Extrusion semi-grouting reinforcement sleeve, connecting structure and construction method thereof

A steel sleeve and connection structure technology, applied in structural elements, building components, building structures, etc., can solve the problems of low processing efficiency and complicated process of grouting sleeves, and achieve the guarantee of construction efficiency and construction quality, simple process, Save the effect of blocking the rubber plug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

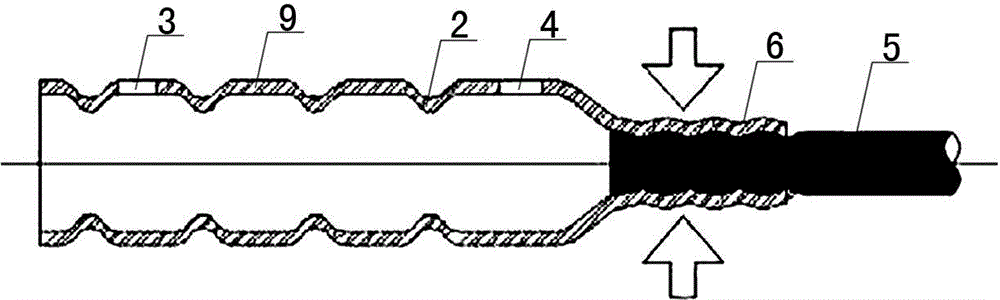

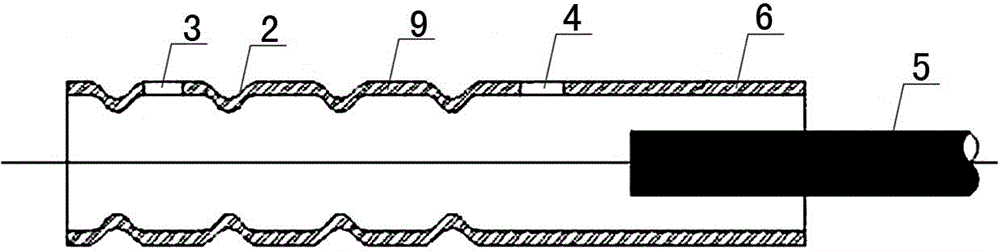

[0041] Examples see image 3 As shown in the extruded semi-grouting reinforcement sleeve, the sleeve 1 is processed from a hot-rolled seamless steel pipe, and the wall of the sleeve is provided with a grouting hole 3 and a grouting hole 4, and the Annular inner protrusions 2 are distributed between the pulp hole 3 and the pulp outlet hole 4. The annular inner protrusions 2 are single rings distributed at even intervals and can be processed by three-axis rolling, rolling or other cold and hot processing techniques. One end of the sleeve 1 is an extruded end 6, and the rest is a slurry anchor end 9. The inner diameter of the extruded end 6 is equal to the outer diameter of the connected steel bar and is smaller than the inner diameter of the slurry anchor end 9. The length of 6 satisfies the strength requirements of extrusion joints, and the length of the grout anchor end 9 meets the strength requirements of steel grouting sleeve connection joints; the grouting hole 3, the grout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com