Technology for preparing synthetic natural gas through methanation of coal-based synthetic gas

A technology for synthesizing natural gas and coal-based synthesis, applied in the petroleum industry, gas fuels, fuels, etc., can solve the problems of high price, complicated reactor manufacturing, long time consumption, etc., so as to reduce wasted time and reduce the number of reactors. Number, the effect of improving the refining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

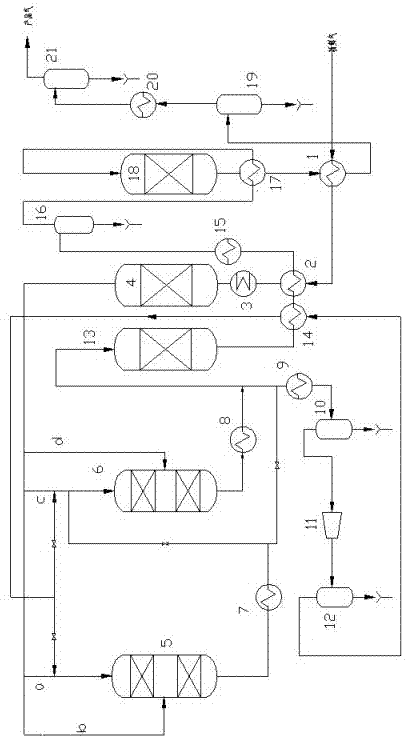

[0033] as attached figure 1 As shown, the 3.0MPa, 40°C methane synthesis gas from the gas purification section rises to 172°C after heat exchange with the three-reverse air cooler 1, and then rises to 290°C after heat exchange with the second-reverse air cooler 2 , after being purified by fine desulfurization reactor 4, the total sulfur is less than 0.1*10 -6 and f = (n H2 -n CO2 ) / (n CO +n CO2 )=2.8~3.1 The fresh air is divided into four streams (fresh air a, b, c, d), the temperature is 285°C. Among them, the fresh gas a and the recycle gas are mixed to form a section of intake air, which enters the first section of the first methane synthesis reactor A 5 (one reaction A). The gas inlet temperature is 285°C, and the temperature rises to about 534°C after the reaction. After the gas b is mixed, it forms a second-stage intake air and enters the second stage of the first reaction A. The inlet temperature is about 488°C, and the temperature rises to about 661°C after the r...

Embodiment 2

[0039] as attached figure 1 As shown, the 1.0MPa, 40°C methane synthesis gas from the gas purification section rises to 177°C after heat exchange with the three-reverse air cooler 1, and then rises to 295°C after heat exchange with the second-reverse air cooler 2 , after being purified by fine desulfurization reactor 4, the total sulfur is less than 0.1*10 -6 and f = (n H2 -n CO2 ) / (n CO +n CO2 )=2.8~3.1 The fresh air is divided into four streams (fresh air a, b, c, d), the temperature is 290 ℃. Among them, the fresh gas a and the circulating gas are mixed to form a section of intake air, which enters the first section of the first methane synthesis reactor A 5 (one reaction A). The gas inlet temperature is 290°C, and the temperature rises to about 537°C after the reaction. After the gas b is mixed, it forms a second-stage air inlet and enters the second stage of the first reaction A. The inlet temperature is about 485°C, and the temperature rises to about 658°C after the...

Embodiment 3

[0041] as attached figure 1 As shown, the 7.5MPa, 40°C methane synthesis gas from the gas purification section rises to 166°C after heat exchange with the three-reverse air cooler 1, and then rises to 285°C after heat exchange with the second-reverse air cooler 2 , after being purified by fine desulfurization reactor 4, the total sulfur is less than 0.1*10 -6 and f = (n H2 -n CO2 ) / (n CO +n CO2 )=2.8~3.1 The fresh air is divided into four streams (fresh air a, b, c, d), the temperature is 280 ℃. Among them, the fresh gas a and the recycle gas are mixed to form a section of intake air, which enters the first section of the first methane synthesis reactor A 5 (one reaction A). The gas inlet temperature is 280°C, and the temperature rises to about 524°C after the reaction. After the gas b is mixed, it forms a second-stage intake air and enters the second stage of the first reaction A. The inlet temperature is about 469°C, and the temperature rises to about 636°C after the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com