Surface modification method for calcium sulfate whiskers

A calcium sulfate whisker and surface modification technology, applied in the field of applied chemistry, can solve the problems of large waste of raw materials, high cost of water treatment, low tensile strength of paper, tear strength, folding resistance, and low bursting strength. Effects of lightening the burden and reducing the amount of Ca2+

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

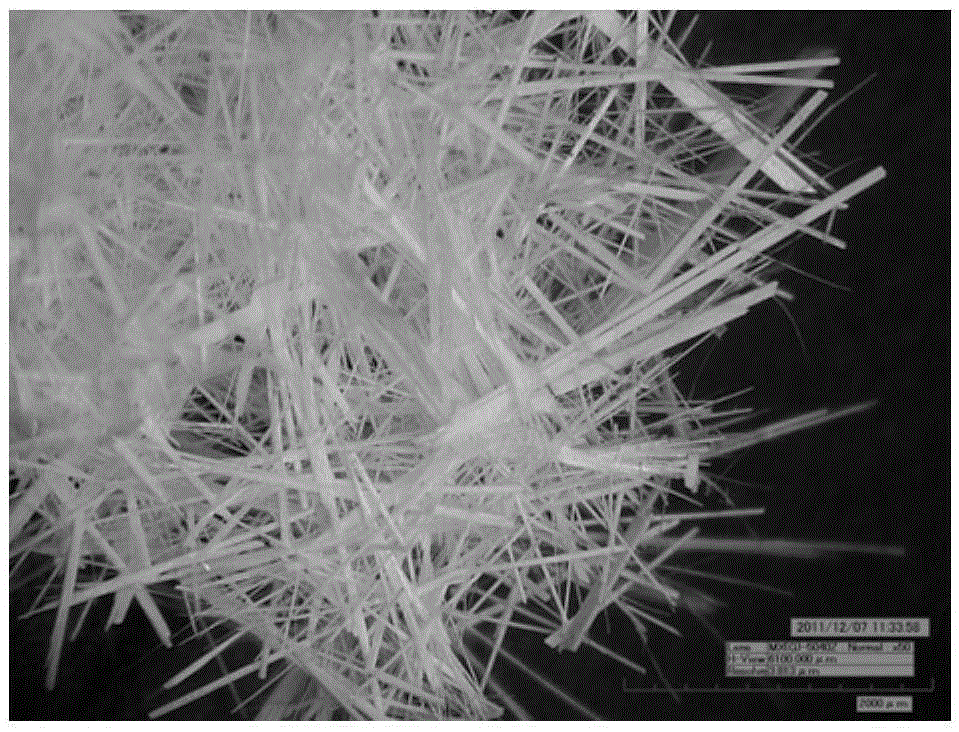

Image

Examples

Embodiment 1

[0028] The surface modification method of the calcium sulfate whisker of the present application, comprises the following steps:

[0029] Preparation of anhydrous calcium sulfate whiskers: weigh Ca(NO 3 ) 2 4H 2 Dissolve O11.8g in 500ml tap water, configure 0.1mol / L calcium nitrate solution, add crystal growth agent MgCl 2 ·6H 2 O, the molar ratio of calcium to magnesium is 13:1. Filter out insoluble impurities and set aside, this is solution A. Heat in a water bath to keep solution A above 40°C, and add H at a concentration of 10% drop by drop. 2 SO 4 solution to Ca 2+ Precipitate completely, sink for 8 hours, filter, wash, and dry at 450°C to obtain anhydrous calcium sulfate whiskers.

[0030] Prepare the surface modifier solution: weigh 0.735 g each of sodium hexametaphosphate and sodium tripolyphosphate, and 0.525 g of zinc sulfate, and mix them evenly. Dissolve in 40mL tap water, add standard NaOH solution to adjust pH to 8, and form a stable solution.

[0031] ...

Embodiment 2

[0034] The surface modification method of the calcium sulfate whisker of the present application, comprises the following steps:

[0035] Preparation of anhydrous calcium sulfate whiskers: weigh Ca(NO 3 ) 2 4H 2 O35.4g is dissolved in 500ml tap water, configure 0.3mol / L calcium nitrate solution, add crystal growth agent MgCl 2 ·6H 2 O, the molar ratio of calcium to magnesium is 13:1. Filter out insoluble impurities and set aside, this is solution A. Heat in a water bath to keep solution A at 50°C, and add 20% H 2 SO 4 solution to Ca 2+ Precipitate completely, sink for 6 hours, filter, wash, and dry at 400°C to obtain anhydrous calcium sulfate whiskers.

[0036] Prepare the surface modifier solution: weigh 0.12 g each of sodium hexametaphosphate, sodium tripolyphosphate, and zinc sulfate, and mix them evenly. Dissolve in 100mL tap water, add standard NaOH solution to adjust the pH to 9 to form a stable solution.

[0037] Anhydrous calcium sulfate whisker modification:...

Embodiment 3

[0040] The surface modification method of the calcium sulfate whisker of the present application, comprises the following steps:

[0041] Preparation of anhydrous calcium sulfate whiskers: weigh Ca(NO 3 ) 2 4H 2 O47.2g is dissolved in 500ml tap water, configure 0.4mol / L calcium nitrate solution, add crystal growth agent MgCl 2 ·6H 2O, the molar ratio of calcium to magnesium is 13:1. Filter out insoluble impurities and set aside, this is solution A. Heat in a water bath to keep solution A at 60°C, and add 30% H 2 SO 4 solution to Ca 2+ Precipitate completely, sink for 2 hours, filter, wash, and dry at 200°C to obtain anhydrous calcium sulfate whiskers.

[0042] Preparation of surface modifier solution: weigh 0.30 g of sodium hexametaphosphate, 0.27 g of sodium tripolyphosphate, and 0.27 g of zinc sulfate, and mix them evenly. Dissolve in 270mL tap water, add standard NaOH solution to adjust pH to 10, and form a stable solution.

[0043] Anhydrous calcium sulfate whisk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com