An energy-saving ultra-large-scale methanol synthesis method and device for producing different grades of steam

A methanol synthesis, ultra-large-scale technology, used in bulk chemical production, chemical instruments and methods, hydroxyl compound preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

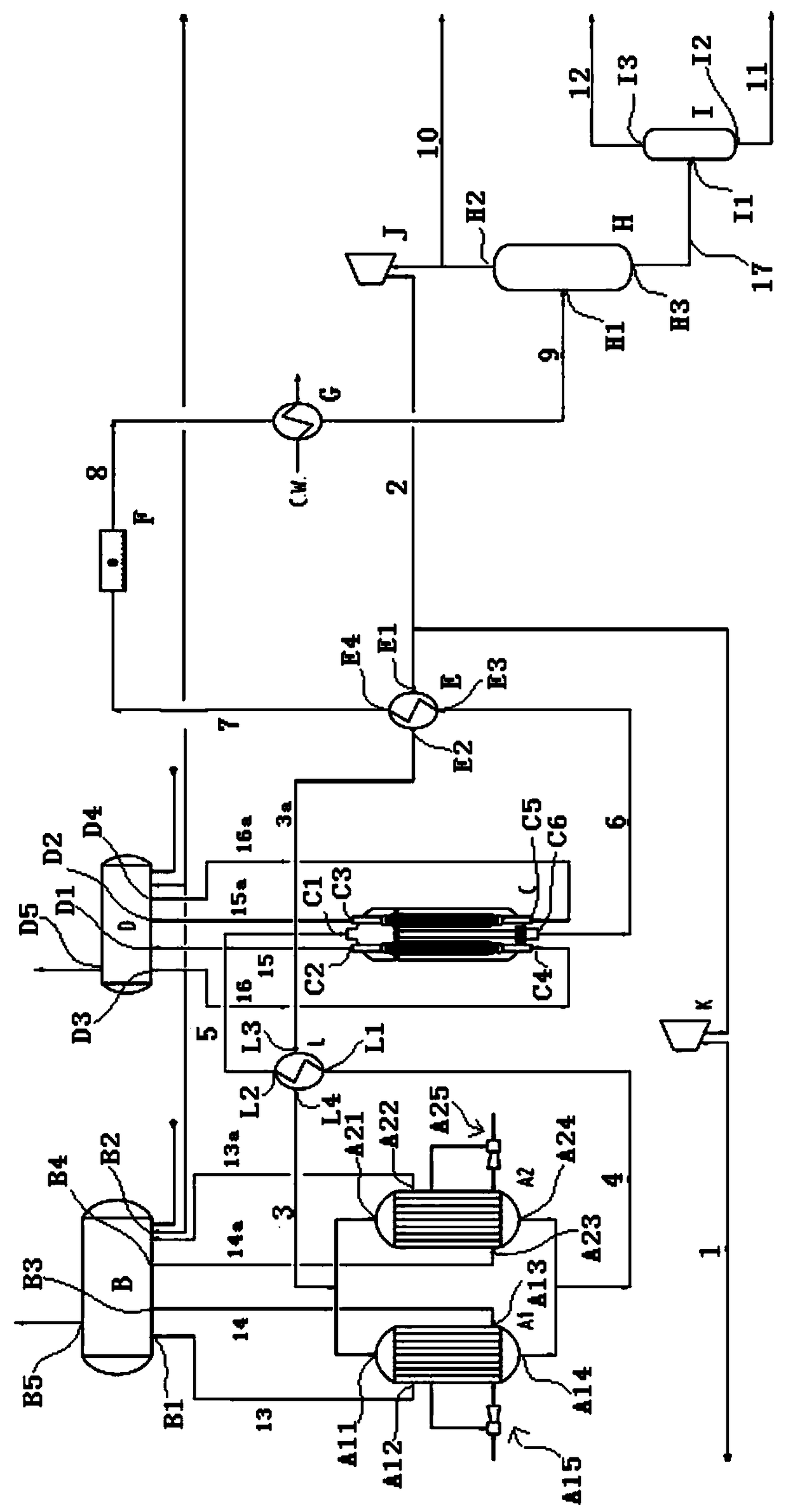

Embodiment 1

[0089] see figure 1 , the energy-saving ultra-large-scale methanol synthesis plant for producing different grades of steam shown in the figure includes two water-cooled methanol reactors A1 and A2, a methanol reactor C with another structure, and two vapor-liquid separators B , D, one gas-liquid separator H, one compressor K, two gas-gas heat exchangers L, E, one air cooler F, one water-cooled heat exchanger G, one circulating compressor J, one Taiwan decompression flash tank I.

[0090] Water-cooled methanol reactors A1 and A2 are equipped with mixed gas inlets A11 and A21 on the top, gas-liquid mixture outlets A12 and A22 on the upper part, separated water return ports A13 and A23 on the lower part, and unreacted synthesis gas and methanol at the bottom Steam mixture outlets A14 and A24, and heating devices A15 and A25 for start-up are also arranged at the lower part of the water-cooled methanol reactors A1 and A2. A number of reaction tubes are arranged in the water-coole...

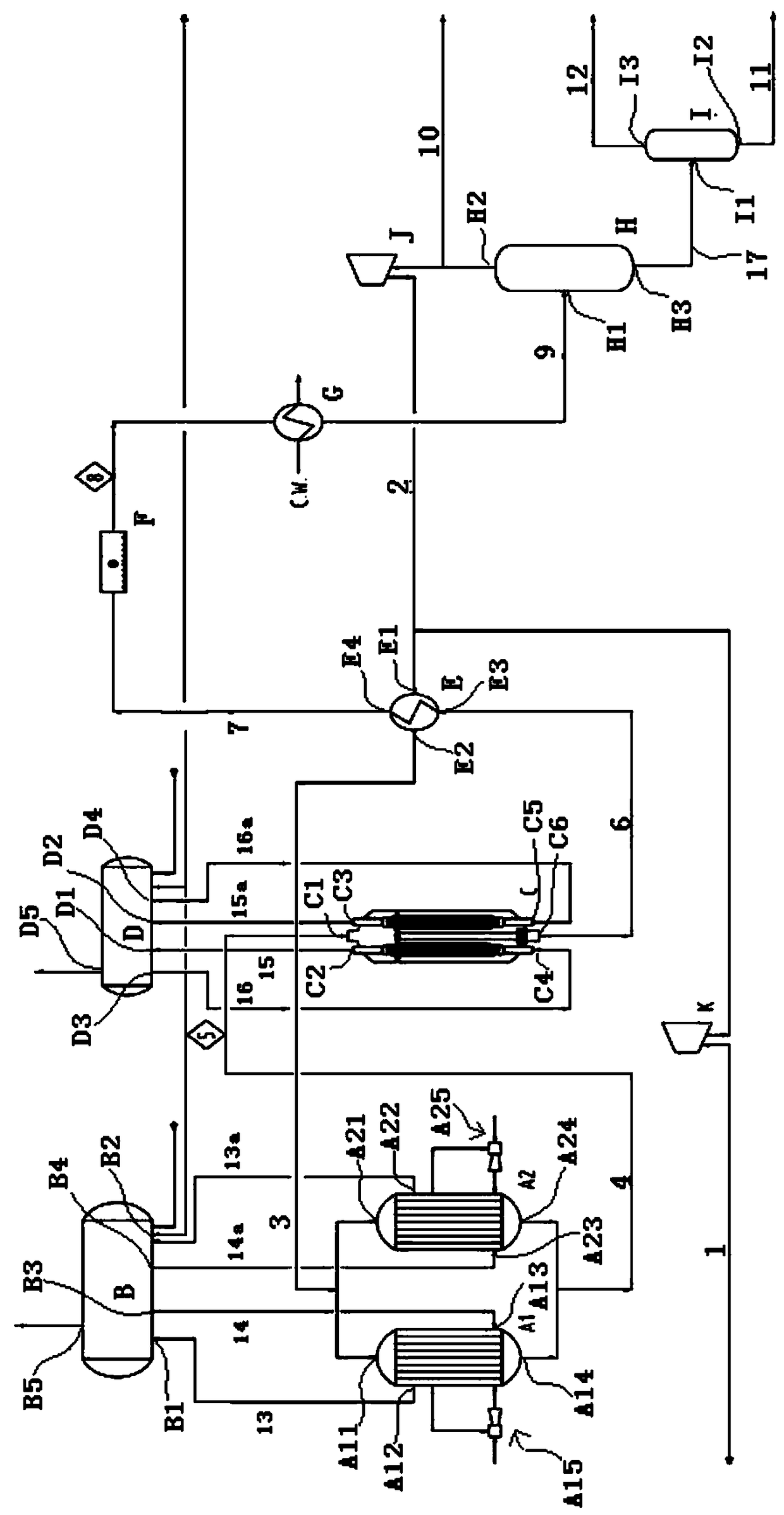

Embodiment 2

[0112] see figure 2 , the difference between the energy-saving ultra-large-scale methanol synthesis device for producing different grades of steam in the figure and the embodiment 1 is that the gas-gas heat exchanger L is canceled, the unreacted synthesis gas at the bottom of the water-cooled methanol reactor A1, A2 and Methanol vapor mixture outlets A14, A24 are directly connected with the unreacted synthesis gas and methanol vapor mixture inlet C1 at the top of methanol reactor C of another structural form through the unreacted synthesis gas and methanol vapor mixture delivery pipe 4. The mixed gas outlet E2 of the gas heat exchanger E is directly connected to the mixed gas inlets A11 and A21 at the top of the water-cooled methanol reactors A1 and A2 through the mixed gas delivery pipe 3 .

[0113] The fresh gas enters the compressor K through the fresh gas delivery pipe 1, the pressure rises to 7.9MPag, and then mixes with the circulating gas from the circulating gas deliv...

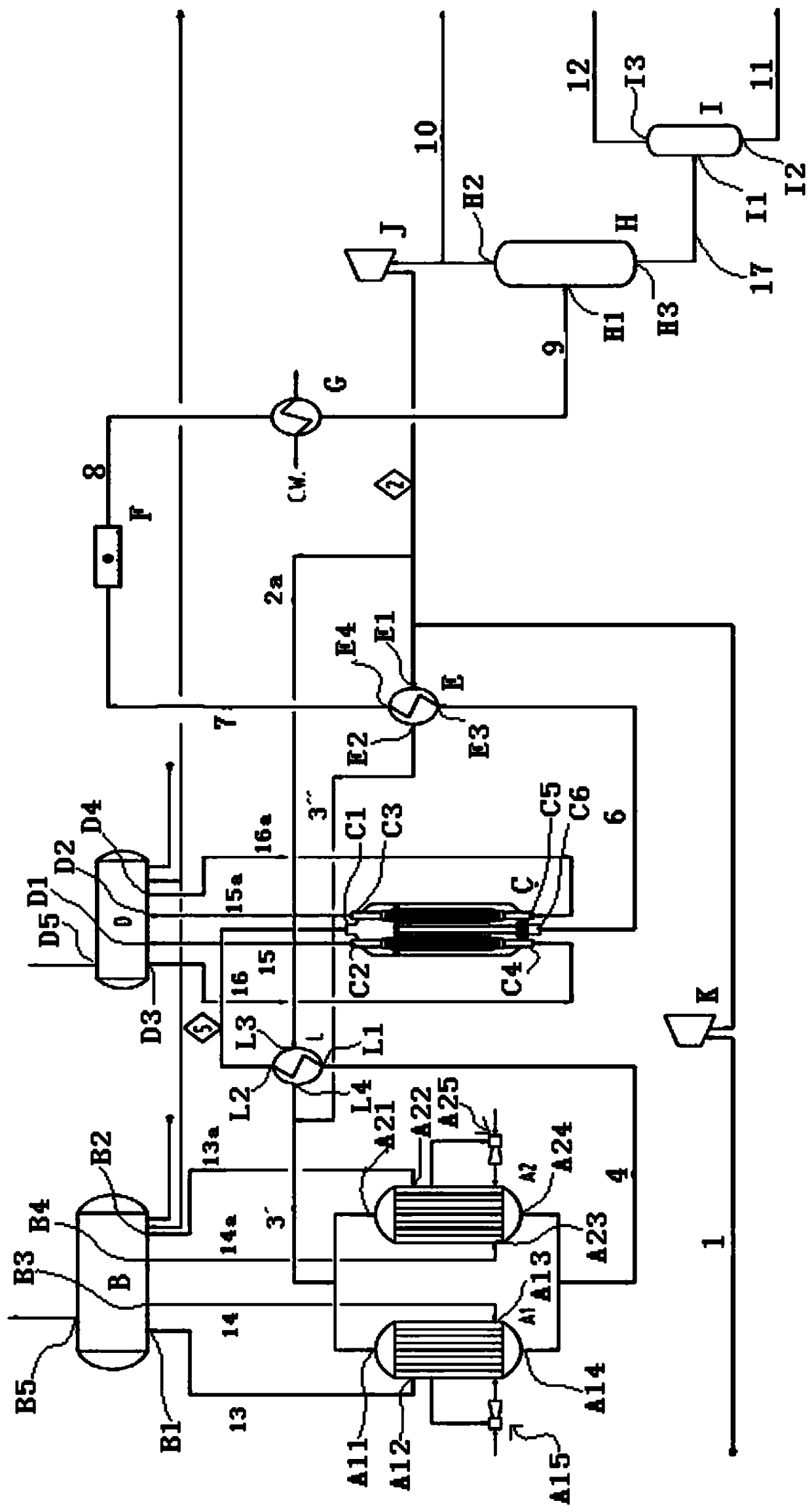

Embodiment 3

[0121] see image 3 , the difference between the energy-saving ultra-large-scale methanol synthesis plant producing different grades of steam shown in the figure and Example 1 is that the gas-gas heat exchanger L has an inlet L1 for unreacted synthesis gas and methanol steam mixture, and an inlet L1 for unreacted synthesis gas. Gas and methanol vapor mixture outlet L2, recycle gas inlet L3', recycle gas outlet L4', recycle gas delivery pipe 2 is also connected with recycle gas inlet L3' of gas-gas heat exchanger L through a recycle gas delivery pipe 2a, gas The recycle gas outlet L4' of the heat exchanger L is connected to the mixed gas inlets A11 and A21 at the top of the water-cooled methanol reactors A1 and A2 through the mixed gas delivery pipe 3', and the mixed gas outlet E2 of the gas-gas heat exchanger E is transported through the mixed gas The pipe 3" is connected with the mixed gas delivery pipe 3'.

[0122] The fresh gas enters the compressor K through the fresh gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com