Combined Bed Methanol to Gasoline Process

A methanol-to-gasoline and combined-bed technology is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, and biological raw materials. process, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

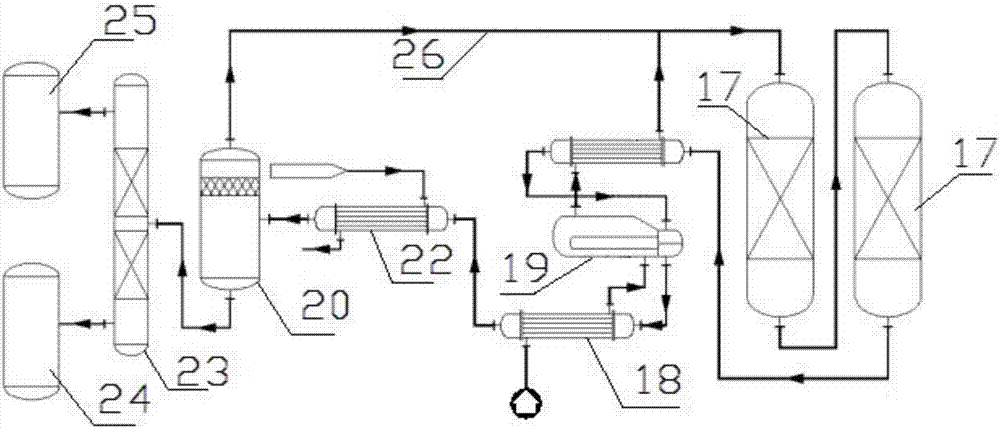

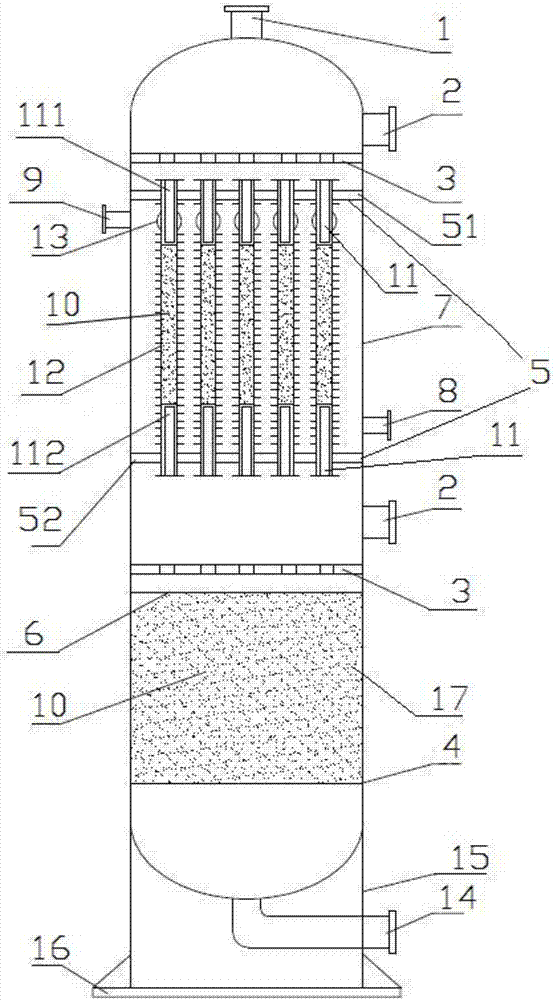

[0034] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

[0035] Referring to the accompanying drawings, it can be seen that the combined bed methanol-to-gasoline process comprises the following process steps:

[0036] Step 1: preheating the raw material methanol through a preheater 18;

[0037] Step 2: input the preheated raw material methanol into the evaporator 19, and the gasification temperature is 120-160°C, so that the raw material methanol reaches a complete gasification state;

[0038] Step 3: The gasification raw material methanol output in the evaporator 19 and the recycle gas 26 output by the gas-liquid separator 20 are input into the combined constant temperature reactor 21 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com