Preparation method of biological mechanical pulp through synergy of hot water treatment and biological enzyme treatment

A technology for hot water treatment and mechanical pulping, which is used in fiber raw material treatment, cellulose treatment with microorganisms/enzymes, textiles and papermaking, etc., can solve the problem of inability to fully utilize wheat harvesting waste, and solve the shortage of papermaking fiber raw materials. , to eliminate incineration, to achieve the effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] In a first typical embodiment of the present disclosure, a method for preparing biomechanical pulp in which hot water treatment is coordinated with biological enzyme treatment is provided, the method includes the following steps:

[0023] (1) Use the waste wheat straw after obtaining wheat grain as raw material, carry out hot water treatment to wheat straw according to the liquid ratio of 1:4-1:8, add trace alkali at the same time, adjust the pH value of hot water to be 10-14, treat The temperature is 80-100°C, and the time is 15-60min;

[0024] (2) After the hot water treatment is finished, the wheat straw is extruded and divided;

[0025] (3) Acting on the divided wheat straw and the alkaline biological complex enzyme, the treatment temperature is 40-60°C, and the treatment time is 30-90min;

[0026] (4) Refining the biologically treated wheat straw.

[0027] The raw material used in this disclosure is the waste wheat straw after obtaining wheat grain, including whe...

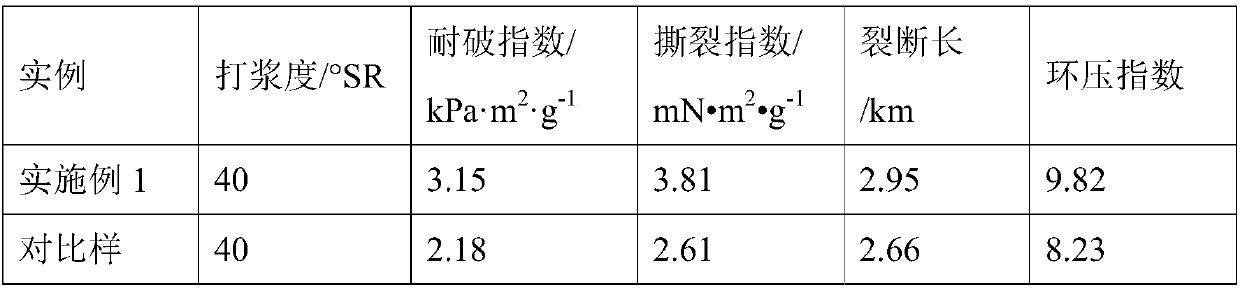

Embodiment 1

[0046] A process for preparing biomechanical pulp by coordinating biological enzyme treatment with hot water from wheat straw. This example prepares biomechanical pulp and tests its pulping performance.

[0047] (1) Cut the air-dried wheat straw after physical selection and dedusting into 5cm long spare raw materials, put it in a normal temperature reaction kettle, and carry out hot water treatment to the wheat straw according to the liquid ratio of 1:5 (g / mL), the temperature is at 90°C, The processing time is controlled at 20min.

[0048] (2) Add a small amount of NaOH to the hot water in the reactor and the wheat straw mixture, adjust the pH value of the hot water at 14, and dissolve a small amount of hemicellulose, lignin and pectin in the wheat straw. Simultaneously with the softening of the water, the pH of the wheat straw water reaches 9 at the end of the treatment.

[0049] (3) Extrude the water-saturated wheat straw on a screw extruder, and adjust the pressure of the...

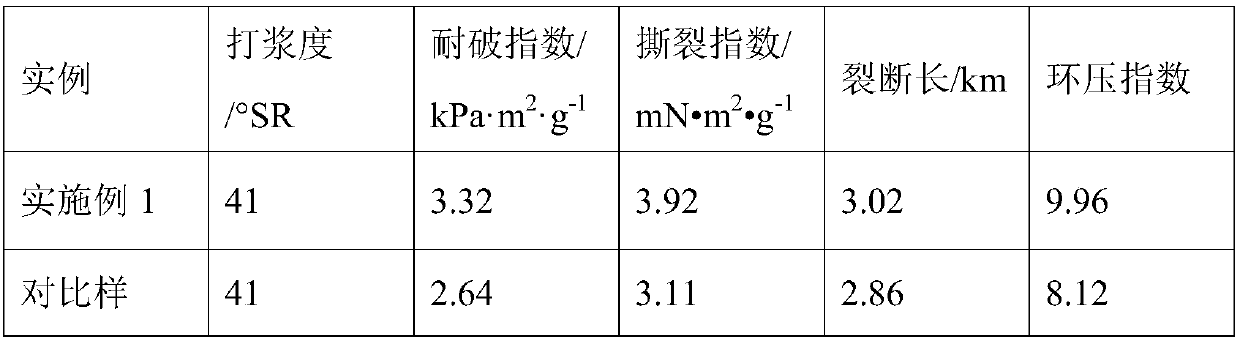

Embodiment 2

[0059] A process for preparing biomechanical pulp by coordinating biological enzyme treatment with wheat straw hot water. In this example, biomechanical pulp is prepared to prepare primary-color corrugated paper, and its pulping performance is tested.

[0060] (1) Cut the air-dried wheat straw after physical selection and dedusting into 5 cm long spare raw materials, put it in a normal temperature reaction kettle, and carry out hot water treatment to the wheat straw according to the liquid ratio of 1:4 (g / mL), the temperature is at 100 °C, The processing time was controlled at 25min.

[0061] (2) Add a small amount of alkali KOH to the hot water in the reactor and the wheat straw mixture, adjust the pH value of the hot water at 13, and dissolve a small amount of hemicellulose, lignin and pectin in the wheat straw. Simultaneously with softening with water saturation, the pH value of the water content of the wheat straw reaches 8 at the end of the treatment.

[0062] (3) Extrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com