Pulping method and auxiliary pulping preparation for papermaking pulp

A slurry and preparation technology, applied in the field of papermaking, can solve the problems that the paper strength has not been improved, the fiber contact bonding is less, and the fiber strength has not been improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

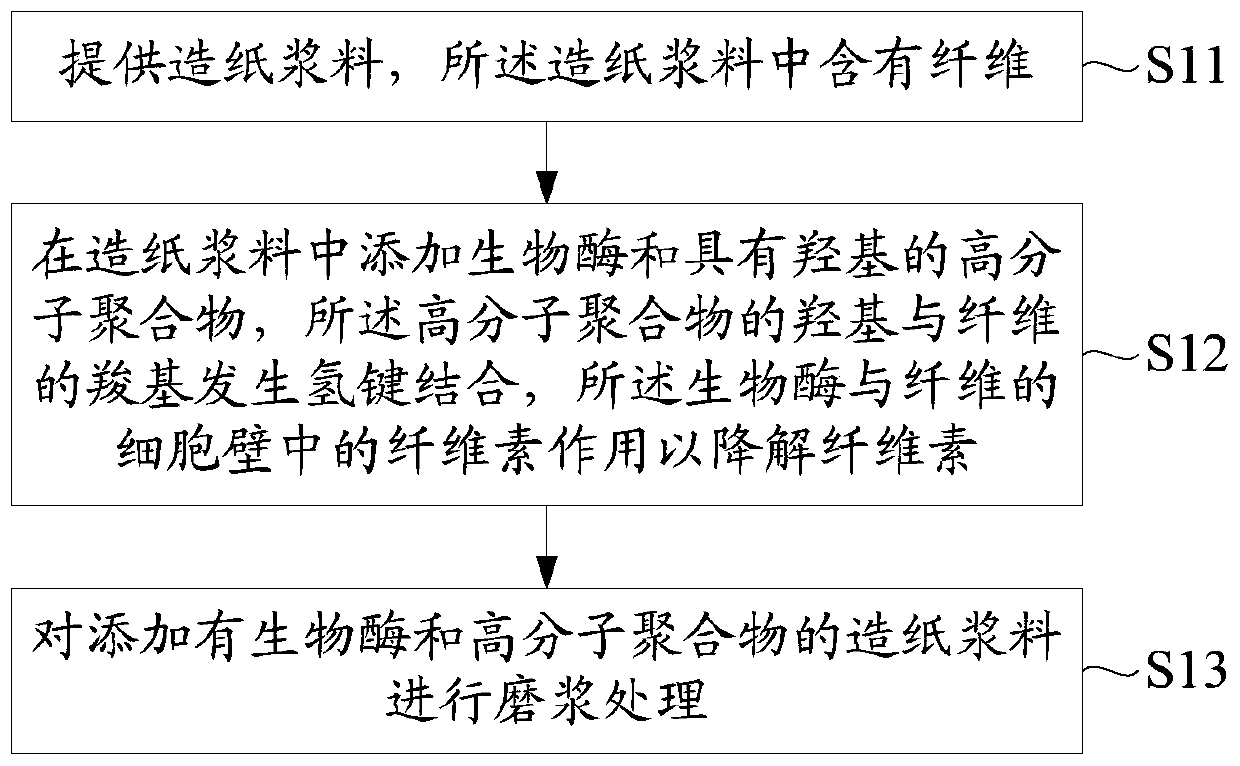

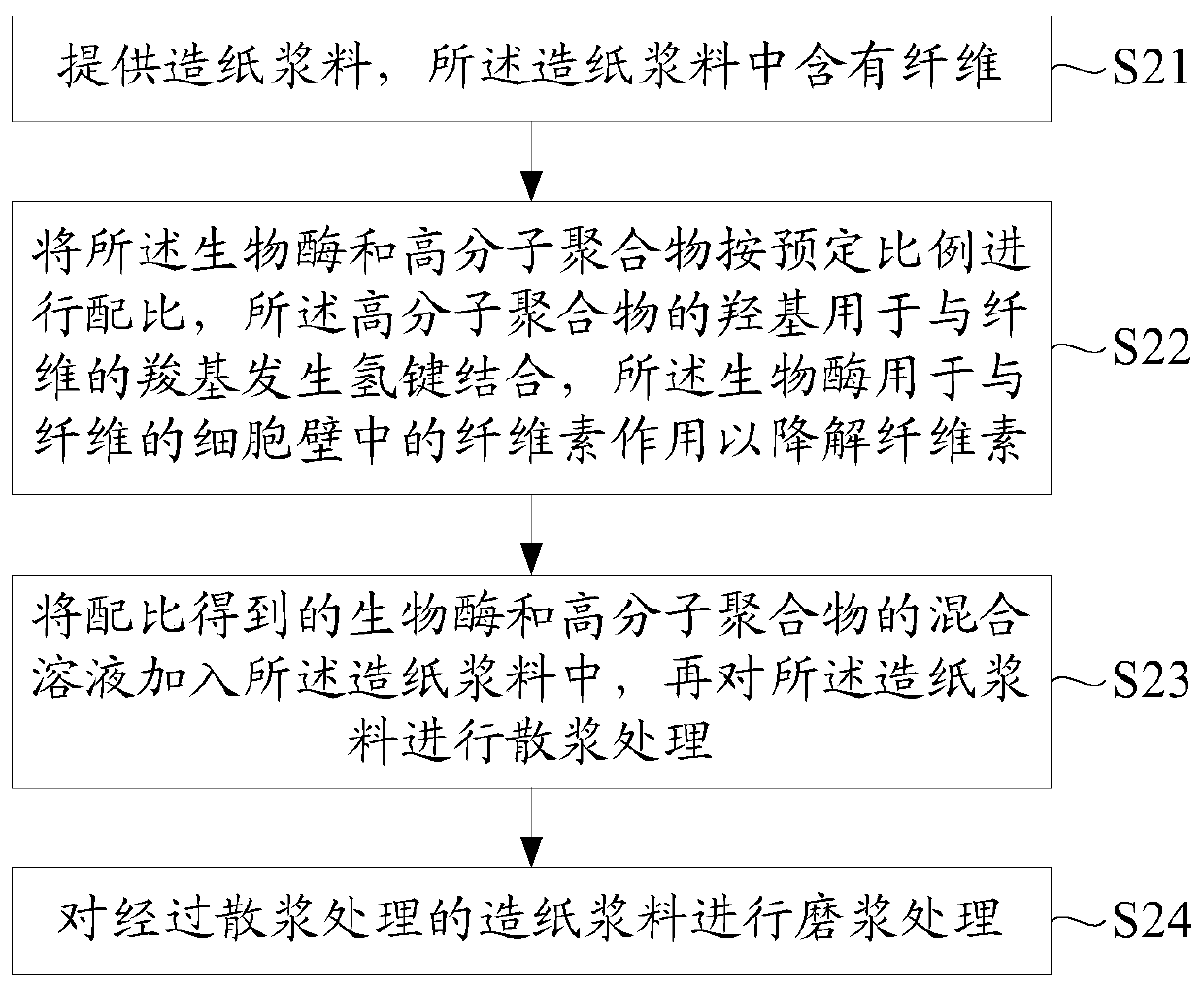

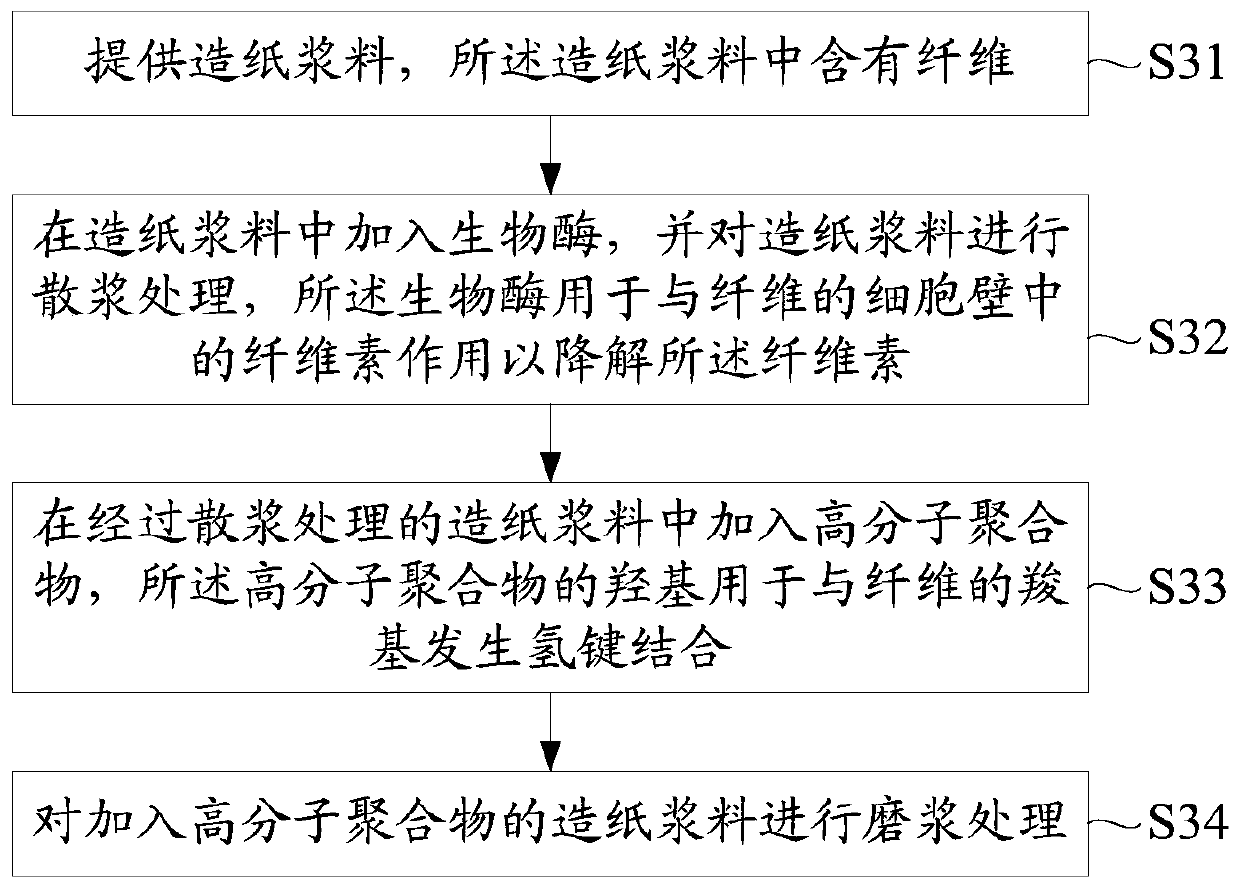

[0015] The primary purpose of this application is to add a high molecular polymer with hydroxyl groups in the papermaking slurry, and use the hydroxyl groups of the high molecular polymer to hydrogen bond with the carboxyl groups of the fibers to make the fibers more contact-bonded, thereby improving the quality of the paper fibers. strength. As for the application of biological enzyme technology in papermaking pulping, that is, in the application scenario where biological enzymes are used to interact with cellulose in the cell wall of fibers to degrade cellulose to reduce energy consumption for refining, the polymer added in this application Polymers increase paper fiber strength while reducing refining energy consumption.

[0016] Based on this purpose, the following will clearly and completely describe the technical solutions in the embodiments of the present application with reference to the drawings in the embodiments of the present application. It should be understood t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com