Method for recovery and utilization of waste heat from low temperature flue gas

A technology of waste heat recovery and low-temperature flue gas, applied in heating methods, applications, preheating, etc., can solve problems such as waste and achieve the effect of heat energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

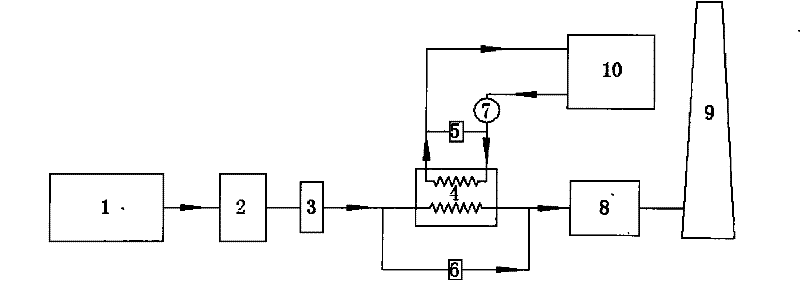

[0012] like figure 1 As shown: this embodiment is a device for heating circulating water, mainly composed of a boiler or kiln 1, a dust collector 2, an induced draft fan or a booster fan 3, an air-water heat exchanger 4, a waterway bypass regulating valve 5, The flue bypass regulating valve 6, the circulation pump 7, the desulfurization absorption tower 8, the chimney 9, and the heat user 10 constitute. Each part is connected by pipes, accessories, valves, etc. The air-water heat exchanger 4 (patent applied for separately) is connected in series or in parallel in the flue between the induced draft fan or booster fan 3 and the desulfurization absorption tower 8, the hot side inlet end of the air-water heat exchanger 4 is connected to the induced draft fan Or the booster fan 3 is connected, the outlet end of the hot side is connected with the desulfurization absorption tower 8 or the chimney 9, the inlet end of the cold side is connected with the return water end of the hot use...

Embodiment 2

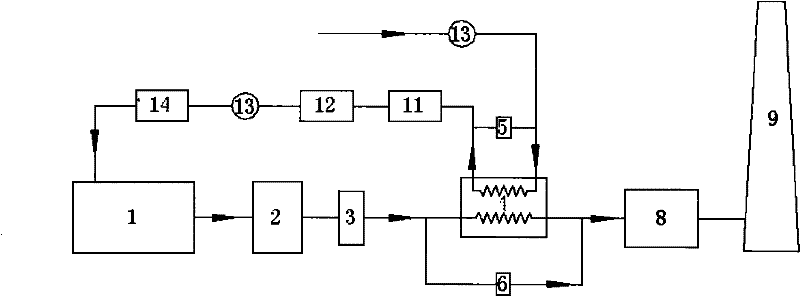

[0014] like figure 2 As shown: this embodiment is the device for heating boiler feed water according to the present invention, which is mainly regulated by boiler or kiln 1, dust collector 2, induced draft fan or booster fan 3, air-water heat exchanger 4, and water bypass Valve 5, flue bypass regulating valve 6, circulation pump 7, desulfurization absorption tower 8, chimney 9, low pressure heater 11, deaerator 12, feed water pump 13 and high pressure heater 14. Each part is connected by pipes, accessories, valves, etc. The air-water heat exchanger 4 (patent applied for separately) is connected in series or in parallel in the flue of the induced draft fan or booster fan 3 and the desulfurization absorption tower 8, the hot side inlet end of the air-water heat exchanger 4 is connected with the induced draft fan or The compressor 3 is connected, the hot side outlet is connected to the desulfurization absorption tower 8 or the chimney 9, the cold side inlet of the air-water hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com