Magnetic response type high-efficiency oil-water separation fiber membrane and preparation method thereof

A technology of oil-water separation and fiber membrane, which is applied in the field of functional micro-nano composite fiber materials, can solve problems such as high cost, complicated process steps, and limited amount of oil-water separation materials, and achieve large-scale production, simple experimental operation, and a preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Dissolve polyvinylidene fluoride (weight-average molecular weight 170,000) in analytically pure N,N-dimethylformamide solution, and configure N,N-dimethylformamide with a mass fraction of 18% polyvinylidene fluoride base formamide solution.

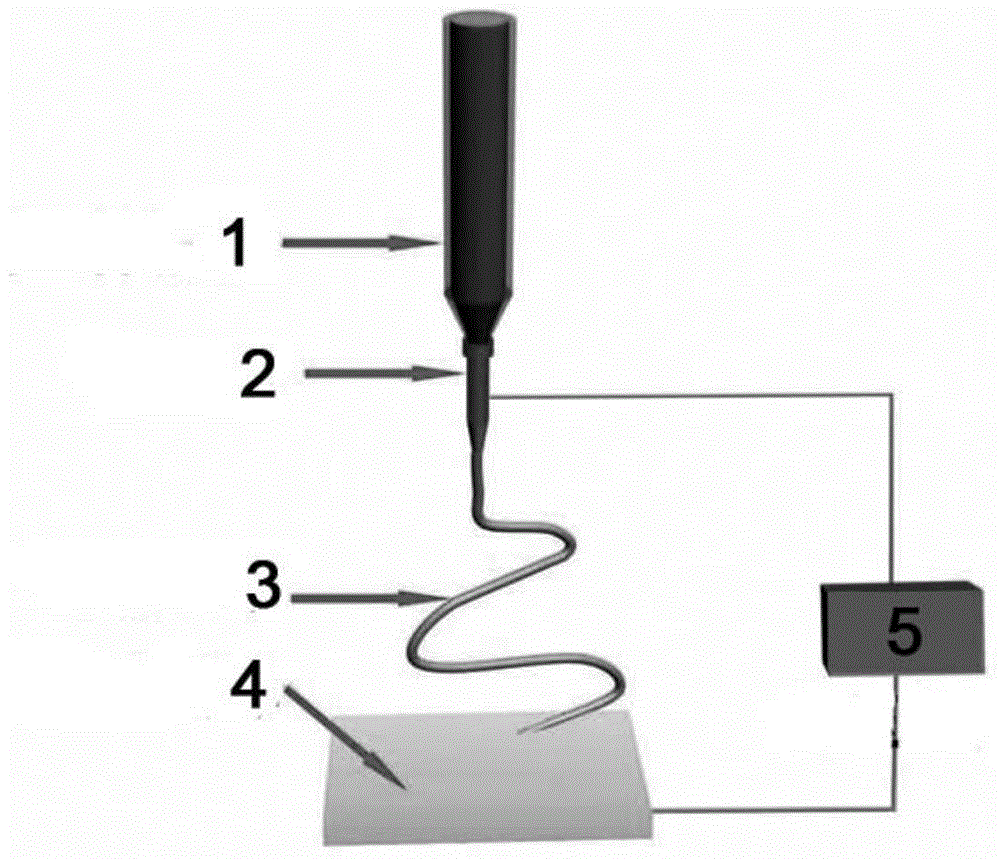

[0028] (2) Place the N,N-dimethylformamide solution of polyvinylidene fluoride configured in step (1) in the electrospinning device ( figure 1 Shown) in the liquid supply syringe 1, the diameter of the metal spinneret 2 is selected to be 0.6mm, and the high voltage power supply 5 provides a power supply voltage of 20KV. Adjust the distance between the metal spinneret 2 and the receiving base 4 to be 25 cm. During the preparation process, the electrospinning solution generates a jet under electrostatic action. When the electric field force is higher than the surface tension of the N,N-dimethylformamide solution (electrospinning solution) of polyvinylidene fluoride, the electrospinning solution is stretched fine During the fall...

Embodiment 2

[0036] (1) Dissolve polystyrene (weight-average molecular weight: 230,000) in analytically pure N,N-dimethylformamide / tetrahydrofuran mixed solution, wherein the mass ratio of N,N-dimethylformamide to tetrahydrofuran is 9:1, configured as a N,N-dimethylformamide / tetrahydrofuran solution with a mass fraction of 25% polystyrene.

[0037] (2) Place the N,N-dimethylformamide / tetrahydrofuran solution of polystyrene prepared in step (1) in the liquid supply syringe of the electrospinning device, select the diameter of the metal spinneret to be 1.0mm, and apply a voltage It is 25KV. Adjust the distance between the metal spinneret and the receiving substrate at 30 cm. During the preparation process, the above-mentioned electrospinning solution generates a jet under the action of electrostatic force. When the electric field force is higher than the surface tension of the N,N-dimethylformamide / tetrahydrofuran solution of polystyrene, the solution is stretched and refined, and the falli...

Embodiment 3

[0044] (1) Polyurethane (Sigma-Aldirich) was dissolved in analytically pure N,N-dimethylformamide solution to prepare a N,N-dimethylformamide solution with a mass fraction of 35% polyurethane.

[0045] (2) The polyurethane N,N-dimethylformamide solution prepared in step (1) was placed in the liquid supply syringe of the electrospinning device, the diameter of the metal spinneret was selected to be 1.8mm, and the applied voltage was 35KV. Adjust the distance between the spinneret and the receiving substrate at 35 cm. During the preparation process, the above-mentioned electrospinning solution generates a jet under the action of electrostatic force. When the electric field force is higher than the surface tension of the N,N-dimethylformamide solution of polyurethane, the solution is stretched and refined. During the falling process, the solvent N , The volatilization of N-dimethylformamide forms a polyurethane electrospun fiber membrane. The diameter of the fibers in the electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com