Responsive oil and water separation net film with underwater super lipophobicity property and preparation method thereof

An oil-water separation mesh membrane, underwater superoleophobic technology, which is applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of no separation mixture system, environmental pollution, complex preparation process, etc., and achieve economical separation. The effect of cost, easy availability of raw materials and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

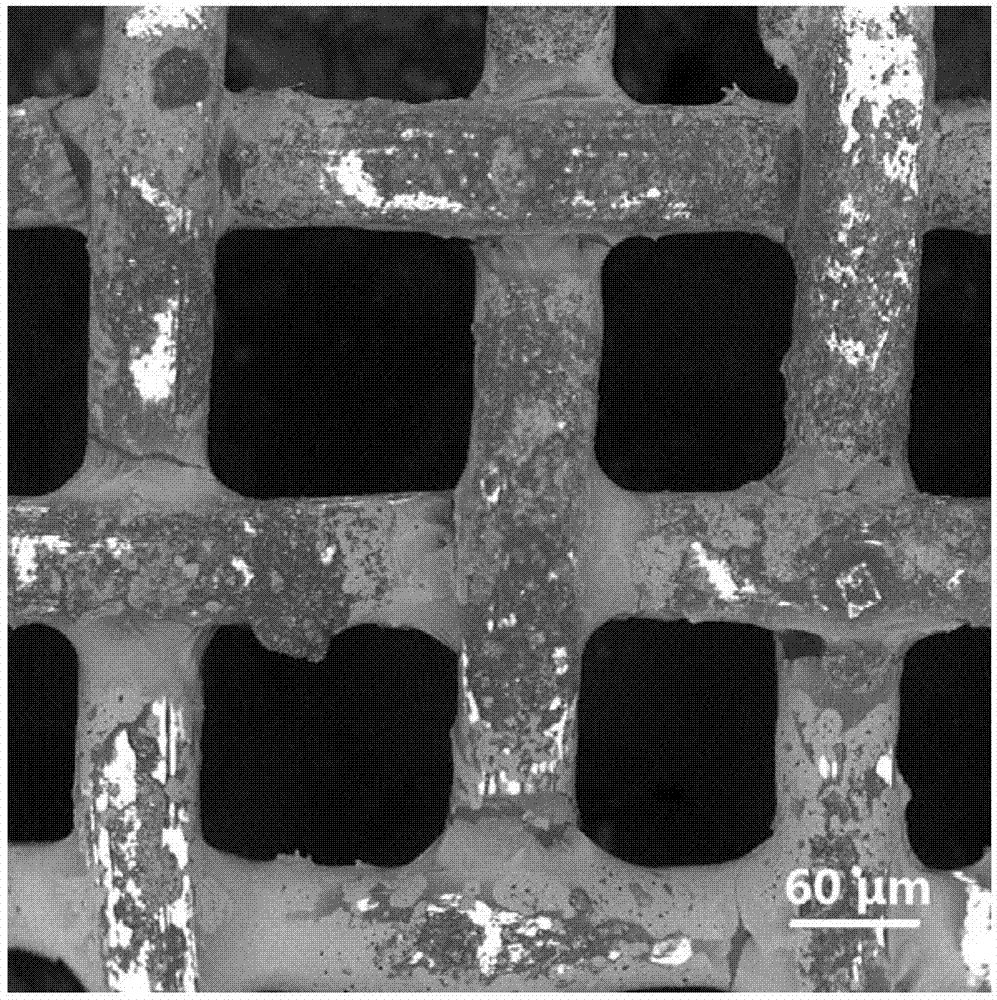

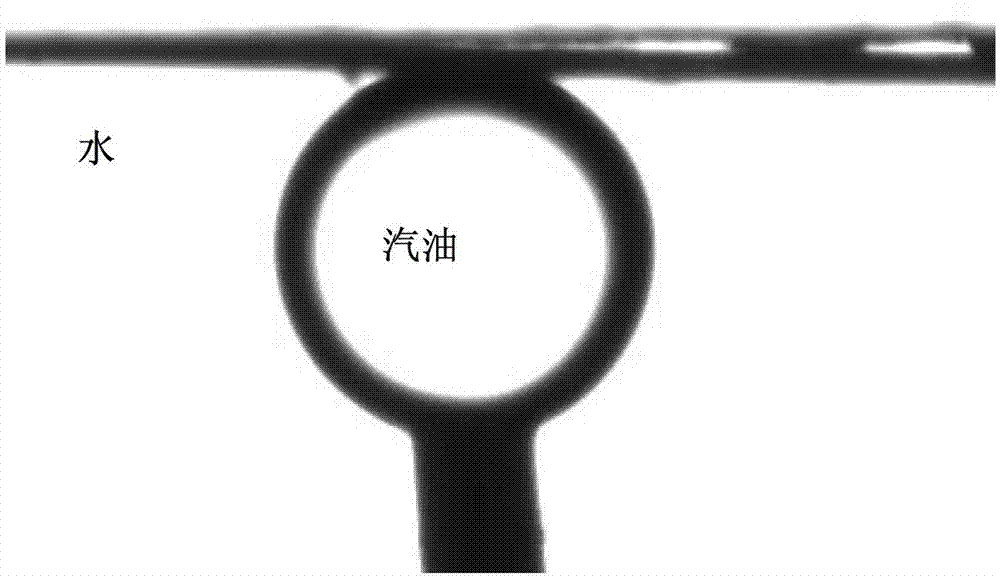

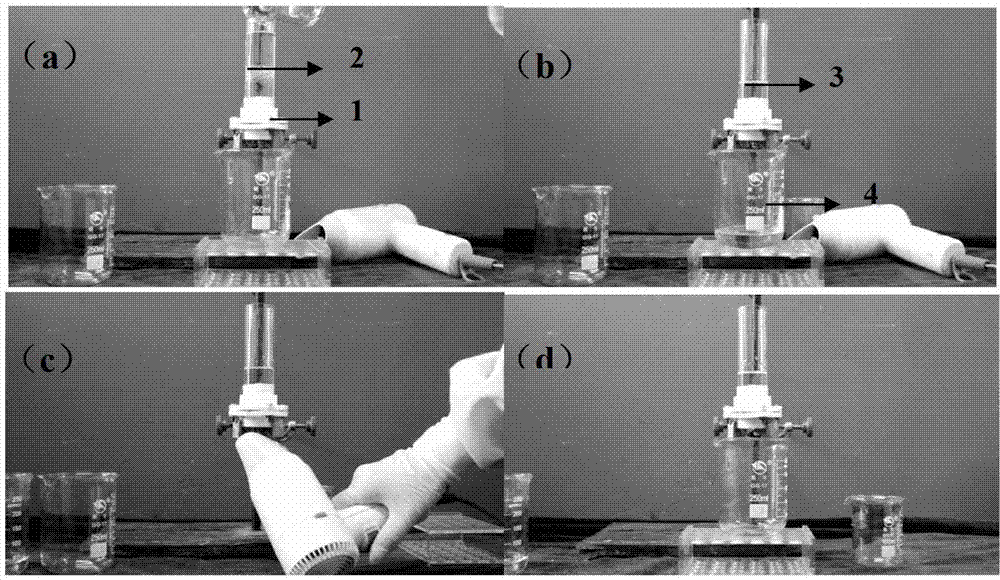

[0037] Example 1. Preparation of a responsive oil-water separation membrane with underwater superoleophobic properties

[0038] (1) Soak the 200-mesh stainless steel mesh in a mixed solution of ethanol and acetone with a volume ratio of 1:1, ultrasonically clean it for 15 minutes, take it out and dry it at room temperature;

[0039] (2) At room temperature, add 25mL of water, 10g of dimethylaminoethyl methacrylate, 0.20g of 2,2-diethoxyacetophenone, 0.30g of N,N'-methylenebis Acrylamide and 0.1g polyacrylamide were uniformly mixed by magnetic stirring to obtain a mixed solution; in the mixed solution, the mass percentage of dimethylaminoethyl methacrylate was 28.09%, 2,2-diethoxybenzene The mass percentage of ethyl ketone is 0.56%, the mass percentage of N,N'-methylenebisacrylamide is 0.84%, and the mass percentage of polyacrylamide is 0.28%;

[0040] (3) Soak the dried stainless steel mesh in step (1) in the mixed solution obtained in step (2) for 2 minutes and take it out; ...

Embodiment 2

[0045] Example 2. Preparation of a responsive oil-water separation omentum with underwater superoleophobic properties

[0046] (1) Soak the 300-mesh copper mesh in a mixed solution of ethanol and acetone with a volume ratio of 1:1, ultrasonically clean it for 15 minutes, take it out and dry it at room temperature;

[0047] (2) At room temperature, add 25mL of water, 10g of diethylaminoethyl methacrylate, 0.20g of 2,2-diethoxyacetophenone, 0.30g of N,N'-methylenebis Acrylamide and 0.1g polyacrylamide were uniformly mixed by magnetic stirring to obtain a mixed solution; in the mixed solution, the mass percentage of diethylaminoethyl methacrylate was 28.09%, 2,2-diethoxybenzene The mass percentage of ethyl ketone is 0.56%, the mass percentage of N,N'-methylenebisacrylamide is 0.84%, and the mass percentage of polyacrylamide is 0.28%;

[0048] (3) Soak the dried stainless steel mesh in step (1) in the mixed solution obtained in step (2) for 5 minutes;

[0049] (4) Take out the s...

Embodiment 3

[0053] Example 3. Preparation of a responsive oil-water separation omentum with underwater superoleophobic properties

[0054] (1) Soak the 400-mesh stainless steel mesh in a mixed solution of ethanol and acetone with a volume ratio of 1:1, ultrasonically clean it for 15 minutes, take it out and dry it at room temperature;

[0055] (2) At room temperature, add 25mL of water, 10g of dimethylaminoethyl methacrylate, 0.25g of 2,2-diethoxyacetophenone, 0.36g of N,N'-methylenebis Acrylamide and 0.20g polyacrylamide were uniformly mixed by magnetic stirring to obtain a mixed solution; in the mixed solution, the mass percentage of dimethylaminoethyl methacrylate was 27.93%, 2,2-diethoxybenzene The mass percentage of ethyl ketone is 0.70%, the mass percentage of N,N'-methylenebisacrylamide is 1.01%, and the mass percentage of polyacrylamide is 0.56%;

[0056] (3) Soak the dried stainless steel mesh in step (1) in the mixed solution obtained in step (2) for 10 minutes;

[0057] (4) T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com