Coating for power lithium battery diaphragm, power lithium battery diaphragm and preparation thereof

A lithium battery diaphragm and power technology, applied in the field of coatings for power lithium battery diaphragms, can solve the problems of easy lint and powder loss of the diaphragm, increase in production costs, etc., and achieve enhanced coating leveling and water retention, improved liquid absorption, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Containing 10% chlorinated polyvinylidene fluoride, 15% glycerol, 2.5% sodium hypochlorite, 70% N,N-dimethylformamide, 2.5% nano silicon carbide whiskers (average diameter Preparation method of composite coating for power lithium battery separator with a diameter of 50nm and an aspect ratio of 50):

[0033] 1) Dissolve 10g of chlorinated polyvinylidene fluoride into a mixture of 15g of glycerol, 2.5g of sodium hypochlorite and 70g of N,N-dimethylformamide at a temperature of 80°C to form a viscous transparent liquid;

[0034] 2) Add 2.5 g of nano silicon carbide whiskers to the viscous transparent liquid prepared in 1), stir at high speed until it is completely homogenized and dispersed, that is, prepare 100 g of composite paint with a paint viscosity of 6350 mPa·s.

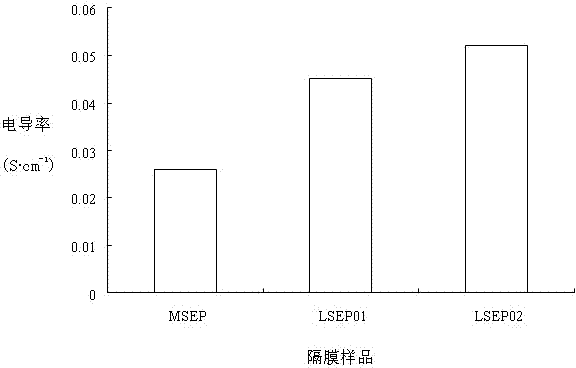

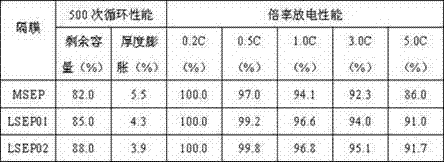

[0035] The preparation method of the power lithium battery separator (LSEP01): The MSEP separator in Comparative Example 1 is used as the wet-laid non-woven fabric substrate. The composite coating can be coat...

Embodiment 2

[0038] Containing 10% chlorinated polyvinylidene fluoride, 20% glycerol, 5% sodium hypochlorite, 60% N,N-dimethylformamide, 5% nano silicon carbide whiskers (average diameter Preparation method of composite coating for power lithium battery separator with a diameter of 80nm and an aspect ratio of 50):

[0039] 1) Dissolve 10g of chlorinated polyvinylidene fluoride into a mixture of 20g of glycerol, 5g of sodium hypochlorite and 60g of N,N-dimethylformamide at a temperature of 80°C to form a viscous transparent liquid;

[0040] 2) Add 5g of nano-silicon carbide whiskers to the viscous transparent liquid prepared in 1), stir at high speed until it is completely homogenized and dispersed, that is, prepare 100g of composite coating with a coating viscosity of 7320mPa·s.

[0041] The preparation method of the power lithium battery separator (LSEP02): The MSEP separator in Comparative Example 1 is used as the wet-laid non-woven fabric substrate, and the composite coating can be coated ...

Embodiment 3

[0044] Containing 15% chlorinated polyvinylidene fluoride, 20% glycerol, 2.5% sodium hypochlorite, 60% N,N-dimethylformamide, 2.5% nano silicon carbide whiskers (average diameter Preparation method of composite coating for power lithium battery separator with a diameter of 100nm and an aspect ratio of 30):

[0045] 1) Dissolve 15g of chlorinated polyvinylidene fluoride into a mixture of 20g of glycerol, 2.5g of sodium hypochlorite and 60g of N,N-dimethylformamide at a temperature of 80°C to form a viscous transparent liquid;

[0046] 2) Add 2.5g of nano-silicon carbide whiskers to the viscous transparent liquid prepared in 1), stir at high speed until it is completely homogenized and dispersed, that is, prepare 100g of composite coating with a coating viscosity of 6410mPa·s.

[0047] The preparation method of the power lithium battery separator (LSEP03): The MSEP separator in Comparative Example 1 is used as the wet-laid non-woven fabric substrate. The composite coating can be co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com