Phosphorus-containing flame retardant based on polyhedral oligomeric silsesquioxane (POSS) and preparation method of phosphorus-containing flame retardant

A polysilsesquioxane and flame retardant technology, which is applied in the field of flame retardant materials, can solve the problems of low flame retardant efficiency, large proportion of flame retardant silicone rubber, and low decomposition temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

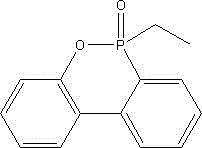

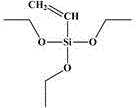

[0028] 1) Vacuum dry 216g DOPO at 110°C for 8 hours, completely dissolve the dried DOPO with N,N-dimethylformamide, put it in a high-pressure reactor, pass through nitrogen protection and mechanically stir for 3 hours;

[0029] 2) Add an isopropanol solution of chloroplatinic acid (1% mass fraction of chloroplatinic acid) into the above autoclave, raise the temperature to 80°C, and keep stirring for 0.5 hours;

[0030] 3) Slowly add 228g of VTES dropwise into the above autoclave, keep the temperature at 80°C, and keep stirring for 25 hours. To obtain a phase-separated solution, take the light yellow liquid in the upper layer, distill under reduced pressure, and remove the solvent to obtain the adduct DOPO-VTES, with a yield of 88%.

[0031] 4) Add 150g DOPO-VTES into the reaction vessel equipped with a condenser, raise the temperature to 40~80°C, add 3g of 37% concentrated hydrochloric acid dropwise, continue to stir, the stirring speed is 50r / min, the stirring time is 30h, af...

Embodiment 2

[0033] 1) Vacuum dry 216g DOPO at 110°C for 4 hours, completely dissolve the dried DOPO with isopropanol, put it in a high-pressure reactor, pass through nitrogen protection and stir mechanically for 3 hours;

[0034] 2) Add platinum-tetrahydrofuran complex into the above autoclave, raise the temperature to 90°C, and keep stirring for 0.4 hours;

[0035] 3) Slowly add 190g of VTES dropwise into the above autoclave, keep the temperature at 90°C and keep stirring for 20 hours. To obtain a phase-separated solution, take the light yellow liquid in the upper layer, distill under reduced pressure, and remove the solvent to obtain the adduct DOPO-VTES, with a yield of 80%.

[0036] 4) Add 150g DOPO-VTES into a reaction vessel equipped with a condenser, raise the temperature to 70°C, add 1.75g 85% concentrated phosphoric acid dropwise, continue stirring at a stirring speed of 50r / min for 20h, after cooling, suction filter to obtain a white powder, After washing with deionized water...

Embodiment 3

[0038] 1) Vacuum dry 216g DOPO at 110°C for 8 hours, completely dissolve the dried DOPO with 1,4-dioxane, put it in a high-pressure reactor, pass through nitrogen protection and stir mechanically for 3 hours;

[0039] 2) Add platinum(0)-1,3-diethylene-1,1,3,3-tetramethyldisiloxane complex into the above autoclave, raise the temperature to 85°C, and keep stirring for 0.8 hours ;

[0040] 3) Slowly add 202g of VTES dropwise into the above autoclave, keep the temperature at 85°C, and keep stirring for 25 hours. To obtain a phase-separated solution, take the light yellow liquid in the upper layer, distill under reduced pressure, and remove the solvent to obtain the adduct DOPO-VTES, with a yield of 79%.

[0041] 4) Add 150g DOPO-VTES into the reaction vessel equipped with a condenser, raise the temperature to 75°C, add 2g of 65% concentrated nitric acid dropwise, continue stirring at a stirring speed of 50r / min for 25h, after cooling, suction filter to obtain a white powder, use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com