Steel bar connection device and using method thereof

A connecting device and steel bar technology, which is applied in the processing of building materials, structural elements, building components, etc., can solve the problems that grouting holes cannot be grouted, there are too many threaded connections, and cannot be applied, so as to simplify the steps of installation and connection. The effect of simplifying the connection method and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

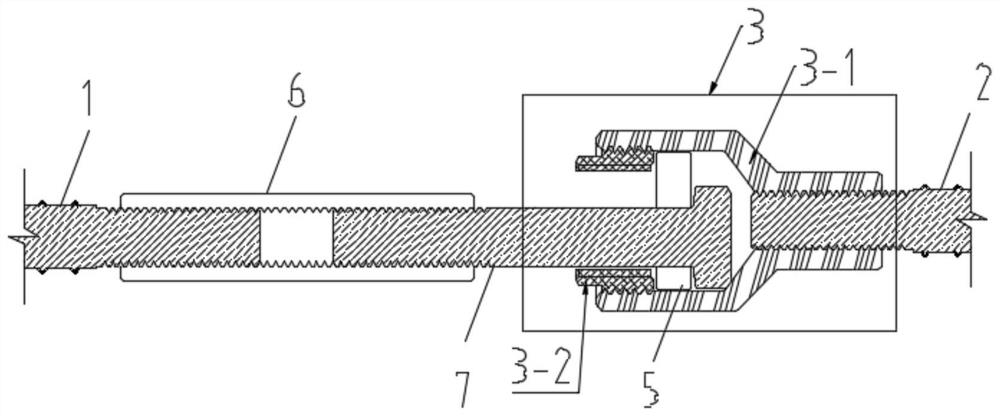

[0038] Such as figure 1 As shown, the first steel bar 1 and the second steel bar 2 in the existing position are fixed. The first steel bar 1 and the second steel bar 2 are parallel to each other, but different axes. The distance between the first steel bar 1 and the second steel bar 2 Is the eccentric distance, and the relative angle between the first steel bar 1 and the second steel bar 2 is the eccentric angle. If the steel bar connection device mentioned in the prior art is used, when there are multiple groups of steel bars with different eccentricities, the steel bar connection device cannot connect the first steel bar 1 and the second steel bar 2 anymore.

[0039] In order to solve this problem, the reinforcing steel connecting device of the present invention is introduced below.

[0040] Such as figure 1 , image 3 As shown, the reinforcing bar connecting device of the present invention includes an eccentric adjusting device 5, a reinforcing bar connector 7, and an eccentric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com