Neutralization process for ammonia in a mother liquor used for producing nitric acid phosphate fertilizer

A technology for nitrophosphate fertilizer and mother liquor, which is applied in the field of ammonia neutralization technology of nitrophosphate fertilizer mother liquor, can solve the problems of harsh operating environment, large loss of ammonia escaping, and material in the neutralization tank, so as to improve the absorption efficiency, reduce the process cycle ratio, The effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

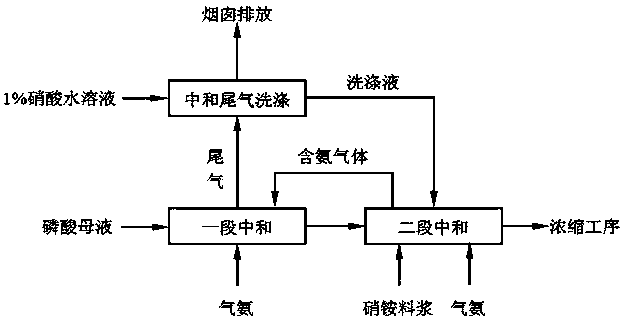

[0050] Implement a kind of mother liquid ammonia neutralization process of producing nitrophosphate fertilizer, wherein neutralization process flow is as figure 1 As shown, the specific process steps are as follows:

[0051] 1. A period of neutralization

[0052] Carry out the reaction of mother liquor and ammonia in a normal-pressure reaction tank, the addition of gas ammonia is 50% of the total amount of gas ammonia required for neutralization, and prepares acidic slurry with pH=1.6-2.0;

[0053] 2. Two-stage neutralization

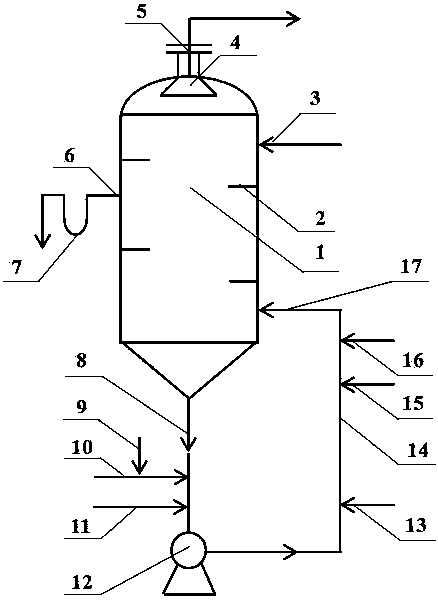

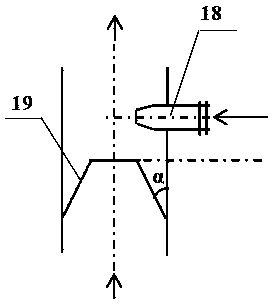

[0054] The two-stage neutralization process is carried out in a forced circulation tubular reactor, such as figure 2 with image 3 , this process adopts a multi-point feeding method, the acid slurry from the first stage of neutralization is divided into two, 50% of the acid slurry is added from the first stage of the neutralization slurry inlet I11, and 50% of the acidic slurry is fed from the first stage of the neutralization slurry The inlet II15...

Embodiment approach 2

[0061] Implement a kind of mother liquid ammonia neutralization process of producing nitrophosphate fertilizer, its technological process is as follows figure 1 As shown, the concrete process steps are as follows:

[0062] 1. A period of neutralization

[0063] Reaction of mother liquid and ammonia gas is carried out in a normal pressure reaction tank, the amount of gas ammonia added is 50% of the total amount of gas ammonia required for neutralization, and acid slurry with pH=1.6-2.0 is prepared.

[0064] 2. Two-stage neutralization

[0065] The two-stage neutralization process is carried out in a forced circulation tubular reactor, such as figure 2 with image 3 , this process adopts a multi-point feeding method, the acid slurry from the first stage of neutralization is divided into two, 50% of the acid slurry is added from the first stage of the neutralization slurry inlet I11, and 50% of the acidic slurry is fed from the first stage of the neutralization slurry The in...

Embodiment approach 3

[0072] Implement a kind of mother liquid ammonia neutralization process of producing nitrophosphate fertilizer, its technological process is as follows figure 1 As mentioned, the specific steps are as follows:

[0073] 1. A period of neutralization

[0074] Reaction of mother liquid and ammonia gas is carried out in a normal pressure reaction tank, the amount of gas ammonia added is 50% of the total amount of gas ammonia required for neutralization, and acid slurry with pH=1.6-2.0 is prepared.

[0075] 2. Two-stage neutralization

[0076] The second-stage neutralization device is carried out in a forced circulation tubular reactor, such as figure 2 with image 3 , this process adopts a multi-point feeding method, the acid slurry from the first stage of neutralization is divided into two, 50% of the acidic slurry is added from the first stage of the neutralization slurry inlet I11, and 50% of the acidic slurry is fed from the first stage of the neutralization slurry Slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com