Method for preparing diesel oil component or jet fuel component by using animal and plant oil

A technology for animal and vegetable oils and jet fuels, which is used in the preparation of liquid hydrocarbon mixtures, biological raw materials, and the petroleum industry. high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

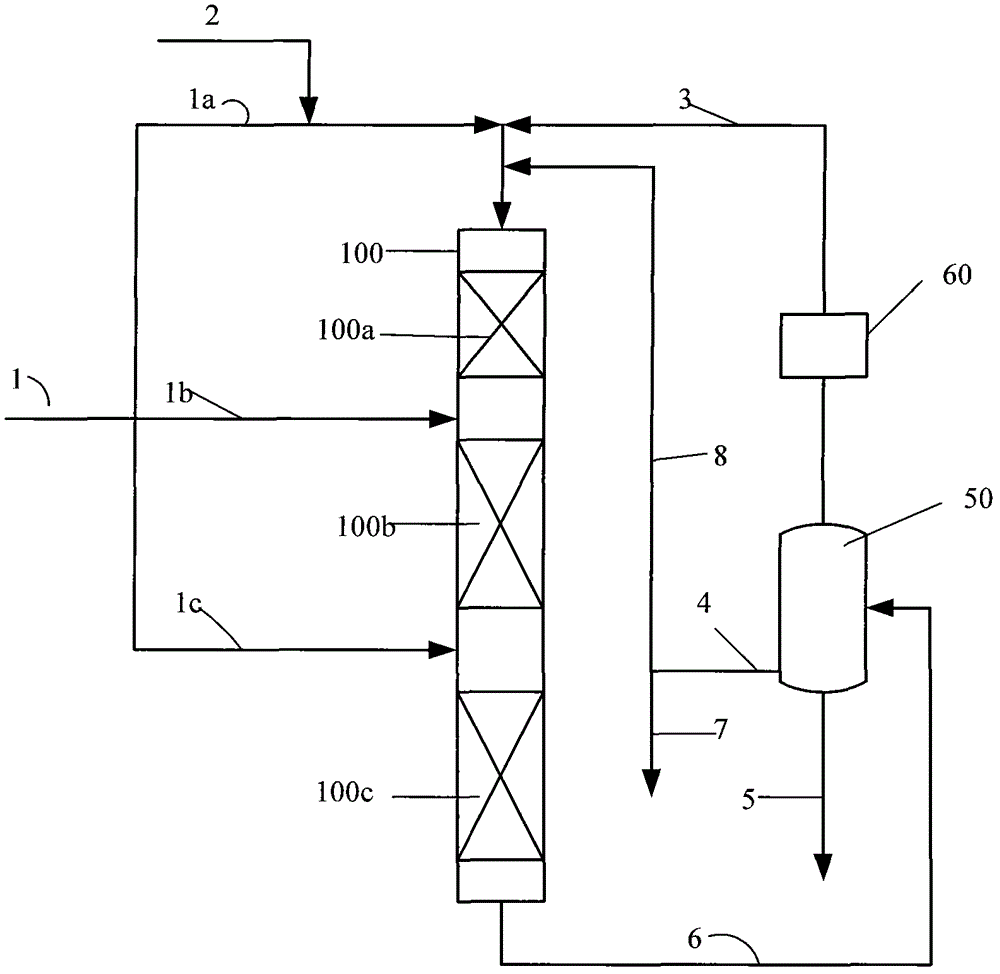

[0059] (1) Hydrodeoxygenation: take palm oil obtained through traditional vegetable oil refining methods as raw material, and add thiophene with a sulfur content of 1000ppm to the raw material. The first hydrogenation reactor was loaded with RN-10 catalyst. Among them, the catalyst is loaded in two stages, the loading amount of the first stage of the catalyst is 45%, the raw material is divided into two feeds, and the ratio of the first feed is 45%; the normal paraffin part obtained by hydrodeoxygenation is used as the circulating oil It returns to the first hydrogenation reactor together with the raw material, and the volume ratio of the circulating oil to the raw material is less than 1.8:1. Then the dilution ratio of each catalyst zone is 4:1. After palm oil is completely deoxygenated, it is mainly normal alkanes with 13-20 carbon atoms.

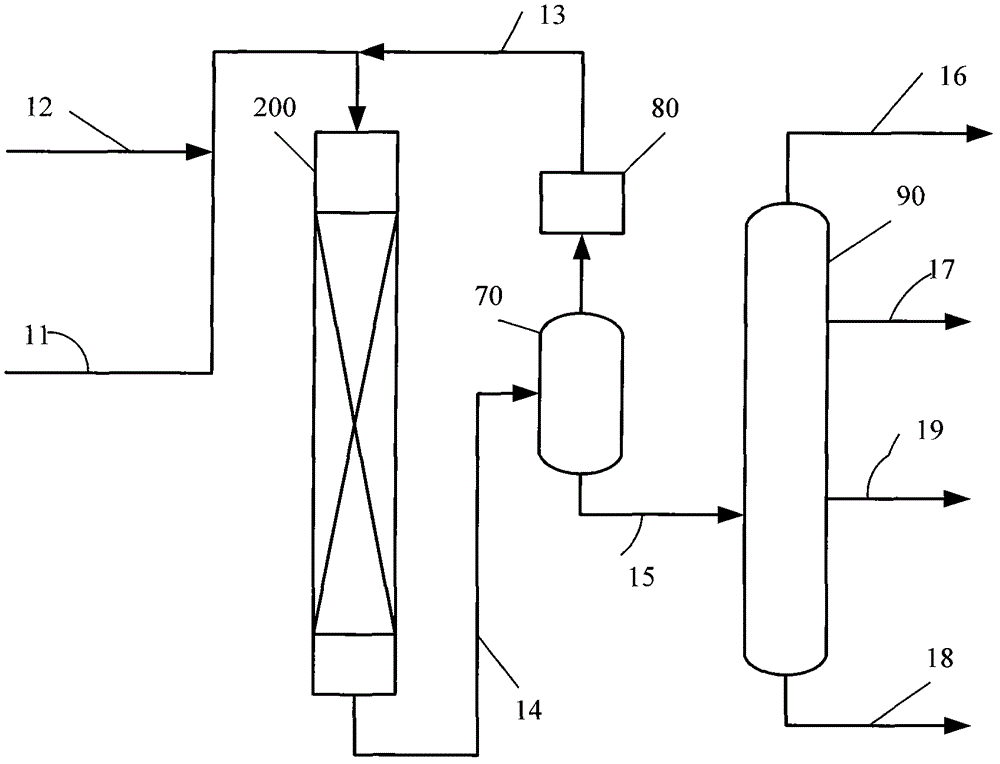

[0060] (2) Hydroisomerization: catalyst A is filled in the second hydrogenation reactor, and the n-alkanes of 13 to 20 after hydrodeox...

Embodiment 2

[0063] (1) The catalyst used in the hydrodeoxygenation process and the raw oil are the same as the step (1) of embodiment 1, the difference is that the catalyst is packed in three stages, the loading of the first stage of the catalyst is 30%, and the filling of the second stage The amount is 35%, and the rest is the third paragraph. The raw material is divided into 3 feeds, the ratio of the first feed is 30%, and the ratio of the second feed is 35%; For the hydrogen reactor, the volume ratio of circulating oil to raw material is 1.8:1. Then the dilution ratio of each catalyst zone is 6:1. After palm oil is completely deoxygenated, it is mainly normal alkanes with 13-20 carbon atoms.

[0064] (2) Hydroisomerization: Catalyst A is filled in the second hydrogenation reactor, and the n-alkanes and hydrogen of 13 to 20% after hydrodeoxygenation obtained in step (1) are introduced into the second hydrogenation reactor, and hydrogenation The isomerization reaction is carried out u...

Embodiment 3

[0067] The hydrodeoxygenation process of step (1) and the selective cracking and isomerization process of step (2) are all the same as in Example 1, except that the reaction raw material is a mixture of palm oil and lard, wherein palm oil and lard The weight ratio is 80:20. After the reaction, the stream is subjected to fractional distillation to obtain a diesel component with a cold filter point of -6°C. The properties of raw materials are shown in Table 1, and the properties of operating conditions and products are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com