Preparation method and application of oxidized starch

A technology for oxidizing starch and starch, applied in the addition of water repellent, coating, paper coating, etc., can solve the problems of poor starch granule concentration, affecting product application, low degree of oxidation, etc., to improve smoothness and gloss, improve Bursting strength and folding strength, the effect of modified oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

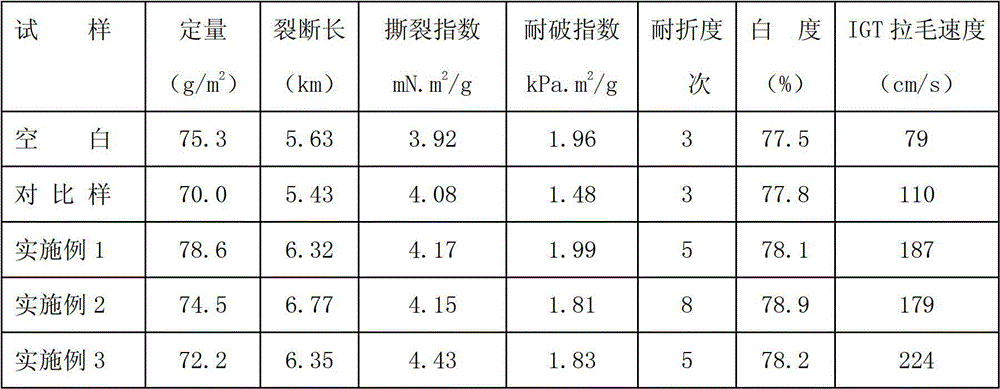

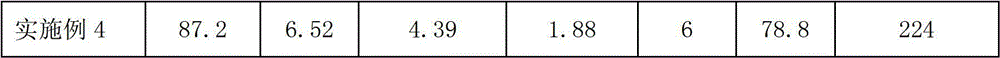

Examples

Embodiment 1

[0028] (1) Add 300g of starch into the mixer, start stirring, spray 13g of sodium hydroxide solution with a weight concentration of 2% with a sprayer, and after stirring for 10 minutes, spray 7.7g of hydrogen peroxide with a weight concentration of 17%, and heat up to 50°C ;

[0029] (2) Stir once every 15 minutes within one hour, spray 7.7g of hydrogen peroxide with a weight concentration of 17% every 1 minute, and react for 4 hours at a temperature of 50°C;

[0030] (3) Cool to 25°C, spray into hydrochloric acid solution with a weight concentration of 10% to neutralize the pH of the system to 7.0, stir, pulverize, and pass through a 100-mesh sieve to obtain the product, using WS-SD d / O chroma white The whiteness of the oxidized starch is 92% by the degree meter, tested by the GB / T 20374-2006 standard, the carboxyl content is 0.35%, tested by the HG / T3933-2007 standard, the spots (pcs / cm2) = 0,6% The viscosity of the solution was 34 cps, which remained essentially unchanged ...

Embodiment 2

[0032] (1) Add 300g of starch into the mixer, start stirring, spray 26g of sodium hydroxide solution with a weight concentration of 2% with a sprayer, stir for 5 minutes, spray 5g of hydrogen peroxide with a weight concentration of 14%, and heat up to 50°C;

[0033] (2) Stir once every 15 minutes within one hour, spray 4.4g of 14% hydrogen peroxide for 2 minutes each time, and react for 6 hours at a temperature of 40°C;

[0034] (3) Cool to 25°C, spray 5g of hydrochloric acid solution with a weight concentration of 10%, the pH of the neutralization system is 6.8, stir, pulverize, and pass through a 100-mesh sieve to obtain the product.

[0035] The whiteness of oxidized starch is 94% by WS-SD d / O chromaticity and whiteness meter, the carboxyl content is 0.22% by GB / T 20374-2006 standard, and the test is by HG / T3933-2007 standard, the spot ( pieces / cm2)=0,6% solution has a viscosity of 42cps, basically unchanged within 24 hours.

Embodiment 3

[0037] (1) Add 300g of starch into the mixer, start stirring, spray 34.8g of 3% potassium hydroxide solution with a sprayer, stir for 8 minutes, spray 5.5g of 23% hydrogen peroxide, and heat up to 35°C;

[0038] (2) Stir once every 15 minutes within one hour, spray 11.7g of 23% hydrogen peroxide for 3 minutes each time, and react for 7 hours at a temperature of 35°C;

[0039] (3) Cool to 25°C, spray into 10% by weight hydrochloric acid solution to neutralize to pH 8.0, stir, pulverize, and pass through a 100-mesh sieve to obtain the product;

[0040] The whiteness of oxidized starch is 93% when tested by WS-SD d / O color and whiteness meter. It is tested by GB / T 20374-2006 standard. The carboxyl content is 0.41%. It is tested by HG / T3933-2007 standard. Spots (piece / cm2)=0,6% solution has a viscosity of 28cps, basically unchanged within 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com