Air distribution device of fluidized bed reactor

A technology of fluidized bed reactor and air distribution device, which is applied in the direction of fluidized bed combustion equipment, burning fuel in molten state, lighting and heating equipment, etc. Uneven wind and other problems, to achieve the effect of strengthening uniform air distribution, preventing hardening, and smooth slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

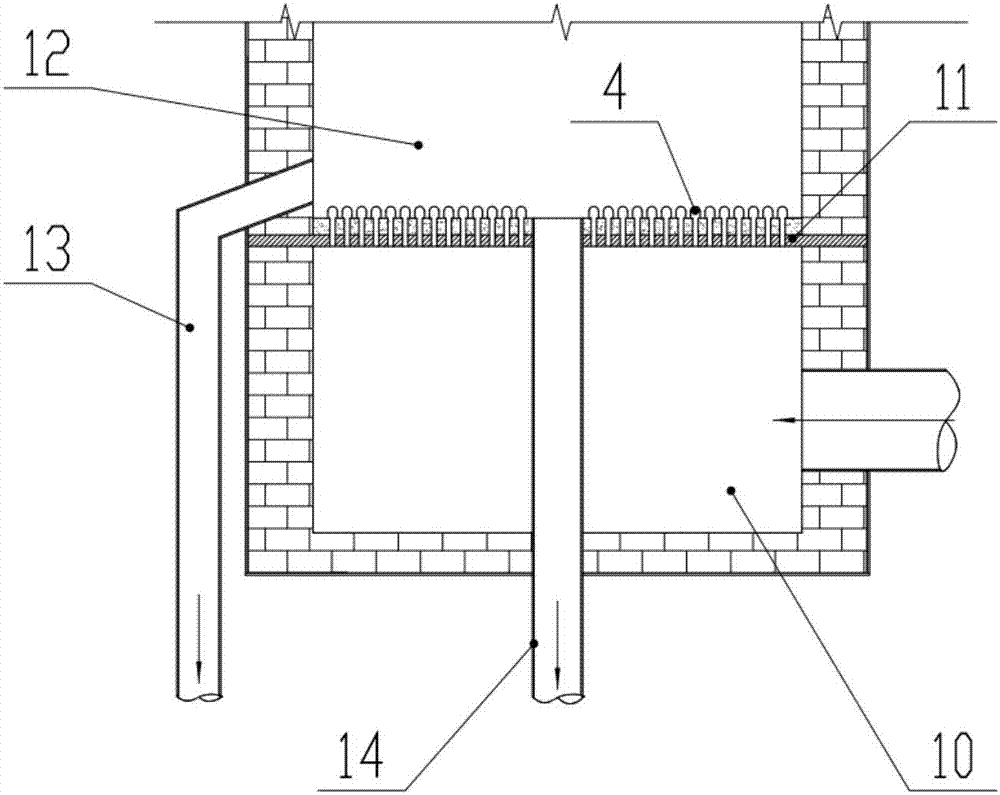

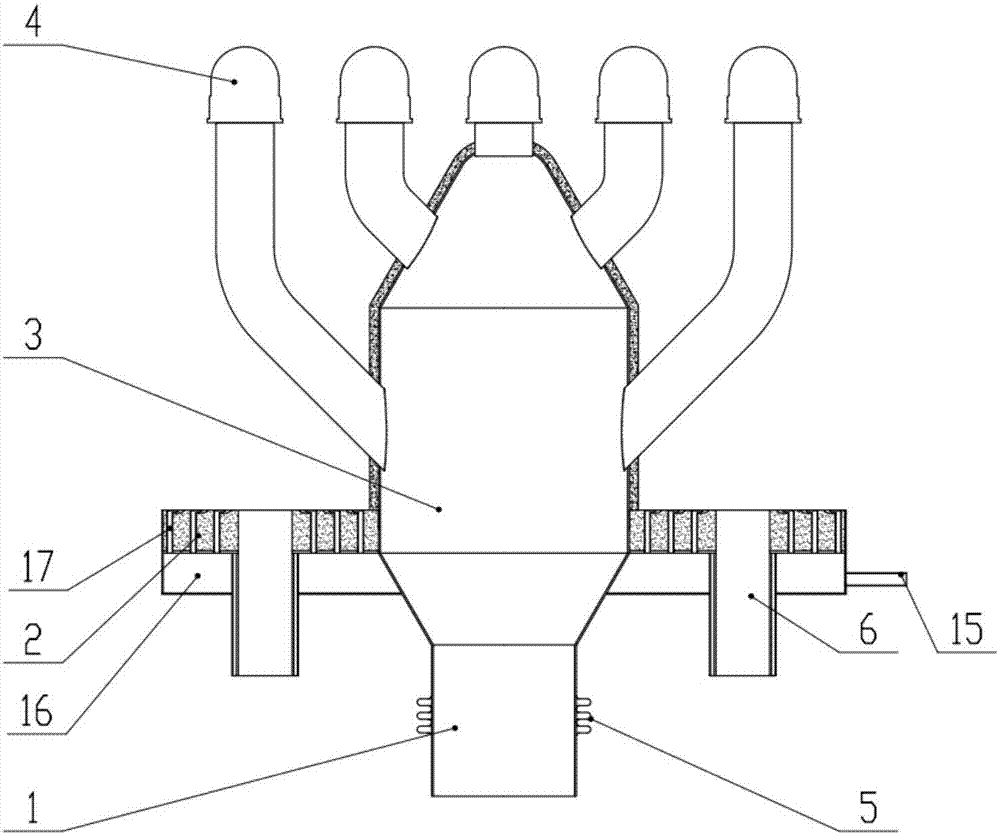

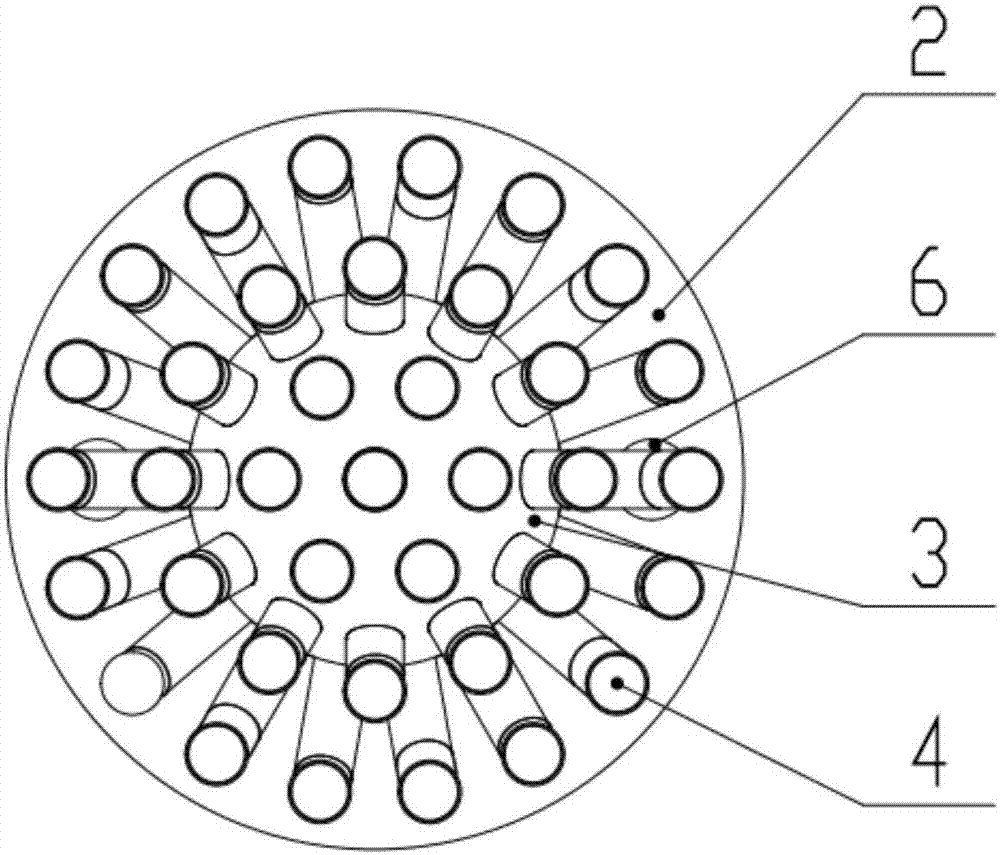

[0043] Such as figure 2 and image 3 As shown, an air distribution device for a fluidized bed reactor includes an air inlet pipe 1, a base plate 2, a gas distribution chamber 3, and a plurality of wind caps 4; the gas distribution chamber 3 is a tree structure with an inlet and a plurality of outlets, the diameters of each outlet are equal, and the axis of each outlet is parallel to the inlet; the inlet end of the gas distribution chamber 3 passes through and is fixed on the base plate 2 vertically, and it is connected to the The air inlet pipe 1 is coaxially connected, and its diameter is not smaller than the air inlet pipe 1; each outlet of the gas distribution chamber 3 is connected with one of the wind caps 4; the base plate 2 is provided with a discharge port 6.

[0044] Such as Figure 4 As shown, the coaxial connection between the inlet pipe 1 and the gas distribution chamber 3 in this embodiment avoids the bias flow of the gas, and at the same time, the gas with a ...

Embodiment 2

[0046] A kind of air distribution device of fluidized bed reactor, is basically the same as embodiment 1, difference is, as Figure 5 As shown, each outlet of the gas distribution chamber 3 has a layer of branches, which are composed of several identical branch manifolds 7; Figure 9 As shown, each of the branch manifolds 7 has a main pipe 8 and a plurality of branch pipes 9, and the outlet section of the branch pipes 9 is parallel to the axis of the main pipe 8; the diameters of each branch pipe 9 are equal, and each of the branch pipes 9 The outlet of the branch pipe 9 is flush; the wind cap 4 is arranged on the outlet of the branch pipe 9 .

[0047] In this embodiment, the gas passes through the air inlet pipe 1 through the gas distribution chamber 3 and the branch manifold 7 and finally comes out of the wind cap 4. The whole air distribution device presents a tree structure of multi-layer branch manifolds 7, which not only ensures the air distribution Uniformity, and at t...

Embodiment 3

[0049] A kind of air distribution device of fluidized bed reactor, is basically the same as embodiment 2, difference is, as Figure 6 and 7 As shown, each outlet of the gas distribution chamber 3 has a double-layer branch, and the second-layer branch replaces the air cap 4 in the second embodiment with the outlet of the branch pipe 9, and the air cap 4 is arranged at the second On the outlet of the branch pipe 9 of the branch manifold 7 in the 2-layer branch, specifically, such as Figure 8 as shown,

[0050] The outlet of the branch pipe 9 of the branch manifold 7 in the first layer of branches is coaxially connected with the inlet of the main pipe 8 of the branch manifold 7 in the second layer of branches;

[0051] The female pipe 8 described in this embodiment is a warhead structure, which is composed of a cylinder body and a head, and the head has a curved shape; the curved shape of the head is a cone or a sphere; the benefits of this feature The effect is: after the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com