Method for casting large main-bearing seat

A main bearing seat and bearing seat technology, applied in the field of material molding, can solve the problems of easy cracks, poor heat preservation effect, easy sand sticking, etc., to reduce the occurrence of secondary oxidation inclusions, improve purity, and reduce pouring volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

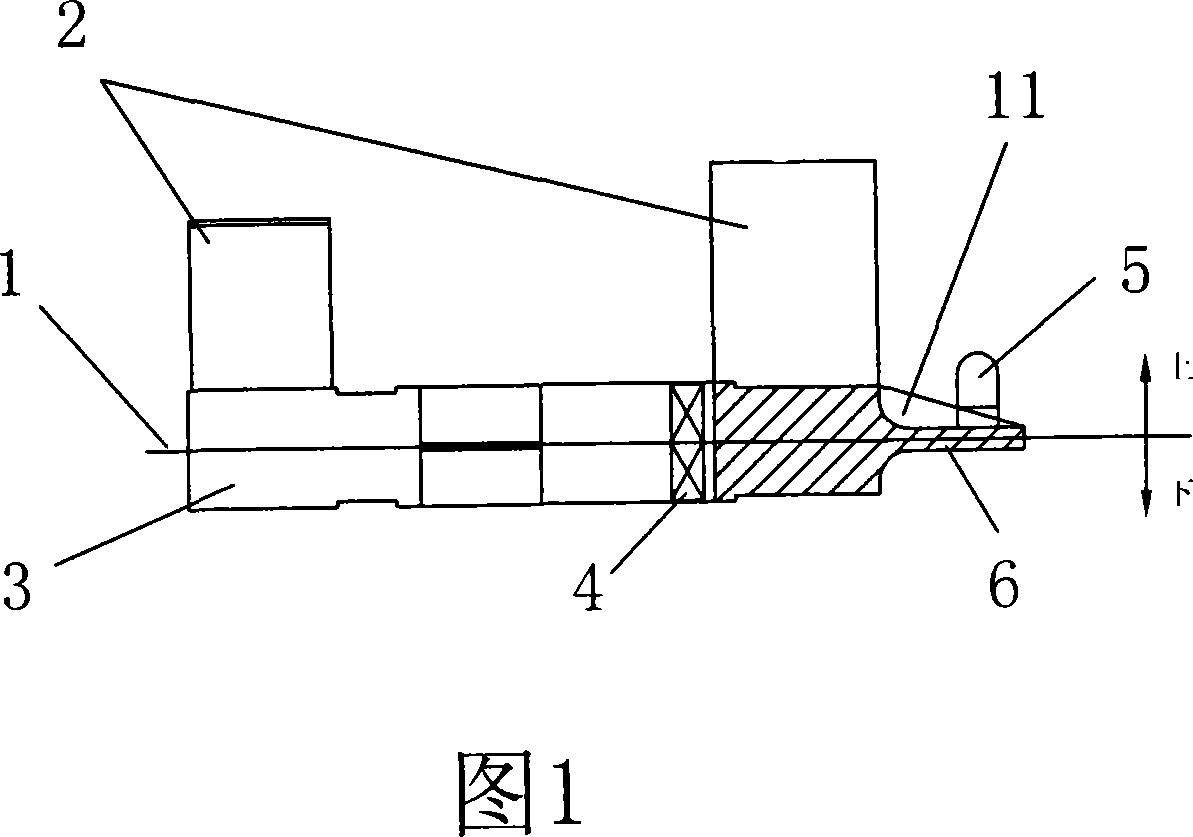

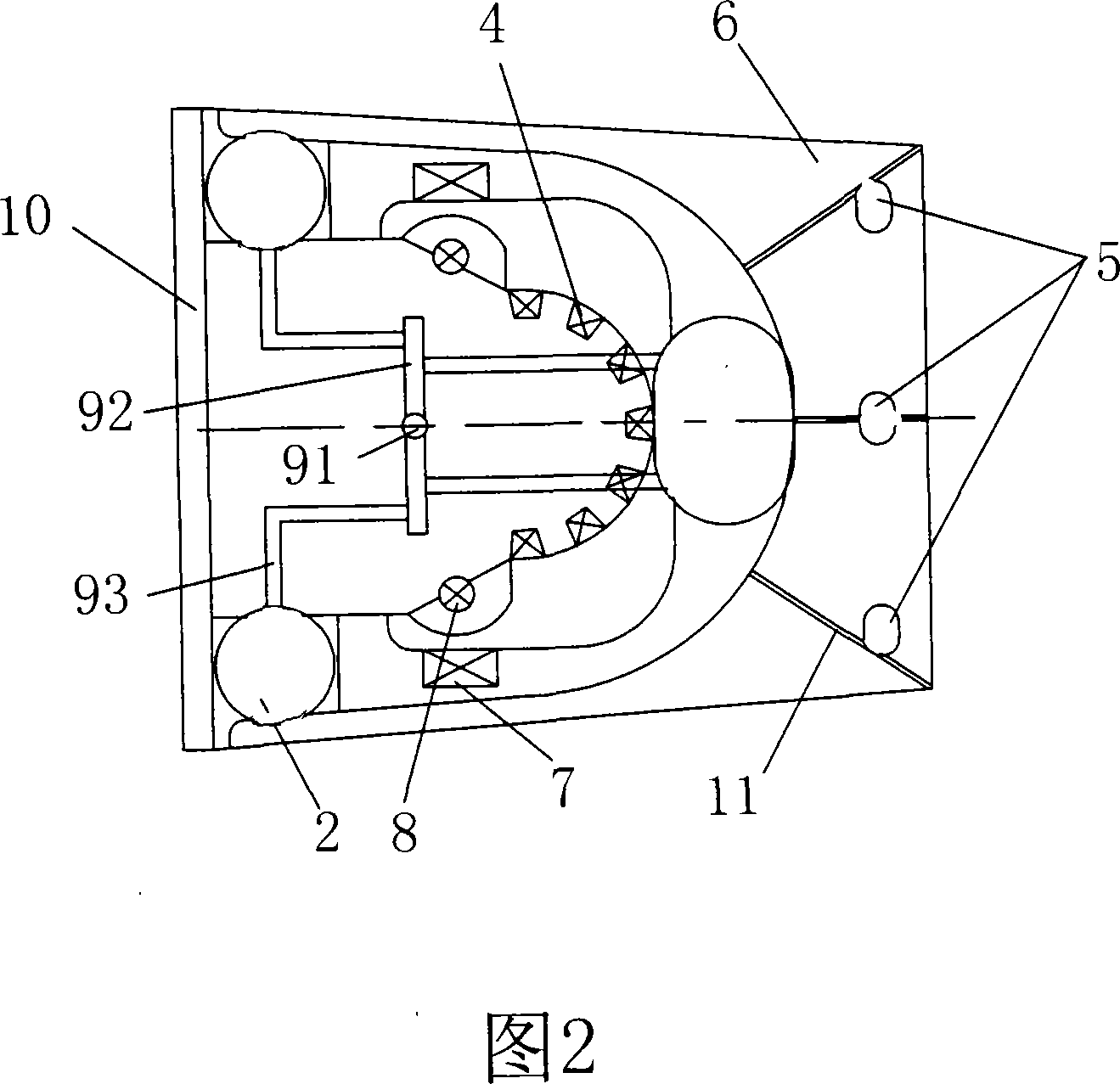

[0031] In order to illustrate the casting method of the large-scale main bearing seat of the present invention, this embodiment takes the casting process of the main bearing seat of the K98MCC marine low-speed diesel engine as an example to illustrate the practical application of the method of the present invention in detail.

[0032] The parameters of main bearing housing castings of K98MCC marine low-speed diesel engine are as follows:

[0033] Dimensions of casting: 2944mm×2650mm×455mm;

[0034] Maximum wall thickness of casting (bearing hole): 455mm;

[0035] Minimum wall thickness of castings: ~76mm;

[0036] Casting blank weight: ~10200Kg;

[0037] Partial weight of bearing gear: ~5000Kg;

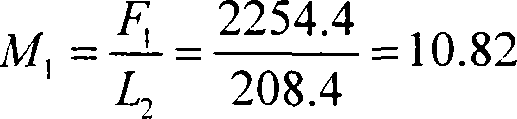

[0038] Sectional area of bearing gear: ~2254.4cm 2 ;

[0039] Circumference of the section of the bearing gear: ~208.4cm;

[0040] Partial weight of front deck: ~1331Kg;

[0041] Sectional area of front deck: ~2182.1cm 2 ;

[0042] Circumference of front deck section: ~22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com