Low pressure methanol carboxylating process to synthesize acetic acid

A technology of oxo synthesis and acetic acid, which is applied in the preparation of carboxylic acid by carbon monoxide reaction, organic chemistry, etc., can solve the problems of not being able to increase production capacity more greatly, and the concentration of rhodium complexes is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

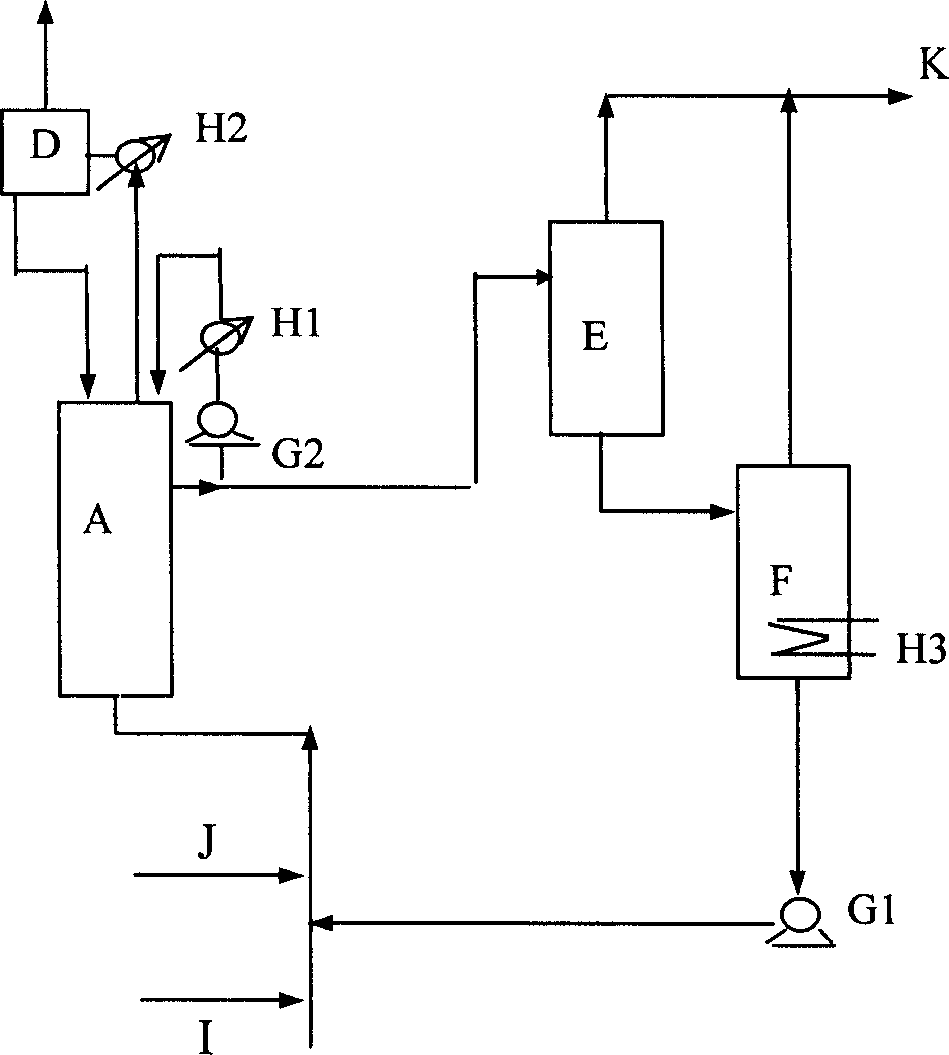

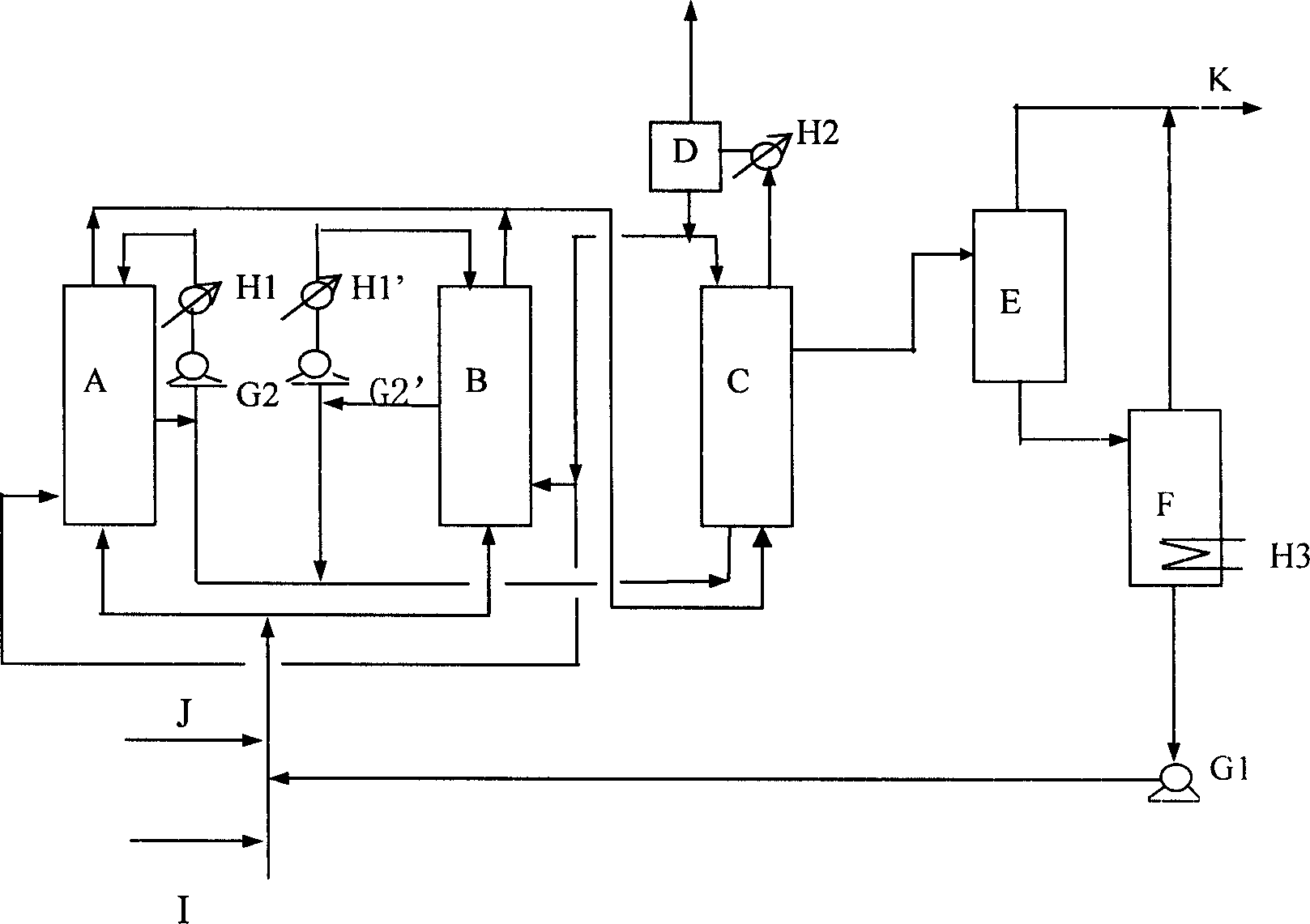

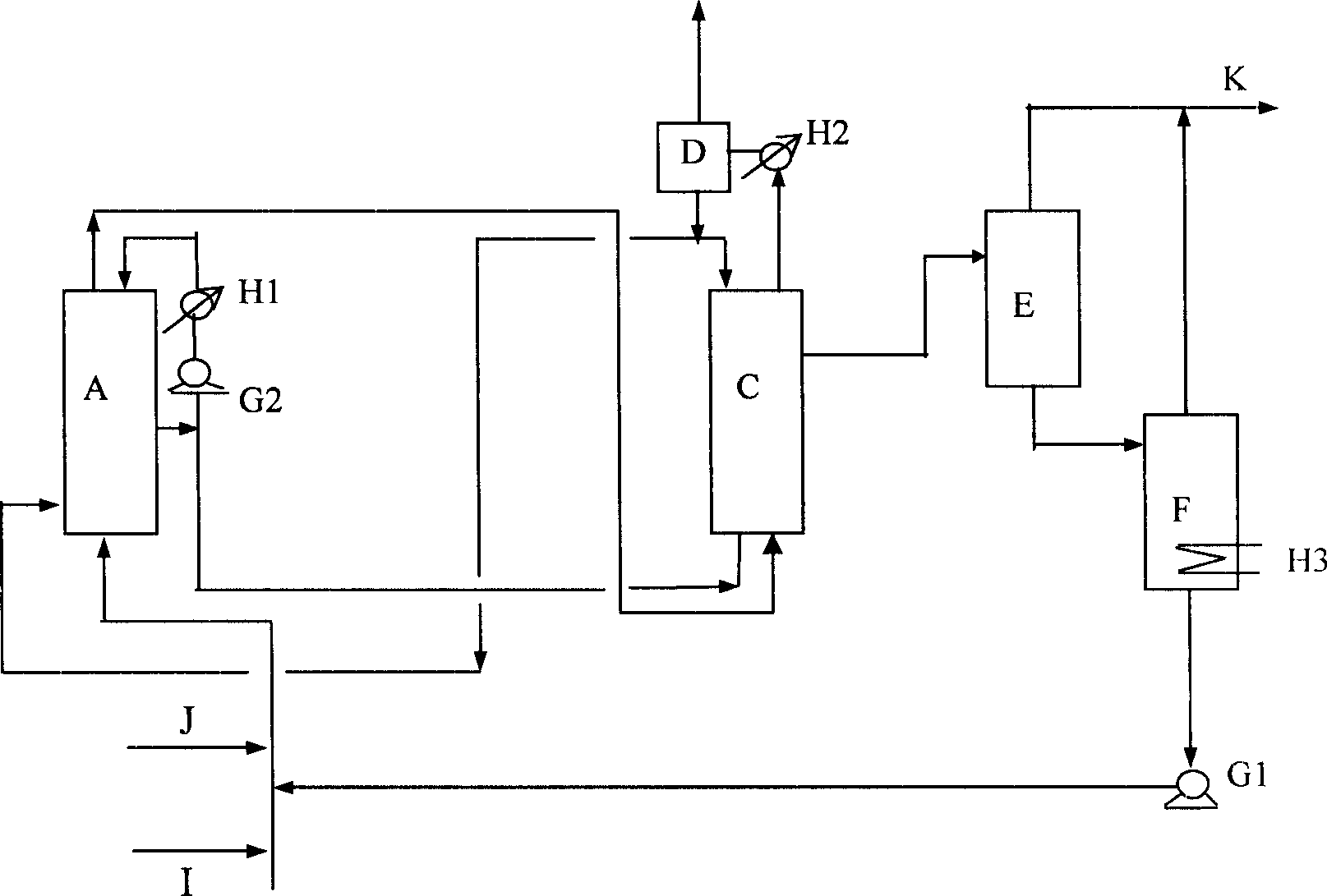

Image

Examples

Embodiment 1

[0029] Methanol 6%, rhodium 300ppm, methyl iodide 10%, hydrogen iodide 1%, water 5%, morpholine, the molar ratio of morpholine and rhodium is 1:1, and the rest is acetic acid.

Embodiment 2

[0031] Methanol 10%, rhodium 400ppm, methyl iodide 14%, hydrogen iodide 1%, water 8%, formylmorpholine, the molar ratio of formylmorpholine and rhodium is 30:1, and the rest is acetic acid.

Embodiment 3

[0033] Methanol 10%, rhodium 700ppm, methyl iodide 12%, hydrogen iodide 1%, water 7%, acetylmorpholine, lithium iodide, the molar ratio of acetylmorpholine and lithium iodide to rhodium is 70:1, and the rest is acetic acid .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com