Wastewater treatment method and device combining electrochemical degradation and photocatalysis oxidation technologies

A technology for photocatalytic oxidation and wastewater treatment, which can be used in oxidized water/sewage treatment, chemical instruments and methods, light water/sewage treatment, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

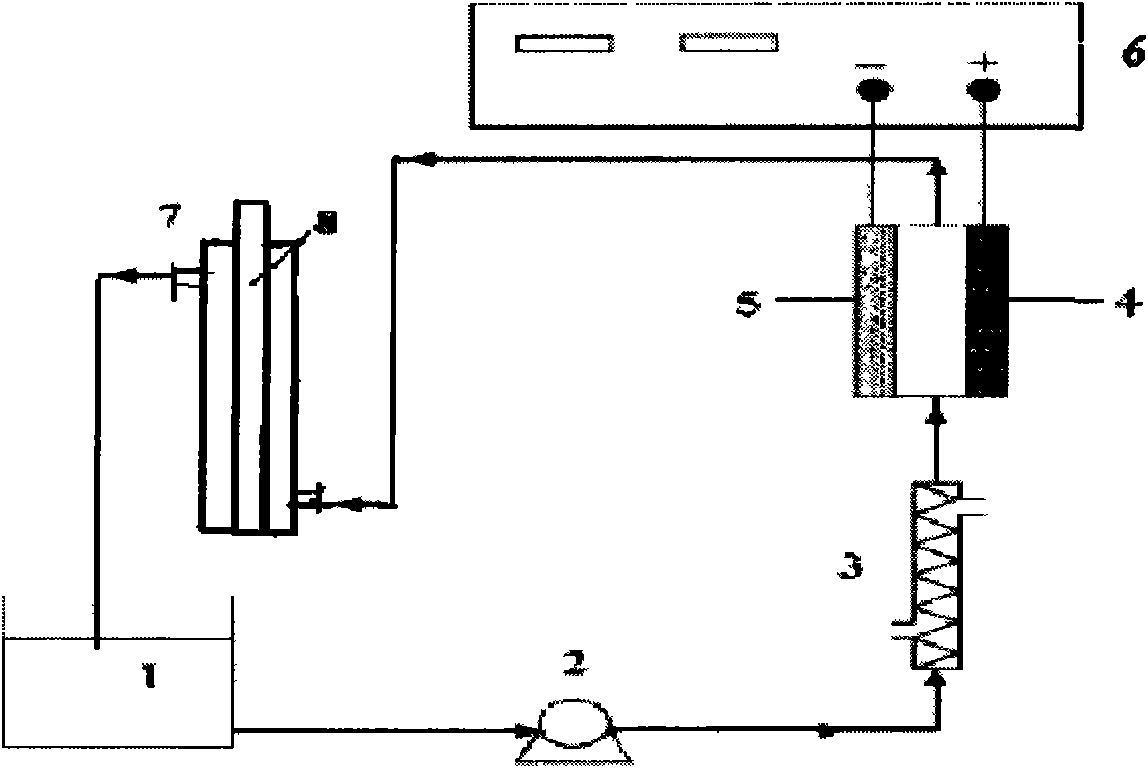

[0044] Such as figure 1 As shown, the device for wastewater treatment combined with electrochemical degradation and photocatalytic oxidation technology includes a liquid storage tank 1, a centrifugal pump 2, a constant temperature component 3, an anode 4, a cathode 5, a constant current power supply 6 and a photocatalytic reactor 7 .

[0045] The liquid storage tank 1 is connected to the liquid inlet of the centrifugal pump 2 through a pipe, the liquid outlet of the centrifugal pump 2 is connected to the liquid inlet of the thermostat 3 through a pipe, and the liquid outlet of the thermostat 3 is connected to a pipe with high boron-doped The diamond film electrode is the anode 4, and the stainless steel electrode is connected to the flow electrolytic cell composed of the cathode 5. The liquid outlet of the flow electrolytic cell is connected to the liquid inlet of the tubular ring-shaped photocatalytic reactor 7 through a pipeline. There is a double-layer quartz sleeve with w...

Embodiment 2

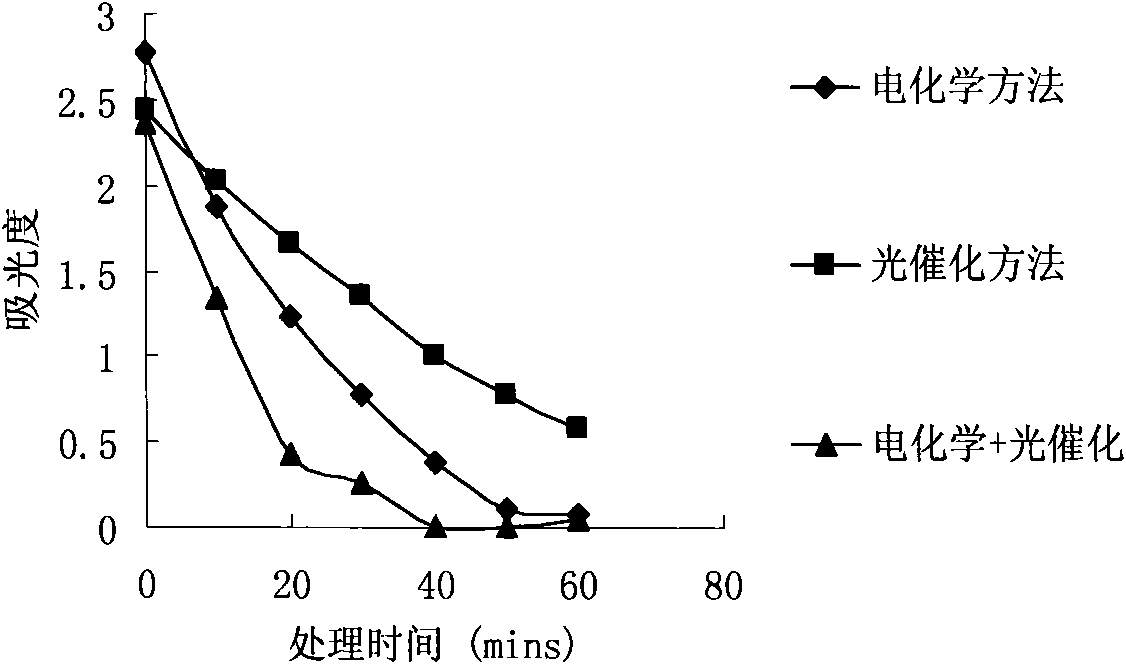

[0049] The device is the same as that in Example 1, and the TiO is loaded with foamed nickel mesh 2 As a supported photocatalyst, the effects of three different processes on the treatment of methylene blue dye wastewater were investigated: electrochemical method, photocatalytic method, and electrochemical and photocatalytic combination. When 500ml concentration is 0.05mmol / l methylene blue dye wastewater is processed, when adopting BDD electrode as anode (boron atomic density is: 10 18 20 cm -3 ), the current density is 50mA / cm 2 , supporting electrolyte 0.1mol / l Na 2 SO 4 Under the conditions, a separate electrochemical degradation method is carried out, and the decolorization rate of methylene blue dye wastewater is 55.36% after 20 minutes of electrochemical degradation. When nickel foam is used to load TiO 2 For photocatalyst (nickel foam carrier area: 280cm 2 , the load is: 5.5mg / cm 2 ), when the 18W low-pressure mercury lamp was used as a light source for separate ...

Embodiment 3

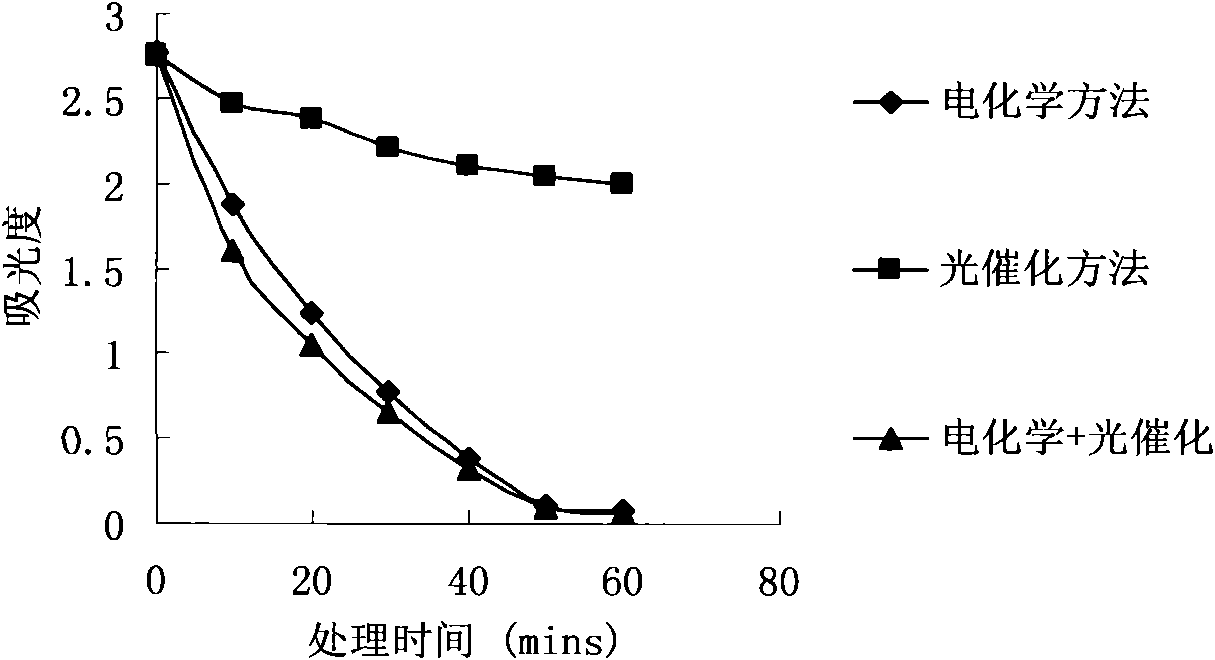

[0051] Device is the same as embodiment 1, adopts BDD electrode as anode (boron atom density is: 10 18 20 cm -3 ), at a current density of 50mA / cm 2 , supporting electrolyte 0.1mol / l Na 2 SO 4 Under the conditions, 500ml of methylene blue dye wastewater with a concentration of 0.1mmol / l was first treated electrochemically for 40 minutes, and then photocatalytic process was used for degradation. The photocatalyst was 0.5g / L P25 powder dispersed photocatalyst. After electrochemical degradation for 40 minutes, the decolorization rate of methylene blue was 31.73%, and then photocatalytic degradation was continued for 150 minutes, and the decolorization rate of methylene blue reached 93.86%. The decolorization effect of methylene blue in the experiment is shown in Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com