Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Seamless integration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vehicular phone device and seamless automatic conversion system and method with the mobile phone

InactiveCN101018067ASeamless integrationOperational securityAutomatic call-answering/message-recording/conversation-recordingTransmissionMobile Telephone NumberComputer hardware

The vehicle-carried telephone device comprises: a vehicle-carried telephone with a master controller connected with keyboard / wireless communication module / microphone array / vehicle igniting / extinguishing sensor, a user mobile phone, a call-diverting center stored phone number and communication database, a mobile communication network, and an external telephone. Wherein, the master controller also includes a message storage module and a command transmission module. This invention prevents user from missing calling.

Owner:GUANGZHOU SUNRISE COMM EQUIP

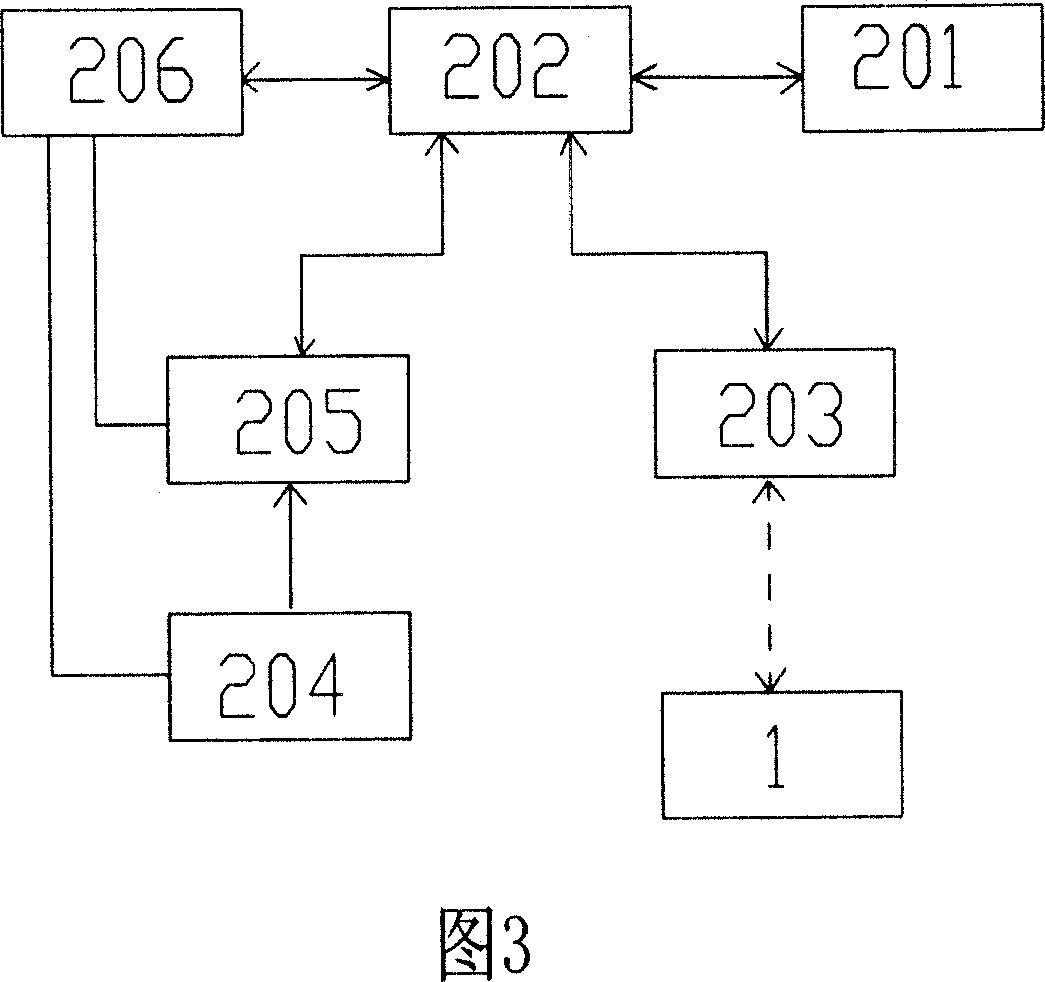

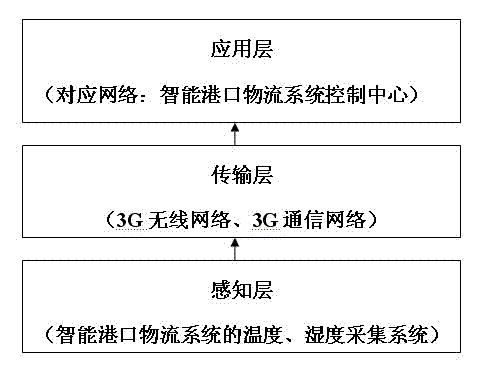

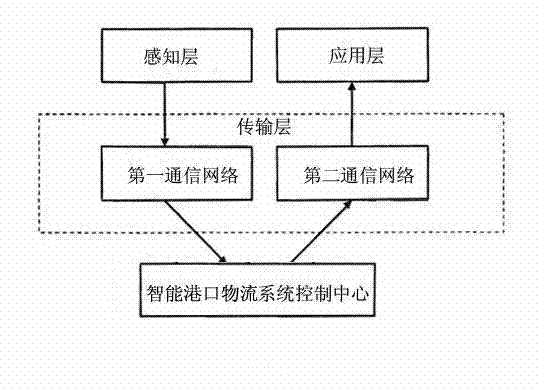

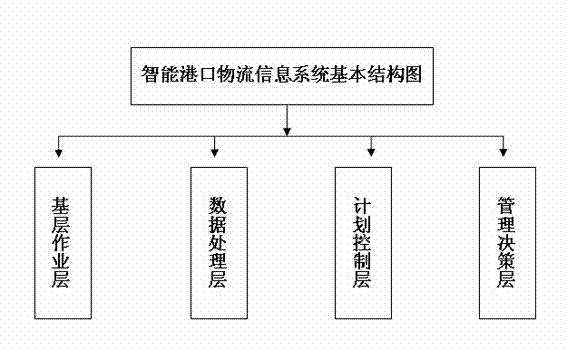

Intelligent port logistics system and device based on third-generation (3G) internet of things application platform

InactiveCN102968704AQuickly identify entry and exit situationsAccurate identificationLogisticsTransmissionLogistics managementRemote control

The invention discloses an intelligent port logistics system and device based on a third-generation (3G) internet of things application platform and relates to collection and distribution, transit shipment, storage, trading, processing, ports, multimodal transport, cargo agency and device dispatching management of port cargoes. The intelligent port logistics system and device comprises a port logistics system and device and is characterized in that the 3G technology and the internet of things technology are integrated into the port logistics system and device to form the intelligent port logistics system and device. The intelligent port logistics system and device is provided with a real-time remote data collection processing system, a monitoring system and an operation system and device, and improves operation efficiencies in links of port logistics operation, transport service, port management, the port logistics system and device and the like. The intelligent port logistics system has individuality identification and data sharing functions due to internet of things chips arranged on the port logistics device and cargoes, can achieve mutual connection of things, achieves remote control and reduces port logistics cost, and a modern port logistics system which is real-time, accurate, efficient and high-quality in the port service range can be built in future.

Owner:倪晓旺

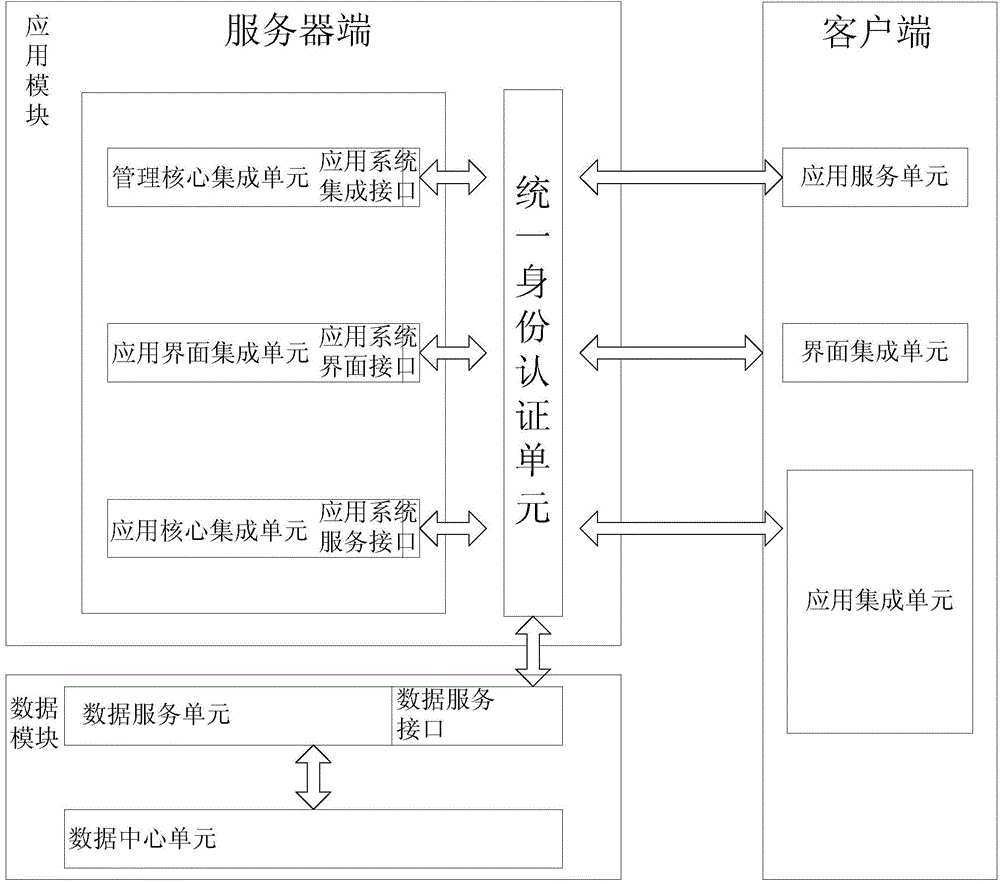

Cloud terminal platform integrating application systems and integrating method

InactiveCN104660680ASeamless integrationEfficient integrationTransmissionTeam workingInformation sharing

The invention provides a cloud terminal platform integrating application systems and an integrating method, and discloses an information system integrating platform. The information system integrating platform comprises a server side and a client side, wherein the server side comprises a data module, an application module, and an interface unit communicating data with the client side; the data module comprises a data center unit and a data service unit; the application module comprises an application core integrating unit, an application interface integrating unit, a management core integrating unit and a unified identity certification unit; the client side comprises an application integrating unit, an interface integrating unit and an application service unit. The information system integrating platform disclosed by the invention effectively integrates all business application systems, and realizes not only integrated display of a B / S framework system and a C / S framework system, but also functions such as information sharing, function sharing and interface sharing, and inter-system team working.

Owner:青岛市环境信息中心 +1

Method for realizing video advertisement injecting in video on demand based on HLS (HTTP Live Streaming) protocol

InactiveCN104135678AIncrease flexibilityAvoid black screenSelective content distributionComputer graphics (images)Http live streaming

The invention discloses a method for realizing video advertisement injecting in video on demand based on an HLS (HTTP Live Streaming) protocol, and belongs to a video advertisement injecting method. The method for realizing video advertisement injecting in video on demand based on the HLS protocol is a method for realizing video advertisement injecting in video on demand in a video on demand system. The video on demand system comprises a server side, a network and a client, wherein the server side is communicated with the client through the network; a video advertisement server is arranged on the server side; video advertisements need to be subjected to the preprocessing of classification, transcoding, slicing and the like; and in case of client user video on demand, the video on demand system is used for dynamically generating a m3u8 video file, and the video advertisement server is used for inserting a sliced file of a video advertisement into the m3u8 video file. By adopting the method, the problem of black screen caused by switching of video advertisements and videos is solved. Moreover, the method is convenient to modify, and has high flexibility.

Owner:INSPUR QILU SOFTWARE IND

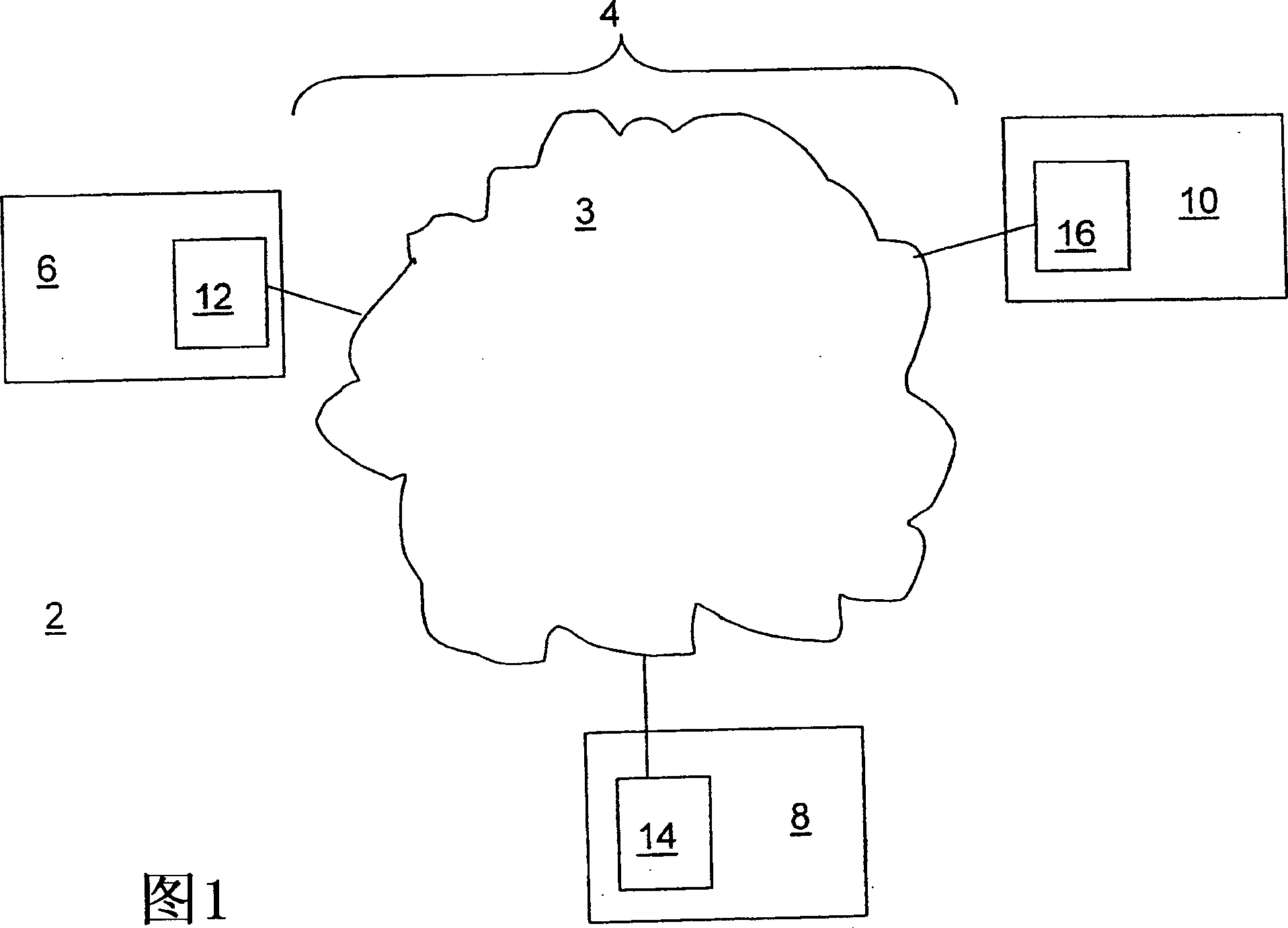

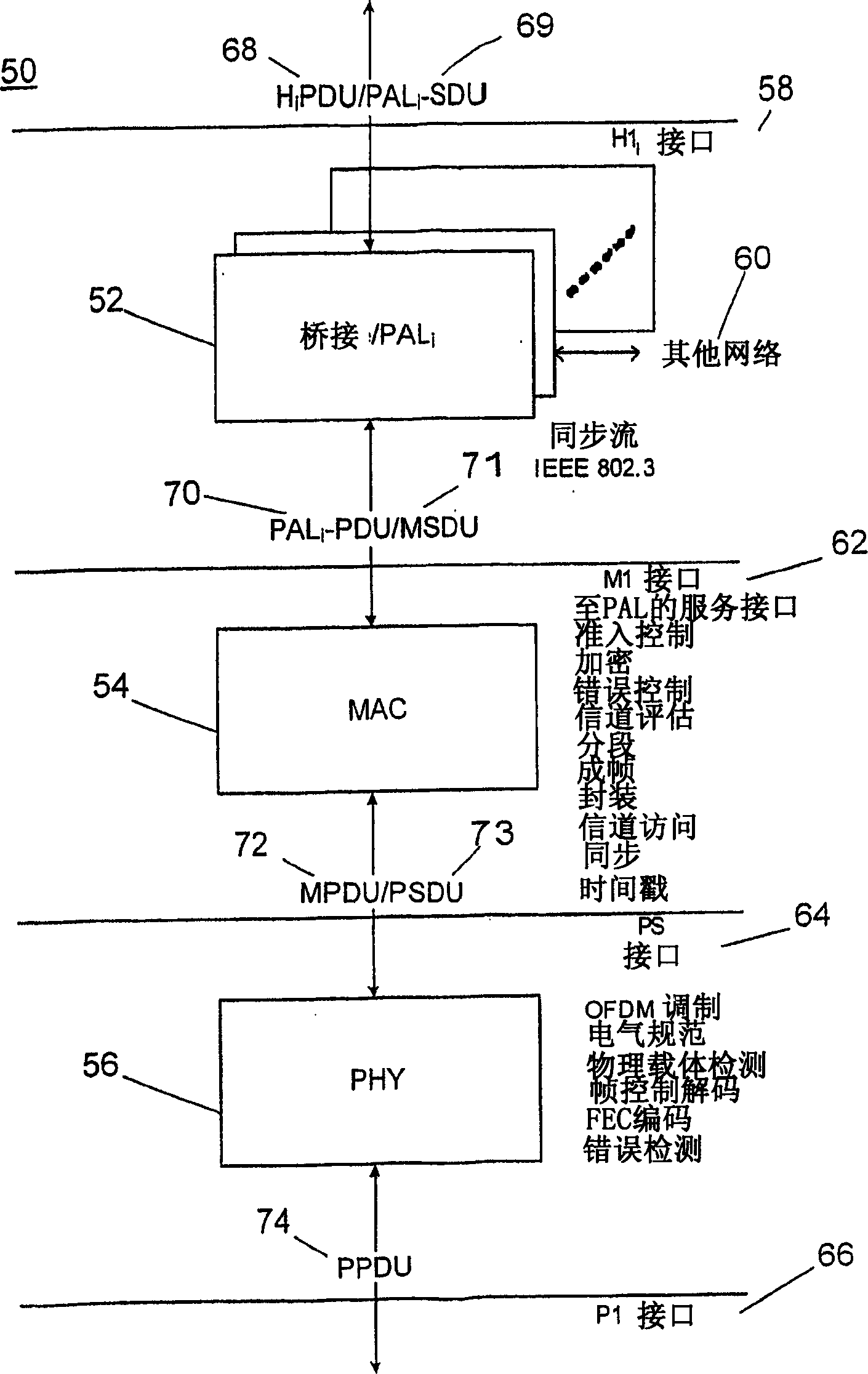

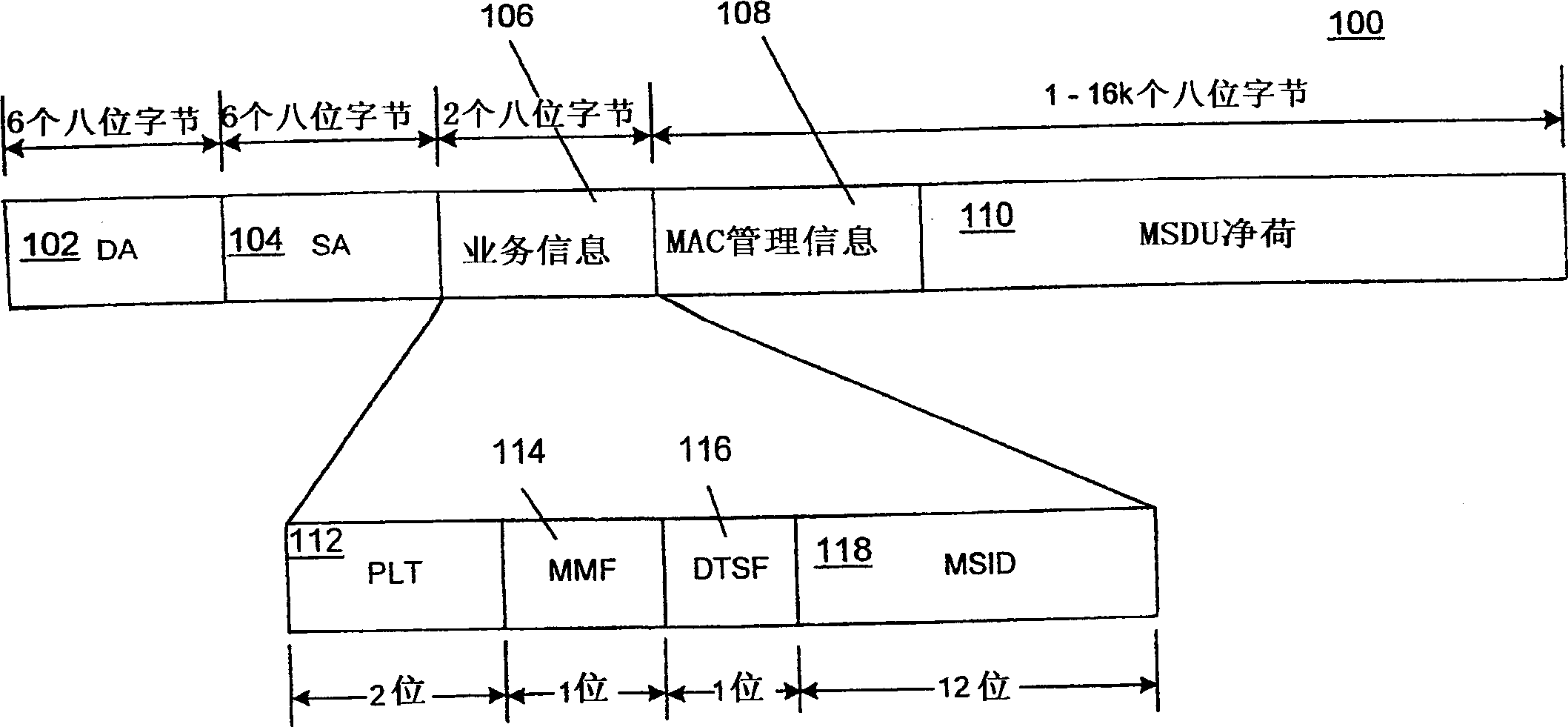

Operation method of multiple network communication based on shared medium

ActiveCN1918558AImprove service qualityAchieve retransmissionError prevention/detection by using return channelDigital computer detailsPALShared medium

A method of operating in a network in which a plurality of stations communicate over a shared medium, comprising providing a physical layer (e.g., PHY) for handling physical communication over the shared medium; providing a high level layer (e.g., PAL) that receives data from the station and supplies high level data units (e.g., MSDUs) for transmission over the medium; providing a MAC layer that receives the high level data units from the high level layer and supplies low level data units (e.g., MPDUs) to the physical layer; at the MAC layer, encapsulating content from a plurality of the high level data units; dividing the encapsulated content into a plurality of pieces (e.g., segments) with each piece capable of being independently retransmitted; and supplying low level data units containing one or more of the plurality of pieces.

Owner:QUALCOMM INC

Network public whiteboard system and method based on cloud computing

InactiveCN102916998ALow computing power requirementsEasy to importTransmissionComputer networkWhiteboarding

The invention discloses a network public whiteboard system based on cloud computing, and the system comprises terminals and a network public whiteboard platform, wherein the terminals communicate with the network public whiteboard platform through a browser, the network public whiteboard platform further comprises a transmitting unit, a foreground U1 unit and a network public whiteboard processing unit, the foreground U1 unit at least comprises a display subunit and an interaction subunit, the display subunit is used for displaying the data in the browser of the terminals, and the interaction subunit is used for intercepting and capturing input operation on the browser of the terminals through a message hook and sending the input operation to the network public whiteboard processing unit through the transmitting unit; and the network public whiteboard processing unit is used for receiving operation data on the browser of the terminals, processing requests of different users, coordinating the parallel processing of the users, transmitting the processing result through the transmitting unit and displaying the processing result on the corresponding terminal browser through the foreground U1 unit.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

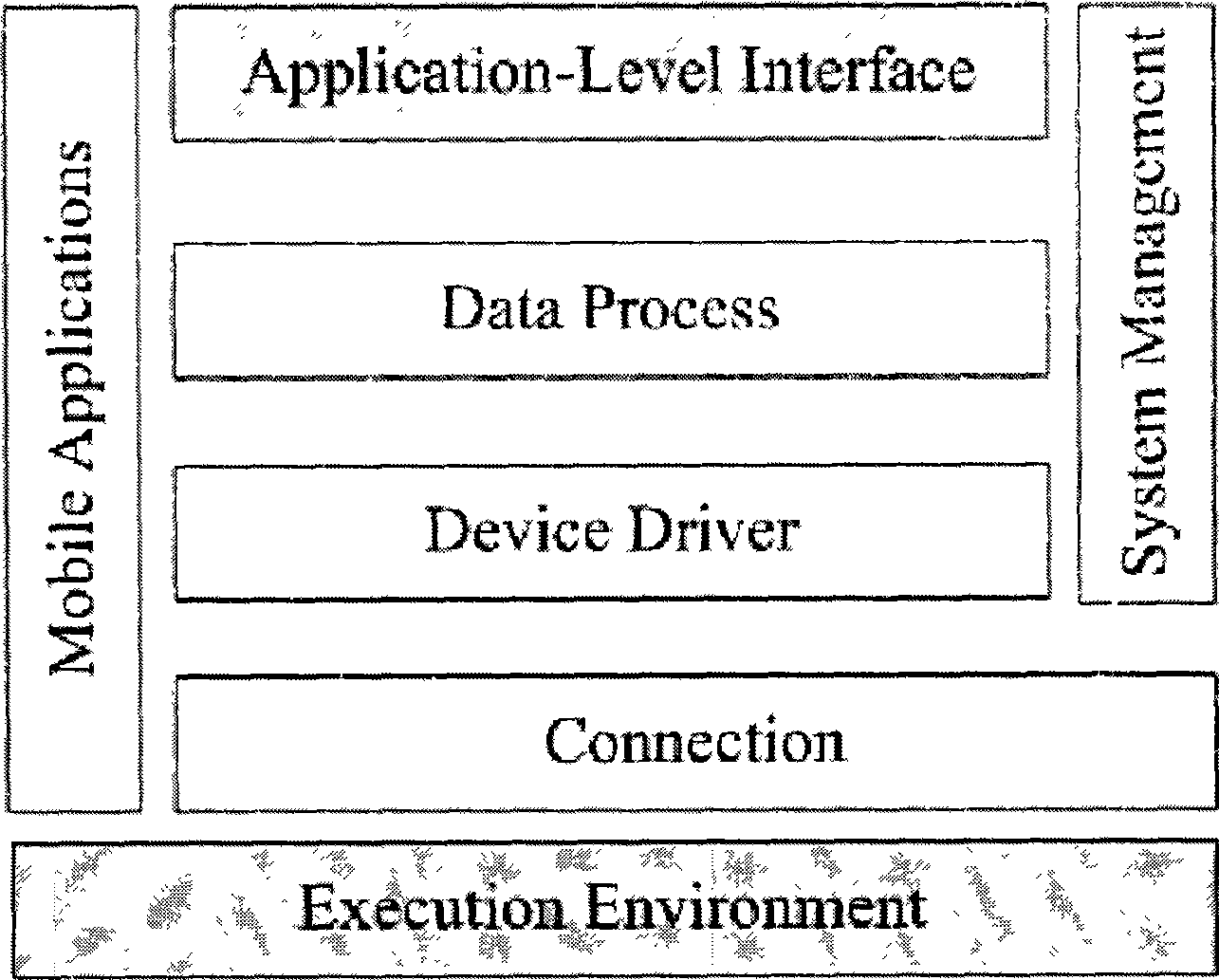

Embedded RFID middleware based on light-weight ALE

ActiveCN101477635AImprove work performanceReduce resource burdenCo-operative working arrangementsSensing record carriersExtensibilityProcess mechanism

The invention provides an embedded-type RFID middleware based on lightweight ALE. The embedded-type RFID middleware comprises a lightweight ALE module, a mobile proxy module, a data buffer pool, a middleware configuration management module and an equipment management module, wherein, the lightweight ALE module is connected with an application service logic layer upwards; the mobile proxy model isconnected with an external background RFID middleware or an RFID application system and simultaneously connected with the internal lightweight ALE module; the data buffer pool module is connected with the equipment management module downwards and connected with the lightweight ALE module upwards; the middleware management module is connected with the other four modules respectively; and the equipment management is connected with a physical reader downwards. By arranging the lightweight ALE module, the embedded-type RFID middleware can achieve multi-event handling and user subscription and processing mechanism. Through data buffer pool mechanism, seamless connection between the ALE layer and the equipment management layer and the tag information distribution can be achieved to solve the problem of over-high coupling degree among the modules and to improve the re-configurability and the extensibility of the system, thereby realizing transparent application layer.

Owner:SOUTH CHINA UNIV OF TECH

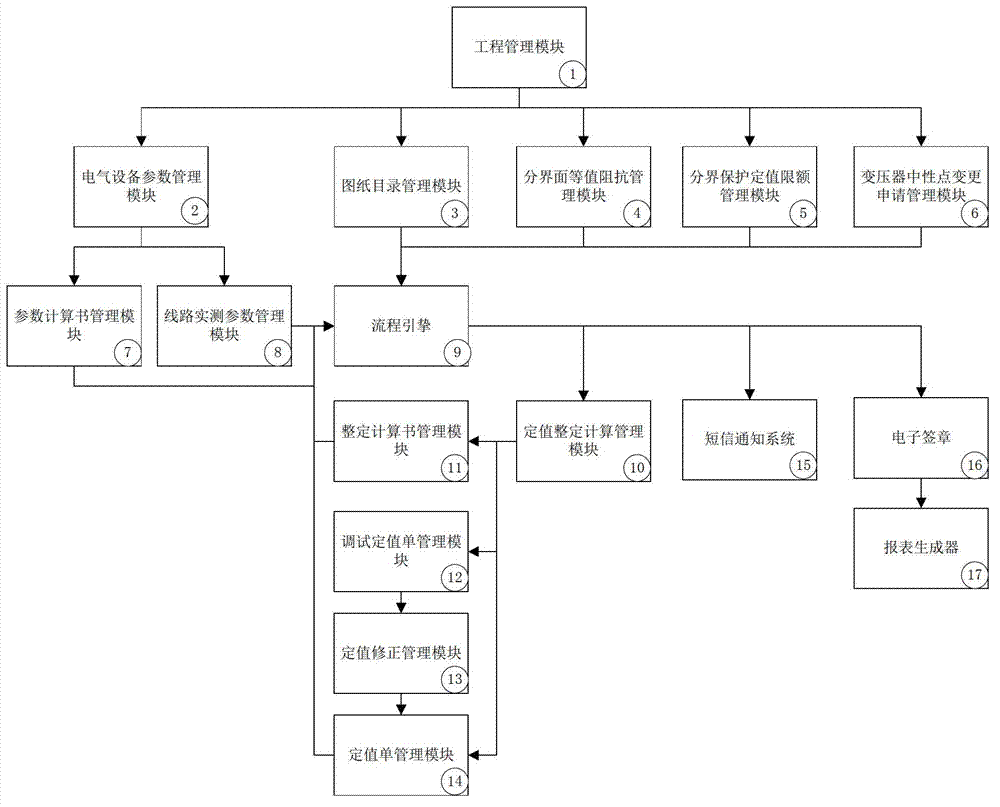

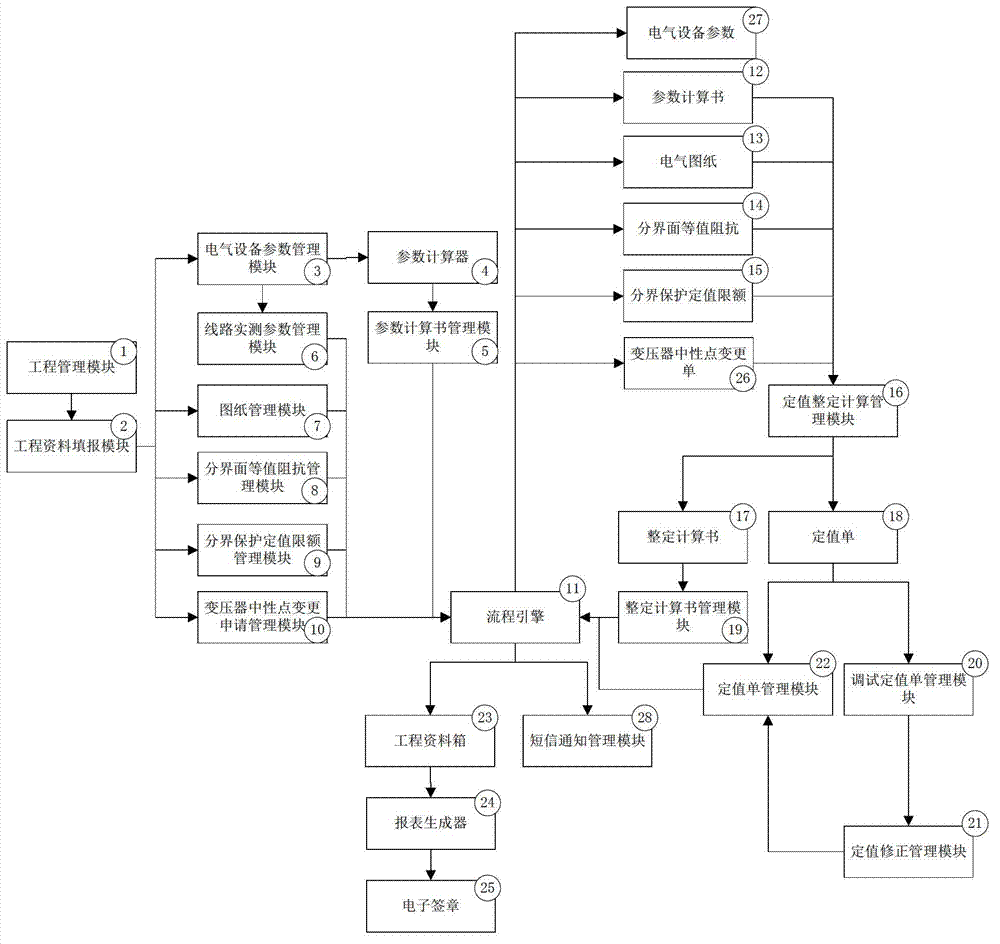

Implementation method of province, city and county integrated relay protection setting calculation overall-process management system

InactiveCN102768750AImprove reliabilityImprove stabilityData processing applicationsValue setElectrical devices

The invention provides an implementation method of a province, city and county integrated relay protection setting calculation overall-process management system. The system comprises an engineering management module (1), an electrical equipment parameter management module (2), a drawing list management module (3), a boundary surface equivalent impedance management module (4), a boundary protection fixed-value quota management module (5), a transformer neutral point management module (6), a parameter calculation sheet management module (7), a circuit actual measurement parameter management module (8), a process engine (9), a fixed-value setting management system (10), a setting calculation sheet management module (11), a debugging report form management module (12), a report form amendment management module (13), a report form management module (14), a short message notification management module (15), an electronic seal (16) and a report form generator (17). The invention provides a richer data showing means; the workloads of full-time staff for setting calculation are greatly reduced; the working efficiency and the economic benefit are increased; and paperless, informationized and standardized process closed-loop management on the whole process of relay protection setting calculation is realized.

Owner:YUNNAN POWER GRID CORP TONGFANG TECHCO

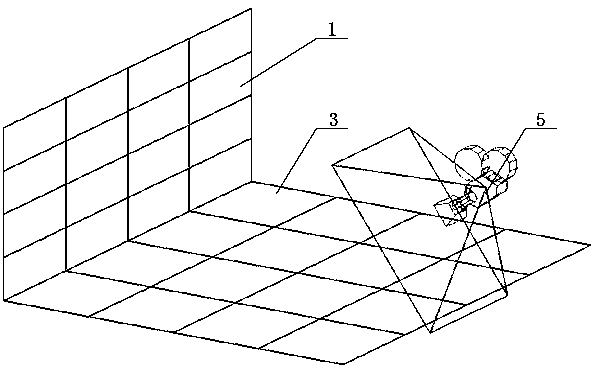

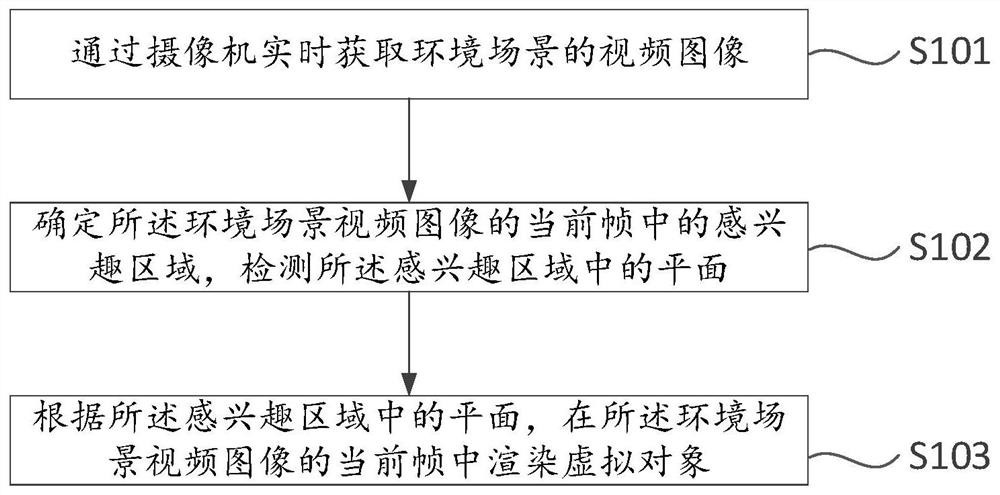

Method and device for realizing augmented reality based on plane detection

ActiveCN107665505AImprove fitAchieve seamless integrationDetails involving 3D image data3D-image renderingRegion of interestVideo camera

The present invention provides a method and device for realizing augmented reality based on plane detection. The method comprises the following steps that: the video images of an environment scene areobtained in real time through a camera; a region of interest in the current frame of the video images of the environment scene is determined, and a plane in the region of interest is detected; and avirtual object is rendered in the current frame of the video images of the environment scene according to the plane in the region of interest. The present invention also provides a device for realizing augmented reality based on plane detection. According to the method and device for realizing augmented reality based on plane detection of the invention, the plane in the region which a user is interested in of the video images of the environment scene is detected; the pose of the virtual object which is to be subjected to superimposed rendering is made to be consistent with the plane of the superimposed position of the virtual object; and therefore, the fitting degree of the virtual object and the real environment scene is obviously improved, and the seamless integration of the virtual object and the real environment can be realized.

Owner:CHENGDU IDEALSEE TECH

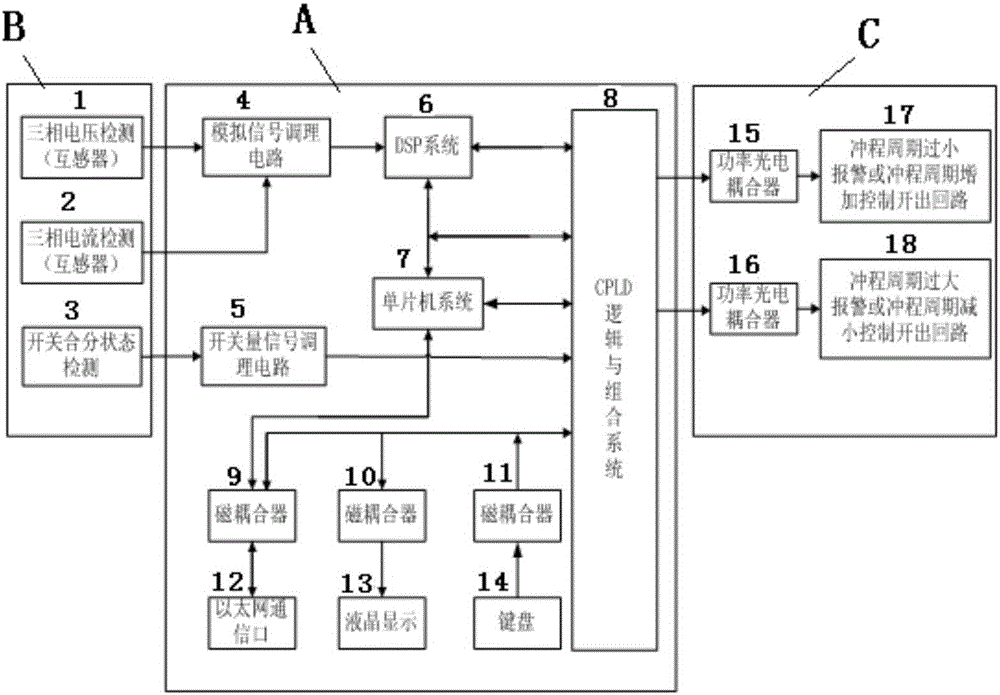

Soft measuring method and device for stroke period of beam-pumping unit

The invention relates to a soft measuring method and device for a stroke period of a beam-pumping unit. A beam-pumping unit driving motor electric parameter and other signal detection unit is used for collecting three-phase instantaneous voltage and current values of a pumping unit driving motor electric energy input circuit, instantaneous active power values of the pumping unit driving motor electric energy input circuit are calculated according to an instantaneous reactive power theoretical formula or an instantaneous power definition formula, a modern information processing method is used for calculating the period of an instantaneous active power function so as to indirectly obtain the stroke period Tc of the pumping unit, and therefore a period adjusting instruction and alarming information are sent out according to whether Tc exceeds the threshold value or not. The device is composed of the beam-pumping unit driving motor electric parameter and other signal detection unit, a beam-pumping unit driving motor electric parameter processing unit and an output executing unit. The device can accurately monitor the stroke period Tc of the pumping unit, and the defects that a conventional measuring method is prone to being interfered by working environments and low in measuring accuracy, a sensor needs to be additionally arranged, and installation and maintenance are not convenient can be effectively overcome.

Owner:XIAN HIRATE NET ELECTRIC EQUIP CO LTD

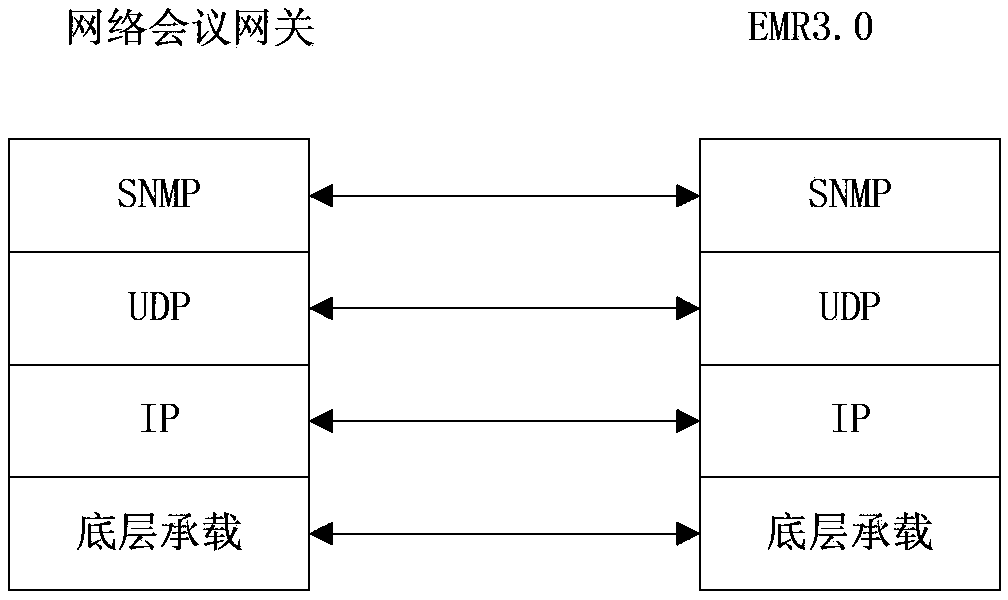

Fusion method based on network video meeting system and broadcasting and television system

ActiveCN103391418ARealize integration and unificationSeamless integrationTelevision conference systemsTwo-way working systemsVoice dataControl set

The invention provides a fusion method based on a network video meeting system and a broadcasting and television system. A network video meeting is connected in a tandem mode through a network meeting station server, a set top box and a personal computer (PC) client are used as terminals of the network video meeting and added into the network video meeting. In the network video meeting, a host terminal in the PC client controls set top box audios and videos through a network meeting server and a fusion meeting gateway, voice data is converted into a transport stream (TS), document data of the network video meeting is converted into the TS, data flow direction is controlled by controlling an enhanced multimedia router (EMR) device, and finally the TS is issued to the set top box. The fusion method absorbs advantages of the PC network meeting system and the broadcasting and television system, and fusion and unification and seamless combination of network meeting control and broadcasting and television networks and devices are achieved.

Owner:天津微医数字医院有限公司

Method and system for monitoring abnormal temperature increase of power supply traction cable on basis of distributed optical fiber temperature measurement

PendingCN106289572ASeamless integrationIncrease distanceThermometers using physical/chemical changesAlarmsTelecommunications linkData center

The invention discloses a method and a system for monitoring abnormal temperature increase of a power supply traction cable on the basis of distributed optical fiber temperature measurement. The system comprises a distributed optical fiber detection position indicator, a data center, a user terminal, a monitoring management terminal, a railway existing communication optical cable and a temperature detection optical cable, wherein the distributed optical fiber detection position indicator is arranged inside a communication machine room of a railway route and is connected with the railway existing communication optical cable paved along the railway route and the temperature detection optical cable fixed on a power supply traction cable; the communication machine room is connected with the railway existing communication optical cable paved along a railway; the temperature detection optical cable is fixed on the power supply traction cable in a hoop or physical contact mode in a parallel connection manner; the distributed optical fiber detection position indicator is used for receiving temperature information of the temperature detection optical fiber and used for transmitting the temperature information to a monitoring platform data center through a communication link.

Owner:SHANGHAI RAILWAY BUREAU +1

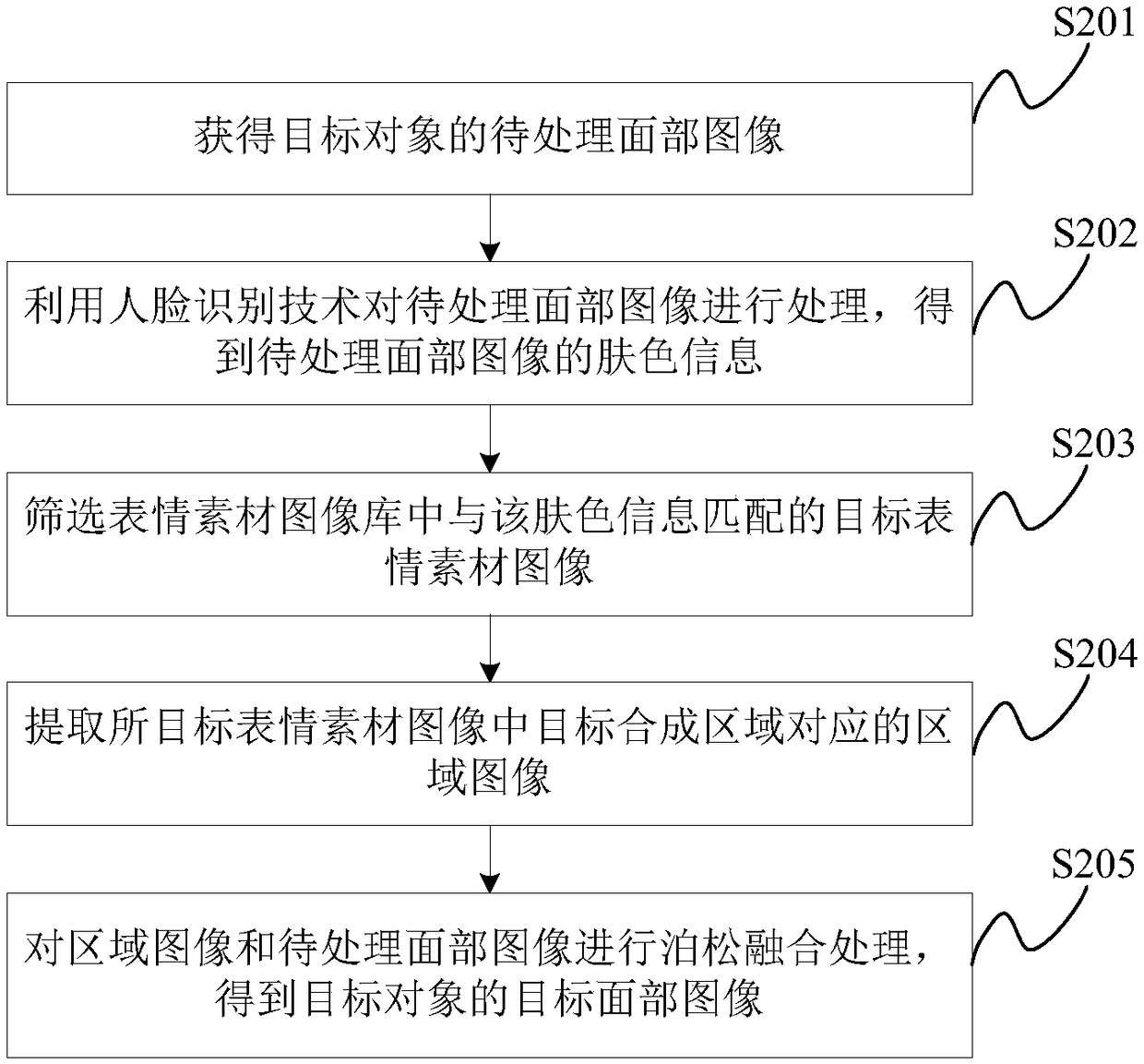

Facial expression synthesis method, device and electronic device

ActiveCN109325988ASkin tone coordinationHigh positioning accuracyImage enhancementImage analysisFacial expressionTarget expression

The embodiment of that present application provide a facial expression synthesis method, device and electronic device, A technology for face recognition is use to process that face image to be processed, get the corresponding skin color information, As such, from that image library of the expression material, screening a target expression material image matching the skin color information, then extracting a region image corresponding to a target composite region in the target expression material image, As such, when that region image is synthesize into the face image to be processed by the Poisson fusion method, seamless fusion is realize, the overall skin color of the final target face image is ensured to be harmonious and natural, the expression details in the region image are retained,the positioning accuracy of the facial organ is improved, and the resultant composite image is more vivid.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Large-current medium-voltage switch cabinet capable of realizing arc light protection

InactiveCN102082419ATrip quicklyAvoid damageEmergency protective circuit arrangementsTransducerEngineering

The invention provides a large-current medium-voltage switch cabinet capable of realizing arc light protection. The switch cabinet comprises a sensor which is used for collecting an arc light signal of the medium-voltage switch cabinet, a photoelectric transducer which is used for converting the arc light signal from the sensor into a current signal to be output, a current transformer which is used for sampling a current of the medium-voltage switch cabinet and outputting the current signal, and an arc short-circuit protection system control unit which is used for receiving signals from the photoelectric transducer and the current transformer simultaneously and making a tripping operation order to a circuit breaker to ensure that the circuit breaker rapidly trips. According to the invention, the fault of an electric distribution network, caused by the arc light short-circuit, in the prior art is solved. Through adopting an arc and overcurrent dual-criterion principle, when arc light occurs, the large-current medium-voltage switch cabinet accurately judges the arc light to ensure that the circuit breaker rapidly trips so as to prevent the arc light from damaging electric equipment, such as the medium-voltage switch cabinet and the like and immediately protect the safety of the personnel and the equipment in real time, thus the arc light protection can be realized.

Owner:湖北省电力公司襄阳供电公司 +2

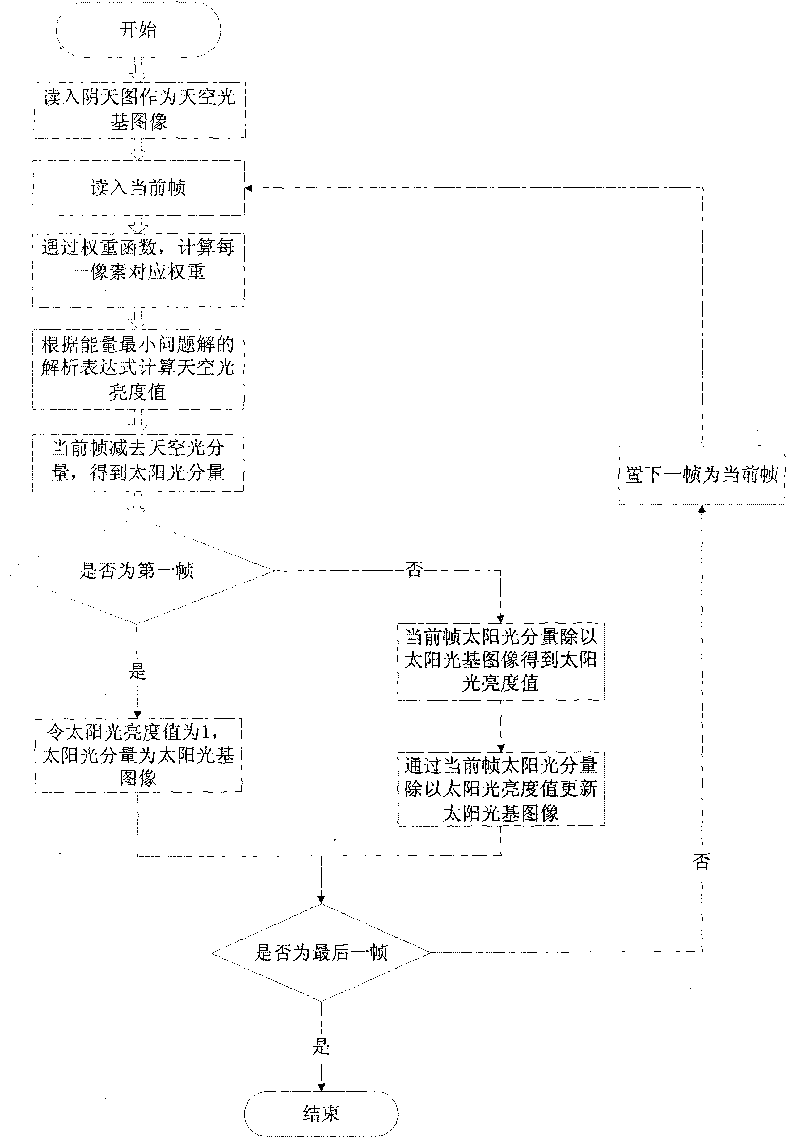

Outdoor scene illumination parameter restoration device and working method thereof

InactiveCN101739710ASeamless integrationLight Restoration Method Practical3D-image renderingSkyRestoration device

The invention discloses an outdoor scene illumination parameter restoration device and a working method thereof. The device comprises a computer and a video camera. The basic working method comprises the following steps: the image or video stream which is shot by the video camera is input to the computer and processed by the computer, and the restoration result of the illumination parameters of the scene is output. The process is divided into a preprocessing phase and an on-line phase. The device has the working principle that any outdoor scene image can be presented as a linear combination of a sunlight and skylight base image, so that the problem of the restoration of the incident light brightness values of the sunlight and the skylight in the image can be included as a problem of optimizing the real-time solving. The method does not need three-dimensional geometric information and material information of the scene, and can acquire the incident light brightness values of the sunlight and the skylight in the outdoor scene in real time. The method can be directly used in an augmented reality system, and can also be used for outdoor scene video sequence preprocessing, such as image segmentation, pattern recognition and the like.

Owner:SHANDONG UNIV

Method for preparing high-silicon steel sheet by powder compression sintering

The invention discloses a method for preparing a high-silicon steel sheet by powder compression sintering, and belongs to the technical field of powder metallurgy. According to the method, gas atomized Fe-6.5 wt.% Si powder is used as a raw material, the powder is in a compact state through powder presetting, the powder is placed in a vacuum sintering furnace to be metallurgically bonded through high-temperature sintering, multi-passes hot rolling are carried out to a certain thickness and then 1-4 times of cold rolling are carried out, and finally annealing is carried out at high temperatureto obtain the high-silicon steel sheet with excellent performance. Compared with adopting water atomized powder, gas atomized high-silicon steel powder is adopted and oxide inclusions of an alloy system are greatly reduced, meanwhile, the problem that spherical gas atomized powder is difficult to form is solved by adopting a direct compression sintering method, so that the process complexity and the subsequent problems of degumming and carbon residue caused by adding a forming agent are avoided, and the method has the advantages of being simple to operate, high in production efficiency, high in product precision, short in process flow, free of pollution and inclusions, excellent in performance and the like.

Owner:UNIV OF SCI & TECH BEIJING

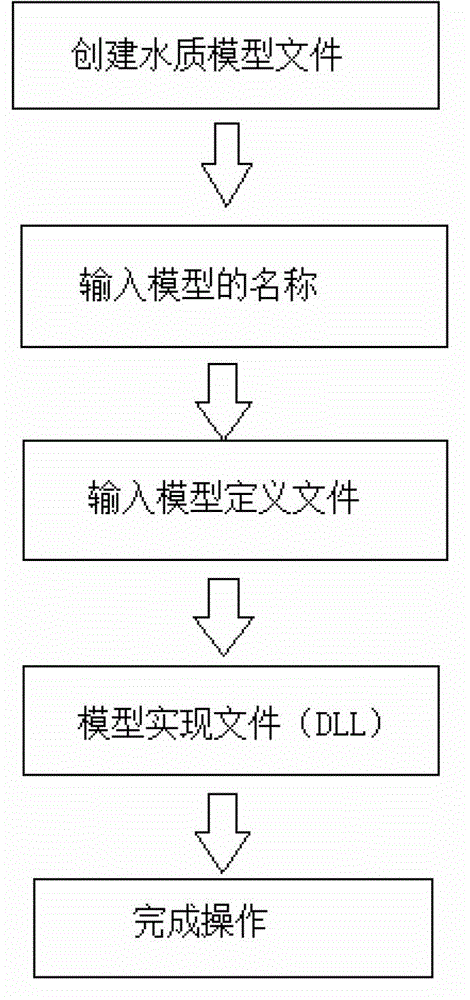

3S-based pollution source monitoring system

ActiveCN102981414AEfficient packagingImprove encapsulationSimulator controlMonitoring systemComputer module

The invention relates to a 3S-based pollution source monitoring system. The system is characterized in that the system comprises a model base module connected with a bottom layer data base, a load control module connected with a programmatic interface of the model base module, and a performance evaluation module connected with the model base module through the programmatic interface, wherein the load control module comprises a regional level lessening model and a pollutant discharging unit level lessening model; and the performance evaluation module comprises a pollution source cost lessening model and a processing agent cost lessening functional model. The system has good encapsulation, the interface only provides input and output, and encapsulation is perfect during processing process; the system has good expansibility, the original interface can accomplish expansion according to the requirements in the condition that the system is not required to be compiled again; and the system has good openness, besides the models provided by the system, a user can dynamically add models of the user to the system according to standards of models and model base interfaces to perform seamless integration.

Owner:CAPITAL NORMAL UNIVERSITY +1

Method for preparing high-silicon steel sheet through powder rolling

ActiveCN110355372AGood for magnetismImprove mechanical propertiesTransportation and packagingMetal-working apparatusIron powderElectrolysis

The invention discloses a method for preparing a high-silicon steel sheet through powder rolling, and belongs to the technical field of powder metallurgy. The method comprises the following steps thatelectrolytic iron powder and silicon powder coated with iron powder are adopted, the raw materials are simply mixed through a v-shaped mixer to form Fe-6.5wt.%Si. A green sheet is formed through a powder rolling method, is subjected to high-temperature sintering so as to be subjected to metallurgical bonding, and is subjected to multi-pass hot rolling to a certain thickness and then is subjectedto cold rolling for 2-4 times, and finally annealing is carried out at a high temperature to obtain the high-silicon steel sheet with excellent performance. By adopting the powder rolling method, theprocess flow for preparing the sheet can be effectively shortened, the formability of a powder system is greatly improved by adopting the silicon powder coated with the iron powder in raw materials, so that the process complexity and the subsequent debinding residual carbon problem caused by addition of a forming agent are avoided, and the method has the advantages of being simple to operate, highin production efficiency, high in product precision, free of pollution and included foreign materials, excellent in performance and the like.

Owner:UNIV OF SCI & TECH BEIJING

Method of using touch screen of mobile phone to control large-screen device

InactiveCN107491277ASeamless integrationImprove user experienceConnection managementSubstation equipmentThe InternetLarge screen

The invention discloses a method of using a touch screen of a mobile phone to control a large-screen device, the smart mobile phone and the large-screen device. In a case where an internet exists, the large-screen device generates a universal two-dimensional code, the smart mobile phone transmits a unique smart mobile phone identifier through scanning the code, connection is respectively established among the smart mobile phone, the large-screen device and a server, and operation instructions on the smart mobile phone are forwarded to the large-screen device through the server; and the large-screen device responds according to the received operation instructions, and generates pictures which are completely the same as pictures of the smart mobile phone. According to the method of using the touch screen of the mobile phone to control the large-screen device of the invention, the mobile phone and certain large-screen devices can be linked to be used, operations are enabled to be carried out on the mobile phone, but viewing can be carried out on a large screen, the use experience is more perfect, and seamless fusion of a multi-screen interaction content flow and display flow is completed.

Owner:成都弈览科技有限公司

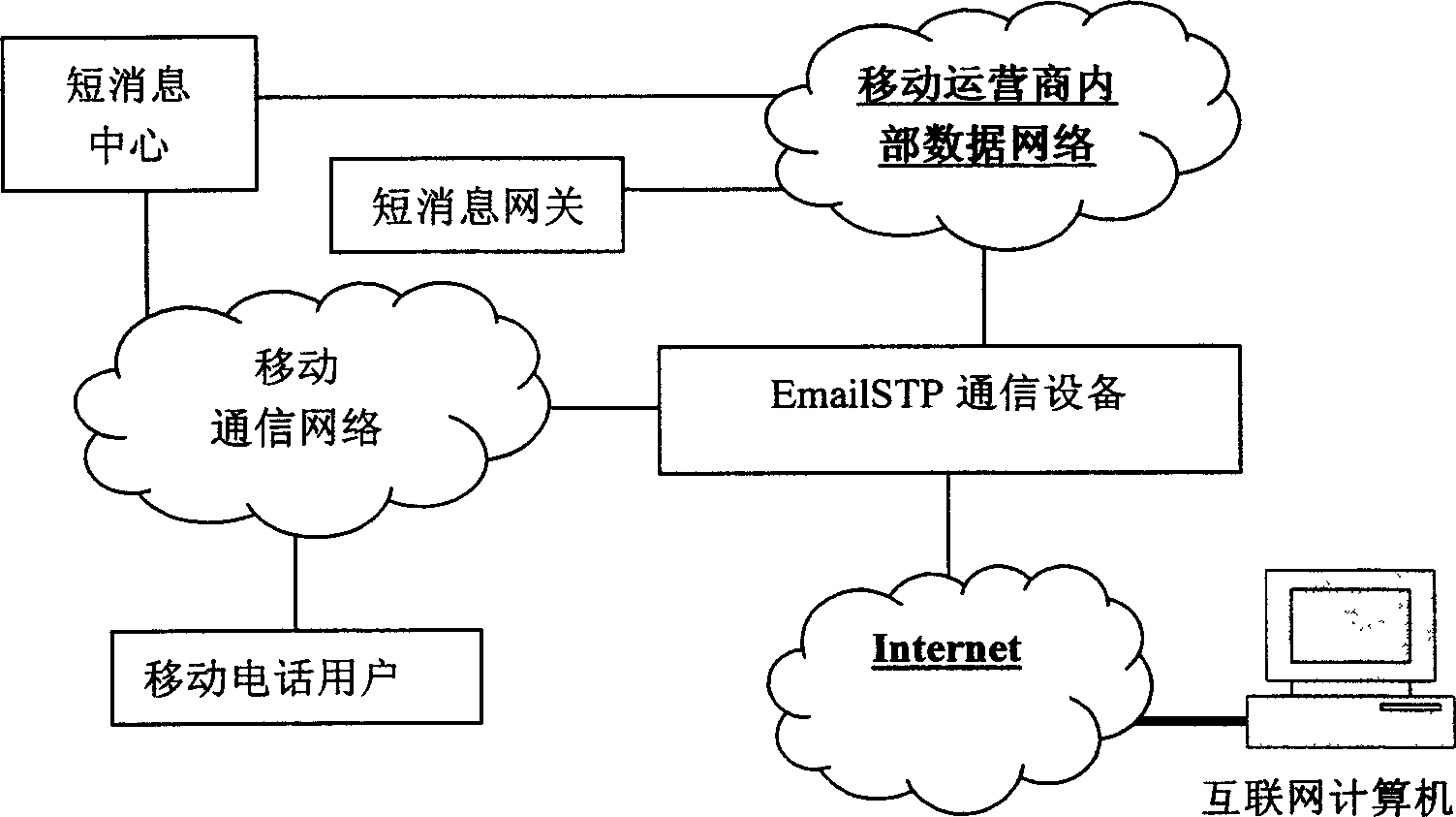

Apparatus and method for providing virtual electronic mail box service based on mobile telephone number

InactiveCN1674581AResolve irregularitiesSolve replacementAutomatic exchangesTransmissionMobile Telephone NumberComputer users

The present invention relates to a mobile telephone number based device for providing virtual electronic mailbox service. It is characterized by that it includes a virtual electronic mailbox server, namely Email STP communication equipment respectively interconnected with data interconnected network, mobile business unit internal data network and mobile communication network, the described Email STP communication equipment can be interconnected with short message gateway and short message centre by means of mobile business unit internal data network, interconnected with mobile telephone user by means of mobile communication network and connected with interconnected net computer user by means of data interconnected network, namely Internet. Said invention also provides the functions of Email STP communication equipment.

Owner:华赛德金投资集团有限公司

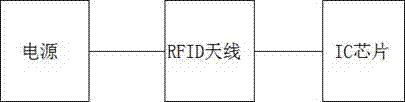

Intelligent garage system based on RFID (Radio Frequency Identification) and power line carrier technology

InactiveCN103400094AEasy to integrateSeamless integrationSensing record carriersProgramme total factory controlPacket lossTransfer procedure

The invention relates to an intelligent garage system based on RFID (Radio Frequency Identification) and a power line carrier technology. The intelligent garage system comprises a private car, an intelligent electric roller shutter door and a home service center server, wherein the private car is provided with an active RFID label; the intelligent electric roller shutter door consists of an electric roller shutter door, an RFID reader module, an information storage module, an LED (Light Emitting Diode) display module, a power line carrier communication module a and an embedded processor module; the home service center server is provided with a desktop computer, a display and a power line carrier communication module b; the RFID reader finishes information acquisition under the control of an embedded processor and sends the information through the power line carrier communication modules a and b. The intelligent garage system disclosed by the invention has the beneficial effects that a garage can be automatically opened and closed in a longer distance, and the problems of packet loss, data delay and the like in the previous transmission process are overcome; the preparation cost is low, expansion and later-stage deployment can be easily implemented, and the intelligent garage system can be seamlessly fused into an intelligent household system; the whole intelligent garage system is simple in formation and reliable to run.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for realizing naked eye 3D viewing effect by multi-screen splicing special-shaped screen theater

InactiveCN108415174AAdaptablePerfect mathematical logicPanoramasIdentification meansComputer graphics (images)Film material

The invention provides a method for realizing a naked eye 3D viewing effect by a multi-screen splicing special-shaped screen theater. The method is applicable to any wall screen and a ground screen toform an L-shaped screen and is also applicable to the splicing of multiple (2 to 4) wall screens and a ground screen to form a BOX-style full-surrounded theater. With the construction of the L-shapedscreen as an example, the operation steps comprise the steps of (A) sampling the physical position of exhibition hall screen hardware and sampling viewpoint positions for an exhibition hall, (B) building a three-dimensional digital exhibition hall according to a sampling result, (C) calculating a screen position mask by using a panoramic camera algorithm based on a hall viewpoint position and theshape of an L-shaped screen, (D) making a panoramic expanded film material needed by a film with the panoramic camera algorithm in CG software, and cutting the panoramic film material by using a mask, (E) projecting a cut film to each screen by using the panoramic camera algorithm, and (F) allowing each screen to output a final film. According to the method, a multi-screen splicing screen of anyshape has no deformation and no deflection when the screen is viewed on a set viewing point.

Owner:上海溯石数字科技有限公司

augmented reality telescope

The invention relates to an AR telescope. The AR telescope comprises a video display module, a microcomputer module, a positioning tracking module, a video input module and a system software module, the positioning tracking module comprises a sensor sub-module and a correction fusion processing sub-module, the sensor sub-module comprises a tri-axial fluxgate sensor, a tri-axial accelerometer and a tri-axial electronic compass, and the correction fusion processing sub-module receives measuring signals output by the sensor sub-module and performs fusion calculation on a corrected measuring value of the tri-axial electronic compass and a corrected measuring value of the tri-axial fluxgate sensor after the measuring value of the tri-axial electronic compass is corrected by employing a measuring value of the tri-axial accelerometer.

Owner:SHENZHEN WOOLEE CREATIVE ENG CO LTD

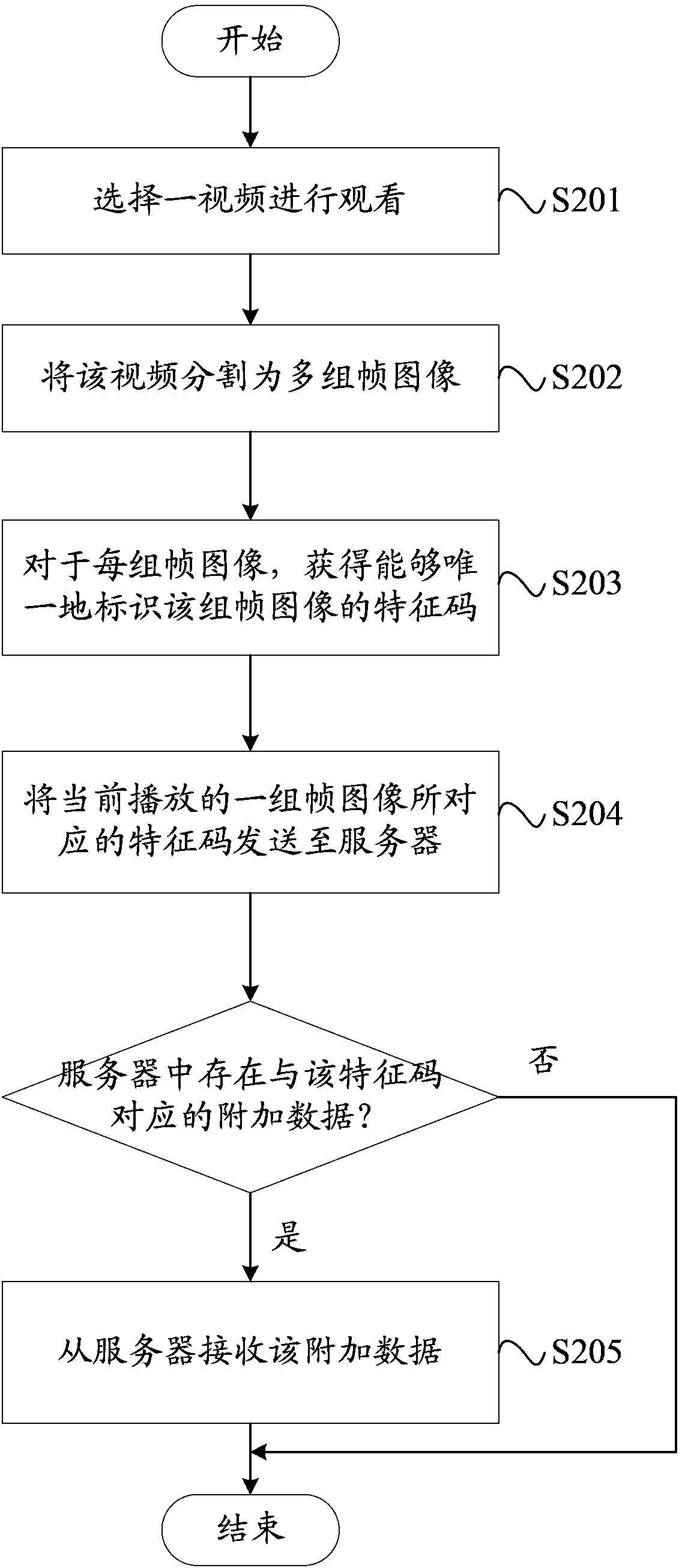

Video processing device and method

ActiveCN103873925ASimplify the addition processEasy to addSelective content distributionComputer graphics (images)Client

Provided are a video processing device and method. The video processing method is used for a client in data connection with a server and comprises the following steps: obtaining a video by a user; dividing the video into a plurality of sets of frame images, wherein the plurality of sets of frame images at least comprise one frame image, and the difference among frame images meets predetermined conditions; for each set of frame images, obtaining a condition code exclusively capable of identifying the set of frame images; selecting one set of frame images among the plurality of sets of frame images by the user and adding additional data; and connectedly sending the condition code corresponded by the set of frame images and the additional data to the server.

Owner:LENOVO (BEIJING) CO LTD

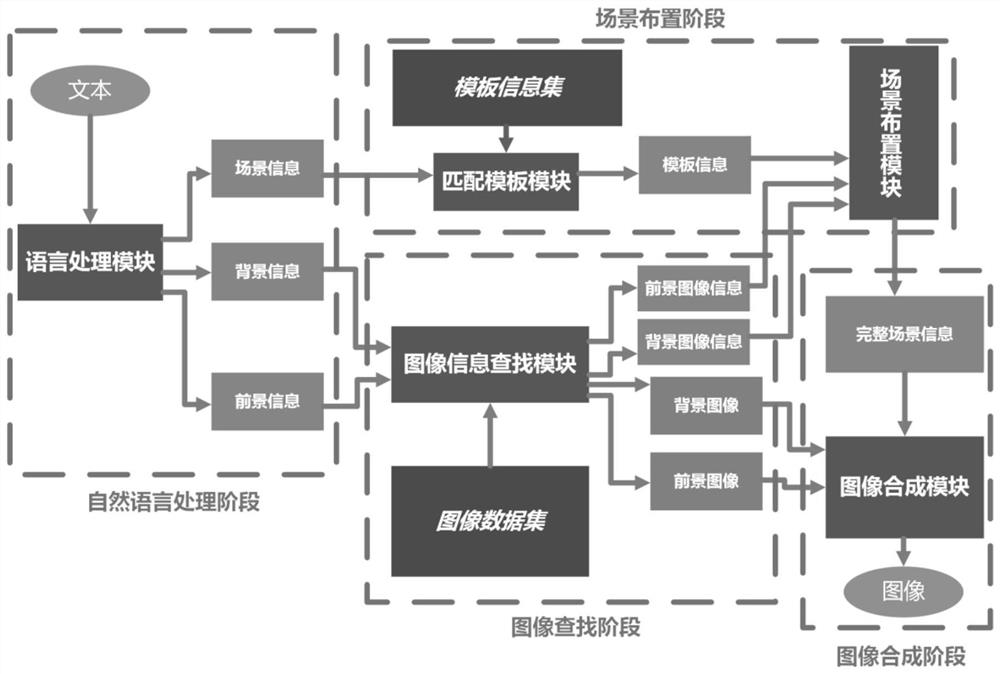

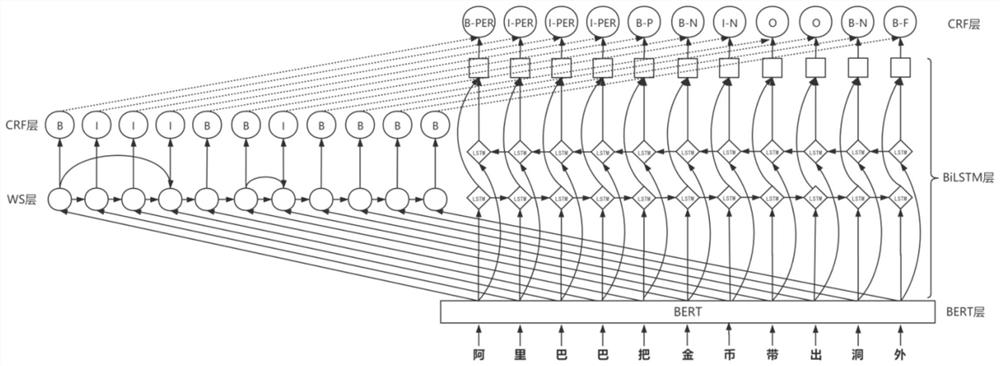

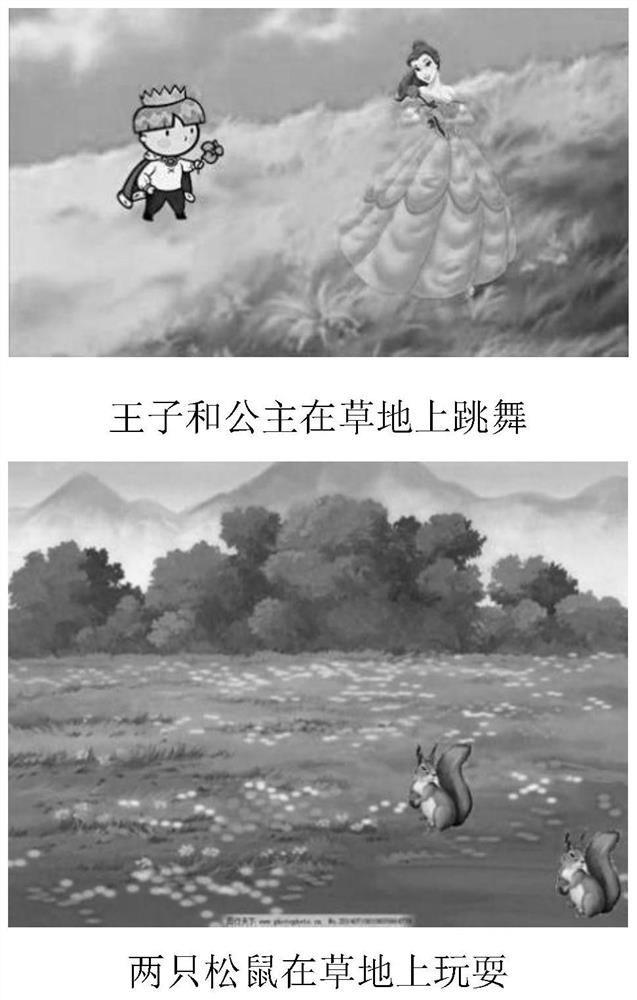

Automatic cartoon generation method and system based on BBWC model and MCMC

PendingCN112417873ARepresentational ambiguityImprove the accuracy of entity boundary recognitionImage enhancementSemantic analysisPattern recognitionMulti-image

The invention provides an automatic cartoon generation method and system based on a BBWC model and an MCMC. The method comprises the following steps: firstly, carrying out entity labeling of an extended range on a Chinese data set; secondly, designing a BERTBiLSTM + WSCRF named entity recognition model, and training on the marked data set to recognize seven types of entities including names, placenames, organization names, common nouns, numerals, prepositions and nouns so as to obtain information such as foreground object types, background templates and the number and position relation of theforeground object types and the background templates; defining different scene templates to describe different scenes so as to supplement scene information; then selecting a proper template accordingto the previously obtained information; then, controlling the scene layout by an MCMC method to generate complete scene information; achieving seamless fusion of multiple image materials by a Poissonfusion algorithm; and finally, inputting the text into the final model, and automatically generating a cartoon conforming to semantics. According to the invention, the size, proportion and position relationship of each image can be reasonably controlled; Seamless fusion of multiple image materials can be realized.

Owner:WUHAN UNIV

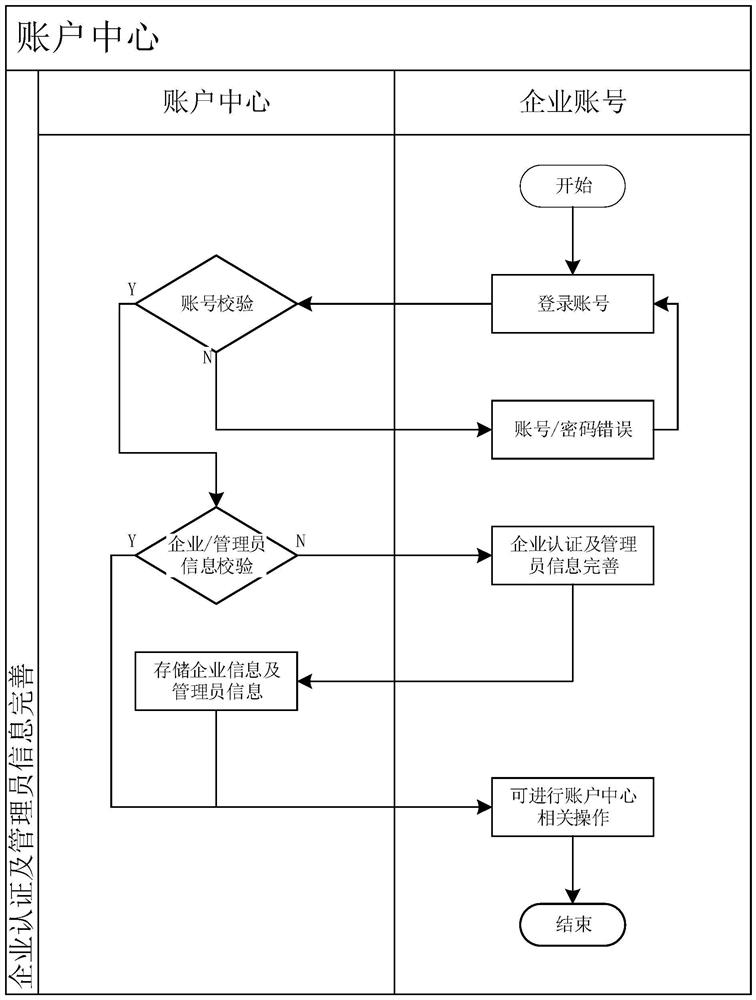

Unified account system for realizing multi-platform business intercommunication

ActiveCN112804193ARealize unified top-level managementTo achieve the purpose of ecological unityTransmissionBusiness enterpriseComputer science

The invention provides a unified account system for realizing multi-platform business intercommunication, and the system comprises a business platform unified access module which is used for providing an access service for a business platform; and the account center is used for centrally storing the original accounts of the business platforms accessed to the business platform unified access module, formulating the registration, login and authority management specifications of the user accounts and formulating the access standards of the business platforms. According to the invention, business intercommunication among a plurality of business platforms under an enterprise name can be realized.

Owner:AEROSPACE INFORMATION

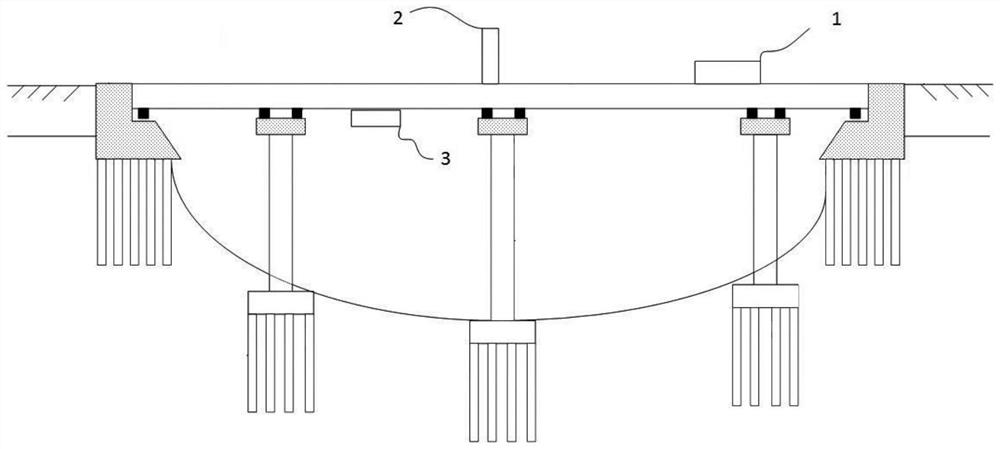

Bridge structure health monitoring system and control method thereof

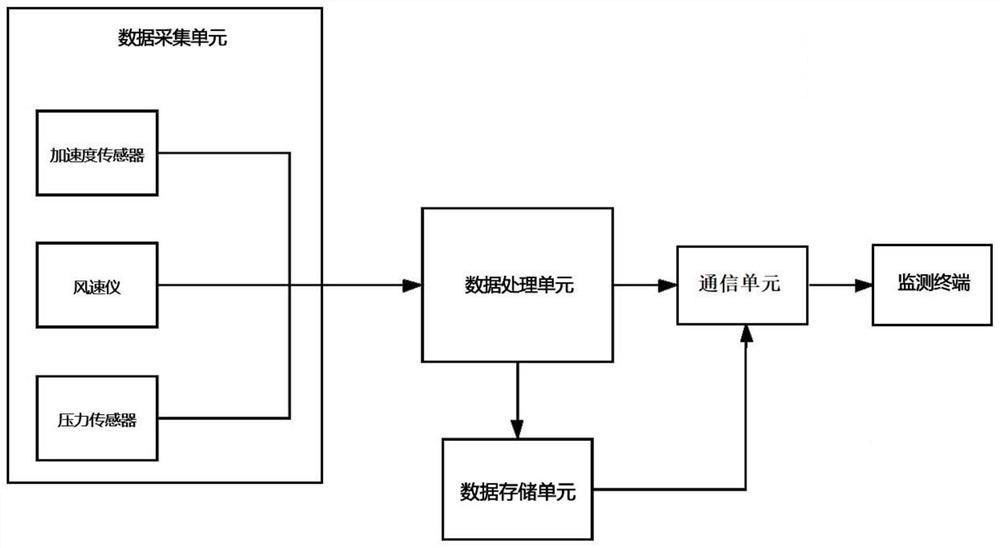

PendingCN112729892AReduce labor costsImprove detection efficiencyStructural/machines measurementData processingData acquisition unit

The invention provides a bridge structure health monitoring system and a control method thereof. The system comprises a data acquisition unit, a data processing unit, a data storage unit, a communication unit and a monitoring terminal, wherein the data acquisition unit comprises an acceleration sensor, an anemograph and a pressure sensor which are arranged on a bridge; the data processing unit comprises an ARM microprocessor, the input end of the ARM microprocessor is connected with the data acquisition unit, and the output end of the ARM microprocessor is connected with the input end of the monitoring terminal through the communication unit; the input end of the data storage unit is connected with the data processing unit, and the output end is connected with the monitoring terminal through the communication unit. According to the invention, automatic real-time regular detection is realized through the monitoring system, traditional manual inspection can be replaced, the labor cost is saved, the manual labor intensity is reduced, the working risk of inspection personnel is reduced, and the detection efficiency is greatly improved.

Owner:南京信息工程大学无锡研究院

Three-dimensional digital deduction method for top cover maintenance hoisting operation and risk identification

PendingCN112182696ARealize safe deduction of maintenance workImplement security deductionGeometric CADDesign optimisation/simulationCollision analysisRisk identification

The invention relates to a three-dimensional digital deduction method for top cover maintenance hoisting operation and risk identification. The method comprises the steps: constructing a top cover three-dimensional refined model and a top cover maintenance operation virtual scene; establishing an early warning rule based on space collision early warning; designing a top cover hoisting path planning method meeting an early warning rule, and determining an optimal top cover hoisting path, so a worker has a vivid feeling and an immersion feeling during operation, and seamless fusion of a model, atool and an overhaul scene in a top cover overhaul process is realized; deducing the field operation scheme, completing collision analysis and optimal path planning, and realizing safe deduction of the top cover maintenance operation.

Owner:STATE GRID CORP OF CHINA +3

Vehicular phone device and seamless automatic conversion system and method with the mobile phone

InactiveCN100508409CSeamless integrationOperational securityAutomatic call-answering/message-recording/conversation-recordingTransmissionMobile Telephone NumberCall forwarding

A vehicle-mounted telephone device and its seamless automatic switching system and method with a mobile phone. The system is composed of a vehicle-mounted telephone device, a user's mobile phone, a call transfer center, a mobile communication network, and an external telephone system. The device is provided with a main controller, which is connected with a keyboard, a wireless communication module, a microphone array and an automobile ignition / extinguishment sensing signal device, and is provided with a call transfer information storage module and a call transfer request instruction sending module. In the call transfer center, there is a database for storing the vehicle phone number, the user's mobile phone number and the user's communication information. The feature of the method of the present invention is to utilize the vehicle-mounted telephone device and system to carry out the sequence control of seamless automatic transfer: when the car is started, the user's mobile phone can be automatically transferred to the vehicle-mounted telephone device, and when the engine is turned off, the call transfer is automatically canceled; When using the car phone to make a call, the other party's mobile phone will display the user's mobile phone number, so that when the user leaves the car, there is no missed call.

Owner:GUANGZHOU SUNRISE COMM EQUIP

Method and device for realizing augmented reality based on plane detection

ActiveCN107665507BImprove fitSeamless integrationDetails involving 3D image data3D-image renderingPattern recognitionComputer graphics (images)

The present invention provides a method for realizing augmented reality based on plane detection, comprising the following steps: acquiring a video image of an environmental scene in real time through a camera; determining an area of interest in a current frame of the video image of the environmental scene, and detecting the area of interest the plane in the region of interest; according to the plane in the region of interest, render the virtual object in the current frame of the video image of the environment scene. The invention also provides a device for realizing augmented reality based on plane detection. The method and device for realizing augmented reality based on plane detection in the present invention detect the plane in the area of interest of the user in the video image of the environment scene, so that the posture of the superimposed and rendered virtual object is consistent with the plane of the superimposed position, which significantly improves the relationship between the virtual object and the plane of the superimposed position. The fitting degree of the real environment scene realizes the seamless integration of virtual objects and real environment.

Owner:CHENGDU IDEALSEE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com