A kind of preparation method of coating silver solder ring

The technology of silver brazing filler metal and coating is applied in the field of preparation of coated silver brazing filler metal ring, which can solve the problems of being easily corroded, easily oxidized, difficult to remove, etc., and achieves self-brazing effect, high activity of coating, and moisture absorption. sexually weak effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of a covered silver brazing filler metal ring, comprising the following steps:

[0025] 1. Preparation of silver solder ring

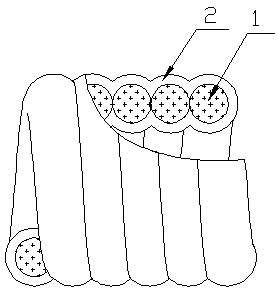

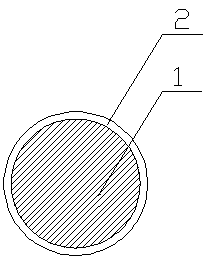

[0026] a. Add Ag 34%, Cu 35.8%, Zn 27%, Sn 1.5%, P 0.4%, Ni 1%, Ge0.15% and Li 0.15% raw materials into the intermediate frequency smelting furnace crucible according to mass percentage, through smelting, casting , extruding and drawing to obtain the silver solder wire, and the silver solder wire is prepared into a multi-circle spring-shaped silver solder ring (the inner diameter of the multi-circle spring-shaped silver solder ring is 3.0 mm, and the cross section is circular);

[0027] Adding a small amount of phosphorus into the silver solder core of the invention can lower the melting point of the solder and improve the fluidity of the solder. Adding nickel to the silver solder core can improve the strength of stainless steel joints, and adding a small amount of lithium has a self-brazing effect. The reason is that lithi...

Embodiment 2

[0037] A preparation method of a covered silver brazing filler metal ring, comprising the following steps:

[0038] 1. Preparation of silver solder ring

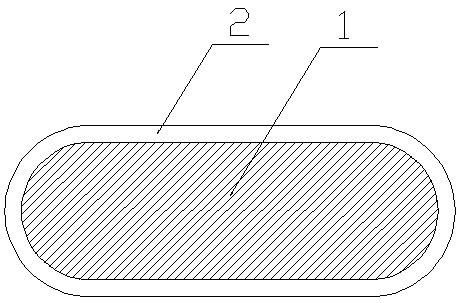

[0039] a. Add Ag 50%, Cu 32%, Zn 14%, Sn 1.75%, P 0.5%, Ni 1.5%, Ge0.1% and Li 0.15% raw materials into the intermediate frequency smelting furnace crucible according to mass percentage, through smelting, casting , extruded and drawn to obtain silver solder wire, and the silver solder wire is prepared into a multi-circle spring-shaped silver solder ring (the inner diameter of the multi-circle spring-shaped silver solder ring is 3.0mm, and the cross-section is circular or oblate shape);

[0040] b. Put the spring-shaped silver solder ring into the ultrasonic cleaning equipment, add metal cleaning agent, and degrease and clean the surface of the solder ring;

[0041] c. Prepare a pickling solution with sulfuric acid and water at a ratio of 1:10, put the decontaminated solder ring into it, and soak for 20 minutes at a tempera...

Embodiment 3

[0048] A preparation method of a covered silver brazing filler metal ring, comprising the following steps:

[0049] 1. Preparation of silver solder ring

[0050] a. Add Ag 40%, Cu 30%, Zn 25%, Sn 2.5%, P 0.5%, Ni 1.6%, Ge 0.2% and Li 0.2% raw materials into the intermediate frequency smelting furnace crucible according to mass percentage, through smelting, casting, Extrude and draw to obtain silver solder wire, and prepare silver solder wire into a multi-circle spring-shaped silver solder ring (the inner diameter of the multi-circle spring-shaped silver solder ring is 8.0mm, and the cross-section is circular or oblate );

[0051] b. Put the spring-shaped silver solder ring into the ultrasonic cleaning equipment, add metal cleaning agent, and degrease and clean the surface of the solder ring;

[0052] c. Prepare a pickling solution with sulfuric acid and water at a ratio of 1:10, put the decontaminated solder ring into it, and soak for 3 minutes at a temperature of 70°C;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com