Process and device for preparing oil product by mixing oil slurry, recycle oil and coker gas oil

A technology of coking wax oil and re-refined oil, which is applied in the direction of multi-stage series refining process treatment, petroleum industry, and hydrocarbon oil treatment, can solve the problem of large utilization space, reduction of CGO nitrogen content and polycyclic aromatic hydrocarbon content, and no FCC oil slurry and re-refined oil treatment methods, etc., to achieve the effect of reducing unit consumption, reducing the circulation ratio and the re-refining ratio of the catalytic unit, and the process requires low temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

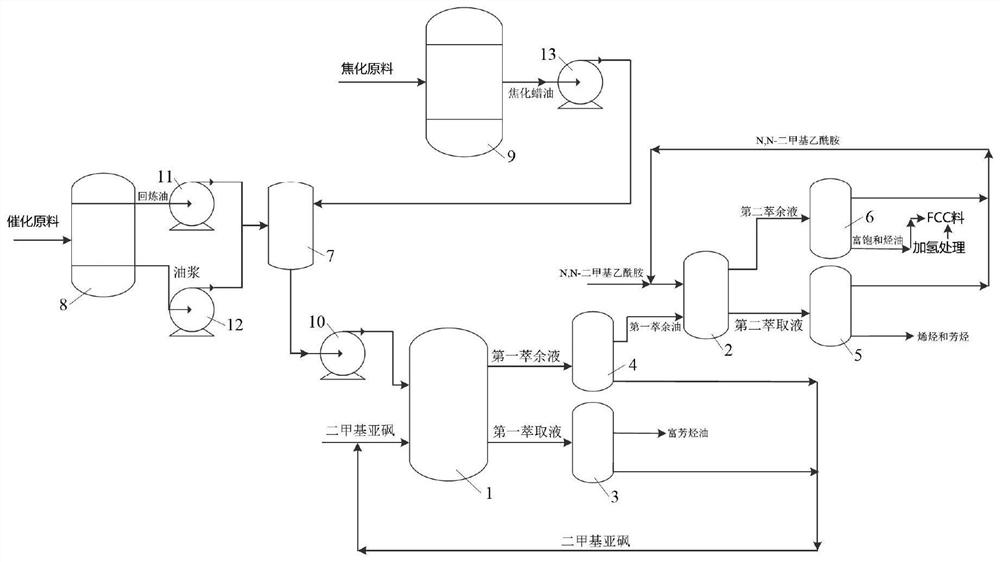

[0054] This embodiment provides a process device for preparing oil products by mixing oil slurry, re-refined oil and coker wax oil, such as figure 1 As shown, the device includes:

[0055] Primary extraction tower 1, secondary extraction tower 2, first stripping tower 3, second stripping tower 4, third stripping tower 5 and fourth stripping tower 6, mixing tank 7, catalytic cracking unit 8, delay A coking device 9 , a first delivery pump 10 , a second delivery pump 11 , a third delivery pump 12 and a fourth delivery pump 13 .

[0056] The primary extraction tower 1 is used to extract the mixed oil of catalytic cracking oil slurry, re-refined oil and coker wax oil; Aromatic oil; the second stripper 4 is used for stripping the primary raffinate obtained by the primary extraction tower 1 extraction, thereby obtaining the primary raffinate; the secondary extraction tower 2 is used for extracting the primary raffinate; the second The third stripper 5 is used for stripping the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com