Method and apparatus for producing hydrocarbons by synthesis gas from coal

A technology for coal-based synthesis gas and hydrocarbon synthesis, which is applied in the field of chemical engineering, can solve problems such as losing the catalytic effect of methanol synthesis, and achieve the effects of saving energy consumption, less equipment, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

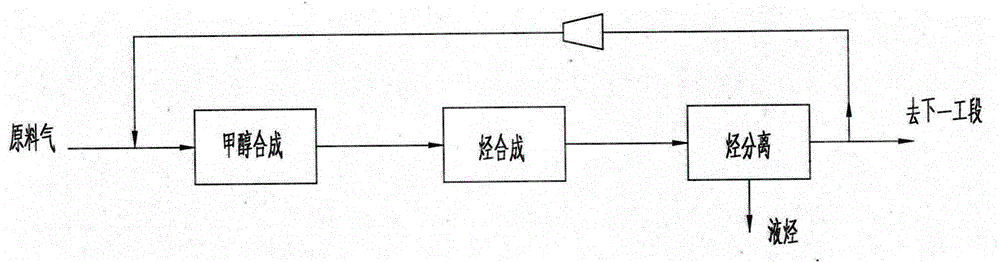

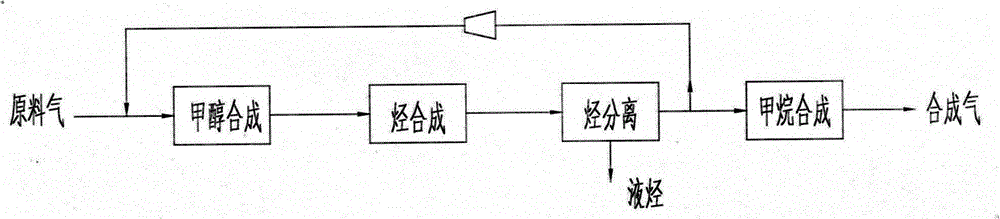

Method used

Image

Examples

Embodiment 1

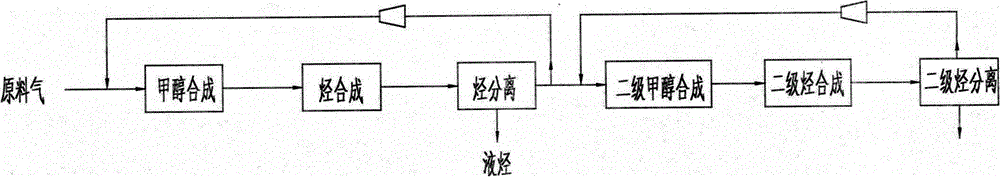

[0051] use as Figure 6 The shown coal-to-synthesis gas-to-hydrocarbons device includes two primary and secondary sets of syngas-to-hydrocarbons devices. The main device includes the first methanol synthesis reactor 1a, the first methanol dehydration reactor 2a, the first gas-liquid separation device 3a, steam drum 4, circulation pump 5, first heat exchanger 11a, preheater 12 and cooler 13, and auxiliary devices include second methanol synthesis reactor 1b, second methanol dehydration reactor 2b, second gas-liquid The separator 3b and the second heat exchanger 11b, the first methanol synthesis reactor 1a, the first heat exchanger 11a, and the first methanol dehydration reactor 2a are connected in sequence, and the gas outlet of the first methanol dehydration reactor 2a is connected to the The first heat exchanger 11a, the preheater 12, the cooler 13 and the first gas-liquid separator 3a are connected successively, and the outlet of the first gas-liquid separator 3a is divided ...

Embodiment 2

[0060] use as Figure 7 The shown coal-to-synthesis gas synthesis hydrocarbon device includes methanol synthesis reactor 1, methanol dehydration reactor 2, gas-liquid separator 3, steam drum 4, circulation pump 5, heat exchanger 11, preheater 12 and Methanation reactor 6, described preheater 12, the first methanol synthesis reactor 1, the first heat exchanger 11, the first methanol dehydration reactor 2 are connected successively, the gas outlet of the first methanol dehydration reactor 2 is connected with The first heat exchanger 11, the preheater 12 and the first gas-liquid separator 3 are connected in sequence, and the outlet of the first gas-liquid separator 3 is divided into two paths, one path is connected with the preheater 12 through a cycle machine, and the other path is connected Methanation reactor 6.

[0061] At a pressure of 3.2MPa and methanol synthesis, only a copper-based methanol synthesis catalyst is installed, at a temperature of 220-270°C and a space veloc...

Embodiment 3

[0065] Using the device and process conditions described in Example 2, the total amount of catalyst loaded in the methanol synthesis reactor 1 is 100M 3 , divided into two groups, the second group consists of the lower 10M 3 Dimethyl ether catalyst and upper layer 20M 3 Methanol synthesis catalyst composition, the first group consists of the lower layer 20M 3 Molecular sieve dimethyl ether catalyst and upper layer 50M 3 Composed of methanol synthesis catalysts, raw material gas passes through the first group of upper layer 50M from top to bottom 3 Methanol is synthesized into methanol, and then through the dimethyl ether catalyst of the first group of lower layer, 70% methanol is dehydrated to generate dimethyl ether and water, and then enters the second group of upper layer 20M 3 Methanol synthesis catalyst synthesizes 5% methanol, and then passes through the second group of lower layer 10M 3 The dimethyl ether catalyst dehydrates 60% methanol into dimethyl ether, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com