Preparation method of porous magnetic polystyrene microspheres

A technology of polystyrene microspheres and polyvinylpyrrolidone is applied in the direction of magnetism of organic materials/organic magnetic materials to achieve uniform distribution, uniform distribution of micropores and good shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

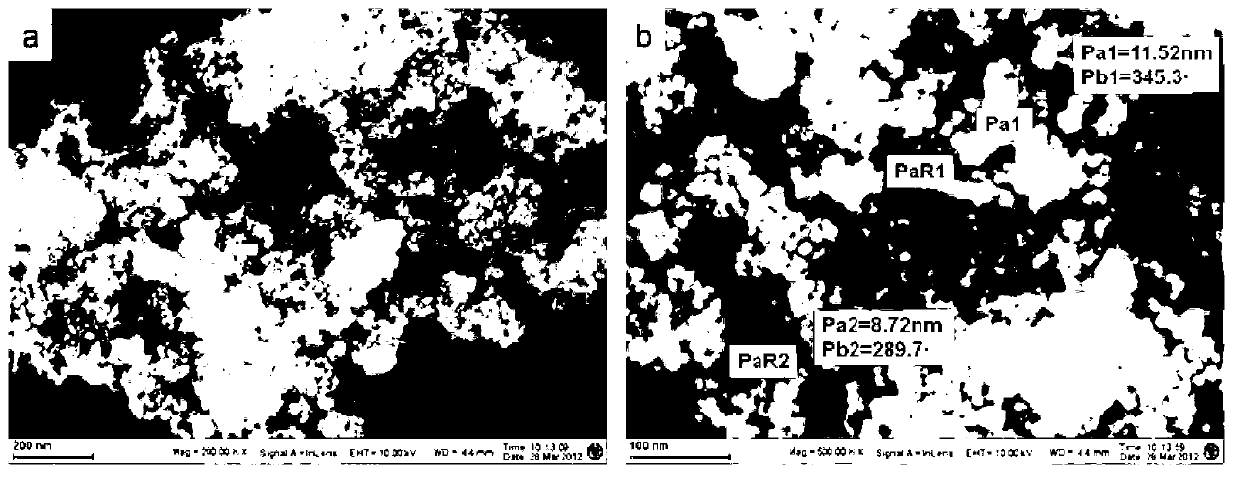

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation of material.

[0031] Refining of styrene: wash repeatedly with 200ml 5wt% NaOH aqueous solution until colorless to remove polymerization inhibitor, wash with distilled water three times, then add anhydrous CaCl 2 Dry and store in brown bottles for later use.

[0032] Refining of benzoyl peroxide (BPO): Dissolve 10g of BPO in 50ml of chloroform and stir to dissolve, filter, drop the filtrate into 100ml of methanol, put it in the refrigerator to stand still, and obtain white needle crystals, wash with a small amount of cold methanol three times, vacuum at room temperature Dry for 10 hours, put into a brown jar, and keep refrigerated for later use.

[0033] Fe 3 o 4 Preparation of magnetic nanoparticles: 4.28g FeCl 2 4H 2 O, 11.70gFeCl 3 ·6H 2 O was dissolved in 180ml of water, stirred and dissolved, and the temperature was raised to 60°C after passing through nitrogen to drive oxygen for 0.5h, and 20.0ml of NH 3 ·H 2 O, the system c...

Embodiment 2

[0034] Example 2: Preparation of porous magnetic polystyrene microspheres.

[0035] Specifically include the following steps:

[0036] (1) get the dry Fe prepared by 0.8g embodiment 1 3 o 4 Magnetic nanoparticles were added to 100ml 50(v / v)% ethanol aqueous solution, and then the mixture was ultrasonically treated for 30min, and 1ml vinyltriethoxysilane was gradually added dropwise until the dissolved Fe 3 o 4in the suspension. Afterwards, transfer to the 250m1 three-neck flask, under N 2 Under protection, it was rapidly stirred at 40°C for 12 hours and aged at a constant temperature. The obtained product was washed three times with absolute ethanol and twice with deionized water, then dried under vacuum at 40° C., and ground into powder.

[0037] (2) Take 0.5g of the powder obtained in step (1) and 0.2g of purified BPO, add it to a test tube containing 6ml of styrene, 2ml of toluene, 1ml of n-heptane and 0.5ml of DVB cross-linking agent, place Ultrasonic mixing in ultr...

Embodiment 3

[0041] Specifically include the following steps:

[0042] (1) get the dry Fe prepared by 1g embodiment 1 3 o 4 Magnetic nanoparticles were added to 100ml 40(v / v)% ethanol aqueous solution, then the mixture was ultrasonically treated for 20min, and 2ml vinyltriethoxysilane was gradually added dropwise until the dissolved Fe 3 o 4 in the suspension. Afterwards, transfer to the 250m1 three-neck flask, under N 2 Under protection, it was rapidly stirred at 50°C for 24 hours and aged at a constant temperature. The obtained product was washed three times with absolute ethanol and three times with deionized water, then vacuum-dried at 60° C., and ground into powder.

[0043] (2) Take 0.34g of powder obtained in step (1) and 0.17g of purified BPO, add it to a test tube containing 8ml of styrene, 2ml of toluene, 1ml of n-heptane and 0.5ml of DVB cross-linking agent, place Ultrasonic mixing in ultrasound for 0.5h.

[0044] (3) Measure 100ml of deionized water into a 150ml beaker, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com