Method for preparing modified calcium sulfate whisker by using desulfurization gypsum

A calcium sulfate whisker and desulfurization gypsum technology, applied in chemical instruments and methods, calcium/strontium/barium sulfate, single crystal growth, etc., can solve problems such as complex process, difficult realization, and difficult industrial scale-up and mass production, and achieve The preparation process is green and environmentally friendly, the production cost is low, and the modification effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

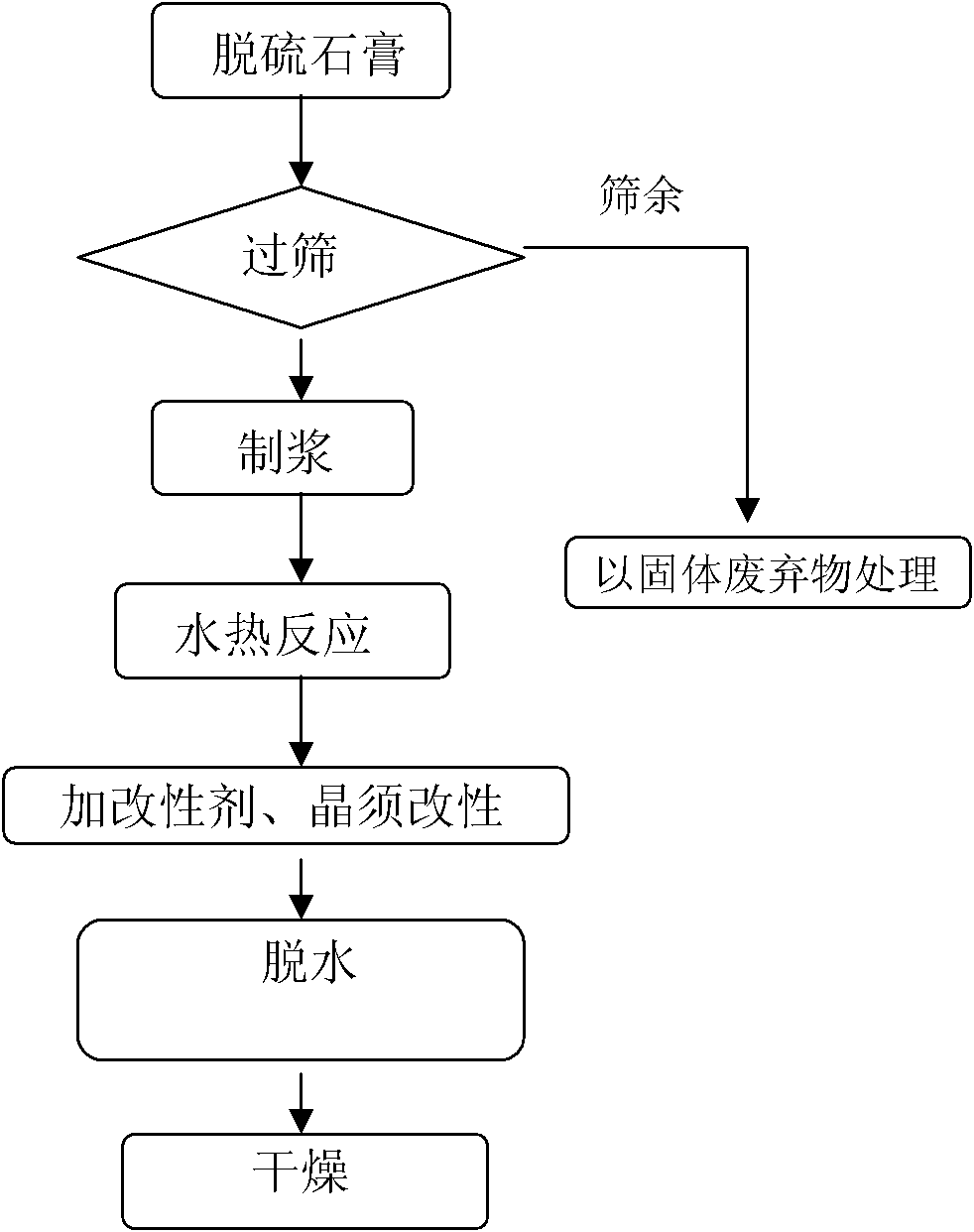

[0025] The process steps are as follows:

[0026] ① Sieving: Sieving the desulfurized gypsum with a 0.08mm sieve to remove sand, stones and other impurities in the desulfurized gypsum. Impurities are treated as solid waste.

[0027] ②Pulping: Weigh 500g of desulfurized gypsum after sieving, measure 10L of tap water with a graduated cylinder, then mix the prepared desulfurized gypsum with water, adjust the pH of the solution to 5 with NaOH and HCl, and finally stir with a mixer for 20 second.

[0028] ③Hydrothermal reaction: Put the stirred slurry in a high-pressure reactor, control the reaction temperature to 125°C, the pressure corresponding to the temperature is about 0.232Mpa, and the holding time is 300min;

[0029] ④Whisker surface modification: Add 0.05% acrylic acid-maleic acid copolymer and 2% sodium lauryl sulfate by weight of desulfurization gypsum to the autoclave, and keep it warm for 60 minutes;

[0030] ⑤Dehydration: Use a centrifuge to separate the calcium sulfate whisk...

Embodiment 2

[0035] The process steps are as follows:

[0036] ①Sieving: sieving the desulfurized gypsum with a 1.18mm sieve to remove impurities such as sand and gravel in the desulfurized gypsum. Impurities are treated as solid waste.

[0037] ②Pulping: Weigh 3300g of desulfurized gypsum after sieving, measure 10L of tap water with a graduated cylinder, then mix the prepared desulfurized gypsum with water, adjust the pH of the solution to 10 with NaOH and HCl, and finally stir with a mixer for 60 second.

[0038] ③Hydrothermal reaction: Put the stirred slurry in a high-pressure reactor, control the reaction temperature to be 180°C, and the pressure corresponding to the temperature to be 1.052Mpa for 30 minutes;

[0039] ④Whisker surface modification: Add 0.3% potassium oleate by weight of desulfurized gypsum to the high-pressure reactor, and keep it warm for 40 minutes;

[0040] ⑤Dehydration: Use a centrifuge to separate calcium sulfate whiskers and water into solid and liquid, so that the moist...

Embodiment 3

[0044] The process steps are as follows:

[0045] ①Sieving: Sieving the desulfurized gypsum with a 1.18mm sieve to remove sand, stones and other impurities in the desulfurized gypsum. Impurities are treated as solid waste.

[0046] ②Pulping: Weigh 1000g of desulfurized gypsum after sieving, measure 10L of tap water with a graduated cylinder, then mix the prepared desulfurized gypsum with water, adjust the pH of the solution to 7 with NaOH and HCl, and finally stir with a mixer for 120 second.

[0047] ③Hydrothermal reaction: Put the stirred slurry in a high-pressure reactor, control the reaction temperature to 130°C, and the pressure corresponding to the temperature to 0.270Mpa, and the holding time for 150min;

[0048] ④Whisker surface modification: Add 5% sodium tetradecyl sulfate by weight of desulfurization gypsum to the high-pressure reactor, and keep it warm for 60 minutes;

[0049] ⑤Dehydration: Use a centrifuge to separate calcium sulfate whiskers and water into solid and liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com