Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Reduce energy consumption for refining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method and application of complex enzyme liquid for chemi-mechanical pulping

ActiveCN103555702AHigh whitenessImprove qualityHydrolasesOxidoreductasesPectinaseEnzymatic hydrolysis

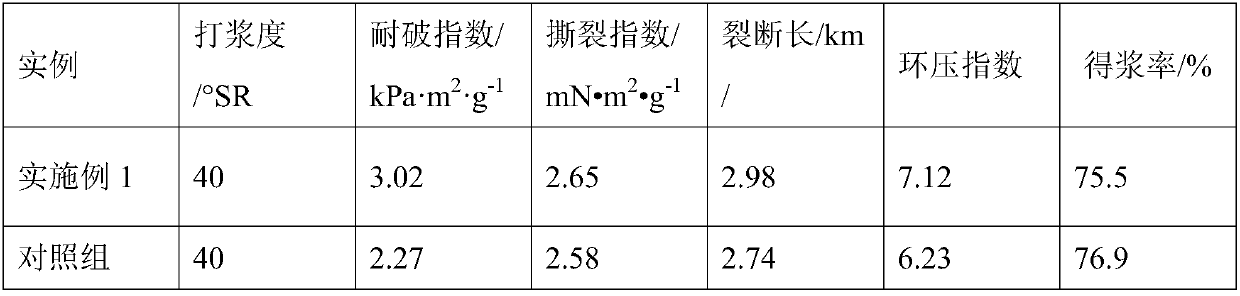

The invention discloses a production method of a complex enzyme liquid for chemi-mechanical pulping. The production method is characterized by comprising the following steps: weighing various component enzymes, mixing and compounding the various component enzymes in a compounding tank, preventing corrosion, inspecting, packaging and storing in a storeroom at 5 DEG C, wherein the various component enzymes comprise alkaline pectinase, xylanase, mannose and ligninase. The application of the complex enzyme liquid in chemi-mechanical pulping is realized as follows: before steaming paper-making raw materials, adding the complex enzyme liquid to the paper-making raw materials through a metering pump, uniformly mixing the complex enzyme liquid with the paper-making raw materials for enzymatic hydrolysis under enzymatic treatment conditions that the temperature is 40-60 DEG C and enzymatic hydrolysis duration is 30-240 minutes; after the enzymatic hydrolysis, performing following processes as normal. The production method, through coupling synergistic effect of multiple enzymes of the complex enzyme liquid in chemi-mechanical pulping, can be used for improving the whiteness of pulp by 2-5% and reducing the pulp yellowing under a condition of guaranteeing high yield and low cost of pulping; the production method can be used for reducing the dosage of chemical raw materials by 20-30% and reducing the pulp grinding energy consumption by 18-30%; meanwhile, the production method can be used for reducing pollution and improving the pulp quality.

Owner:江苏富星纸业有限公司

Method for reducing energy consumption during wet refining of mechanical pulp

InactiveCN101130936AEasy to separate mechanicallyGood physical propertiesPulp beating/refining methodsFiberXylanase

The present invention relates to a method for reducing pulp-grinding energy dissipation of refine grinding stage by using enzyme treatment. Said invention adopts the following steps: adding hydrolytic enzyme into the coarse-ground pulp material, regulating pH value to 5.0-8, temperature is 25-60deg.C, pulp concentration is 6-15% and reaction time is 30-90min, then conveying the pulp material into a pulp-grinding machine to make refine-grinding operation. The described hydrolytic enzyme is one kind or two kinds of xylanase, laccase and white pot enzyme, etc.

Owner:QILU UNIV OF TECH

Method for making package materials from straws

InactiveCN101987473AImprove physical strengthReduce yieldReed/straw treatmentLiquid wasteHigh concentration

The invention discloses a method for making package materials from straws, which is characterized in that corn straws and alkali liquor activating agents are used as major raw materials, and a method of combining chemical pre-treatment with mechanical pulp grinding is adopted for producing the package materials, wherein the chemical pre-treatment adopts a method of combining the corn straw soaking by the alkali liquor activating agents with the heating steaming maintenance, the concentration of soaking liquid is 1.5 to 2.0 percent, the solid-liquid ratio is 1 / 6 to 1 / 7, the soaking time is 1 to 2h, 50 percent of water is filtered out after the pre-soaking, the steaming maintenance is carried out at a temperature between 90 and 120 DEG C, the heat insulation time is between 45 and 120min; the straws subjected to the steaming maintenance are filtered by a filter press, waste liquid is reused as the pre-soaking liquid of a next activation process, then, the straws are subjected to 3 to 4 times of washing and press filtering circulation, the washing liquid is respectively collected, the washing liquid in the first time and the washing liquid in the second time are used as pre-soaking liquid of a next activation process, the washing liquid in the third time and the washing liquid in the fourth time are used as washing liquid of a next process; and the straws subjected to the chemical pre-treatment are ground by a high-concentration disc grinding machine, and ground pulp is formed on a paper forming device. The invention achieves the goals of water saving and waste utilization, and realizes the clean production.

Owner:LUOYANG INST OF SCI & TECH

Method for pre-treating wood chips by hot water before preparing chemi-mechanical pulp and pulping method by using same

ActiveCN103790057AReduce consumption costReduce manufacturing costPretreatment with water/steamPre treatmentWoodchips

The invention relates to a method for pre-treating wood chips by hot water before preparing chemi-mechanical pulp. The method comprises the following steps: after soaking the wood chips, spirally extruding the wood chips; adding water into the wood chips which are spirally extruded, carrying out self-hydrolyzing pre-treatment on a mixture of the wood chips and water, and obtaining a pre-hydrolysate and the wood chips after self-hydrolyzing pre-treatment; and collecting the extruded wood chips as a raw material of chemi-mechanical pulp to obtain the wood chips after pre-treatment by hot water. The pre-treatment method provided by the invention fully uses existing part of equipment in the pulping industry without external complex equipment, and only water, small amount of dilute acids and ethanol are used without purchasing other chemicals, so that the pre-treatment process can be realized, thereby greatly saving the comprehensive production cost. Meanwhile, the method is beneficial for effectively combining pulping and papermaking with bio-refinery by existing enterprises.

Owner:TIANJIN UNIV OF SCI & TECH

Low pressure herbal material blasting pulp making process

InactiveCN1384241AReduce process pressureReduce the temperaturePulping with inorganic basesPre treatmentChemical pulp

The low pressure herbal raw material blasting and pulp making process includes raw material pre-treatment of adding alkali, sodium sulfide and assistant to herbal raw material with stirring at normaltemperature to 90 deg.c high temperature and high pressure treatment of the material in a blast tank at 110-210 deg.c and 0.5-1.9 MPa for 1-15 min; and blowing to blast the material instantaneously to a receiving container. The herbal pulp thus produced has strength equivalent to that of chemical pulp and the present invention has high yield, low power consumption, low cost and high pulp whiteness.

Owner:SOUTH CHINA UNIV OF TECH +1

Low pressure blast pulping method in palm fiber

This invention discloses a low blasting pulp making method in palm fibre. It includes material pretreatment, that is alkali, and sodium-sulfur compound and water are added into palm fibre materials. The bone dry weight percentage is that alkali 0-10%, sodium-sulfur compound 0-16% and water that can make liquid ratio to 0.5-3, then they are placed for 0-24 hours after uniformly blended. Then the materials after pretreatment are low pressure proposed and discharged. The advantages are low cost, low temperature, and low damage to fiber. The waste water after pulp making can be used as fertilizer for crop irrigation, low pollution high gain ratio. It can be used to make high strength card board, corrugated board, writing paper, manifold paper and other culture using paper.

Owner:SOUTH CHINA UNIV OF TECH

Method for pulping through needlebush pre-conditioning refiner chemical alkaline peroxide mechanical pulp (P-RC APMP)

InactiveCN102926253AImprove chemical performancePromote dissolutionPulping with inorganic basesFiberChemical treatment

The invention relates to the technical field of pulping and papermaking, in particular to a method for pulping through needlebush pre-conditioning refiner chemical alkaline peroxide mechanical pulp (P-RC APMP), wherein the first period of extrusion processing of needlebush pieces after being steamed is subjected, the first period of chemical processing is subjected after chemical liquid A is added, the chemical liquid A contains sodium dodecyl benzene sulfonate and octyl phenol polyoxyethylene ether (10), the second period of extrusion processing is subjected, the second period of chemical processing is subjected by adding chemical liquid B after the second period of extrusion, the chemical liquid B contains the sodium dodecyl benzene sulfonate and the octyl phenol polyoxyethylene ether (10), the first period of defibrination is subjected after processing and stops, and then the second period of defibrination and eliminate hidden processing are subjected to obtain needlebush P-RC APMP paper pulp. The method for pulping through needlebush P-RC APMP strengthens chemical action of impregnation liquid and dissolution of reactants, softens fiber materials, reduces subsequent pulping energy consumption, improves fiber quality, increases pulp whiteness, reduces pulp resin content, and reduces resin obstacle.

Owner:QILU UNIV OF TECH

Application of efficient penetrating agent in high-yield pulp making

InactiveCN105178075AEasy to handleHigh degree of processingPretreatment with alkaline reacting compoundsPulp bleachingFiberWastewater

The invention discloses application of an efficient penetrating agent in high-yield pulp making. The application is mainly characterized in that in high-yield pulp making, the efficient penetrating agent which has alkali resistance and oxidative resistance, is easy to dissolve in water and has good emulsifying and penetrating properties is selected to accelerate penetration of pre-immersing chemical liquid and increase the treatment degree of wood chips, improve pulp grinding quality, reduce the wood chip fiber loss in pulp grinding, increase the yield of pulp grinding and improve physical strength of pulp grinding. According to the technological method, the efficient penetrating agent is pumped into an inlet of a chemical mixing tank pump through a metering pump to be mixed with sodium hydroxide, sodium silicate, chelating agents and other chemicals, the mixture is pumped to an MSD outlet expansion pup joint through the chemical mixing tank pump to be mixed with hydrogen peroxide, and then the new mixture enters an immerser to react with the wood chips. According to the quality of needed pulp, the usage amount of H2O2 and NaOH is optimized. The cost of producing the high-yield pulp is lower, the physical strength of the pulp is better, the pulp making yield is higher, and the content of COD in discharged waste water is lower.

Owner:YUEYANG FOREST & PAPER CO LTD

Preparation method of biological mechanical pulp through synergy of hot water treatment and biological enzyme treatment

ActiveCN109629296AGuaranteed recyclingEmission reductionCellulose treatment using microorganisms/enzymesFiberSynergy

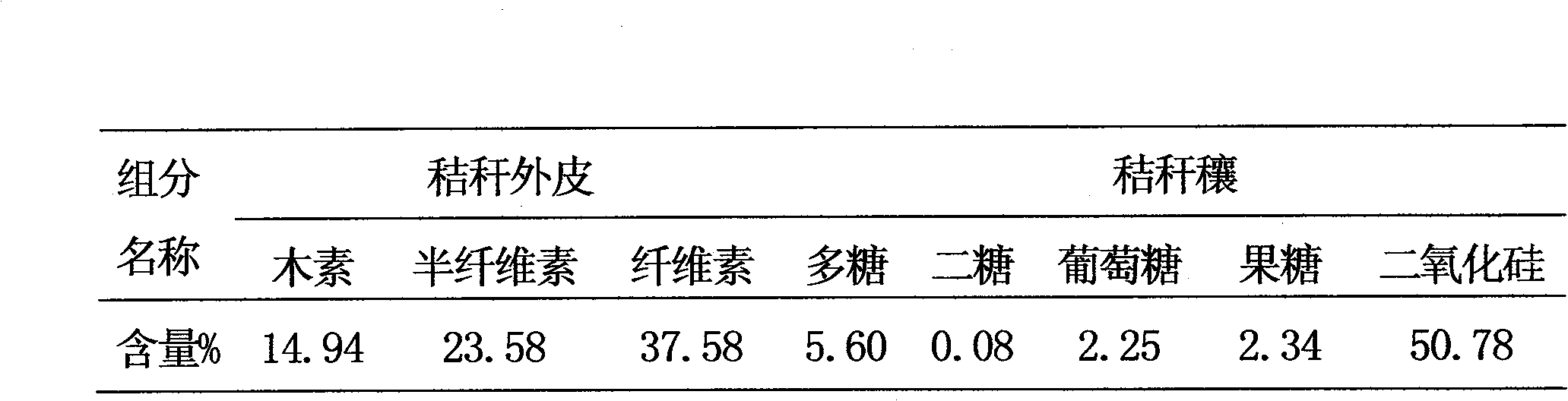

The invention relates to a preparation method of biological mechanical pulp through synergy of hot water treatment and biological enzyme treatment. Waste of crop wheat is used as a raw material for pulp preparation, normal-pressure hot water is adopted for treating wheat straw hoods, meanwhile, a small amount of alkali is added to adjust the pH value of hot water to be 10-14, after part of hemicellulose, lignin, pectin and other substances in the wheat straw hoods are dissolved out, the wheat straw hoods are saturated, softened and treated through spiral extrusion, wheat straw hoods are physically split, then biological enzyme treatment is conducted, then fibers are further softened, then pulp grinding is conducted on the wheat straw hoods, and the demand for producing primary-color package paper and paper-base materials is met.

Owner:QILU UNIV OF TECH +1

Middle-or low-pressure exposion method for making pulp with broad-leaf wood

A low-and medium-pressure blasting method for pulping the broad-leaf wood includes proportioning the alkali (1-6 wt%), Na-S compound (1-16 wt%), assistant (0-1 wt%) and broad-leaf wood (rest), stirring at ordinary temp -90 deg.C for 0-24 hr, treating at 140-220 deg.C and 0.8-2.28 MPa for 3-15 min, and sudden blasting. Its advantages are high strength, output rate, whiteness, toughness and rinsability, and low energy consumption.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for preparing natural biomechanical pulp from wheat straw treated by hot steam combined with biological enzyme

ActiveCN109680530AGuaranteed recyclingEmission reductionCellulose treatment using microorganisms/enzymesNon-woody plant/crop pulpFiberWater vapor

The invention relates to a method for preparing natural biomechanical pulp from wheat straw treated by hot steam combined with biological enzyme. The method comprises the following steps: taking wasteof crop wheat as a pulping raw material, treating the wheat straw with the hot steam, further adding a trace amount of alkali to adjust the pH of hot water to be 10 to 14, after dissolving a part ofsubstances of hemicellulose, lignin, pectin and the like in the wheat straw, and after performing hot-saturated softening on the wheat straw by hot water vapor, rolling filaments, physically separating the filaments of the wheat straw, then treating with the biological enzyme, and then further softening fibers, then grinding the wheat straw into pulp to meet the requirements of producing natural packaging paper and paper-based materials.

Owner:QILU UNIV OF TECH +1

Method for preparing natural-color biological mechanical pulp by wheat straw treatment under synergistic action of hot water and alkaline biological enzymes

ActiveCN109577060AIncrease profitHigh yieldPretreatment with water/steamPretreatment with alkaline reacting compoundsPaper basedPulp treatment

The invention provides a method for preparing natural-color biological mechanical pulp by wheat straw treatment under the synergistic action of hot water and alkaline biological enzymes. The method includes: S1, chopping pretreated wheat straw, adding water for hot water treatment, and adjusting solution to alkaline; S2, subjecting wheat straw treated in the step S1 to thread rolling treatment; S3, adding the alkaline biological enzymes into the wheat straw treated in the step S2 to realize enzymolysis treatment; S4, after enzymolysis treatment of the wheat straw in the step S3, subjecting thewheat straw to pulping treatment to prepare the natural-color biological mechanical pulp. The method of adopting whole wheat straw as a raw material for preparing natural-color biological mechanicalpulp by whole wheat straw treatment under the synergistic action of hot water and the alkaline biological enzymes is put forward for the first time, and requirements of production of natural-color packaging paper and paper-based materials are met. The preparation method is simple, convenient, green, clean and efficient and has a high practical application value and a promising industrial application prospect.

Owner:QILU UNIV OF TECH +1

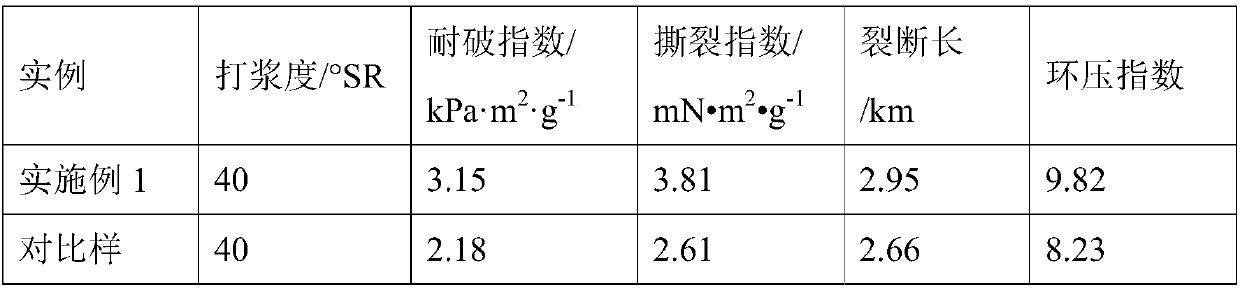

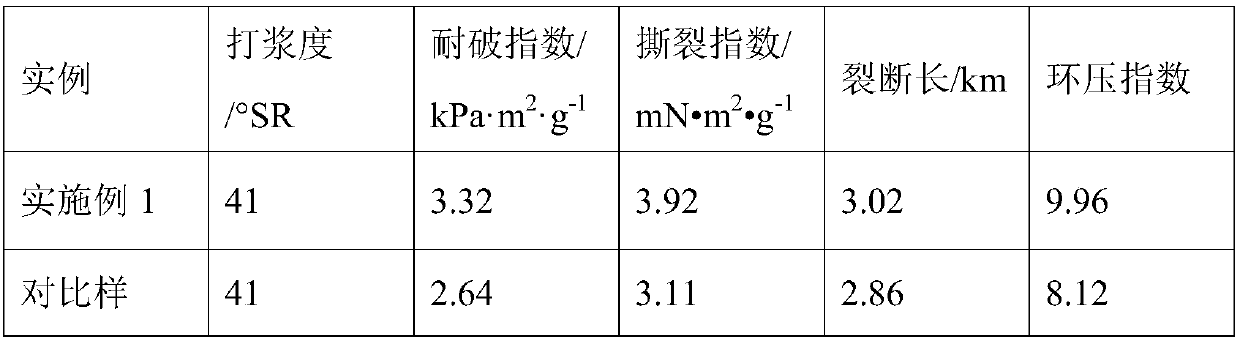

Method for preparing biomechanical pulp from wheat straw sheath

ActiveCN109457532AIncrease profitHigh yieldCellulose treatment using microorganisms/enzymesNon-woody plant/crop pulpWarm waterPre treatment

The invention provides a method for preparing biomechanical pulp from wheat straw sheath. The method comprises the following steps: S1, cutting the pretreated wheat straw sheath section into segments,and treating by means of action of warm water and alkaline complex enzyme; S2, adding hot water into the wheat straw sheath treated in the step S1 for performing saturation softening treatment; S3, grinding the wheat straw sheath, subjected to the softening treatment in the step S2, into thick liquid to prepare the biomechanical pulp. The wheat straw sheath is used as a raw material for the firsttime, and the high-yield primary color biomechanical pulp is prepared by using a hot water combined alkaline complex biological enzyme process, so that the requirements of producing primary color packaging paper and paper-based materials are reached. The preparation method provided by the invention is simple, green, environment-friendly and energy-saving, conforms to the national industrial policy of resource conservation, economic cycle, energy conservation and emission reduction, and can generate good social, economic and ecological benefits, thus having good practical application value andindustrial application prospect.

Owner:QILU UNIV OF TECH +1

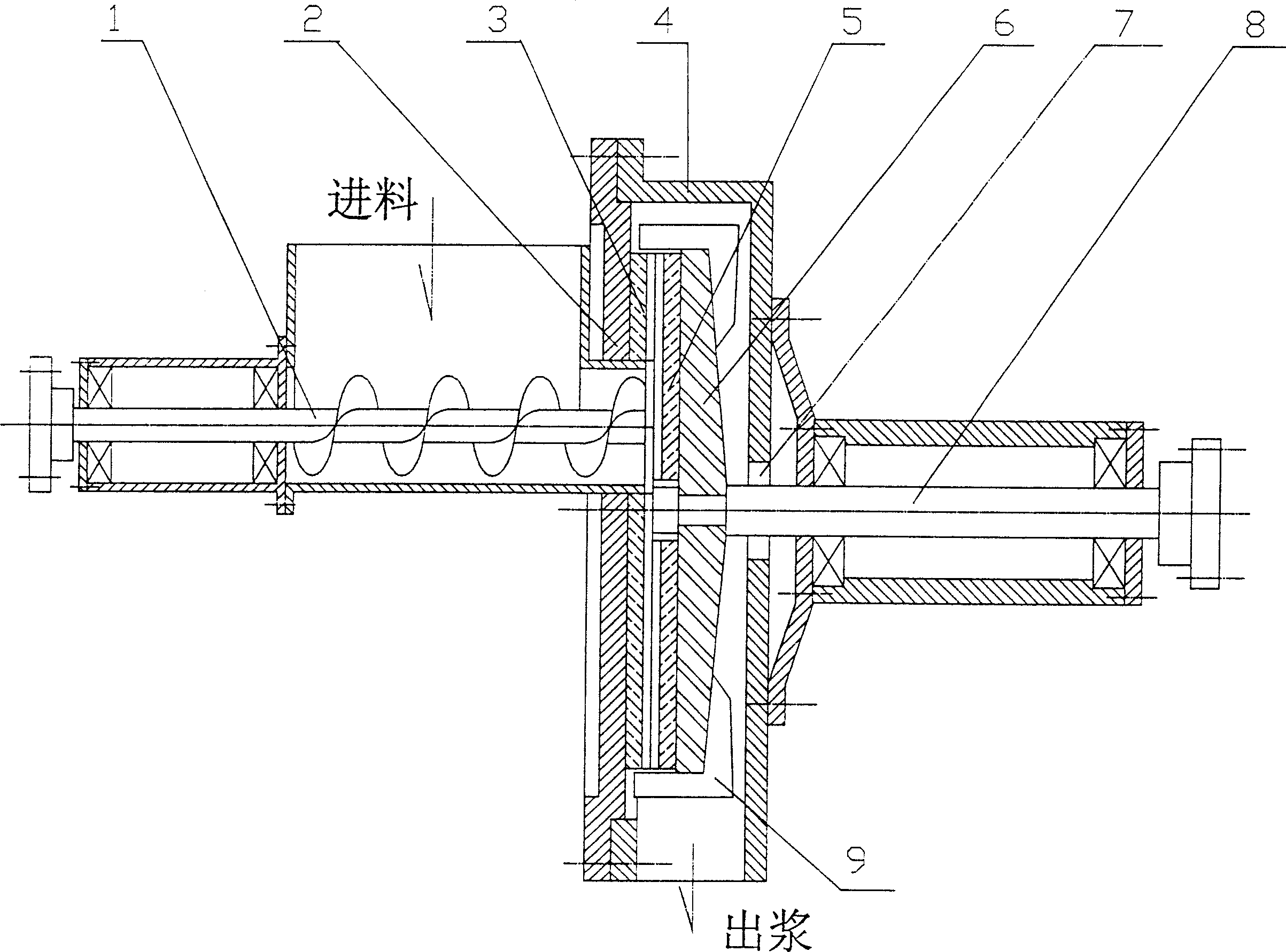

Eccentric input material of paste mill in high concentration

InactiveCN1727573ASmall loadSolution to short lifePulp beating/refining methodsHigh concentrationLocknut

A high-concentration pulp grinder with eccentric feeding inlet is composed of casing, front end cover, feeding screw, rotary and fixed grinding discs with grinding teeth on their opposite surfaces, grinding gap regulator, and drive unit. Its advantages are not blocking and long service life of mainshaft.

Owner:FUJIAN LIGHT IND MACHINERY EQUIP

Plant fiber modified compound enzyme preparation and preparation method and application thereof

The invention discloses a plant fiber modified compound enzyme preparation, a preparation method and application of the plant fiber modified compound enzyme preparation to the field of papermaking. The compound enzyme preparation is prepared from pectinase, cellulose, lipase, xylanase, glucose oxidase and levan hydrolase and is applied to pretreatment of papermaking raw materials, sewage treatment loads can be reduced, pulping energy consumption can be reduced, the paper base strength can be improved, and the finished paper quality can be improved.

Owner:颐思特(武汉)生物科技股份有限公司

Cold charging production process of high-compactness and high-purity fine-grain grinding ball steel

ActiveCN112281061AImprove the ability to adsorb inclusionsImprove purityManufacturing convertersProcess efficiency improvementTemperature controlAustenite grain

The invention discloses a cold charging production process of high-compactness and high-purity fine-grain grinding ball steel. The cold charging production process comprises the following processes ofpre-desulfurizing molten iron, smelting in a converter, refining in an LF furnace, carrying out RH vacuum treatment, continuously casting, slowly cooling a large round billet casting blank, heating,rolling, cooling, high-temperature pit entering slow cooling, pit exiting finishing, packaging and warehousing. According to the production process, a grinding ball steel round billet cold charging temperature control system is adopted for heating, and a mode of combining differential temperature rolling and single-pass high-pressure rolling is adopted, so that the deformation of the center of thebillet is increased, and the internal compactness and the grain size of the steel are improved. The grinding ball steel produced by the production process has the advantages of excellent macrostructure (central porosity is less than or equal to 1.0 grade and general porosity is less than or equal to 0.5 grade), high purity (A-type inclusions are less than or equal to 1.0 grade, B-type inclusionsare less than or equal to 0.5 grade, C-type inclusions are less than or equal to 0.5 grade and D-type inclusions are less than or equal to 1.0 grade) and fine austenite grains (austenite grain size isgreater than or equal to 6.5 grade). The grinding ball obtained by carrying out a conventional rolling process on the produced grinding ball steel is good in impact toughness and long in fatigue life.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Hot steam synergistic bio-enzyme method used for processing wheat straw and preparing original color biomechanical pulp

ActiveCN109706771AGuaranteed recyclingEmission reductionPulping with inorganic basesNon-woody plant/crop pulpFiberPaper based

The invention relates to a hot steam synergistic bio-enzyme method used for processing wheat straw and preparing an original color biomechanical pulp. According to the hot steam synergistic bio-enzymemethod, crop wheat waste is taken as a pulping raw material, hot steam is adopted to process wheat straw, a micro-amount of an alkali is added to adjusted hot water pH value to 10 to 14, when dissolving out of a part of hemicelluloses, lignin, pectin, and the like in wheat straw is realized, and wheat straw steaming hydro-thermal saturation softening is achieved, screw extrusion processing is carried out for wheat straw physical devillicating; then bio-enzyme processing is carried out for fiber further softening; and then wheat straw is subjected to pulp refining so as to obtain a product capable of satisfying requirements of original color packaging paper and paper base material production.

Owner:QILU UNIV OF TECH +1

Method for preparing biomechanical pulp through wheat straw leaves

ActiveCN109629318AIncrease profitHigh yieldPulp beating/refining methodsPaper-making machinesAfter treatmentPaper based

The invention provides a method for preparing biomechanical pulp through wheat straw leaves. The method comprises the steps that S1, pretreated wheat straw leaves are cut off, water is added, and hotwater treatment is conducted; S2, alkali is added in the mixture obtained after treatment in step S1, the solution pH is adjusted to be 10-14, a small part of hemicellulose, lignin, pectin and other substances are dissolved from the wheat straw leaves, and while the wheat straw leaves are waterlogged and softened, the pH value of wheat straw is controlled to be 7-9 when treatment is finished; S3,an alkaline enzyme is added in the wheat straw obtained after treatment in S2, and enzymolysis treatment is conducted; S4, the wheat straw leaves obtained after enzymolysis treatment in S3 is subjected to grinding treatment, and the biomechanical pulp is obtained. Accordingly, the idea of taking the wheat straw leaves as raw materials is put forward for the first time, a process of cooperating hotwater with alkaline complex enzyme is adopted for preparing the high-yield primary-color biomechanical pulp, and then the requirement of producing primary-color packaging paper and paper-based materials is met. The preparation method is simple, environmental friendliness and cleanliness are achieved, and the method has the good practical application value and industrial application prospect.

Owner:QILU UNIV OF TECH +1

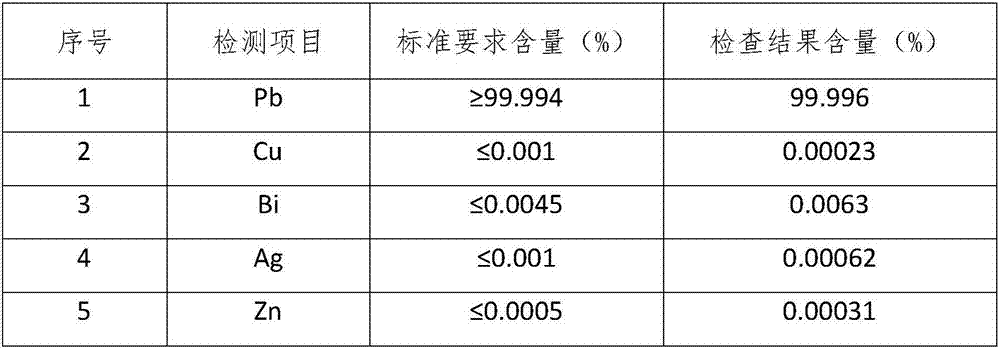

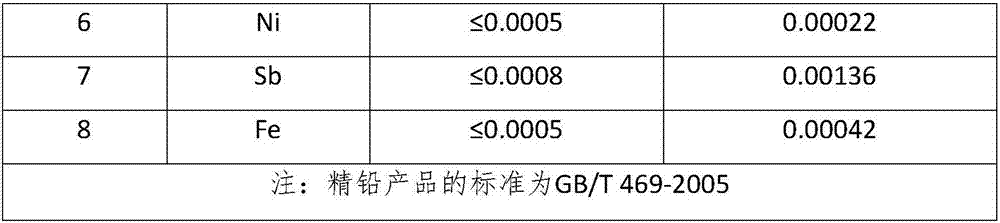

System and method for waste lead storage battery desulfurization lead plaster integrated roasting and smelting

ActiveCN107475529ASimplify the operation processImprove utilizationWaste accumulators reclaimingBattery recyclingMelting tankThermal energy

The invention provides a system and method for integrated roasting and smelting of waste lead battery desulfurization lead paste. The system includes a cylindrical melting pool, which is divided into a rough melting pool and a pre-refining melting pool by a cylindrical partition plate. The lower part of the dividing plate is provided with a through hole, the bottom of the rough smelting pool and the pre-refining molten pool are provided with air nozzles, the side of the pre-refining molten pool is provided with a lead slag outlet and a lead liquid outlet from top to bottom, and the top of the pre-refining molten pool is There is a flue, and a drying and roasting reaction tower is installed inside the flue. The top of the drying and roasting reaction tower is provided with a first feeding port, and the top of the pre-refining molten pool is provided with a second feeding port. The drying and roasting reaction tower and the rough melting pool pass through the filter block The rough smelting pool is connected with the flue through several first flue openings, and the pre-refining melting pool is connected with the flue through several second flue openings. The integrated roasting and smelting system for desulfurization and lead paste of waste lead storage batteries designed by the invention has the advantages of simple material operation process and high utilization of heat energy.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing natural-color bio-mechanical pulp by treating wheat straw with hot steam and biological enzyme and fully utilizing byproducts

PendingCN112761013AGuaranteed recyclingEmission reductionPretreatment with water/steamPulp properties modificationWhole wheatBiomass

The invention relates to a method for preparing natural-color biological mechanical pulp and byproducts by treating wheat straw through hot steam and biological enzyme, and belongs to the technical field of papermaking technology and comprehensive utilization of waste. The invention provides a method for preparing the high-strength natural-color biological mechanical pulp by using the whole wheat straw as a raw material and treating the whole wheat straw with hot water and alkaline bio-enzyme, so that the requirements of producing natural-color packaging paper and paper-based materials are met, byproducts are recycled to prepare the biomass compound fertilizer, solid waste is turned into wealth, and high-valued full utilization of the wheat straw is realized. The preparation method is simple, green, clean and efficient, and has good practical application value and wide application prospect.

Owner:QILU UNIV OF TECH

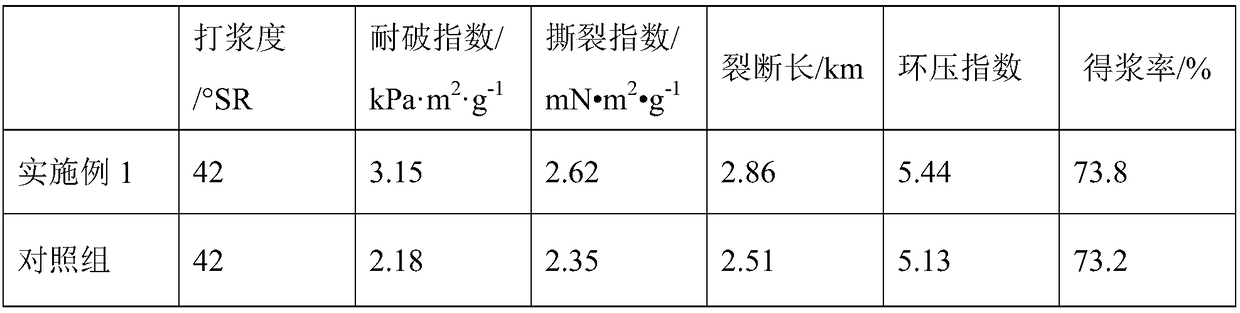

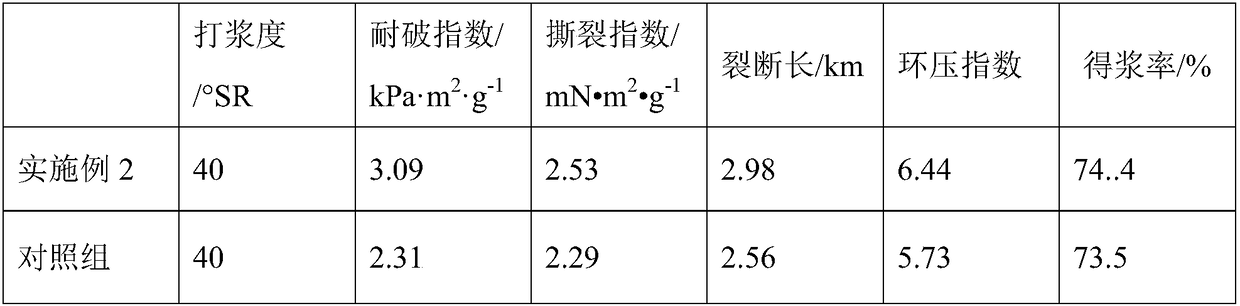

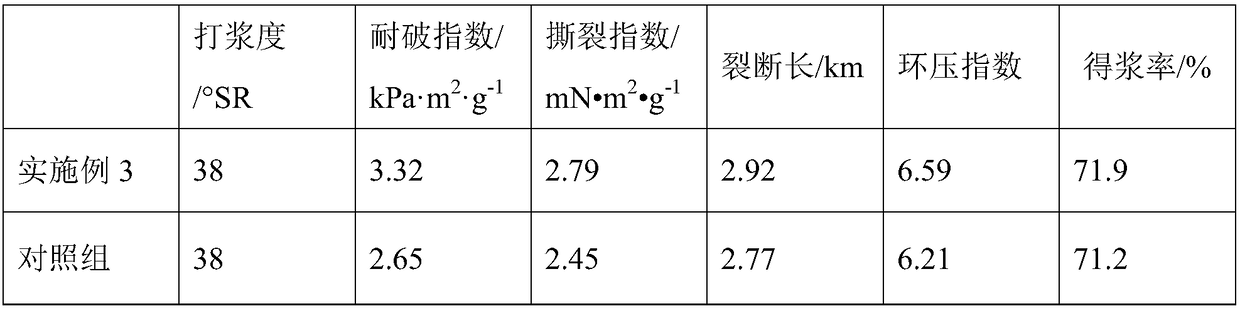

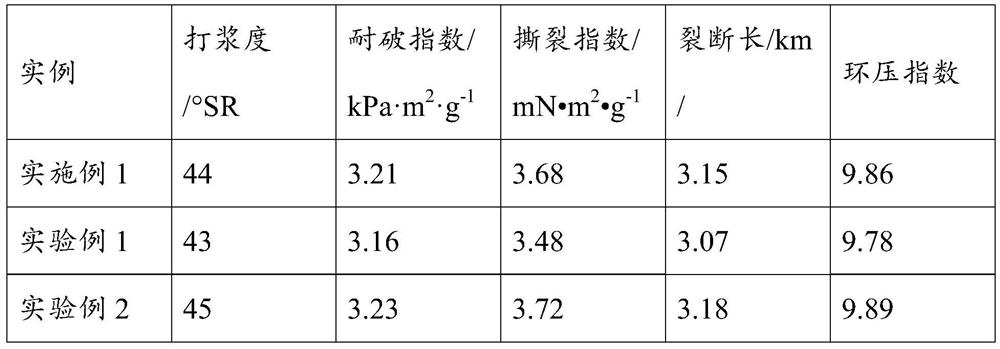

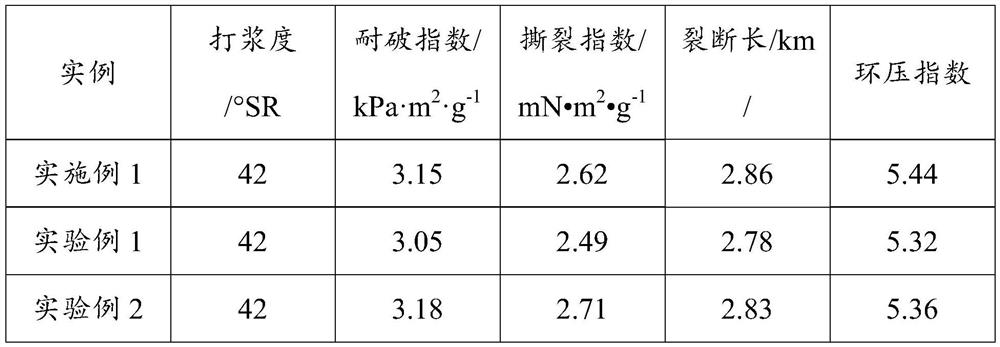

Production method and application of compound enzyme solution for chemical mechanical pulping

ActiveCN103555702BHigh whitenessImprove qualityHydrolasesOxidoreductasesPectinaseEnzymatic hydrolysis

The invention discloses a production method of a complex enzyme liquid for chemi-mechanical pulping. The production method is characterized by comprising the following steps: weighing various component enzymes, mixing and compounding the various component enzymes in a compounding tank, preventing corrosion, inspecting, packaging and storing in a storeroom at 5 DEG C, wherein the various component enzymes comprise alkaline pectinase, xylanase, mannose and ligninase. The application of the complex enzyme liquid in chemi-mechanical pulping is realized as follows: before steaming paper-making raw materials, adding the complex enzyme liquid to the paper-making raw materials through a metering pump, uniformly mixing the complex enzyme liquid with the paper-making raw materials for enzymatic hydrolysis under enzymatic treatment conditions that the temperature is 40-60 DEG C and enzymatic hydrolysis duration is 30-240 minutes; after the enzymatic hydrolysis, performing following processes as normal. The production method, through coupling synergistic effect of multiple enzymes of the complex enzyme liquid in chemi-mechanical pulping, can be used for improving the whiteness of pulp by 2-5% and reducing the pulp yellowing under a condition of guaranteeing high yield and low cost of pulping; the production method can be used for reducing the dosage of chemical raw materials by 20-30% and reducing the pulp grinding energy consumption by 18-30%; meanwhile, the production method can be used for reducing pollution and improving the pulp quality.

Owner:江苏富星纸业有限公司

Production method for preparing chemimechanical pulp by synergy of biological enzyme and alkali

InactiveCN110656525AImprove pulping qualityImprove bindingPulp bleachingPulping with inorganic basesPulp and paper industryPre treatment

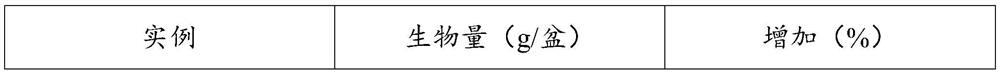

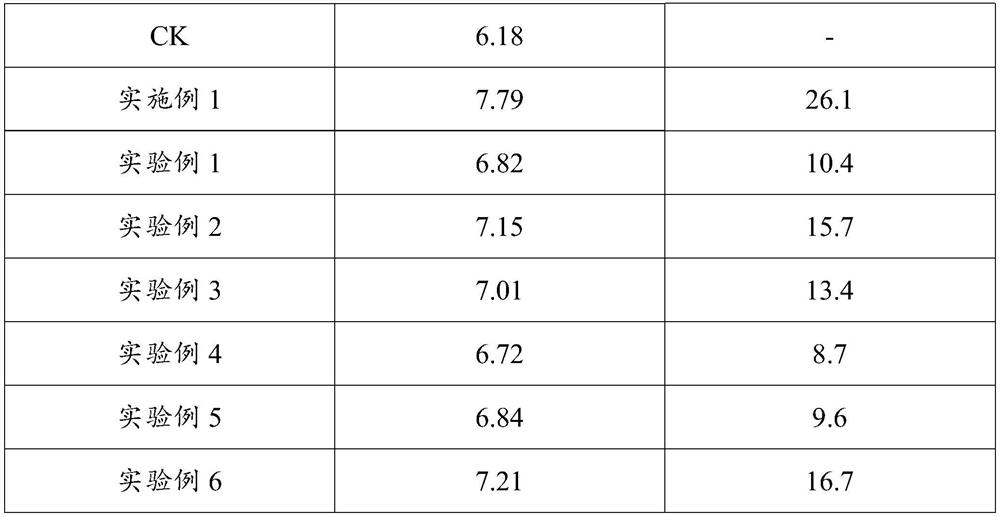

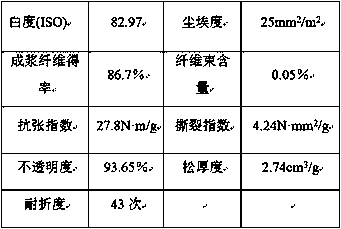

The invention provides a production method for preparing chemimechanical pulp through synergy of a biological enzyme and an alkali. The production method specifically comprises the steps of raw material pretreatment, biological enzyme treatment, primary extrusion defibering, secondary extrusion defibering, liquid medicine dipping, and bleaching. Wastewater generated by the process is adopted for pretreatment of wood chips, biological enzyme treatment is combined, so that residual chemicals are fully utilized, the wastewater discharge is reduced, the consumption of sodium hydroxide and peroxides in the subsequent bleaching process is greatly reduced, and the method has dual significance of environmental protection and reality. The chemimechanical pulp prepared by the production process is good in pulping quality, pulp ISO whiteness reaches 82.97-85.36, pulp tearing index reaches 4.24-4.35 N.mm < 2 > / g, tensile strength reaches 27.8-29.1 N.m / g, and pulp fibers are firmly combined.

Owner:山东晨鸣纸业集团股份有限公司

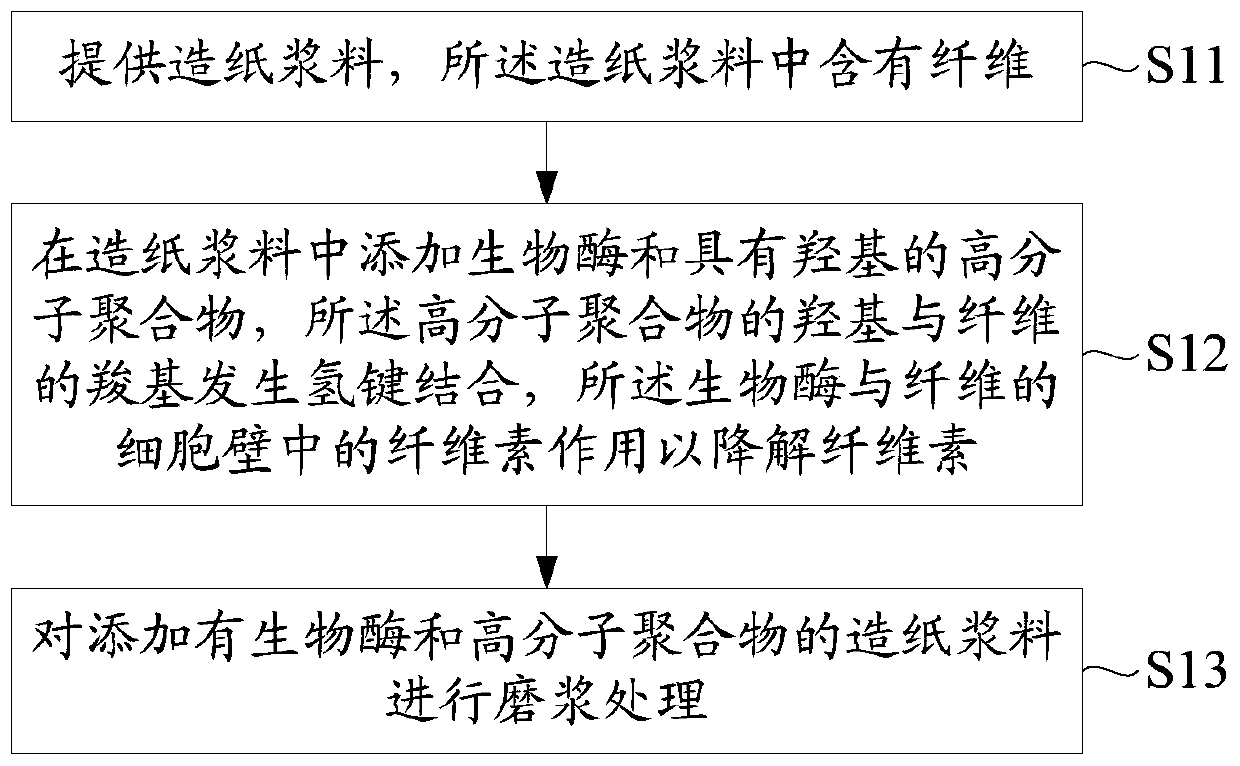

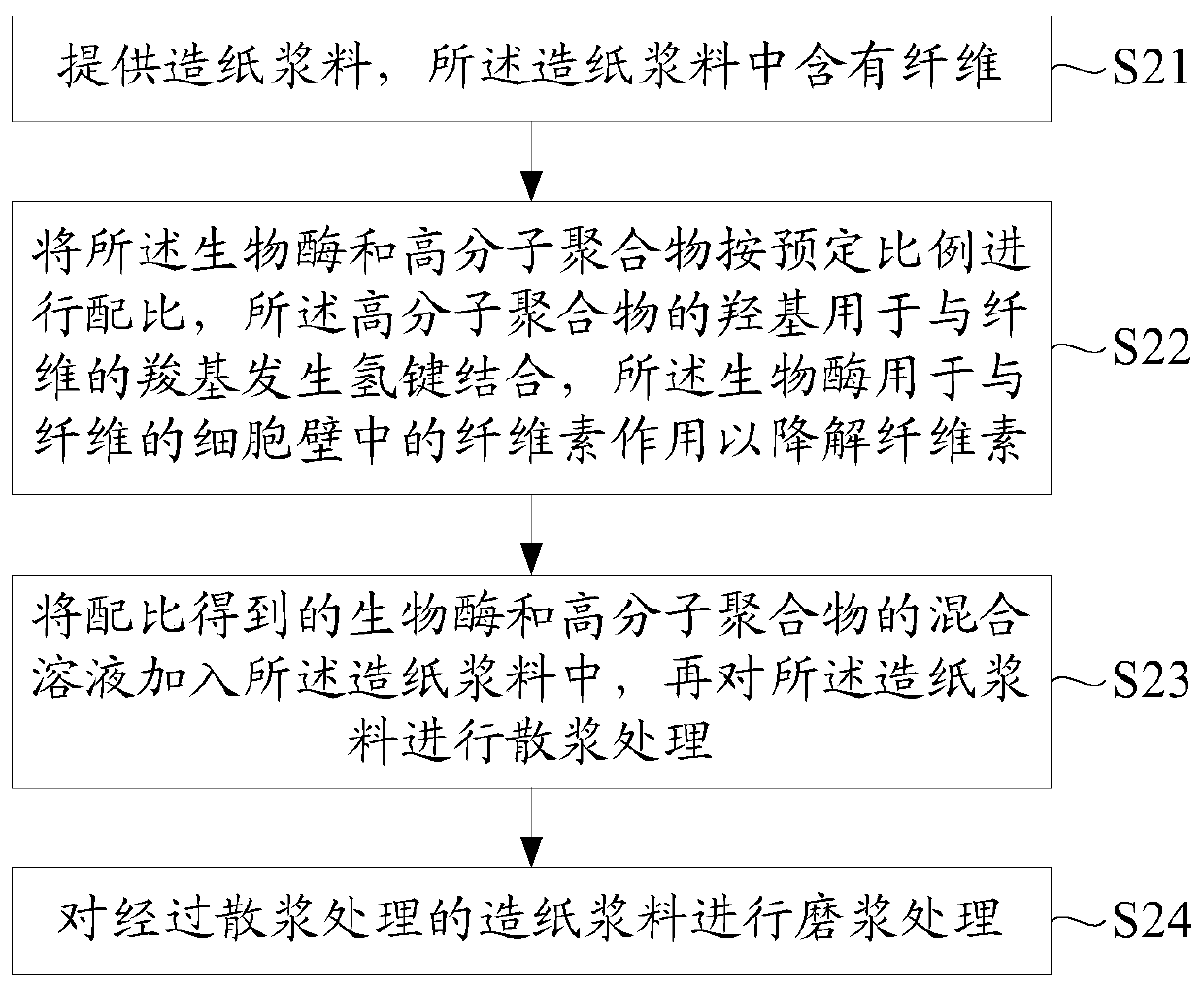

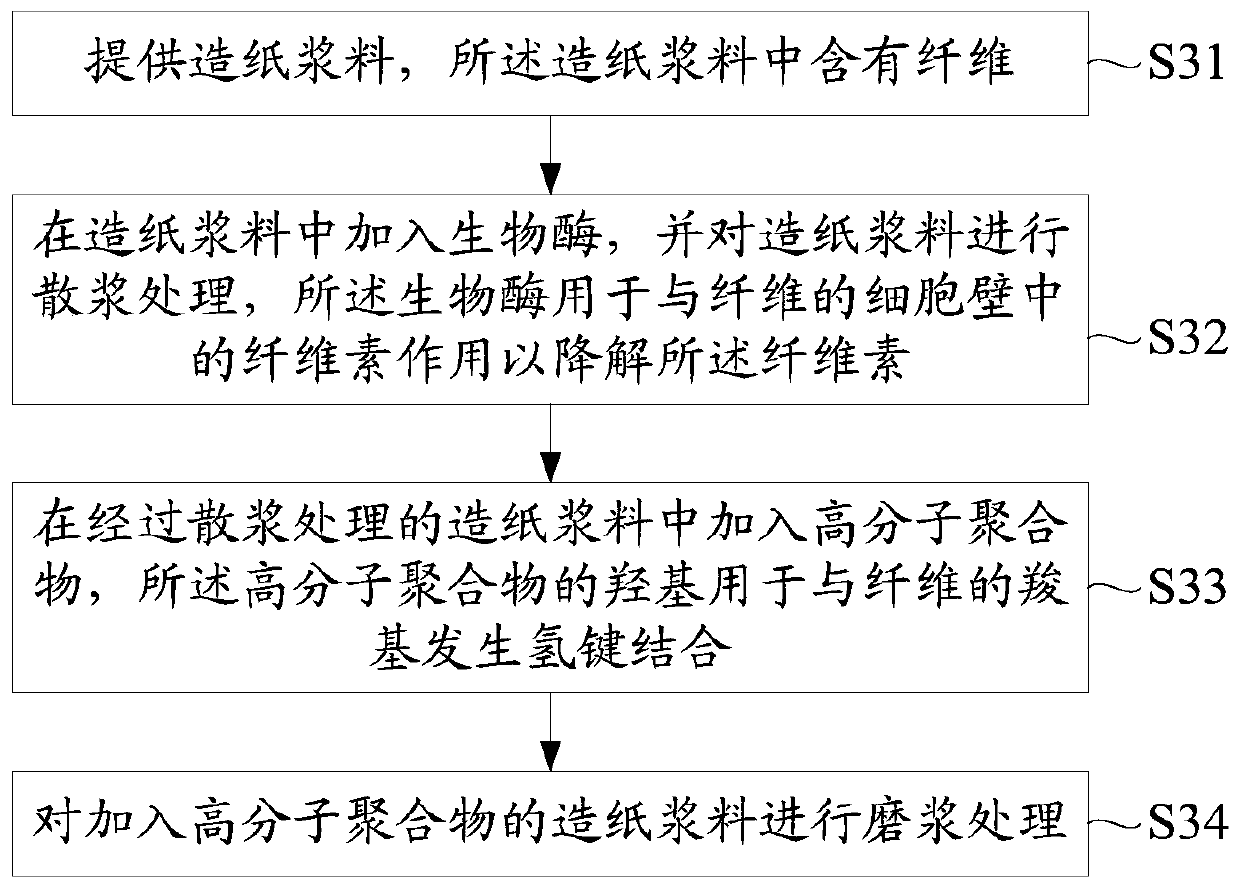

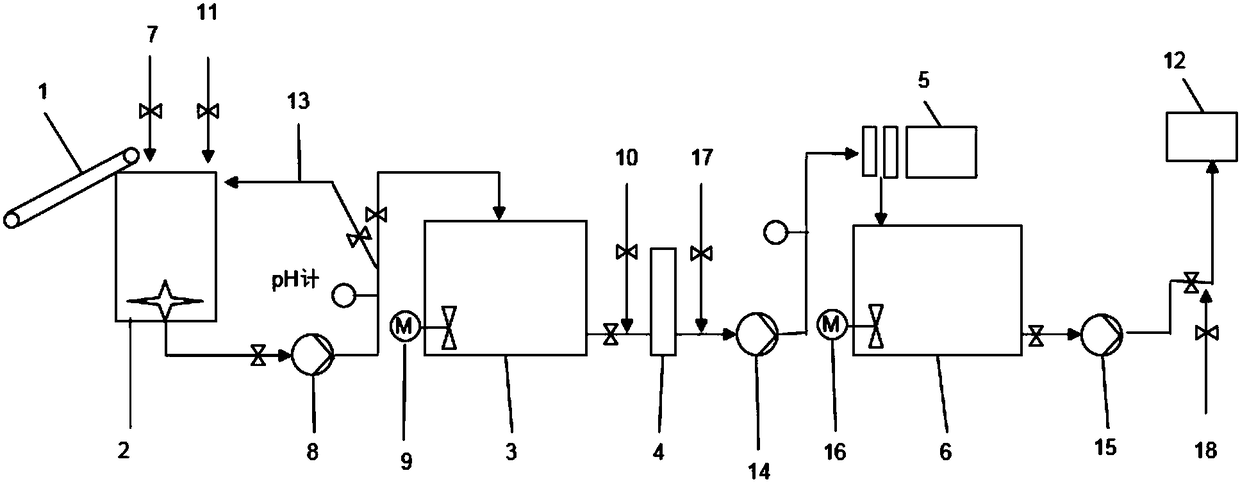

Pulping method and auxiliary pulping preparation for papermaking pulp

InactiveCN111206451AMore contactHigh strengthPulp beating methodsCellulose treatment using microorganisms/enzymesPulp (paper)Paper sheet

The invention discloses a pulping method and an auxiliary pulping preparation for papermaking pulp. According to the invention, a bio-enzyme and a high-molecular polymer with hydroxyl are added into the papermaking pulp; cellulose is degraded under the action of bio-enzyme and cellulose in cell walls of fibers, and hydroxyl of a high-molecular polymer and carboxyl of the fibers are subjected to hydrogen bond combination, so that more fibers are in contact combination, and the strength of the paper fibers can be improved while the pulping energy consumption is reduced.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Low pressure blast pulping method in palm fiber

InactiveCN100500987CSignificant changes in microstructureHigh yieldPulping with inorganic basesCardboardDry weight

This invention discloses a low blasting pulp making method in palm fibre. It includes material pretreatment, that is alkali, and sodium-sulfur compound and water are added into palm fibre materials. The bone dry weight percentage is that alkali 0-10%, sodium-sulfur compound 0-16% and water that can make liquid ratio to 0.5-3, then they are placed for 0-24 hours after uniformly blended. Then the materials after pretreatment are low pressure proposed and discharged. The advantages are low cost, low temperature, and low damage to fiber. The waste water after pulp making can be used as fertilizer for crop irrigation, low pollution high gain ratio. It can be used to make high strength card board, corrugated board, writing paper, manifold paper and other culture using paper.

Owner:SOUTH CHINA UNIV OF TECH

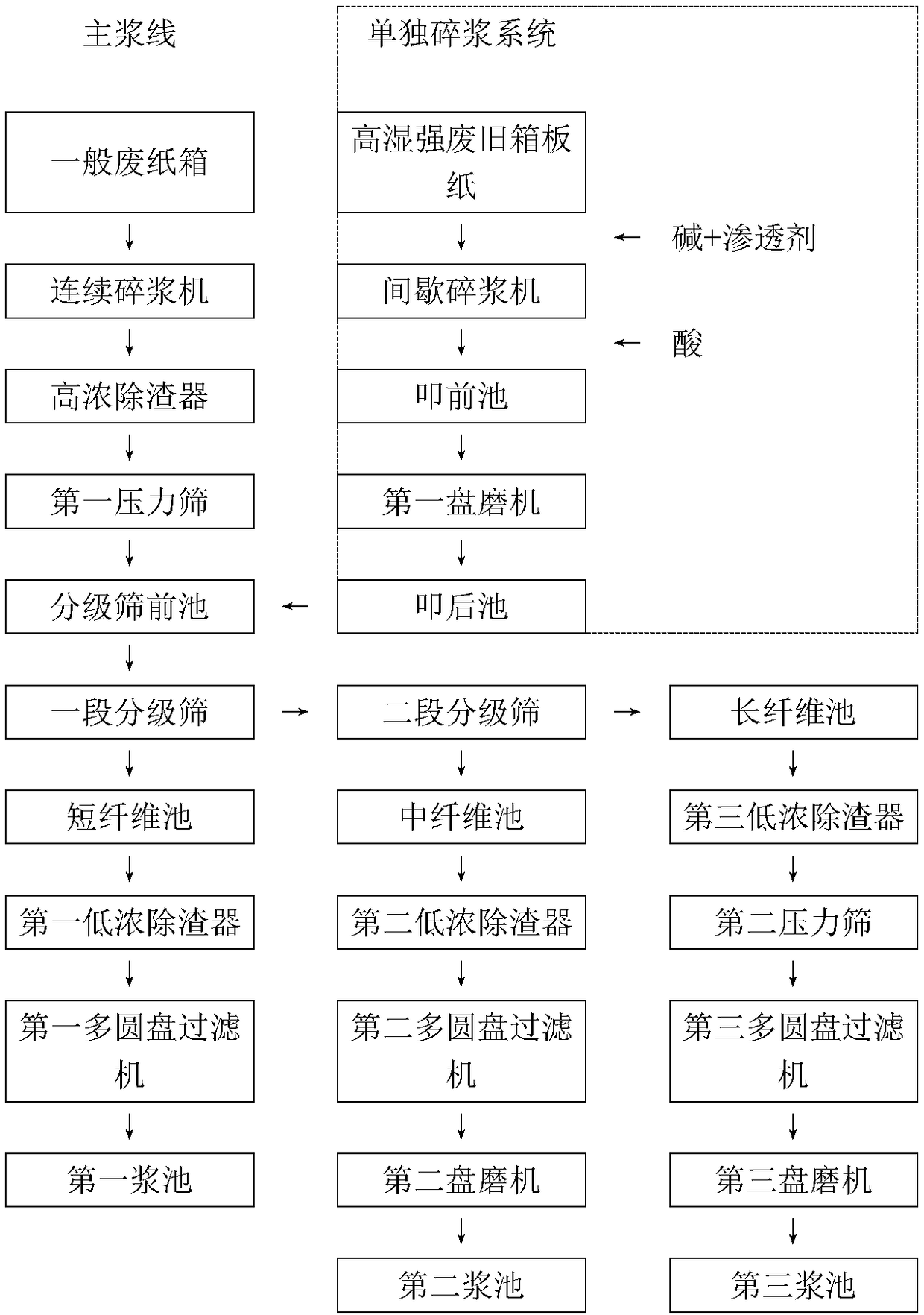

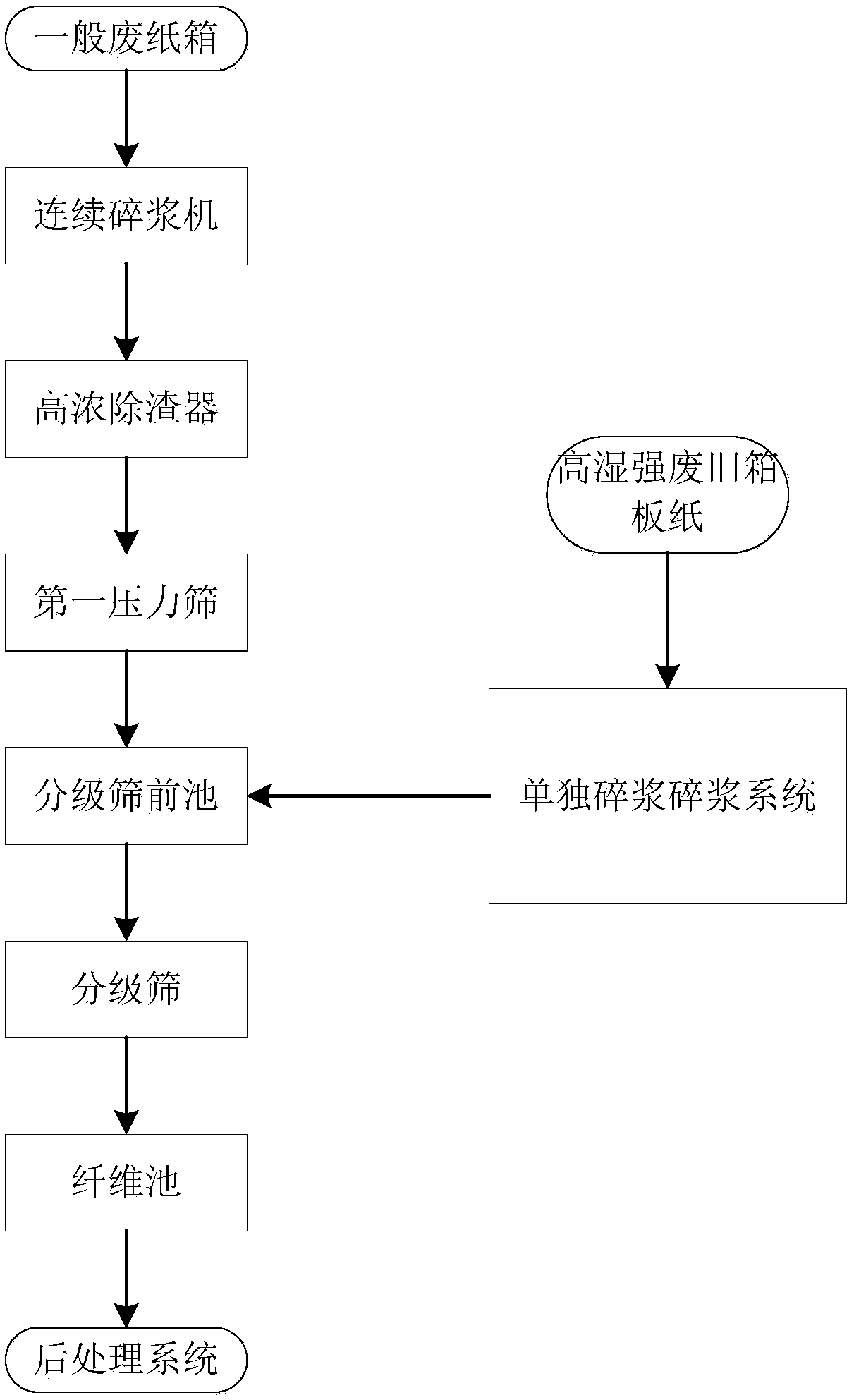

Pulping system for high-humidity-strength waste cardboard paper

PendingCN108316033ASolve the defibrillation problemIncrease profitPaper recyclingPulp beating/refining methodsHigh concentrationCardboard

The invention relates to a pulping system for high-humidity-strength waste cardboard paper. The pulping system comprises a continuous pulp shredder, a high-concentration slag separator, a first pressure screen, a classifying screen forebay, a classifying screen, a fiber tank, a post-treatment system and an independent pulp shredding system, the continuous pulp shredder, the high-concentration slagseparator, the first pressure screen, the classifying screen forebay, the classifying screen, the fiber tank and the post-treatment system are sequentially connected, and the independent pulp shredding system is used for shredding the high-humidity-strength waste cardboard paper and conveying the shredded pulp into the classifying screen forebay. The independent pulp shredding system is additionally arranged in the pulping system, solves the problem of difficulty in defibering the high-humidity-strength waste cardboard paper and improves pulping efficiency and pulping yield when the high-humidity-strength waste cardboard paper serves as raw materials to pulp, the utilization rate of the raw materials is increased, and production cost is saved.

Owner:NINE DRAGONS PAPER TAICANG LTD

Method for APMP (Alkaline Peroxide Mechanical Pulp) pulping of needlebush

InactiveCN102926252AImprove qualityHigh whitenessPulping with inorganic basesPulping with organic solventsFiberChemical treatment

The invention relates to the technical field of APMP (Alkaline Peroxide Mechanical Pulp) pulping, in particular to a method for the APMP pulping of a needlebush. The method comprises steps as follows: extruding a steamed needlebush piece at the first section; adding chemical medicine liquid A to the extruded piece for chemical processing at the first section, wherein the chemical medicine liquid A includes sodium dodecyl benzene sulfonate and octyl phenol polyoxyethylene ether; extruding at the second section after the first chemical processing; chemically processing after the extruding at the second section, wherein the chemical medicine liquid B includes sodium dodecyl benzene sulfonate and octyl phenol polyoxyethylene ether; then washing after the processing; grinding into pulp; and depositing so as to obtain the needlebush APMP pulping. According to the method, a chemical effect of dipping liquid is improved, a reaction product is deposited, a fiber material is softened, so that energy consumption in follow-up pulping is reduced, quality of the fiber is greatly improved, whiteness of the pulp is improved, content of resin of paper pulp is reduced, and a resin barrier is decreased.

Owner:QILU UNIV OF TECH

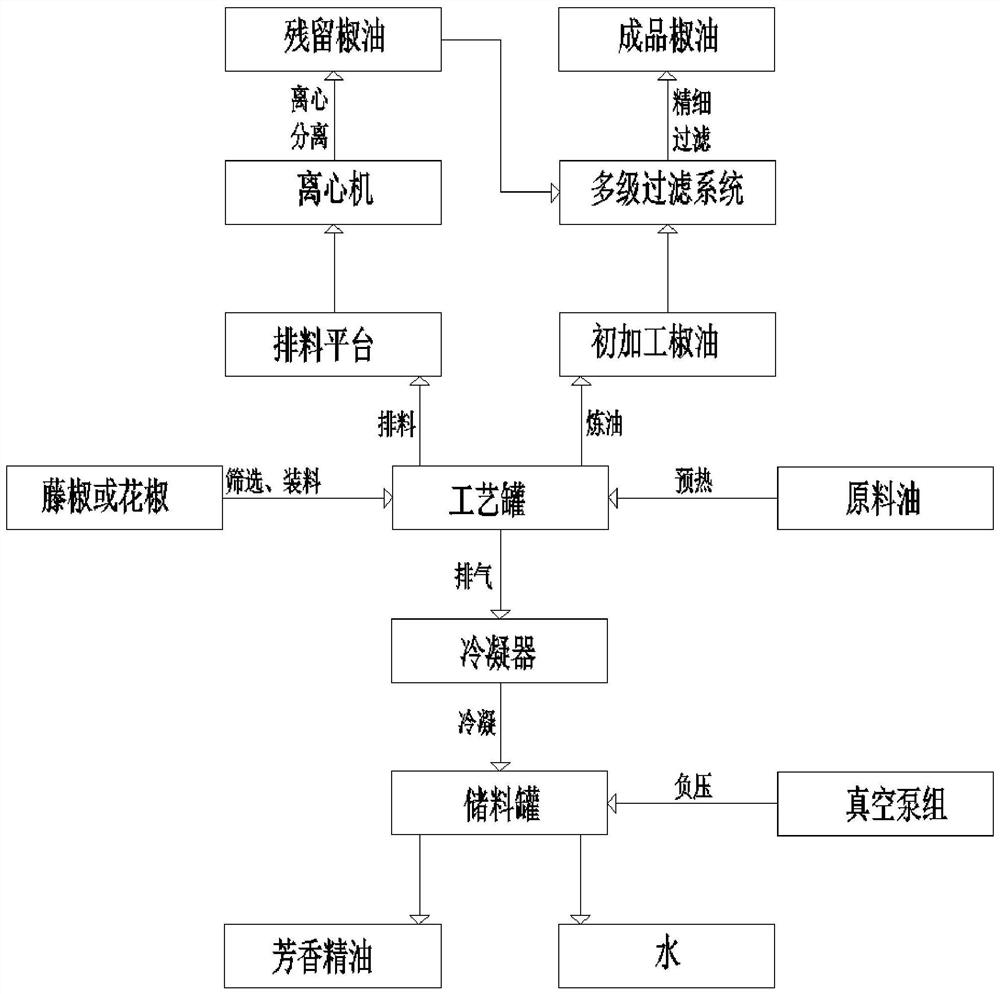

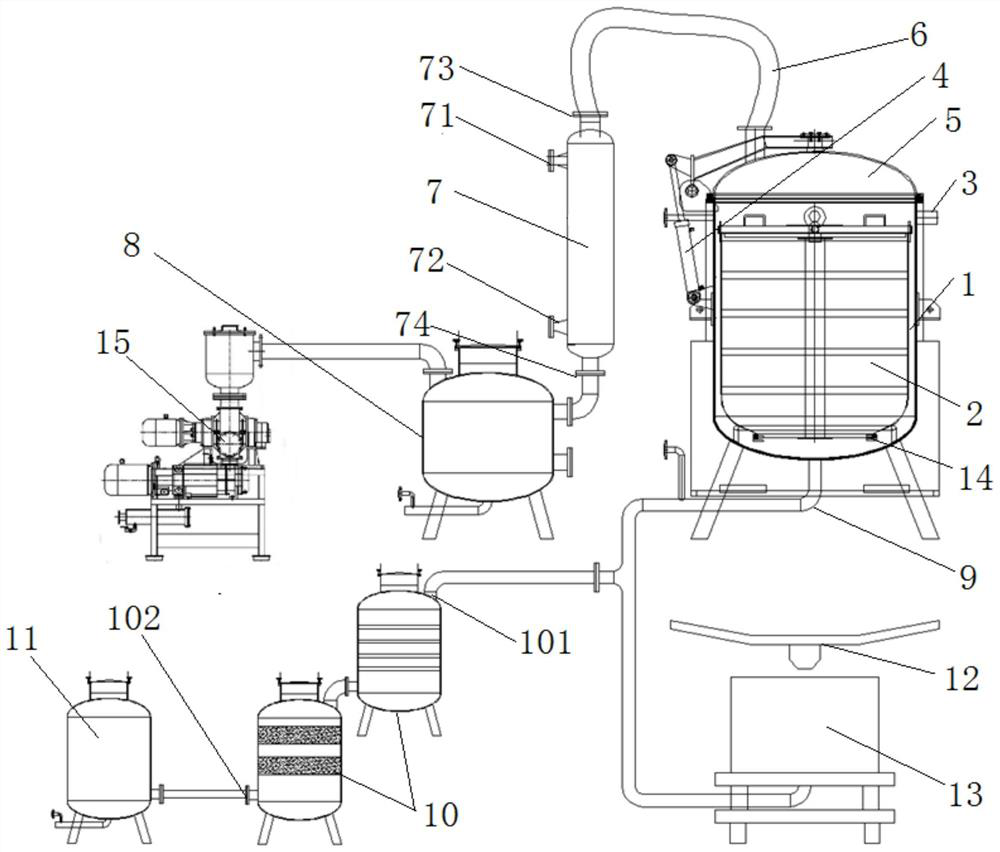

Zanthoxylum armatum and zanthoxylum bungeanum Maxim deep processing and refining process and system

PendingCN113214903ANon-volatile fragranceGood flavor retentionEssential-oils/perfumesFatty-oils/fats productionZanthoxylum bungeanumZanthoxylum armatum

The invention discloses a zanthoxylum armatum and zanthoxylum bungeanum Maxim deep processing and refining process and system, belongs to the technical field of edible oil production, and aims to solve the problems of low raw material utilization rate, low production efficiency and poor product quality of the existing refining process. According to the method, the chilli oil is refined at low temperature, so that the chilli oil does not volatilize fragrance easily, and the flavor retention property of the chilli oil is good; the method is suitable for refining fresh and dry zanthoxylum armatum and zanthoxylum bungeanum Maxim, and the retention property of the aromatic essential oil is good; the aromatic essential oil is recycled in a condensation recycling mode, refined products are enriched, and the utilization rate of raw materials is increased; when the chili oil is refined, the raw oil is preheated, so that the oil refining efficiency is greatly improved; meanwhile, the raw material is refined under negative pressure, so that the refining efficiency is improved, and the bright color of the product is ensured; and the whole refining system is high in streamline degree, the chili oil and the aromatic essential oil can be refined at a time, residual oil in the raw materials is recycled, and the production efficiency of enterprises and the utilization rate of the raw materials are greatly improved. The method is suitable for deep processing and refining of zanthoxylum armatum and zanthoxylum bungeanum Maxim.

Owner:HONGYA HEXIN AGRI TECH DEV

Method for biologically pretreating slurry before grinding

InactiveCN106283800AImprove physical performanceImprove paper strengthCellulosic pulp after-treatmentPulp beating/refining methodsPretreatment methodSlurry

The invention discloses a pretreating method for slurry before grinding. The pretreating method includes the following steps that 1, the type of white rot fungi is selected; 2, the slurry is sterilized; 3, the white rot fungi are added into the slurry for fermentation culture. Lignin can be effectively removed, grinding energy consumption can be reduced, and the physical property of finished paper can be improved. The physical property of the slurry treated through the method is improved, and the strength of the finished paper is improved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

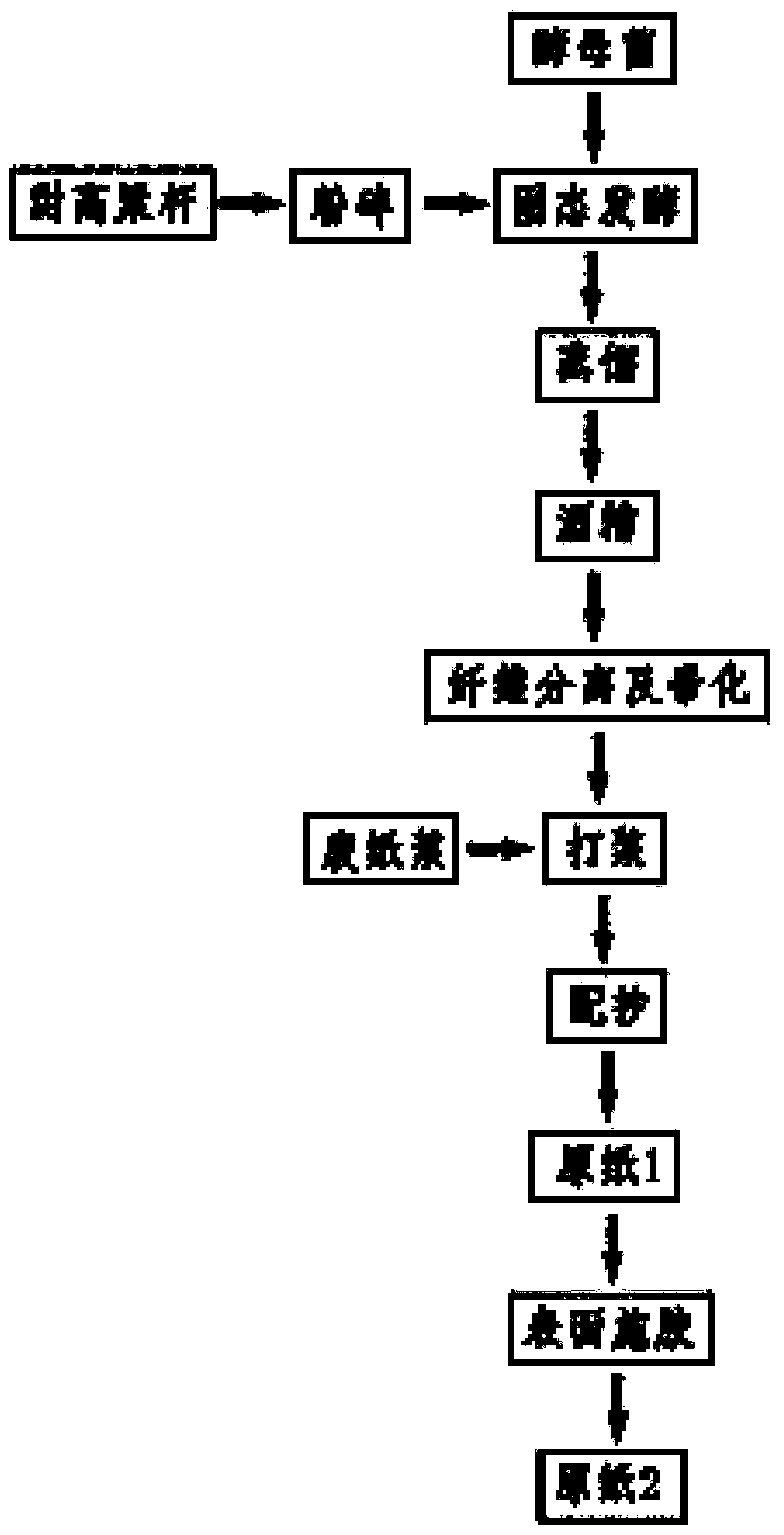

Method for pulping and papermaking by utilizing sweet sorghum stalk vinasse

ActiveCN111118943ARealize economic valueExtend the industrial chainPulp beating methodsSecondary cellulose fibresFiberAlcohol ethyl

The invention discloses a method for pulping and papermaking by utilizing sweet sorghum stalk vinasse. The method comprises the following four steps: step 1, carrying out alcohol fermentation and distillation, namely crushing 16 tons of sweet sorghum stalks with a water content of 70% through a pulverizer, adding cultured yeast seed liquid according to a proportion of 15% (v / m), and carrying out alcohol fermentation and distillation to obtain 1 ton of ethyl alcohol with a mass fraction of 95% and 16 tons of hot vinasse with a water content of 80% and a temperature of 94 DEG C; step 2, directlyfeeding the hot vinasse into a millstone mill pulping machine for fiber separation and brooming with a disc milling interval being 0.002 m and a pulping concentration being 20% (w / w) so as to obtain14 tons of pulp with a water content of 85%; step 3, weighing 2.1 tons of waste paper pulp boards, defibering the waste paper pulp boards by using a defibering device, and then feeding the defiberingwaste paper pulp boards into a Valley beater for beating to a beating degree of 36 oSR so as to obtain 10.5 tons of pulp with a water content of 80%; and step 4, blending the vinasse fiber paper pulpobtained in the step 2 and the waste paper pulp obtained in the step 3 according to a ratio of 1: 1, and carrying out papermaking to obtain 4.2 tons of raw paper. The method is used for pulping and papermaking by utilizing the sweet sorghum stalk vinasse.

Owner:东营市弘力生物科技有限责任公司

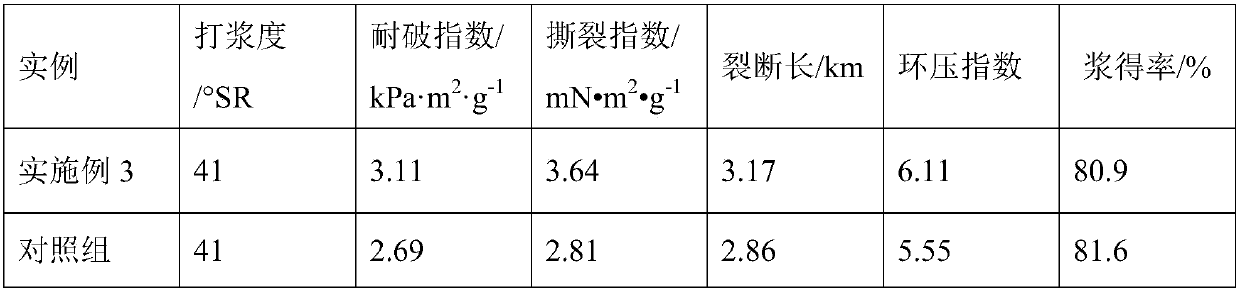

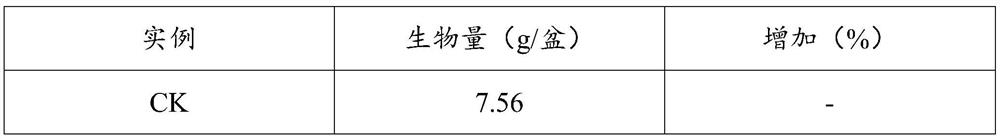

Method for preparing biomechanical pulp and biomass compound fertilizer from leaf sheaths of wheat straw

ActiveCN112811953AIncrease profitHigh yieldNitrogenous fertilisersOrganic fertilisersWarm waterPulp treatment

The invention discloses a method for preparing biological mechanical pulp and a biomass compound fertilizer from leaf sheaths of wheat straw. The method comprises the following steps: S1, cutting pretreated leaf sheaths of wheat straw into sections, and carrying out treatment under the action of warm water and an alkaline compound enzyme; S2, adding hot water into the wheat straw leaf sheaths treated in the step S1, adding KOH to adjust a pH value, and performing saturated softening treatment; S3, grinding the wheat straw leaf sheaths softened in the step S2 to prepare the biomechanical pulp; S4, performing evaporation and concentration treatment on the wastewater obtained after treatment by the warm water and the alkaline compound enzyme, wastewater obtained after the saturated softening treatment and washing water for pulping treatment by adopting a multi-effect evaporator so as to obtain residues, and recovering heat energy for the saturated softening treatment in S2; and S5, mixing the residues with rotten leaves which cannot be processed and used in the step S1 and adjusting acid to prepare the fertilizer. According to the method, the requirements of production of primary-color packaging paper and paper-based materials can be met, byproducts can be recycled to prepare the biomass compound fertilizer, emission of solid waste is greatly reduced, and meanwhile, high-value full utilization of the wheat straw leaf sheaths is achieved.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com