High-performance two-dimensional layered Ti3C2-MXene membrane, preparation method thereof and application of membrane in water treatment

A two-dimensional layered, high-performance technology, applied in water/sludge/sewage treatment, osmotic/dialysis water/sewage treatment, water/sewage treatment, etc., can solve problems such as high cost, unstable anti-pollution ability, etc. Achieve the effect of low cost, high selectivity, and high water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A high-performance two-dimensional layered Ti 3 C 2 -The preparation method of MXene film, comprises the following steps:

[0049] (1) 10g Ti 3 AlC 2 The powder was mixed with 30mL HF solution (the volume concentration of HF solution was 20%), stirred at room temperature for 2 hours (rotation speed was 500rpm), then centrifuged and washed 3 times with deionized water, and dried at 100°C for 12 hours to obtain Ti 3 C 2 powder;

[0050] (2) 1gTi 3 C 2 The powder was mixed with 5 mL dimethyl sulfoxide, stirred at room temperature for 2 hours (200 rpm), washed 3 times with deionized water, and dried at 100 °C for 12 hours to obtain the treated Ti 3 C 2 powder;

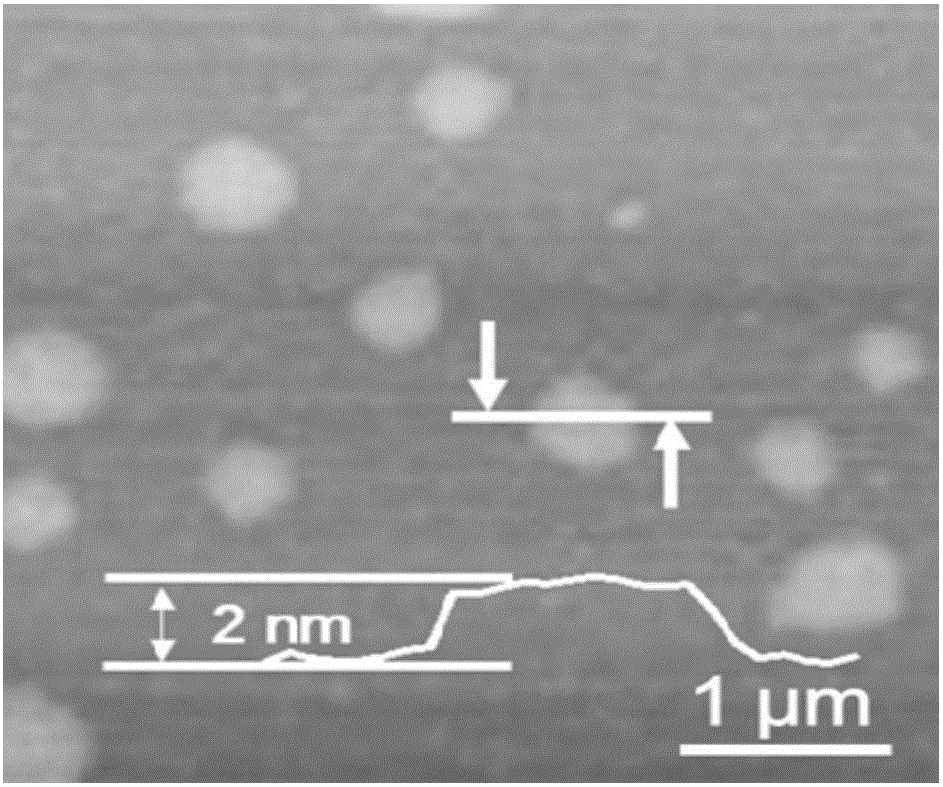

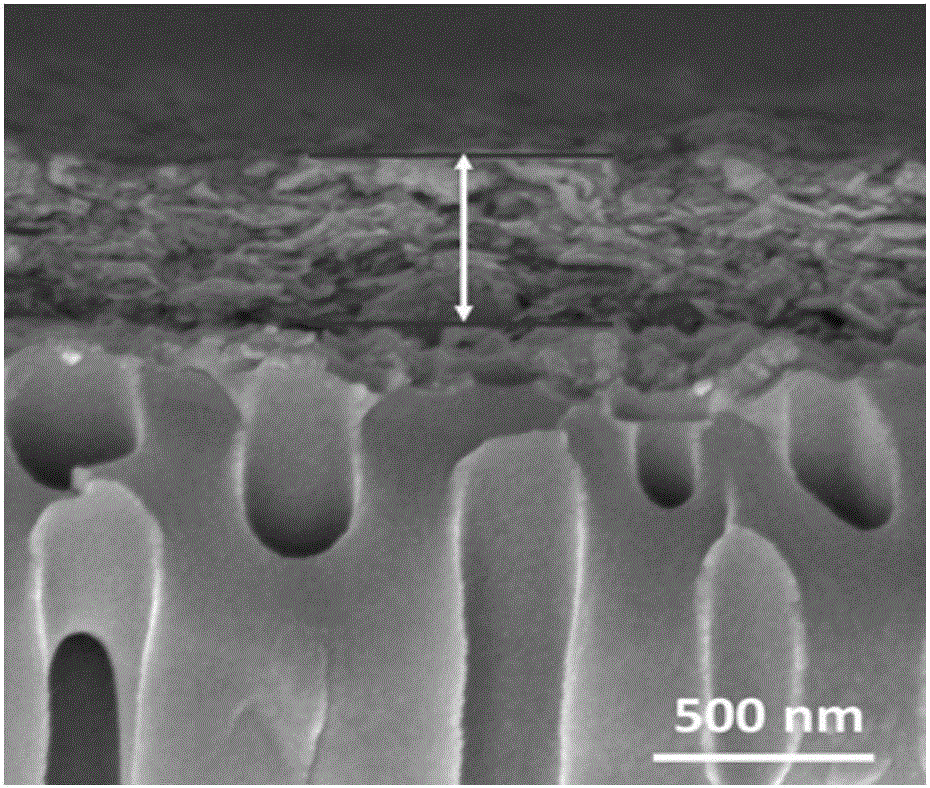

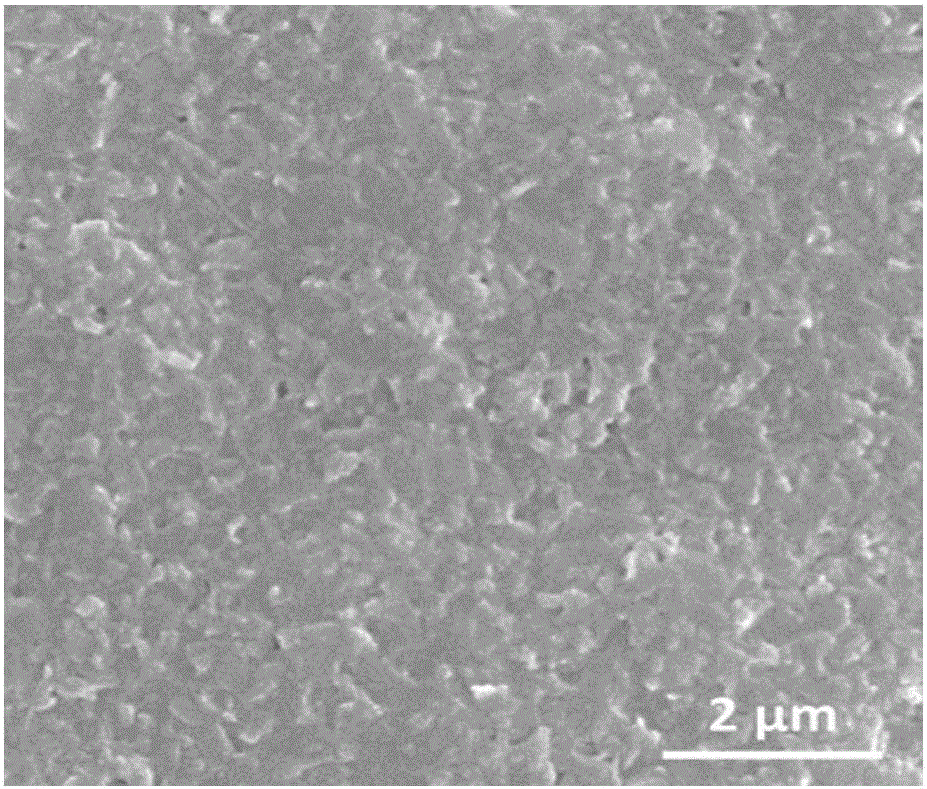

[0051] (3) Take 1g of treated Ti 3 C 2 The powder was dissolved in a mixed solution of 60mL methanol and 140mL water, ultrasonicated for 2 hours (ultrasonic power 400W), centrifuged at 8000rpm for 20min, the supernatant was taken and freeze-dried to obtain a two-dimensional Ti 3 C 2 (MXene) nanosheets; ...

Embodiment 2

[0056] A high-performance two-dimensional layered Ti 3 C 2 -The preparation method of MXene film, comprises the following steps:

[0057] (1) Add 6g Ti 3 AlC 2 The powder was mixed with 85mL HF solution (the volume concentration of HF solution was 10%), stirred at room temperature for 4 hours (rotational speed was 200rpm), then washed twice with deionized water, and dried at 50°C for 24 hours to obtain Ti 3 C 2 powder;

[0058] (2) 5g Ti 3 C 2 The powder was mixed with 20 mL of dimethyl sulfoxide, stirred at room temperature for 10 hours (300 rpm), washed three times with deionized water, and dried at 80 °C for 16 hours to obtain the treated Ti 3 C 2 powder;

[0059] (3) Take 2g of treated Ti 3 C 2 The powder was dissolved in a mixed solution of 100mL methanol and 300mL water, ultrasonicated for 4 hours (ultrasonic power 300W), centrifuged (8000rpm for 20min), and the supernatant was taken and freeze-dried to obtain a two-dimensional Ti 3 C 2 (MXene) nanosheets, t...

Embodiment 3

[0065] A high-performance two-dimensional layered Ti 3 C 2 -The preparation method of MXene film, comprises the following steps:

[0066] (1) Put 8gTi 3 AlC 2 The powder was mixed with 80mL HF solution (the volume concentration of the HF solution was 40%), stirred at room temperature for 8 hours (rotational speed was 200rpm), then centrifuged and washed 3 times with deionized water, and dried at 100°C for 24 hours to obtain Ti 3 C 2 powder;

[0067] (2) Put 2gTi 3 C 2 The powder was mixed with 10 mL of dimethyl sulfoxide, stirred at room temperature for 36 hours (300 rpm), washed three times with deionized water, and dried at 60°C for 24 hours to obtain the treated Ti 3 C 2 powder;

[0068] (3) Take 1g of treated Ti 3 C 2 The powder was dissolved in a mixed solution of 50mL methanol and 200mL water, ultrasonicated for 8 hours (ultrasonic power 300W), centrifuged, the supernatant was taken, and freeze-dried to obtain a two-dimensional Ti 3 C 2 (MXene) nanosheets; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com