System and method for waste lead storage battery desulfurization lead plaster integrated roasting and smelting

A waste lead battery and desulfurization lead paste technology, applied in the field of recycled lead, can solve the problems of unfavorable reduction reaction, unfavorable efficient utilization of heat energy, and influence on the local temperature of the molten liquid, etc., so as to reduce refining energy consumption, high heat energy utilization, The effect of simplifying the refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An integrated roasting and smelting system for desulfurization of lead paste in waste lead storage batteries. The system includes a cylindrical molten pool, which is divided into a rough smelting pool 9 and a pre-refining smelting pool 10 by a cylindrical partition plate 6. A number of through holes 14 are provided at the lower part of the shaped partition plate 6, and the bottoms of the rough smelting pool 9 and the pre-refining bath 10 are provided with a number of air jet nozzles 15. The sides of the pre-refining bath 10 are arranged from top to bottom There is a lead slag outlet 12 and a lead liquid outlet 13, the top of the pre-refining bath 10 is provided with a flue 3, the flue 3 is provided with a dry roasting reaction tower 1, and the top of the dry roasting reaction tower 1 is provided with a first A feeding port 2, the dry roasting reaction tower 1 is provided with a number of inclined plates 5, the top of the pre-refining molten pool 10 is provided with a seco...

Embodiment 2

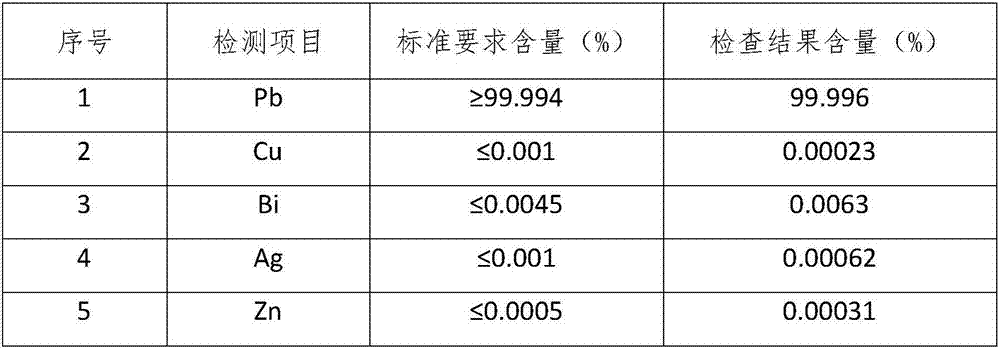

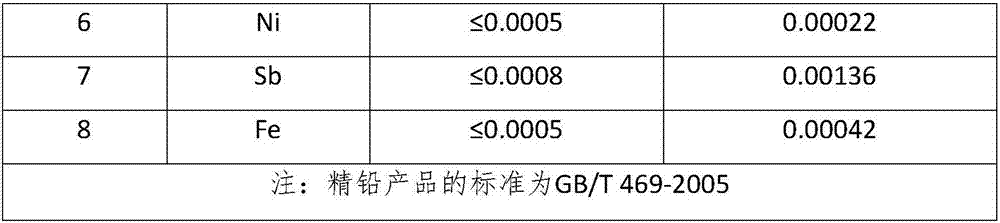

[0023] The integrated roasting and smelting method of desulfurization lead paste for waste lead storage batteries is characterized in that a silicate slagging agent and coke are added to the rough smelting pool 9 and the pre-refining smelting pool 10, and the mixed fuel is sprayed through the jet nozzle 15 to make the two The internal temperature of the desulfurization paste is increased to 700~800℃, and then desulfurization lead paste, iron filings, anthracite and sodium carbonate are injected from the first feeding port 2. The desulfurization lead paste is decomposed into PbO through the drying and roasting reaction tower 1, and then dropped into the coarse smelting tank 9 And the reduction reaction with coke occurs, and the lead droplets precipitated out after reduction accumulate, and CO 2 It reacts with C to generate CO, which promotes the intense reduction of PbO; when the temperature of the molten pool continues to rise to 800-900°C, all the charge is completely melted, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com