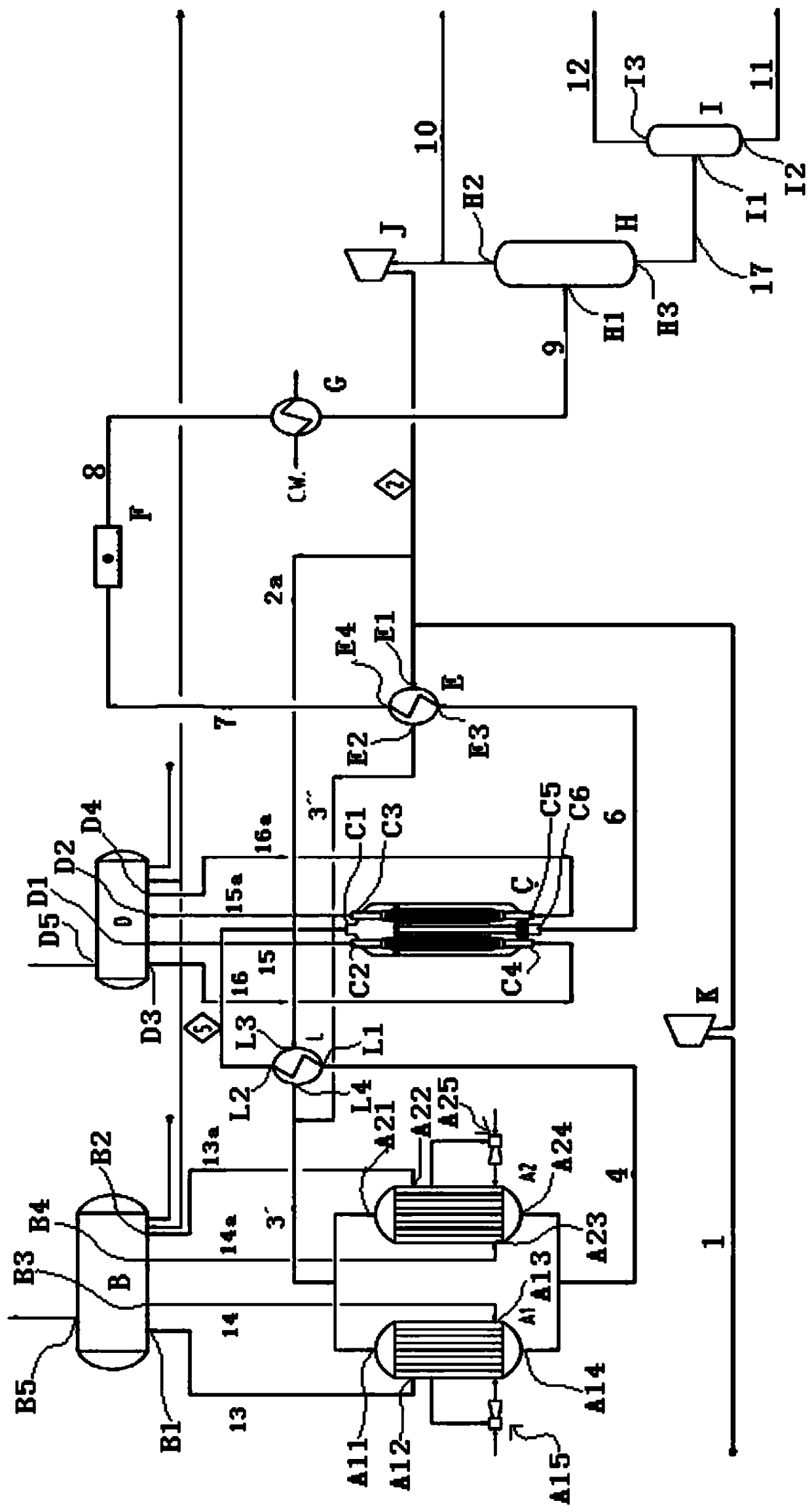

Method for producing methanol and apparatus for producing methanol

ActiveUS10252963B2Weaken energyReduce cycle ratioOrganic compound preparationOrganic chemistry methodsMixed gasMethanol

Synthesizing methanol from a synthesis gas and separating an unreacted gas from a reaction mixture obtained by passing through the synthesis step, the method including a synthesis loop having at least two synthesis steps and at least two separation steps; obtaining a first mixed gas by increasing through a circulator a pressure of a residual gas, obtained by removing a purge gas from the final unreacted gas separated from the final reaction mixture subsequent to the final synthesis step, and by mixing the residual gas with a fraction of a make-up gas; synthesizing methanol; separating a first unreacted gas from the first reaction mixture obtained in the synthesizing step; obtaining a second mixed gas by mixing the first unreacted gas and a fraction of the make-up gas; finally synthesizing methanol; and separating the final unreacted gas from the final reaction mixture obtained in the final synthesis step.

Owner:MITSUBISHI GAS CHEM CO INC

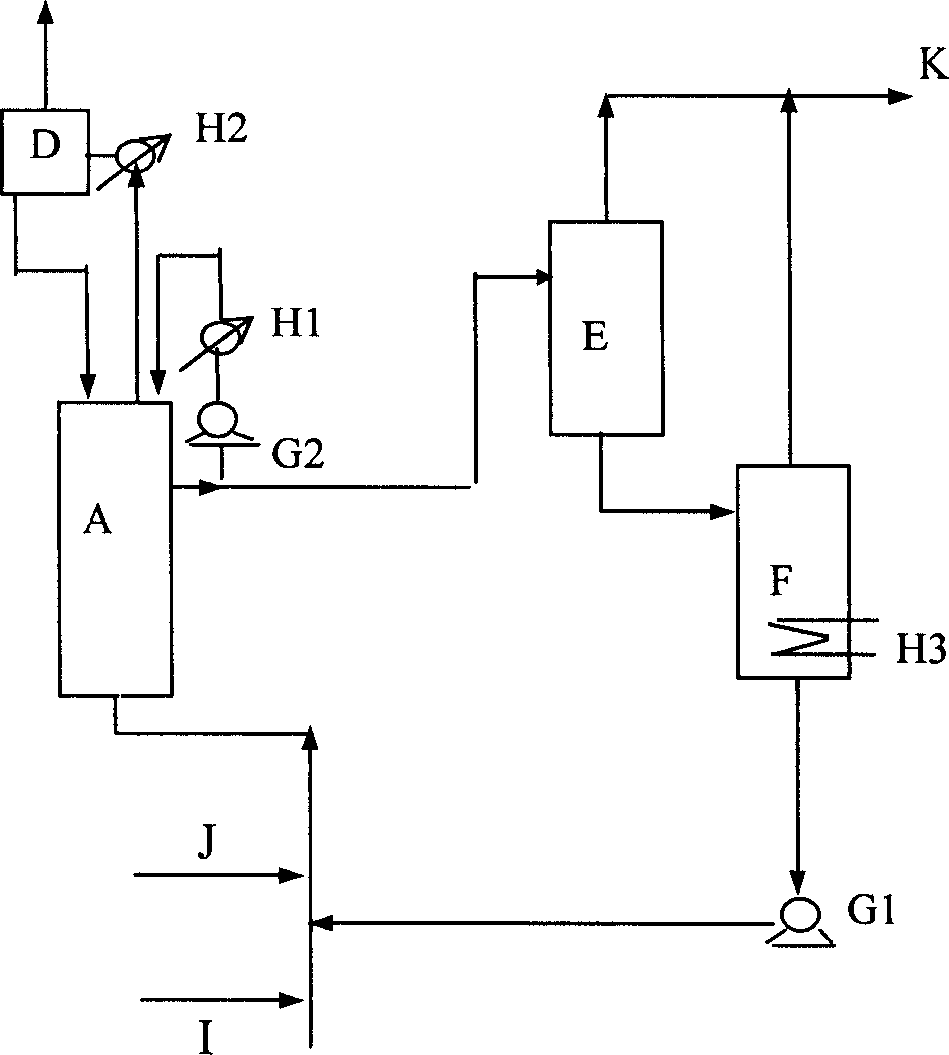

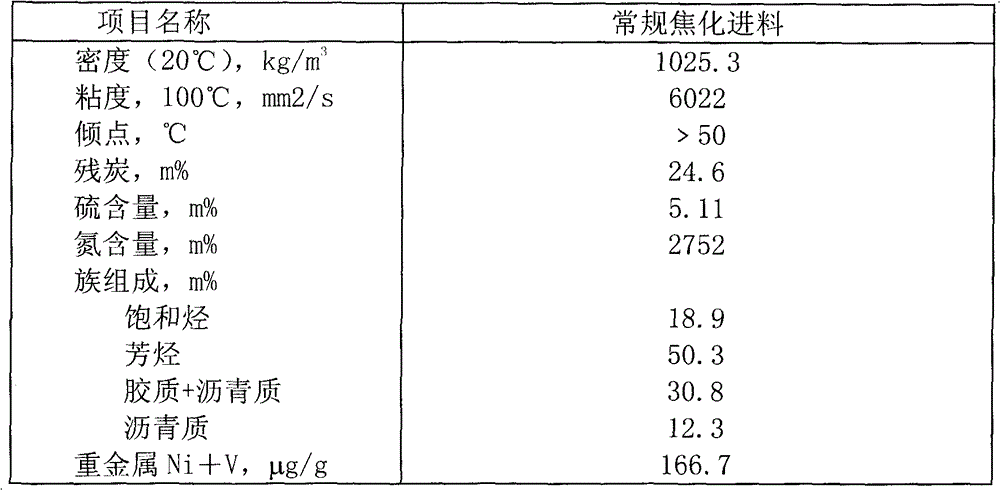

Processing method for heavy oil

InactiveCN104312622ARealize slag-free processingReduce cycle ratioTreatment with plural serial stages onlySocial benefitsGas solid

The invention discloses a processing method for heavy oil. A gas-solid separating zone is formed in the upper part of a reactor, a thermal cracking zone is formed in the middle part, a gasifying zone is formed in the lower part, raw materials are led into the reactor from the bottom part of the gas-solid separating zone and are dispersed into oil drops through an atomizer, the light components in the oil drops are volatilized into oil gas in the process that the oil drops fall down in the thermal cracking zone, and the heavy components are condensed into tar. Therefore, the processing method has obvious social benefit and economic benefit.

Owner:华玉叶

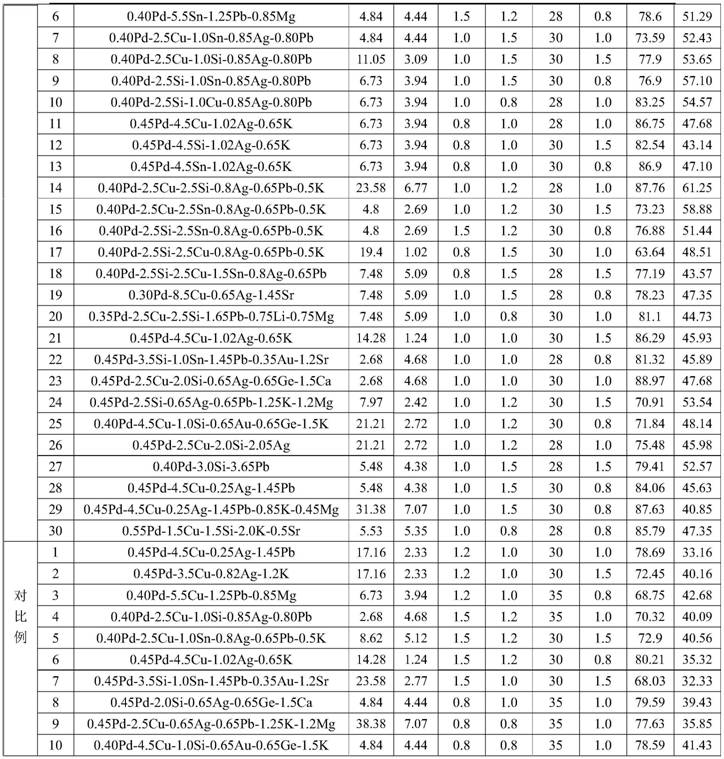

Delayed coking equipment and method capable of optimizing product quality and liquid yield

ActiveCN103468308BPrevents coking tendencySolve cokingTreatment with plural serial stages onlyWaxFour-way valve

The invention discloses coking delay equipment and method capable of optimizing product quality and liquid yield, and belongs to the technical field of hot processing of heavy oil. The equipment is composed of a raw oil feeding line, a fractionating tower, a heating furnace feed pump, a heating furnace, a heating furnace transfer line, a coke chamber feed four-way valve, a coke tower, a coke tower roof anti-coking device, a reaction oil gas pipeline and the like which are connected in sequence. According to the equipment and method disclosed by the invention, a novel flow design and a control method are adopted, so that the defects that coke powder is carried in a product in a conventional coking delay process flow, the quality of wax oil products is poor, the heavy wax oil section of the fractionating tower is easily coked, the coke tower reaction oil gas pipeline is easily coked, the device circulation ratio is difficult to regulate and the like can be overcome, the operation becomes flexible and reliable, and the optimized production requirement of the whole plant can be fulfilled in the actual operation, the coking product quality and liquid yield can be optimized, and the economical benefit of the whole plant can be increased.

Owner:BOYING RUIKE BEIJING TECH

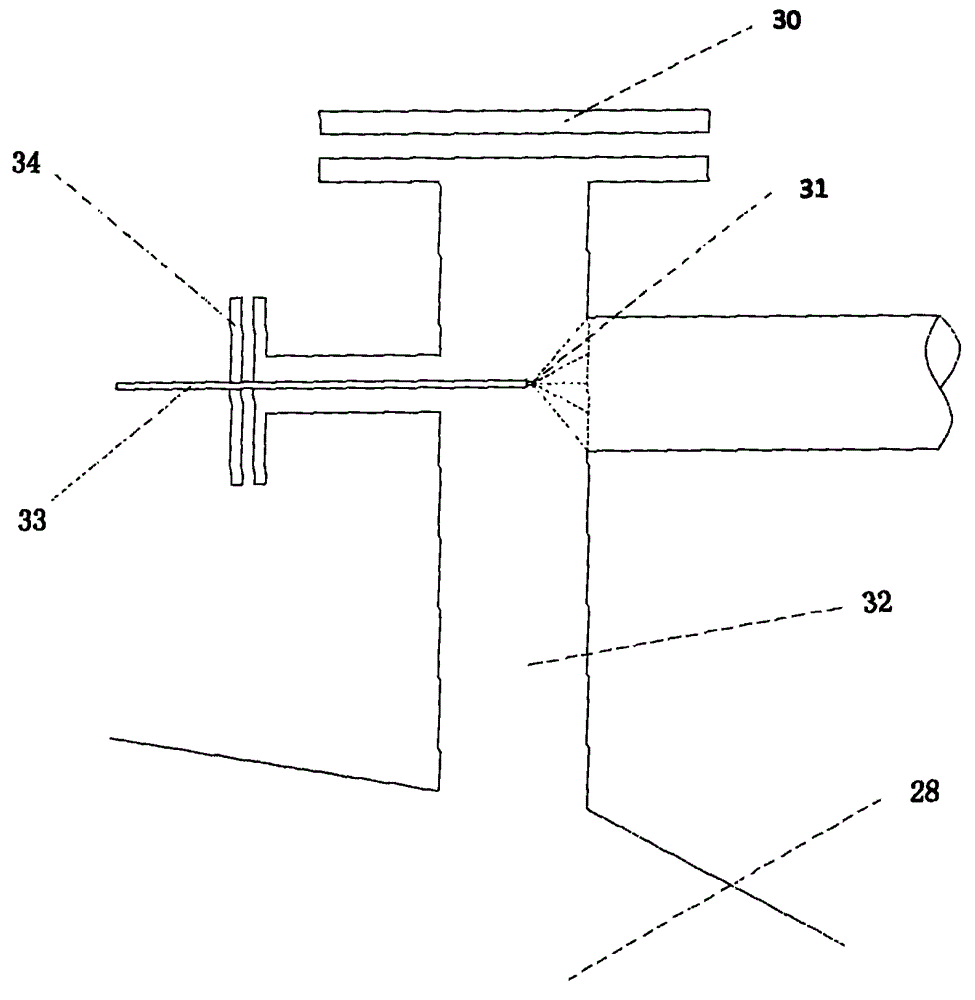

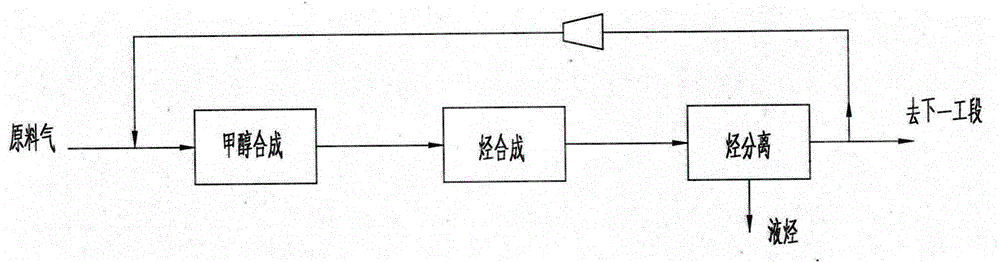

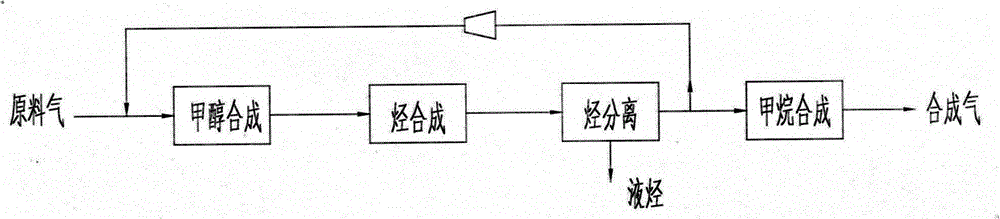

Method and apparatus for producing hydrocarbons by synthesis gas from coal

InactiveCN104419440AShort processLess investmentGaseous fuelsHydrocarbon from oxygen organic compoundsSyngasPressure decrease

The invention discloses a method for producing hydrocarbons by synthesis gas from coal. Methanol or methanol and dimethyl ether are synthesized by raw gas firstly, and then hydrocarbons are synthesized, wherein the methanol or methanol and dimethyl ether are subjected to a dehydration reaction to generate liquid hydrocarbons, reaction gas for hydrocarbon synthesis is subjected to gas-liquid separation to obtain liquid hydrocarbon products, then a part of the reaction gas are circulated and returned to mix with the raw gas before methanol synthesis, so as to perform methanol synthesis and hydrocarbon synthesis reactions again, and the other part of the reaction gas is discharged or sent to the next section for reaction, as needed. The invention also discloses an apparatus used in the method. The method of the invention adopts a two-step reaction isobaric operation of pressure decrease in methanol synthesis or methanol and dimethyl ether synthesis from synthesis gas in hydrocarbon production by synthesis gas, and pressure increase in hydrocarbon production by dehydration; a catalyst for methanol synthesis and a catalyst for dimethyl ether are filled in a layered manner according to the design requirements, which prevents the reduced methanol catalyst of active copper from oxidation poisoning due to mixing and filling of the two catalysts; the method of the invention has the advantages of short flow, few apparatuses, low investment, saved energy consumption and the like.

Owner:杭州林达化工技术工程有限公司

A method for preparing diesel oil component or jet fuel component from animal and vegetable oil

ActiveCN103059901BLower cold filter pointMeet the requirement of -47℃ freezing pointLiquid hydrocarbon mixture productionBio-feedstockOil and greaseCarbon number

The invention provides a method for preparing a diesel oil component or jet fuel component by using animal and plant oil. The method comprises the following steps of: (1) dividing the animal and plant oil into at least two parts, introducing the at least two parts of animal and plant oil to a plurality of catalyst beds of a first hydrogenation reactor, and enabling the at least two parts of animal and plant oil and a hydrodeoxygenation catalyst to contact and react to obtain n-alkanes with the carbon number of 8-24; (2) filling an isomerization catalyst in a second hydrogenation reactor, introducing a reaction product obtained in the step (1) to the second hydrogenation reactor, and reducing a condensation point after isomerization reaction to obtain a diesel oil component; or, (3) filling a selective cracking catalyst in the second hydrogenation reactor, introducing the reaction product obtained in the step (1) to the second hydrogenation reactor, and then, carrying out selective hydrocracking and isomerization to obtain a jet fuel blending component. The method provided by the invention is high in jet fuel yield; and the prepared jet fuel blending component is good in quality and can be mixed with the traditional petroleum-based jet fuel according to any proportion so as to be an excellent blending component.

Owner:CHINA PETROLEUM & CHEM CORP +1

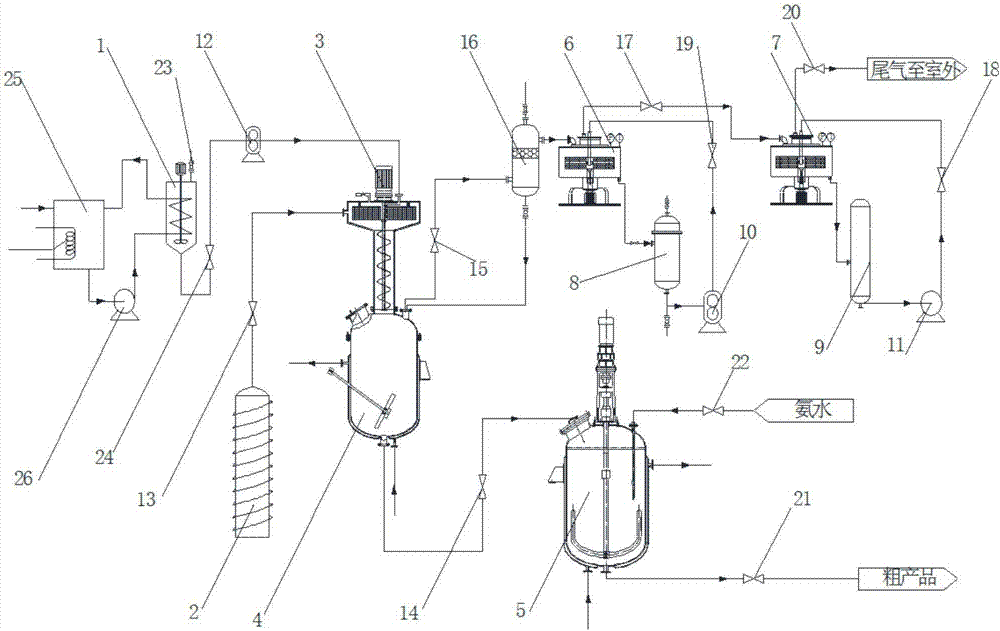

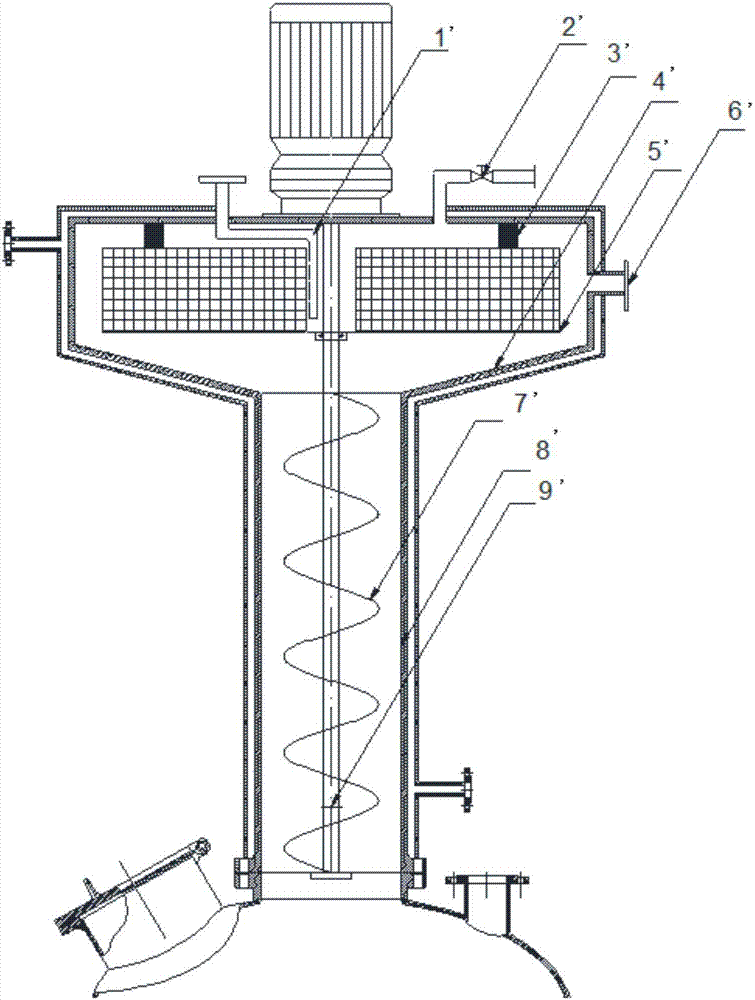

Method for green synthesis of tertiary oil recovery petroleum sulfonates in high gravity reactor

ActiveCN106966930AReduce volumeLow installation requirementsSulfonic acids salts preparationDrilling compositionGas phaseActive matter

The invention a method for green synthesis of tertiary oil recovery petroleum sulfonates in a high gravity reactor and belongs to the field of fine chemicals. The method comprises the steps: using distillate oil as a raw , sulfonating and aging the distillate oil through the high gravity-screw combination reactor to obtain an obtained petroleum sulfonate surfactant, and then neutralizing the obtained petroleum sulfonate surfactant. The method is mainly characterized in that the wide distillate oil is used as the raw material, and gas phase SO3 is used as a sulfonation agent; the petroleum sulfonates obtained after neutralizing with ammonium hydroxide is free of solvent removal process, so that the process is shortened; sulfonation efficiency is high, the content of active matters is high and the interfacial tension is low; and in the method, the production equipment and process which can realize processing strengthening, safety, high efficiency and cleaning are used. The method is suitable for scale and continuous production of the tertiary oil recovery petroleum sulfonates.

Owner:BEIJING UNIV OF CHEM TECH

Catalyst for synthesizing methanol and preparation thereof

ActiveCN101322940BIncrease productivityIncrease the areaOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsAlcoholPromotion effect

The invention relates to a catalyst used for methanol synthesis and a preparation method thereof which belong to the field of chemical catalysts and the preparation thereof. The catalyst used for methanol synthesis is a CuO / ZnO / Al2O3 catalyst that is added with Si element and used for methanol synthesis, the catalyst consists of CuO with the mass percentage of 60 to 70 percent, ZnO with the mass percentage of 21 to 30 percent, Al2O3 with the mass percentage of 4 to 10 percent and SiO2 with the mass percentage of 1 to 3 percent. Compared with congeneric catalysts, the specific surface area andpore volume of the catalyst increase by 10 to 20 percent after being added with the Si element; reaction activity is obviously improved more than 10 percent; the catalyst has great promotion effect onthe technological progress of methyl alcohol industry. By using the catalyst, as for production devices with the same scale, the usage of catalyst is correspondingly reduced; due to high conversion rate, the recycle ratio is lowered and energy consumption is saved, thus being capable of greatly improving the production efficiency of methyl alcohol.

Owner:大连瑞克科技股份有限公司

An energy-saving ultra-large-scale methanol synthesis method and device for producing different grades of steam

ActiveCN105399604BIncrease concentrationIncrease conversion rate per passOrganic compound preparationHydroxy compound preparationProcess engineeringGlycol synthesis

The invention discloses an energy-efficient super-large scale methanol-synthesizing method with production of steam of different grades. Virgin gas is compressed and mixed with circulation gas for forming a gas mixture, the gas mixture is heated and simultaneously enters two parallelly arranged first methanol reactors for carrying out methanol synthesis reactions, and incompletely reacted synthetic gas and a methanol steam mixture are formed; the incompletely reacted synthetic gas and the methanol steam mixture are cooled and enter a second methanol reactor for carrying out a methanol synthesis reaction to obtain a final product; the final product is cooled and separated, and parts of the separated gas is used as circulation gas; and liquid crude methanol enters a downstream rectification unit. The invention also discloses an apparatus for realizing the method. A reasonably configured heat exchanger network is used for improving conversion per pass and concentration of methanol at the outlet of the reactor maximally, and reducing recycle ratio and energy consumption, and producing steam of different grades; the low pressure steam can meet low pressure steam demands of the downstream methanol rectification unit.

Owner:SHANGHAI INT ENG CONSULTING

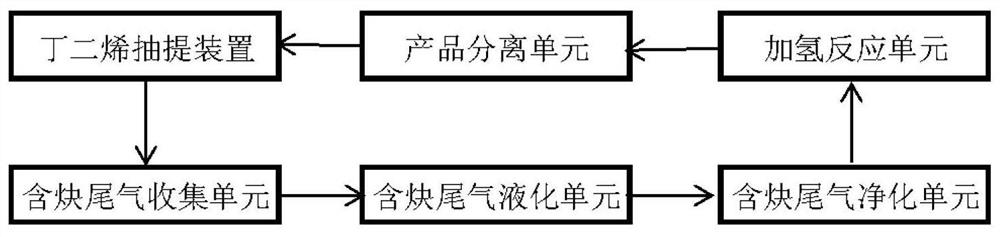

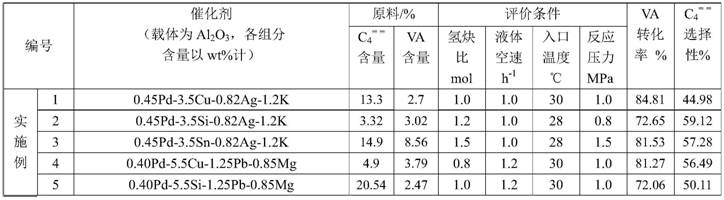

A kind of alkyne selective hydrogenation catalyst and its preparation method and application

ActiveCN108927173BReduce initial activitySignificant effect on activityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrogen selectivity

The invention belongs to the technical field of petrochemical industry, and in particular relates to an alkyne hydrogenation selective catalyst and its preparation method and application. The catalyst is composed of an active component, a catalytic promoter and a carrier. The active component is palladium, and a catalytic promoter is added to improve the hydrogenation stability and selectivity of the catalyst. The catalytic promoter is introduced into the catalyst in different ways In this process, the acidity of the catalyst surface can be reasonably controlled and the dispersion of the active component palladium can be promoted to form more active sites. The catalyst of the present invention is suitable for the selective hydrogenation of alkyne-containing materials, especially for the selective hydrogenation of carbon four materials with high alkyne content discharged from a butadiene extraction device, to convert vinyl acetylene and ethyl acetylene into butadiene Diene and butene, hydrogenation products are returned to the raw material storage tank or butadiene extraction unit to recover butadiene and butene. The catalyst of the invention has mild hydrogenation reaction conditions, high activity and selectivity, especially good stability and long operation period, and is suitable for hydrogenation of materials with high alkyne content.

Owner:沈阳沈科姆科技有限公司

Method for alleviating coking of coke tower top oil gas pipeline

The invention provides a method for alleviating coking of a coke tower top oil gas pipeline. The method comprises the following steps: 1, spraying parts of quenching oil into a coke tower from the upper part or the top of the coke tower, and pre-quenching a coke tower top oil gas; and 2, spraying the other parts of the quenching oil in a tower outlet oil gas pipeline into the pipeline, and quenching the high temperature oil gas in the tower outlet oil gas pipeline. The method allows the temperature of the coke tower top oil gas to be effectively reduced and a secondary reaction to be timely inhibited, so the coking of the coke tower top oil gas pipeline can be effectively alleviated, and the on-stream period of a coking delay apparatus is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low pressure methanol carboxylating process to synthesize acetic acid

ActiveCN100393689CIncrease concentrationIncrease production capacityCarboxylic preparation from carbon monoxide reactionAcetic acidMorpholine

The low pressure methanol carboxylating process to synthesize acetic acid includes acetic acid synthesis inside reaction liquid in the presence of rhodium-iodine catalyst system, adding morphinone compound, morphinone salt derivative or other additive to stabilize the catalyst system, and separating the coarse product through flash evaporation-evaporation process. The present invention has specific component added to constitute high activity and high stability catalyst system and has greatly raised production capacity of the reactor.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

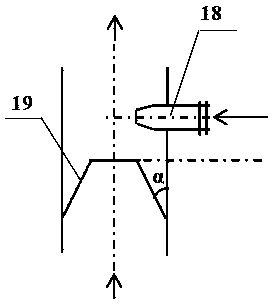

Combined Bed Methanol to Gasoline Process

ActiveCN105925301BOptimal response pressureLower reaction conditionsLiquid hydrocarbon mixture productionBio-feedstockVapor–liquid separatorGasoline

A process for preparing gasoline from methanol by means of a combined bed comprises the following process steps: preheating raw material methanol by means of a preheater (18); feeding the preheated raw material methanol into an evaporator (19) and completely gasifying the raw material methanol; enabling the gasified raw material methanol and a recycling gas enter into a combined constant temperature reactor (21) from a mixed-gas inlet pipe, discharging the raw material methanol and the recycling gas from a mixed-gas outlet pipe, and feeding a catalyst from a feeding port to carry out a reaction; discharging the product from the discharging port, and then feeding the product into a condenser (22) in two paths, condensing the product, and enabling the product to enter a gas-liquid separator (20); outputting the separated gas as circulating gas, and outputting liquid into an oil-water separator (23) for separation, so as to obtain finished oil and water. The process overcomes the defects of high operation pressure, high feeding temperature, large recirculating ratio, much more generated invalid low-temperature heat, inconvenience in reutilization, and inconvenience in large-scale industrial production.

Owner:鲁盈 +2

A process for producing synthetic natural gas by methanation of coal-based syngas

The invention relates to a process for producing synthetic natural gas by methanation of coal-based synthesis gas, belonging to the technical field of comprehensive application of coal gasification, including high-temperature, medium-temperature and low-temperature methanation reaction parts. The high-temperature methanation reaction part is equipped with two adiabatic reactors, both of which adopt a series-parallel two-stage air intake mode. In order to meet the high-temperature catalyst replacement requirements, the two reactors can be isolated from the system without affecting normal operation. An adiabatic reactor is installed in each of the medium and low temperature methanation sections. A water separation heat exchanger is installed at the outlet of the medium-temperature reactor, and the outlet gas is refined by a low-temperature reactor to produce synthetic natural gas that meets the requirements of pipeline transportation. The invention has the characteristics of low circulation ratio, long continuous operation period of the system, short refining reaction process and high product gas quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

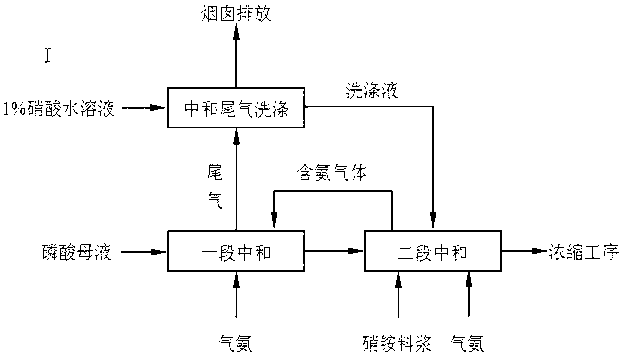

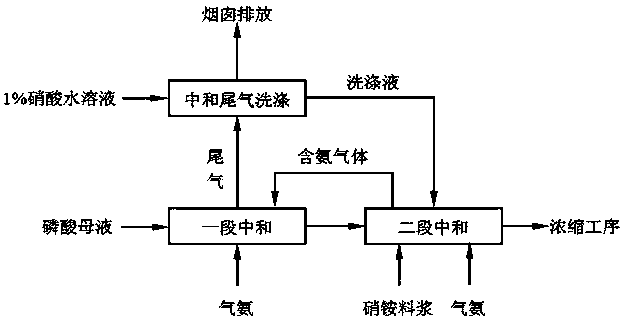

Neutralization process for ammonia in a mother liquor used for producing nitric acid phosphate fertilizer

ActiveCN102731191BEmission reductionImprove absorption efficiencyFertilizer mixturesPhosphoric acidSlurry

Neutralization process for ammonia in a mother liquor used for producing nitric acid phosphate fertilizer is that the neutralization reaction is carried out on the phosphoric acid mother liquor from a calcium nitrate filtering operation and gaseous ammonia under normal pressure in a first section neutralization apparatus to prepare an acidic slurry with a pH value of 1.6-2.0; sending the acidic slurry to a second section forced circulation apparatus to continue the ammoniation neutralization reaction until the pH value of the outlet slurry is 5.6-6.0, and the water content is 10-15%; sending ammonia-containing gas escaping from the second section neutralization apparatus to the first section neutralization apparatus to carry out absorption and purifying; carrying out neutralization and tail gas washing on the tail gas escaping from the first section neutralization apparatus; discharging the the tail gas after being washed and absorbed; and sending the washing liquid to the second section neutralization apparatus. The specific thickness region generated in the phosphoric acid mother liquor neutralization process is avoided by the technology provided in the invention, and material is uniformly mixed, fluidity of slurry is good and loss of NH3 is small.

Owner:TAIYUAN UNIV OF TECH +1

A kind of continuous liquid phase wax oil hydrogenation treatment method

ActiveCN104560132BLow investment costLow operating costHydrocarbon oils treatment productsRefining to eliminate hetero atomsSulfurDistributor

The invention relates to a method for hydrotreatment of continuous liquid-phase wax oil. Wax oil raw oil, an effluent from a reactor and hydrogen are mixed in mixers to form a mixture, hydrogen can be dissolved in hydrocarbon oil in a form of bubbles by virtue of hydrogen distributors arranged inside the mixers, the amount of hydrogen is higher than the saturated solubility of liquid or the total hydrogen consumption, a plurality of bed layers are arranged in the reactor, the mixers are arranged among the bed layers, the mixture and fresh hydrogen or a mixture of hydrogen and partial reaction products are mixed again, a partial effluent from the reactor is partially circulated and a partial effluent is subjected to cooling, separating and fractional distillation to obtain the product. By the method, the problems that reaction process is difficult to process due to the limitation on the solubility of hydrogen in the hydrocarbon oil and the chemical hydrogen consumption is relatively high are solved and the adaptability of raw oil is expanded and furthermore, under the condition of relatively low circulation ratio, low-sulfur refined wax oil can be produced to provide high-quality feedstock for catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

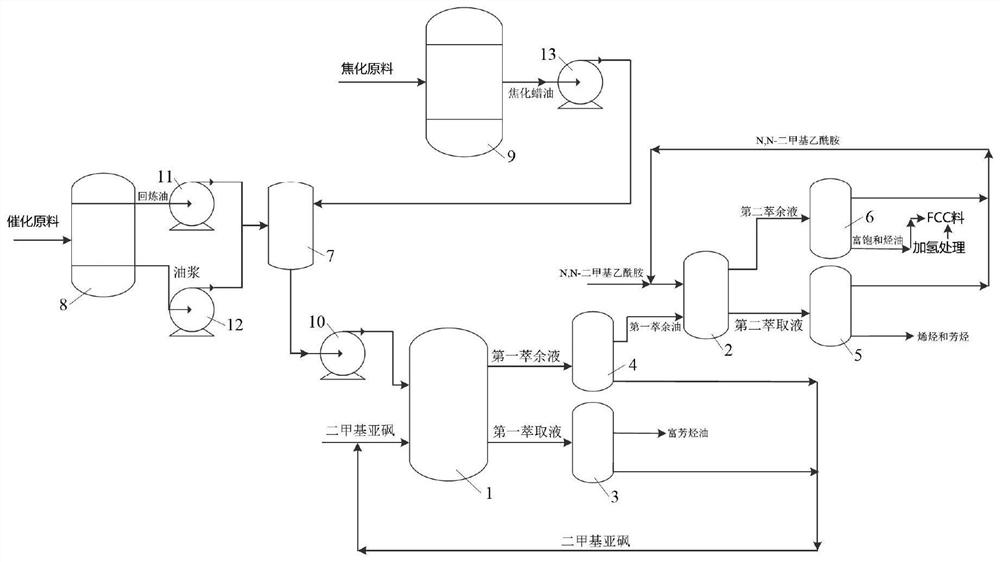

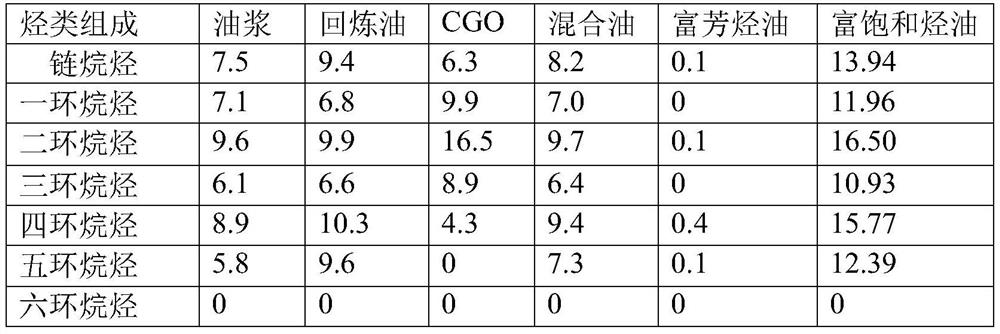

Process and device for preparing oil product by mixing oil slurry, recycle oil and coker gas oil

ActiveCN112980504ALess carbon residueReduce gum contentTreatment with plural serial refining stagesSlurryRaffinate

The invention provides a process and a device for preparing an oil product by mixing oil slurry, recycle oil and coker gas oil. The process comprises the following steps: mixing oil slurry generated by a catalytic cracking process, recycle oil and coker gas oil generated by a delayed coking process to obtain mixed oil, and carrying out a two-stage extraction process on the mixed oil, wherein extracting agent dimethyl sulfoxide is adopted in the first-stage extraction, and first-stage extraction liquid and first-stage raffinate are obtained after extraction; performing steam stripping on the first-stage extraction liquid to obtain aromatic hydrocarbon-rich oil, and performing steam stripping on the first-stage raffinate to obtain first-stage raffinate oil, wherein the first-stage raffinate oil is subjected to second-stage extraction, extraction agent N, N-dimethylacetamide is adopted for second-stage extraction, and second-stage extraction liquid and second-stage raffinate are obtained after extraction; and performing steam stripping on the secondary extraction liquid to obtain olefin and aromatic hydrocarbon, and performing steam stripping on the secondary raffinate to obtain oil rich in saturated hydrocarbon. According to the method, three oil products are firstly mixed and extracted, an extraction phase is used for producing carbon materials such as asphalt blend oil and needle coke, and a raffinate phase is used as a catalytic raw material or is used for producing lubricating oil through hydrogenation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

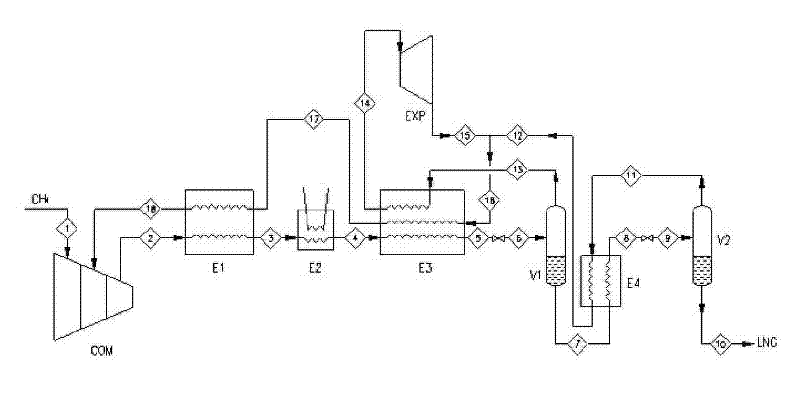

Method for preparing liquefied natural gas by using coke-oven gas

The invention discloses a method for preparing liquefied natural gas by using coke-oven gas, which mainly comprises the steps of methanation reaction, rectification separation and liquefaction, wherein the methanated gas first enters a rectification column after heat exchange and cooling; a tower kettle reboiler is heated by the methanated gas; liquid methane flows to an overhead condenser to evaporate to provide cold; under the rectification action of the rectification tower, methane with a purity of over 99.5 percent is obtained and a mixture of H2, N2 and a small amount of methane is obtained in the tower top; and the methane is heated again and delivered to a liquefying device to be liquefied. The method has the advantages that: the separation and liquefaction are separate, so the operation is smooth and flexible; LNG and methane gas can be output; the refrigerant is derived from the product methane rather than external supply, so investment is reduced and the cost for other refrigerants is saved; and in addition, according to an preferred scheme, a rear methane expander is adopted, the amount of methane entering the methane expander is increased and the refrigerating capacityis increased, so a circulation ratio is reduced to 4.0 to 4.5.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com