Aqueous slurry material containing silicon dioxide aerosol, preparation method and application thereof

A technology of silica and water-based slurry, applied in the direction of coating, etc., can solve the problems of difficulty in controlling the hydrophobic and hydrophilic properties of airgel, cumbersome process, etc., achieve low cost, simple preparation process, and avoid the effect of powder release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

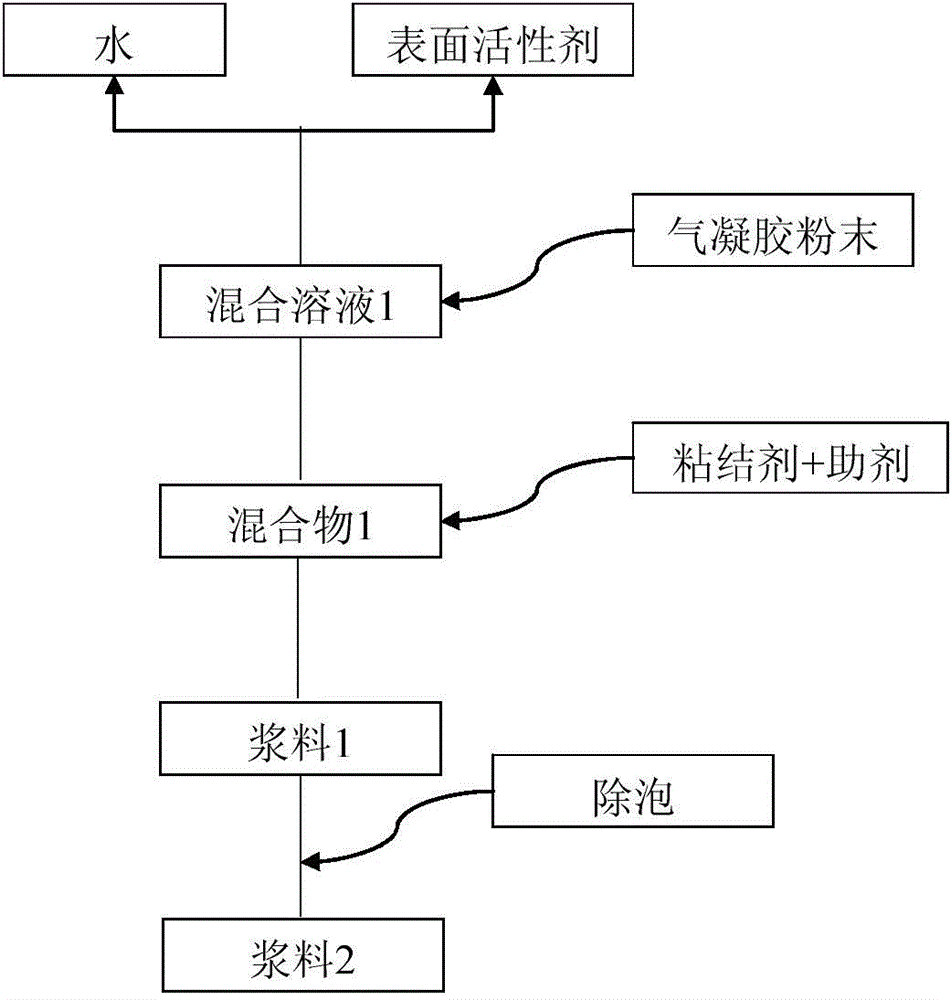

[0042] see figure 1 , as a typical embodiment of the present invention, the preparation method of the aqueous slurry containing silica airgel comprises:

[0043](1) Mix water and surfactant evenly to form a mixed solution (mixed solution 1);

[0044] (2) Add silica airgel powder to the mixed liquid, mix uniformly to form a suspension (mixture 1),

[0045] (3) Add binder and additives that may or may not be added to the suspension, and mix uniformly to form the aqueous slurry (slurry 1).

[0046] Further, in this typical embodiment, after the slurry 1 is prepared, defoaming treatment can be carried out according to actual needs to obtain the slurry 2, wherein the defoaming method can be defoaming by using a defoaming agent or vacuum stirring.

[0047] Further, the mixing method adopted in the preparation method is at least selected from ball milling, mechanical stirring, sand milling, and ultrasonic mixing methods.

[0048] The mixing method adopted in step 1) of the present...

Embodiment 1

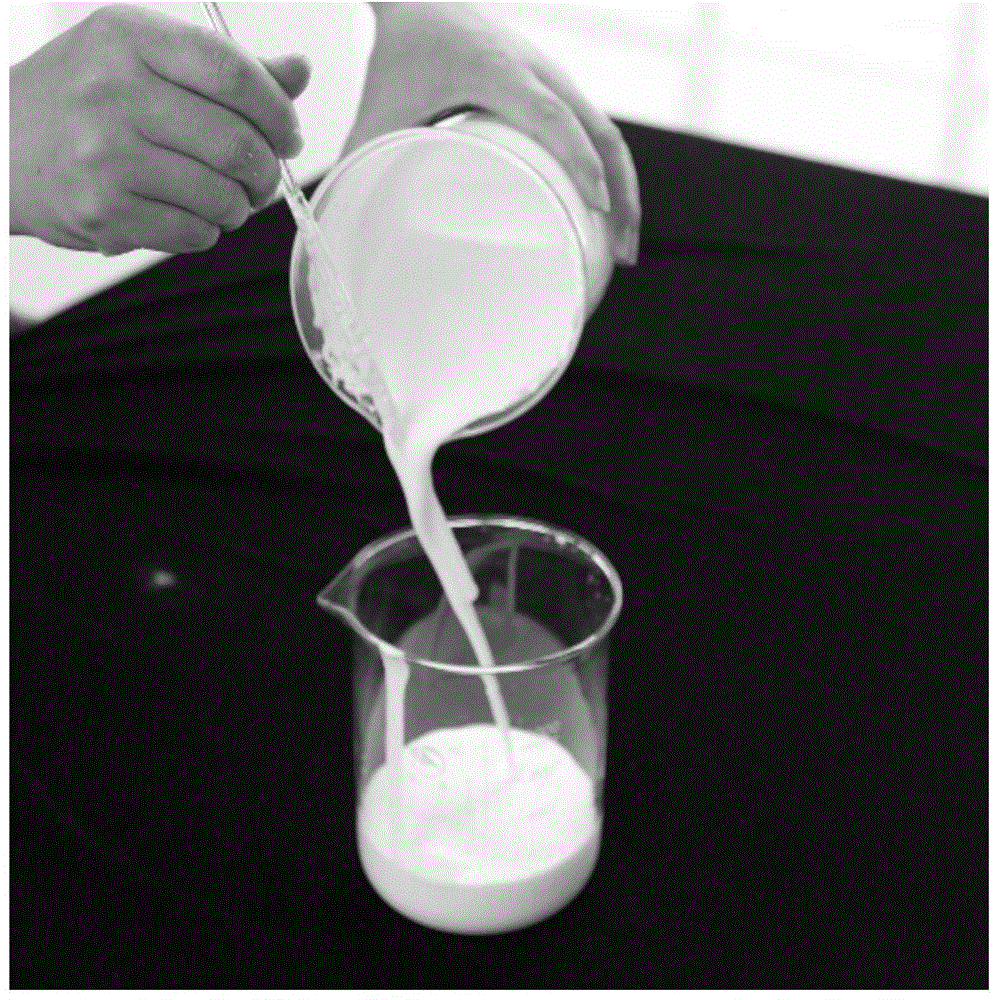

[0061] Example 1 Mix 80g of deionized water and 2g of triethanolamine with a mechanical stirrer, the stirring speed is 100rpm, and the stirring time is 5 minutes to obtain a uniform mixed solution. Add 10g of silica airgel powder to the mixed solution. The density is 0.1g / ml, the average particle size is 50μm, the stirring speed is 500rpm, and the stirring time is 30 minutes. The prepared airgel dispersion should be a milky white stable dispersion system. Add 5g polyvinyl alcohol to the dispersion 1500, 1.5g polyethylene glycol 400 and 1.5g dibutyl phthalate, use a mechanical stirrer to stir for 30 minutes, the stirring speed is 200rpm, the slurry obtained is defoamed in a vacuum defoamer for 20 minutes, defoaming The stirring speed is 10 rpm, and the vacuum degree is 0.08 atm. The airgel aqueous slurry was obtained, and the viscosity of the slurry was 2000mPa / s. The airgel slurry was sprayed onto the aluminum alloy base plate by spraying, with a spray thickness of 0.5mm, and...

Embodiment 2

[0062] Example 2 20g of deionized water and 2g of triethanolamine were mixed with a mechanical stirrer, the stirring speed was 100rpm, and the stirring time was 5 minutes to obtain a uniform mixed solution, and 10g of silica airgel powder was added to the mixed solution, the powder Density is 0.1g / ml, and average particle diameter is 50 μ m, and stirring speed is 500rpm, and stirring time is 30 minutes, and the airgel dispersion liquid of preparation should be milky white stable dispersion system, add 64g deacrylic acid emulsion and 20 g of water and 4 g of Texanol were mixed for 10 minutes using a mechanical stirrer at a stirring speed of 200 rpm. The obtained slurry was defoamed in a vacuum defoamer for 20 minutes, the defoaming stirring speed was 10 rpm, and the vacuum degree was 0.08 atm. The airgel water-based slurry was obtained, and the viscosity of the slurry was 3500 mPa / s. The airgel slurry was sprayed onto the aluminum alloy base plate by spraying with a spray thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com